2024 Best CNC Machines for Every Need and Budget

Are you doing research on how to DIY CNC machine kits for wood, metal, foam, stone, plastic, acrylic, leather, fabric, textile, and glass with styles & types of mini, small, benchtop, tabletop, desktop, handheld, portable, and large format? Are you looking for a trustworthy store to buy new CNC machines online at lower prices or pick up the used CNC machine tools in store from local shops or overseas makers for small business, home shop, school, education, teaching, training, hobbyists, commercial use, industrial manufacturing? Are you looking for custom online & offline CNC machining services from local dealers or overseas manufacturers? Review the easy-to-follow buying guide to machinists, operators, beginners, shop owners, homeowners, woodworkers, carpenters, artisans, builders, metal fabricators, metalworkers, stone fabricators, stone workers, foam fabricators, agents, distributors, merchants, brokers, wholesalers, commercial users, and industrial manufacturers. STYLECNC is the most trusted place to purchase the best CNC machines for beginners and professionals in 2024, selling the most popular and affordable CNC machines with the cheapest price, and offering 24/7 free expert 2D/2.5D/3D customer service to meet your needs within your budget. At STYLECNC, you can find out various types of budget-friendly automatic computer numerical controlled router machines, lathe machines, milling machines, laser cutters, laser engravers, laser markers, plasma cutters, digital cutters, edge banders, laser cleaners, laser welders for every need, and shop online or pick up in store for your business plans with ease.

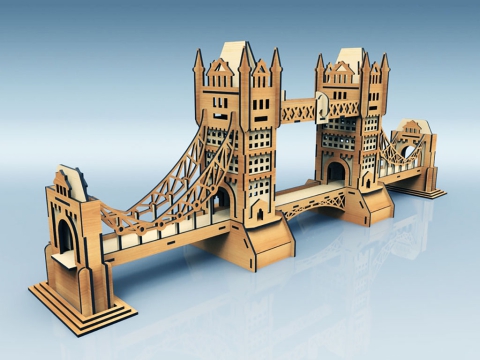

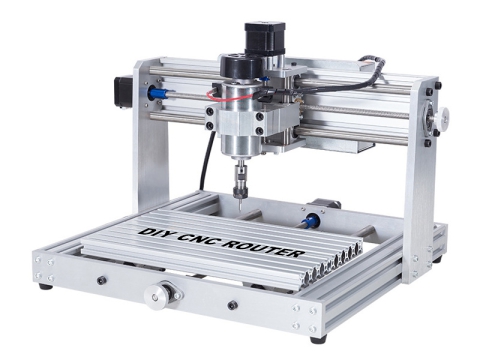

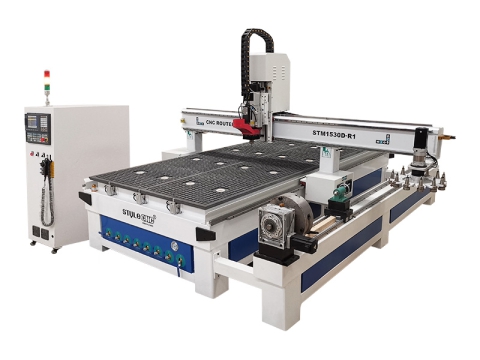

A CNC router is a professional automatic machine tool that uses a computer numerical controller with the monitoring system to drive the X, Y, and Z axis to move, uses G-code commands to control the router bit to cut along the tool path generated by the CAD/CAM software, and removes the excess parts on the substrate to achieve the final results of cutting texts and patterns. CNC router kits can work with DSP, Mach3, Mach4, NcStudio, LNC, OSAI, LinuxCNC, PlanetCNC, Syntec, Siemens, FANUC, and more controllers based on the business requirements. CNC routers can do relief carving, rotary carving, flatbed cutting, 3D routing for wood, aluminum, copper, brass, glass, plastic, acrylic, and foam.

