This laser cutter does what it is intended to do - cuts very clean shapes and outlines in sealing materials. It's budget friendly, and easy to operate for starters with precision and quickness. I have to say, the STJ1610-CCD is an ideal choice if you need to make seals or cut washers from rubber stock at a low cost.

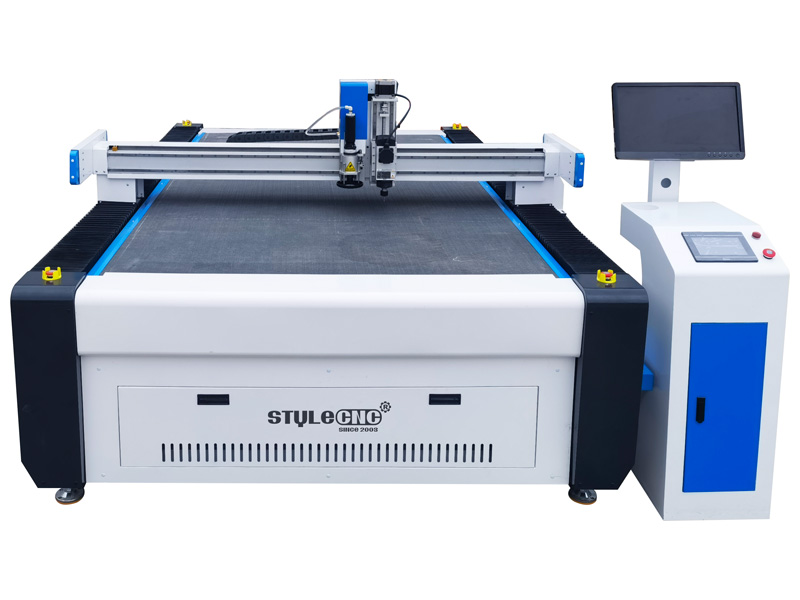

CNC Laser Cutter With CCD Camera Visual Recognition System

STJ1610-CCD CNC laser cutter integrates a CCD camera visual recognition system for crafting intricate embroidered badges from fabrics such as premium fabric, canvas, and cotton twill, which is user-friendly and easy to use for beginners to accurately position cutting for a clean and smooth edge to create high-quality cuts.

- Brand - STYLECNC

- Model - STJ1610-CCD

- Maker - Jinan Style Machinery Co., Ltd.

- Sizing - 1600mm x 1000mm

- Category - CO2 Laser Cutting Machine

- Laser Source - Yongli, RECI

- Power Option - 80W, 100W, 130W, 150W

- 360 Units in Stock Available for Sale Every Month

- Meeting CE Standards in Terms of Quality & Safety

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- 30-Day Money Back Guarantee for Your Purchase

- Free Lifetime Technical Support for End-Users & Dealers

- Online (PayPal, Alibaba) / Offline (T/T, Debit & Credit Cards)

- Global Logistics and International Shipping To Anywhere

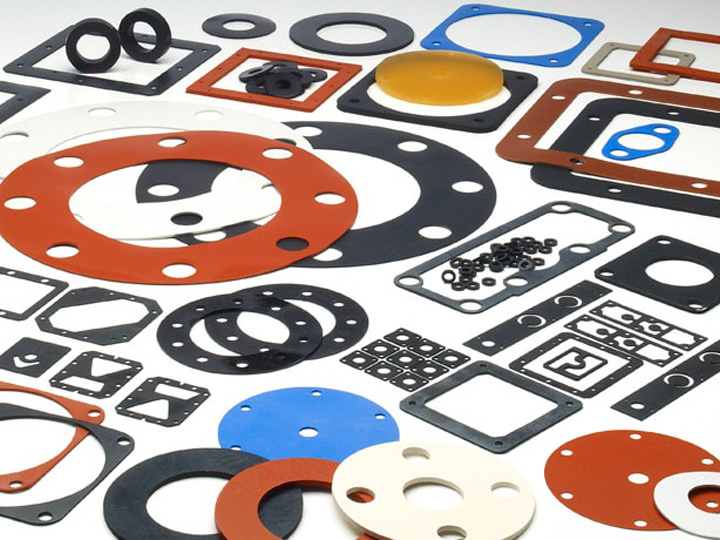

STJ1610-CCD CNC laser cutter with CCD camera is a precision cutting system fo gaskets & seals made of neoprene, nitrile (Buna-N), ethylene propylene diene monomer (EPDM), silicone rubber, viton, styrene butadiene rubber (SBR), butyl rubber, natural rubber, cloth-inserted rubber, polyurethane rubber, food grade (FDA approved) rubber, graphite, CNAF, PTFE. The CNC laser cutter is also known as gasket laser cutting machine, rubber laser cutting machine, laser gasket cutting machine, laser rubber cutting machine, laser seal cutting machine, seal laser cutting machine.

