The automated edge bander machine is great and works as expected. As long as you stick to the recommended settings you will make some cool pieces. The ends are flush with the top and side pieces, and the trimmer will cut away any excess fringe strips.

2026 Best Automatic Edge Bander Machine with Trimmer

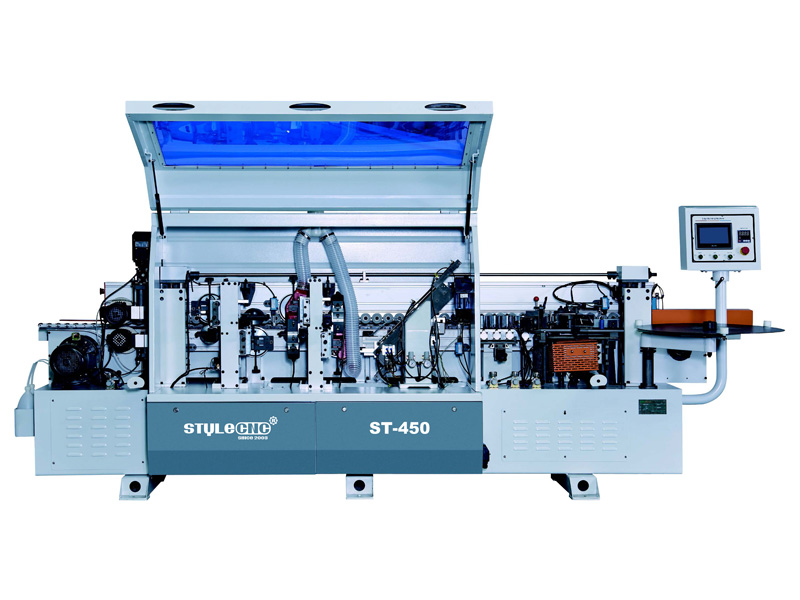

Need custom edge banding solutions to make cabinets, doors and decorations? The 2026 best automatic edge bender machine ST-450 will help you to upgrade your business plans.

- Brand - STYLECNC

- Model - ST-450

- Maker - Jinan Style Machinery Co., Ltd.

- Table Size - 3980x1000*1600mm

- 360 Units in Stock Available for Sale Every Month

- Meeting CE Standards in Terms of Quality & Safety

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- 30-Day Money Back Guarantee for Your Purchase

- Free Lifetime Technical Support for End-Users & Dealers

- Online (PayPal, Alibaba) / Offline (T/T, Debit & Credit Cards)

- Global Logistics and International Shipping To Anywhere

2026 Best Automatic Edge Bander Machine Features

1. The steel sheet of the base of the fuselage is cut by laser, and the fuselage formed by one-time welding is firm and not deformed, which increases the stability of the whole machine and ensures that each processing group can work precisely.