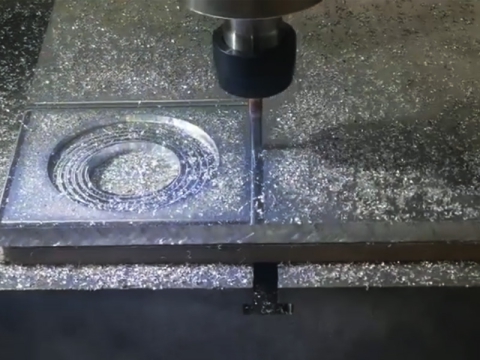

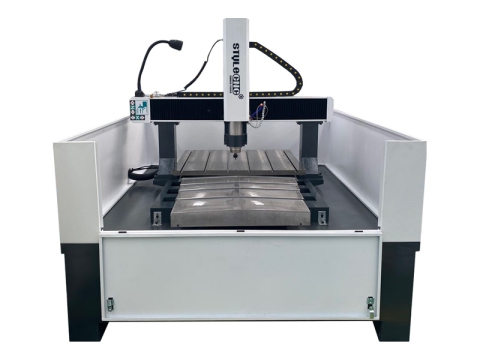

A CNC milling machine is an automatic machining tool that works with a computer numerical controller to drive a milling cutter to move along the tool path to cut out CAD/CAM designed shapes or contours, which is upgraded on the basis of a handheld mill. A CNC mill can perform drilling, boring, tapping, 2D and 3D milling. The most popular milling machines include vertical mill and horizontal mill, which can complete 3-axis, 4-axis or 5-axis linkage to cut and mill aluminum, brass, copper, iron, and steel with high-power spindle motor and servo motor to ensure the spindle to run with high speed to improve the machining accuracy, precision, and tolerance of the metal parts. A computer-controlled milling machine is used for aviation parts, auto parts, mold making, machinery parts, train parts, and shipbuilding parts. A automatic computer-controlled mill with tool changer is also known as a CNC machining center.

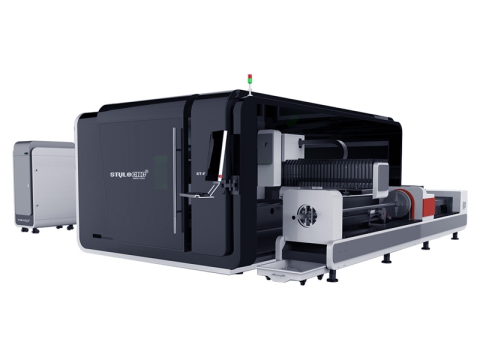

A CNC laser machine is an automatic laser machining system with computer numerical controller for cutting, engraving, marking, welding, cleaning various substrates with laser beam. Laser cutters are used to cut shapes and profiles on metal, wood, foam, acrylic, plastic, leather and fabric. Laser engravers are used to etch and mark texts and patterns on metals and nonmetals. Laser welders are used for metal joints. Laser cleaners are used for surface treatment for rust removal, paint stripping, coating removal, oil, stain, dirt cleaning on metal, stone, wood, and rubber. A laser machine features with dieless, contactless, no deformation, no damage, high speed, high precision, stable and reliable machining quality. CNC lasers have been applied in personal customization for hobbyists, commercial use in small business and industrial manufacturing.

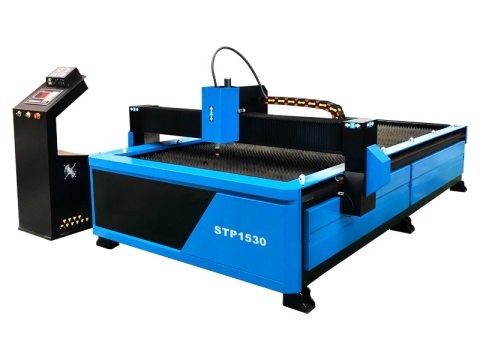

A CNC plasma cutting machine is an automated metal cutter that uses a computer numerical controller to instruct the plasma cutting torch to cut through metals on a custom-sized cutting table (4x4, 4x8, 5x10, 6x12) to create shapes or outlines for your needs. It is ideal to cut ferrous and non-ferrous metals including steel, iron, brass, copper, bronze, aluminum, titanium and their alloys for automotive manufacturing, welding, repair and restoration, industrial machinery, shipbuilding, aerospace, commercial construction, as well as salvage and scrap operations. CNC plasma tables can handle cutting of various sizes of sheet metals, tubes, rods, straps and profiles, which are an upgraded version of handheld plasma cutters for both beginners and professionals.