How does a Laser Cut Gaskets and Seals from Rubber?

The laser cutter cuts the rubber gaskets and seals by first locating the cut through a CCD camera, followed by a focused beam of light that melts and vaporizes the excessive parts of rubber and other sealing materials in a highly precise manner. The CNC controller drives the CO2 laser beam to automatically move along a tool path based on the gasket and seal design. High-accuracy material ablation with minimal thermal distortion allows for complex shapes and subtle details that are impossible to get with traditional cutters, resulting in clean, smooth cutting edges with tight tolerances for effective sealing in industrial manufacturing.

Technical Parameters of CNC Laser Gasket Cutter with CCD Camera

| Model | STJ1610-CCD camera |

| Cutting area | 1600x 1000mm |

| Laser power | 100W (80W, 130W, 150W for option) |

| Laser type | CO2 sealed laser tube, water-cooled, 10.6um |

| Cutting speed | 0-40000mm/min |

| Engraving speed | 0-70000mm/min |

| Laser Output | 1-100%software setting |

| Resetting positioning accuracy | ≤±0.01mm |

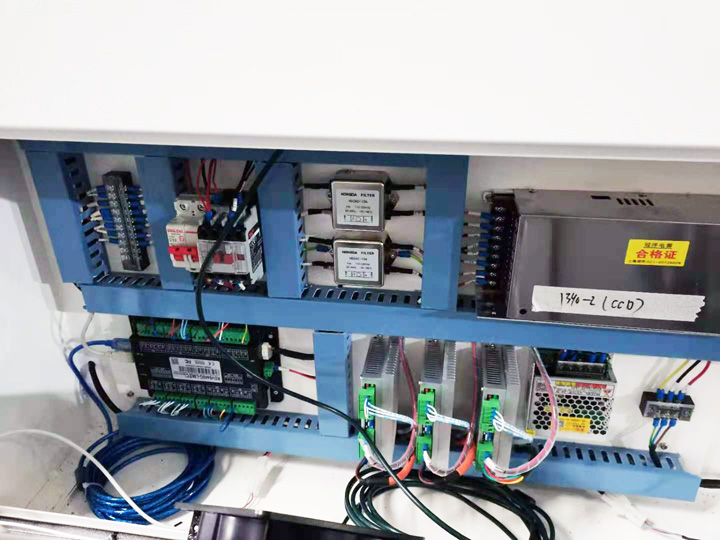

| Power supply | AC 110 - 220V ± 10%, 50 - 60Hz |

| Operating temperature | 0 - 45°C |

| Operating humidity | 5 - 95% |

| Min shaping character | English 1.0mm x 1.0mm |

| Graphic format supported | BMP, PLT, DST, DXF, AI |

| Software supported | Tajima, CorelDraw, PhotoShop, AutoCAD |

| Driving system | Stepper |

| Cooling mode | Water-cooling and protection system |

| Optional Spare Parts | Up-down table, Rotary System, Honeycomb table |

| Recommended Spare Parts | Laser Tube and Lens |

Features of CNC Laser Rubber Cutter for Gaskets & Seals with CCD Camera

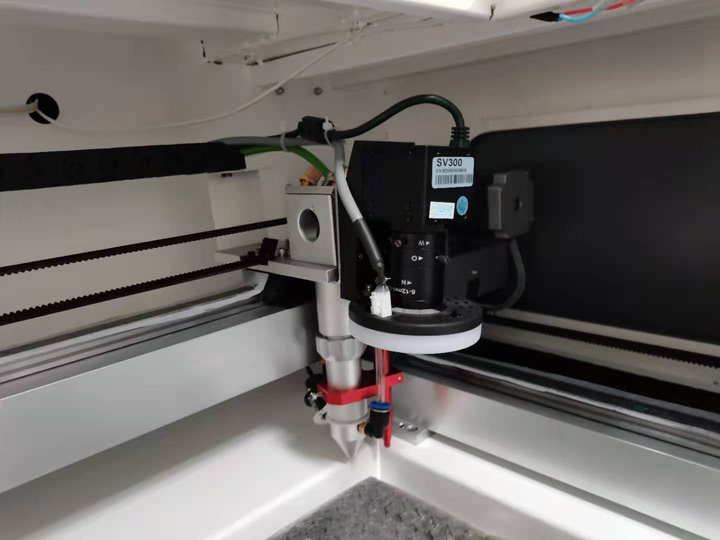

1. The CCD camera can automatically compensate for material positioning to ensure cutting accuracy.

2. A CCD camera can capture every edge of the object and extend it inward or forward a predetermined distance before cutting.