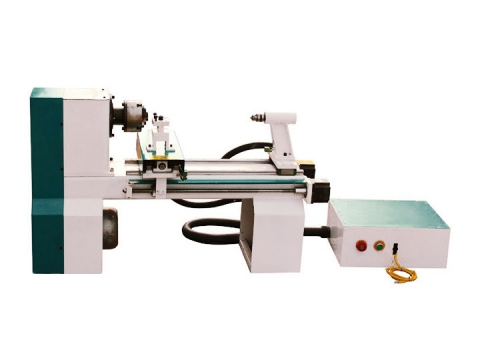

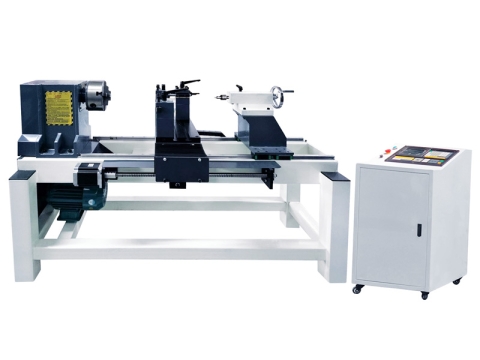

A CNC lathe machine is an automatic computer numerical controlled machine tool for turning conical, cylindrical, and curved surfaces of round shaft parts or disc parts. An automatic lathe uses a computer numerical controller to drive the cutting tool to move and turn the parts according to the designed files by CAD/CAM software. A primary computer-controlled lathe consists of I/O device, CNC control system, servo motor and driver, measurement feedback system, auxiliary device and machine bed frame. A professional CNC lathe can perform facing, OD turning, taper turning, thread turning, grooving, eccentric turning, surface turning, balling, quasi-turning, boring, embossing, cutting, reaming, and drilling. Compared with manual lathes, it can automatically turn parts based on the customer requirements without manual operation. The most common types of automatic lathes include metal lathes and wood lathes.

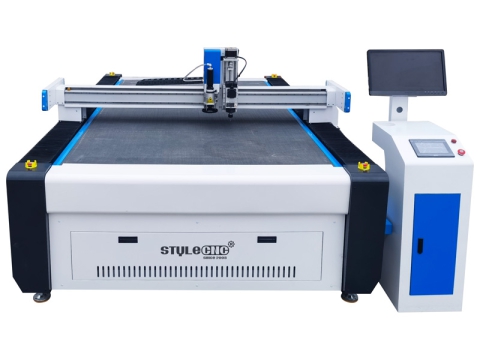

A CNC digital cutting machine is a professional automated precision cutting system that uses the up and down high-frequency vibration of the blade to cut flexible materials. It features with high precision, high speed, automatic loading and unloading, intelligent typesetting, and low cost of smooth incision processing. CNC digital cutters will take the place of the traditional manual flexible material cutting tools step by step. In the manufacture of automobile interiors, it is suitable for car mats, trunk mats, leather covers, seat covers, and cushions. In the advertising and packaging industry, it can quickly locate and identify, automatically find and cut edges, which is suitable for cutting KT board, Chevron board, self-adhesive, corrugated paper, and honeycomb board. In the field of garment processing, it adopts high-power knife cutter and special fabric cutting blade with more flexible corners, which is used for high-end custom garment manufacturers. In addition, you can also add a knife cutter on a CNC router table to do precision cutting for flexible materials.

Most Profitable Relevant Project Ideas You Can Use for Free

Most Popular Relevant CNC Machining Videos In Action

Most Insightful Relevant CNC Stories & Articles Worth Reading

An Ultimate Guide To Buying Your First CNC Machine

Definition & Meaning

A CNC machine is an automatic computer numerically controlled power tool kit capable of cutting, turning, milling, carving, engraving, marking, etching, printing, drilling, grooving, welding, cleaning, bending, grinding, slotting to get the machining done with various materials from wood (hardwood, softwood, plywood, MDF, bamboo) to metal (stainless steel, carbon steel, mild steel, brass, copper, aluminum, iron, titanium, alloy), as well as foam, stone, fabric, leather, rubber, paper, and plastic, which is popular in hobby shop, home store, small business, commercial use, training, school education, industrial manufacturing, and modern smart factory.

A CNC machine tool is an intelligent machining kit for business automation from home use to industrial smart manufacturing, which is composed of bed frame, controller, spindle, gantry, operating system, software, motor, driver, T-slot table or vacuum table, ball screw, guide rail, power supply, collet, vacuum pump, limit switch, rack, pinion, bits, and additional parts & accessories. It can smoothly cut through soft wood and accurately mill out shapes on hard metal. No matter what the material is, a computer-controlled machine tool can handle it easily.

CNC stands for Computer Numerical Control. CNC refers to an idea of controlling a machine tool via computer instead of manually controlled by a machinist. New machine tools in CNC programming have enabled the industry to consistently produce parts to accuracies undreamed of only a few years ago. The same part, can be reproduced with the same degree of accuracy any number of times if the program has been properly prepared and the computer properly programmed. The G-Code commands which control the machine tool are executed automatically with high speed, accuracy, and efficiency.

Working Principle

CAD refers to Computer Aided Design, that is, computer aided design, which is used for 2D or 3D workpiece or stereo design. CAM stands for Computer Aided Manufacturing, that is, computer aided manufacturing, which is used to generate G-Code. The full form of CNC is Computerized Numerical Control.

A CNC machine works with CAD software to design 2D/3D layout files and CAM software to make G-Code, and starts machining with an automatic computerized controller to read G-Code, start programming, and drive the spindle with bits to move along the tool path, and gets the job done automatically. In modern computer numerical control systems, the design of workpieces highly depends on software such as computer aided design (CAD) and computer aided manufacturing (CAM). The computer aided manufacturing software analyzes the design model and calculates the movement instructions during the processing. The movement instructions and other auxiliary instructions required during the machining are converted into a format that can be read by the numerical control system through the post-processor. The generated file is loaded into the computer numerical control machine tool for part machining. After importing the program instructions into the memory of the computer numerical control system, the computer compiles and calculates, and through the displacement control system, the information is transmitted to the driver to drive the motor to cut the designed parts.

Step 1, Design a 2D or 3D drawing via CAD software.

Step 2, Convert the CAD file into G-code via CAM software.

Step 3, Setup machine tool.

Step 4, Start programming.

Step 5, Start machining.

Types

CNC machines come in 16 most common types with different pros and cons for various machining processes, including lathes, laser machines, router machines, plasma cutters, knife cutters, drilling machines, milling machines, punching machines, boring machines, bending machines, inspection machines, wire cutting machines, water jet cutting machines, planers, grinders, and plotters. In addition, types can also be defined based on the concepts, end uses, functions, and materials.

Six Types Based On Concepts

There are 6 different types according to the concepts, including mills, lathes, routers, lasers (laser cutters, laser engravers, laser etchers, laser markers, laser cleaners, laser welders), digital cutters, plasma cutters.

Two Types Based On End Uses

You will meet 2 basic types according to the end uses, including hobby kits for small business and home shop (mini types, small types, benchtop types, desktop types, tabletop types, portable types), and industrial kits for commercial use (wood, stone, metal, foam, plastic, wood plastic).

Sixteen Types Based On Functions

There are 10 most popular types according to the functions, including cutting, milling, routing, carving, engraving, marking, printing, welding, cleaning, turning, drilling, grooving, slotting, grinding, sanding, and nesting.

More Types Based On Materials

You will meet much more types according to the machining materials, including woodworking, metalworking, foam fabrication, stone fabrication, plastic fabrication, and so on.

Cost

When you are in need of a new CNC machine, you may wonder how to start. There a few things to consider including the table size, the parts, the accessories, the controller, the software, the service, and the setup options that are available to you. Whether entry-level or high-end types, we will help you get to the bottom of all of these concerns and have you on your way to enjoying your new automated computer numerical controlled machine tool in no time. The first thing most buyers want to know is how much does it usually cost.

The average cost of new CNC machines can range from $2,000 to $260,000, depending on the hardware and software it uses. The used CNC machines are relatively cheap, which cost anywhere from $1,200 to $180,000 with limited guarantee and warranty of quality & service. The entry-level small CNC kits start at $1,800 for hobbyists and startups, while the high-end industrial CNC machines can cost as expensive as $298,000 for commercial use. If you are looking to buy new or used computerized machine tools overseas, the shipping costs, taxes and customs clearance charges should be included in the final price.