3. 2-3 megapixel color HD camera can accurately locate objects with inconvenient edges.

4. High-quality CO2 laser tube, longer service life and more stable power output.

Details of CNC Laser Gasket Cutter with CCD Camera

Auto Focus Laser Rubber Cutting Machine

High-Resolution Camera of CNC Laser Rubber Gasket Cutting Machine

WIFI Receiver of CCD Laser Rubber Seals Cutting Machine

Easy Operate RD Controller of CNC Laser Gasket Cutting Machine

Projects of CNC Laser Rubber Cutter with CCD Camera

Laser Cut Realistic Leather Badges Labels

Laser Cut Badge Patches Projects

Laser Cut Embroidered Badges Projects

Laser Cut Woven Labels

Advantages of Using CNC Laser Cutting for Embroidered Badges

CNC laser cutting in processing embroidered badges has revolutionized the industry by incorporating many advantages over traditional methods. This technology spans different aspects, such as precision to efficiency; it confers excellent benefits, especially in dealing with complex rubber materials.

High Precision and Accuracy

CNC laser cutting is one of the most precise cutting techniques. The laser beam is condensed to a minute size, enabling the making of complex cuts with very small tolerances. It will result in rubber parts with clean edges, perfect for applications requiring exact measurements with minimal deviation.

Fast Cutting Speed

Laser cutting is faster compared to many traditional methods, hence improving overall production efficiency. This speed is very valuable in high-demand environments, reducing downtime while increasing throughput, especially when working with large volumes of rubber parts.

Minimal Material Waste

Laser cutters have small kerfs, which means minimal material can be wasted. The precision of laser cutting allows for the manufacture of each part as near to the design as possible to optimize material use, thereby reducing overall costs, especially those involving expensive rubber material.

Material Thickness Versatility

Some of the strong points associated with laser cutting systems include their versatility, which makes them able to work with different thicknesses of rubber without any tool changes or adjustments. Whether the rubber is thin or thick, the laser cutter can adjust the power to suit the material, hence flexibility in production.

Non-contact Process

Since it does not physically touch the material, there is no mechanical stress on the rubber, which avoids deformation or even damage to the parts during the cutting process.

Benefits of Integrating a CCD Camera in Laser Cutting Systems

The integration of a CCD camera in laser cutting systems marks a new epoch for precision and automation. This technology enhances cutting accuracy, simplifies alignment, and improves the overall effectiveness of the laser cutting process, therefore proving particularly useful when it comes to difficult designs or high volumes.

Improved Alignment and Accuracy

A CCD camera aligns the cutting path precisely to the material. The camera automatically scans and readjusts the positioning of the workpiece to minimize human error and ensure cuts are aligned with specifications, especially for intricate or irregular patterns.

Smoother Workflow

The CCD camera smoothes out the workflow, allowing for real-time adjustments during the cutting process. This allows for quicker setup times and reduces manual recalibration, improving overall production speed and reducing any type of downtime.

Less Waste and Material Cost

By improving the alignment and precision of each cut, a CCD camera helps minimize errors that could lead to material waste. This ensures that the rubber is used efficiently, contributing to cost savings, especially when working with expensive rubber materials.

Easy Integration with Automation

The CCD camera can be integrated with automated laser cutting systems for increased speed and accuracy in processing. Automation reduces the need for manual input and helps maintain consistent results throughout a long production run, thereby improving operational efficiency.

Versatility in Handling Complex Designs

A laser cutting system with a CCD camera can execute more complicated designs. Since the camera is accurate in tracking the position of the material, the cuts will be more precise and detailed, which could be quite challenging to do manually; this allows more design flexibility.

Comparison: CNC Laser Cutting vs. Traditional Rubber Cutting Methods

Your choice between CNC laser cutting and traditional rubber cutting methods will depend on your specific project needs. The strengths of each are different, so knowing this will enable the most efficient production of your rubber gasket and seal.

In summary, CNC laser cutting provides greater precision, speed, and flexibility compared to traditional rubber-cutting methods. However, traditional techniques may still be useful for specific, simpler applications or larger production volumes.

CO2 laser cutting and engraving machines with other size and power options are available at STYLECNC. Please feel free to inquire at any time.

If you want more precise and faster cutting, you might want to take a look at our CNC digital knife cutting machine for gaskets and seals, which is more professional and ideal for high-volume gasket cutting in industrial manufacturing.

Cary Shelby

Fred Evans

When the machine first arrived, i was a little confused about how to install the laser tube, but i found an English manual which is sooo helpful! With videos, detailed training steps.

I really appreciated!