By tracking virtually every supplier in the world, the data shows the average transaction price of a new automatic machine tool has risen to $3,698 due to rising raw material costs and shipping costs in 2024. Looking back at pre-pandemic and early 2023 data, you have to pay an extra $896 for the same automated machine tool.

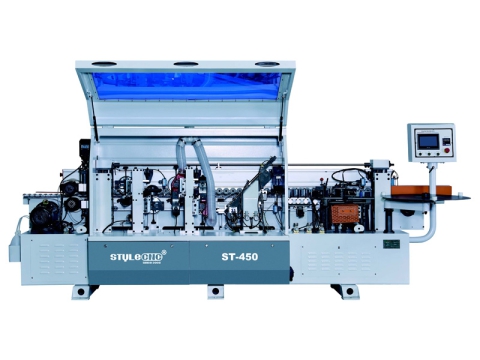

An affordable C and C router machine costs anywhere from $2,580 to $150,000. The best budget computerized milling machine is priced from $3,000 to $120,000. The most common C & C laser engraving cutting machines are priced from $2,400 up to $260,000, while some brand new laser welding machines and laser cleaning machines are already as low as $6,000. The top rated computer numerical controlled lathe machines start from $2,800, while some professional types can be expensive as $11,180. The cheapest computer controlled plasma cutting machine costs from minimum $4,000 up to $30,000. A low cost automatic edge banding machine is priced from $8,000 for woodworking. The high precision computer-controlled automatic knife cutters and digital cutting machines cost start around $15,800 for flexible materials.

Pricing

| Types | Minimum Price | Maximum Price | Average Price |

|---|---|---|---|

| Router Machine | $2,580 | $150,000 | $6,580 |

| Laser Machine | $2,400 | $260,000 | $5,120 |

| Plasma Cutter | $4,000 | $30,000 | $6,260 |

| Milling Machine | $3,000 | $120,000 | $8,210 |

| Lathe Machine | $2,800 | $11,180 | $5,680 |

Uses

A CNC machine is a smart computer-controlled power tool used for hobbyists, small business, and industrial manufacturing, which can mill, turn, drill, grind, engrave, etch, cut materials such as wood, metal, foam, plastic in the field of machinery manufacturing and automation.

CNC lathes are used in automobile manufacturing, aviation, aerospace, electronics, arts, crafts, gifts, woodworking, and instruments.

CNC mills and boring machines are used for the processing of large and complex structural shells, brackets, boxes, and precision parts such as aerospace and automotive engines.

CNC machining centers are used for parts processing of industries such as military, aerospace, energy, machinery manufacturing, ship manufacturing, and large-scale mold making.

CNC grinders are used to meet precision grinding cemented carbide, hardened steel, granite, glass, and more high hardness and brittle materials..

CNC EDM machines are used for precision parts processing and mold making, taper hole or special-shaped hole drilling.

CNC press brakes are used for mass production of sheet metal in motorcycles, automobiles, electronics, home appliances and other industries.

CNC automatic production line is aimed at the mass production of bulk shell and box parts in the industries of home appliances and automobiles.

Specifications

| Brand | STYLECNC |

| Table Sizes | 2' x 2', 2' x 3', 2' x 4', 4' x 4', 4' x 6', 4' x 8', 5' x 10', 6' x 12' |

| Types | Router, Laser, Mill, Plasma, Lathe |

| Functions | Carving, Engraving, Marking, Cutting, Turning, Drilling, Milling, Grooving |

| Applications | Hobbyists, Small Business, Small Shop, Home Business, Home Shop, School Education, Industrial Manufacturing |

| Materials | Metal, Wood, Foam, Plastic, Fabric, Leather, Acrylic, Glass, Stone, Paper |

| Capability | 2D Machining, 2.5D Machining, 3D Machining |

| Styles | Mini, Small, Benchtop, Tabletop, Desktop, Handheld, Portable, Large Format |

| Price Range | $2,000 - $260,000 |

Pros & Cons

CNC machine kits are electric discharge machining tools that integrate mechanical, electrical, hydraulic, pneumatic, and information technologies with the advantages of high precision, high efficiency, high automation, and high flexibility, stability and reliable quality in mechanical manufacturing processes. The technical level and its percentage of the output and total ownership is one of the important indicators for measuring a country's national economic development and the overall level of industrial manufacturing.

Pros

Automation

As the name implies, CNC indicates that this form of machining relies on computer control. This means a higher level of automation, which is the best solution for high-precision work. The main function of CNC machining is the ability to create other things from a piece of material. Traditional machining methods can achieve these goals, but CNC automation makes it more efficient to save time and reduce errors, lowering operating costs and material costs for many businesses.

Multipurpose

For example, computer controlled turning makes it possible to manufacture "complex external and internal geometries, including the generation of various threads." Computer controlled milling is better for making holes, grooves, and repeated movements to create complex 3D shapes. It is versatile, easy to set up repetitive motions, and is usually used to make molds.

Multifunction

There are no cutting tools in this industry that can handle all the manufacturing processes, but CNC is the closest. It can create curves and angles in flat and smooth substrates. It can add grooves and threads to create a locking mechanism. It can stamp and mill, cut and drill, and add texture and contour. CNC technology makes it possible to make complex interior and exterior geometries. Since it's run by a computer program, you can customize it to do almost anything you can imagine. CNC programming uses CAD to create a model of the final product. As the process progresses, this is a rough draft. It can also identify any problems in the design. Then take a picture of the prototype, which will create a copy and enter it into the machine tool.

Safety

CNC machinist uses the computer to control the machine tool to run, which creates a safe working environment and reduces the occurrence of workplace accidents. This is particularly important because workers have to bear the repeated manual labor in the past. CNC machining ensures that the products produced are consistent to meet quality control guidelines. Human operation error is a common safety hazard, which can lead to accidents, so there is no need to worry.

Convenient

CNC machining process is efficient and computer-led, it is easy to mass produce to save time. You only need to make multiple machine tools run on the same program. For many companies, how to expand scale while maintaining good profit margins is a challenge. The benefits of automatic computer numerical controlled machining make it the best solution for manufacturers. It has the function of storage, so there is no need to worry about reloading the program every time, and there is no need to re-enter commands every time.

Cons

• Compared with manual or semi-automatic mechanical tools, it is expensive and requires a large initial investment when purchasing.

• It has higher technical requirements for operation and maintenance personnel.

• Manual programming requires a lot of work when machining complex shaped parts.

User Guide

Nine basic steps to operate a computer numerical controlled machine tool in workshop.

Step 1. Edit & Input File.

Before machining, you should analyze and compile the file of the project. If the file is more complicated, do not program on the machine tool, but use the programming tool or computer programming, and then back up to the control system through the U disk or communication interface. This can avoid increasing the auxiliary time of machining when using the machine tool.

Step 2. Power On.

Generally, the main power is turned on first, so that the machine tool has the power-on conditions. Start an control system with a key button and the machine tool is powered on at the same time. Information is displayed on the CRT of the control system. At the same time, check the hydraulic, pneumatic, and input Give the connection status of the shaft and other auxiliary equipment.

Step 3. Solid Reference Point.

Establish the movement datum of each coordinate before machining. For machine tools with control systems, this step should be performed first.

Step 4. Import & Call To Programming.

According to the program medium (U disk), it can be input by computer, programming tool or serial communication. If it is a simple program, it can be input directly on the control panel with the keyboard, or input section by section in MDI mode, and process in sections. Before machining, the origin, tool parameters, offset amount and various compensation values in the machining program must also be input.

Step 5. Program Editing.

If the input program needs to be modified, the working mode selection switch should be placed in the editing position. Use the edit key to add, delete, and change.

Step 6. Program Inspection & Debugging.

First lock the machine tool and only run the system. This step is to check the program, if there is an error, you need to edit it again.

Step 7. Project Installation & Alignment.

Install and align the lower spare parts to be processed and establish benchmarks. The method adopts manual incremental movement, continuous movement or handwheel to move the machine tool. Align the starting point to the beginning of the program, and set the tool benchmark.

Step 8. Start The Coordinate Axis for Continuous Machining.

Continuous machining generally adopts the program machining in the memory. The feed speed of computer numerical controlled machining can be adjusted by the feedrate override switch, and the feed hold button can be pressed during machining to pause the feed movement to observe the machining conditions or perform manual measurement. Press the cycle start button again to resume machining. In order to ensure that the program is correct, you should review it again before machining.

In the machining process, you can use a pencil instead of a tool to draw the outline of the project on paper for flat curve projects. If the system has a tool path, the simulation function can be used to check the correctness of the program.

Step 9. Shut Down.

After machining and before turning off the power, pay attention to check the status of the machine tool and the position of the spare parts.

Turn off the power of the device first, then turn off the power of the system, and finally turn off the main power.

Buying Guide

There are a variety of CNC machines in the world, and there are also various machine tool brands and manufacturers. This phenomenon has pros and cons for buyers. The advantage is that customers have more choices, and buy more useful machine tools from dealers. The bad thing is that after seeing more, they don't know which one is the best to buy. As the saying goes, cheap is not good, and good is not cheap.

So, what things should be considered when buying?

STEP 1. Meet Your Requirements

A computer-controlled machine tool cannot do all the work. In order to be able to process different materials professionally, the manufacturers classify them into many types. If you buy a mill to carve bakelite, or buy a certain large industrial kit to cut small crafts, it will not only waste a lot of money but also have a bad effect. Similarly, if you buy a desktop kit for home door making, it may not work properly at all. So before you buy, you must communicate clearly with the salesperson to let him know your purpose, including the size of the workpiece, the material of the workpiece, the machining effect and so on.

STEP 2. Types & Models Selection

If you need to cut a sign in your advertising shop, you should buy professional hobby kits with custom configurations. If you need to turn wood, you should buy a lathe machine for woodworking. If it is used for mold making, you need a milling machine, and then determine the model of the mill according to the size of your milling project. If it is used to cut metal, you should buy a plasma cutter, or a laser cutter with fiber laser source. If the material to be milled is graphite, you must choose a mill dedicated to graphite, because the protection level of ordinary machine tools is not enough, which will cause damage or even paralysis. Therefore, you should buy professional machine tools according to your own business plans and projects.

STEP 3. Sample Making

Before buying, in order to ensure the ability of the machine tool you selected, you must let the sale manager to make samples based on your designs. The advantage is that you can see the the actual machining effect, as well as the time it has used.

STEP 4. Contract Signing

After the above three points are completed, the signing of the procurement contract must be carried out. A complete contract is the best guarantee to guarantee one's legal rights. First of all, the contract should clearly indicate the purchased model, configuration, price, delivery time and delivery method, training method, warranty terms, and specific payment methods. After the contract is signed, the corresponding deposit shall generally be paid according to the contract. For the signed contract, we must abide by its content agreement to avoid unnecessary conflicts with the seller in the future.

STEP 5. Delivery & Training

After the computer-controlled machine tool is shipped on time, the technician from the supplier will help you to open the packing box and inspect it in your workshop (if you have paid for door to door service, the technician will arrive at your workshop before it arrives). You should carefully check the machine appearance whether it is damaged during transportation. If it is good, check the parts and accessories according to the packing list and the terms of the contract. Next, let the technician setup the machine (including the hardware assemble, software installation & debugging). After setup, make a sample test on the machine. If the finished project is well, the delivery inspection will be completed. According to the contract, the user shall pay off the balance. The operators are required to have a strong sense of safety responsibility, and they must have proficient machine tool operation skills before starting their jobs. In the training process, you should be proficient in choosing different cutting speeds and using different bits & tools for different materials. This requires the skills and experience. A good mastery is better for extend the service life of the machine and tools.

STEP 6. Service & Support

When you are troubled with hardware & software problems in use, you need to get in touch with the dealer, communicate clearly to make the service staff aware of issues and start troubleshooting, and do not deal with it yourself, which can lead to accidents when you are not familiar with the machine tool, and the manufacturer may refuse to continue to provide warranty service for the equipment. In terms of after-sales service, we can require the CNC machine manufacturer to strictly follow the contractual agreement. If you encounter deliberate delay or have a bad attitude, you can complain to the person in charge.

Things To Consider

Most buyers start concentrating on the online shopping instead of the traditional offline buying approach. In your online researching and purchasing process, you must consider the things listed above. It will take you down the easy-to-follow buying guide to CNC machines. You can pickup from a local machine shop with higher price, you can also purchase online from CNC maker at low cost with manufacturer's direct service and support. All depends on your budget plan and business needs. In short, what suits your job is the most important thing.

If you have more questions about CNC machines for sale, don't hesitate to ask for help, and let us know if you need any further assistance.