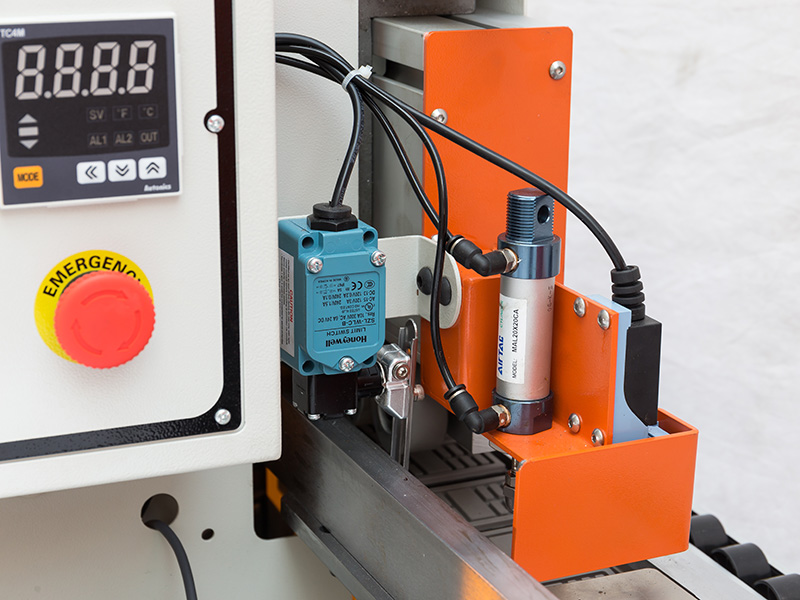

2. TAIWAN AIRTAC air-operated to ensure the accuracy.

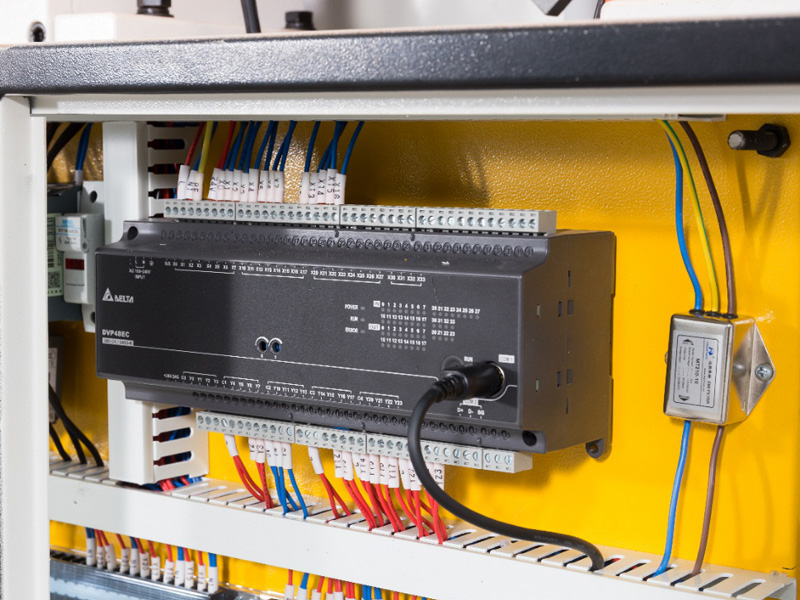

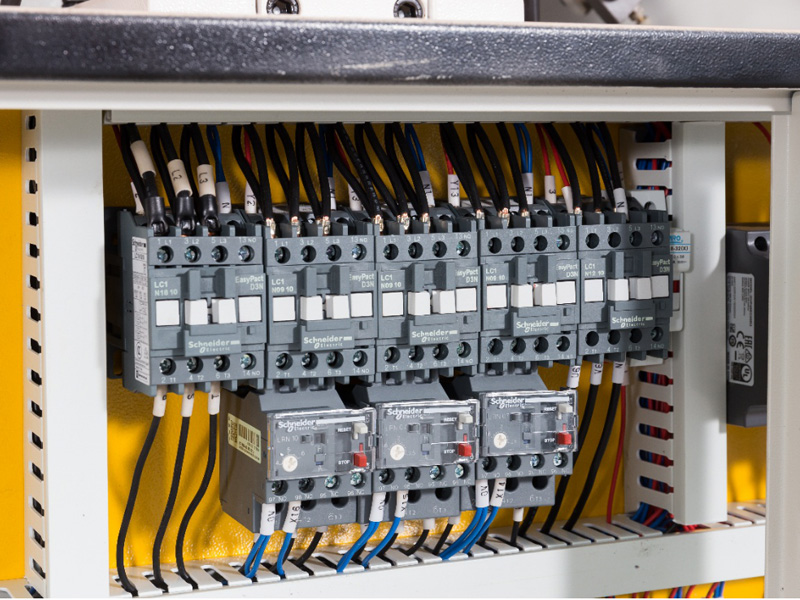

3. The electrical components are supplied by SCHNEIDER, OMRON, DELTA.

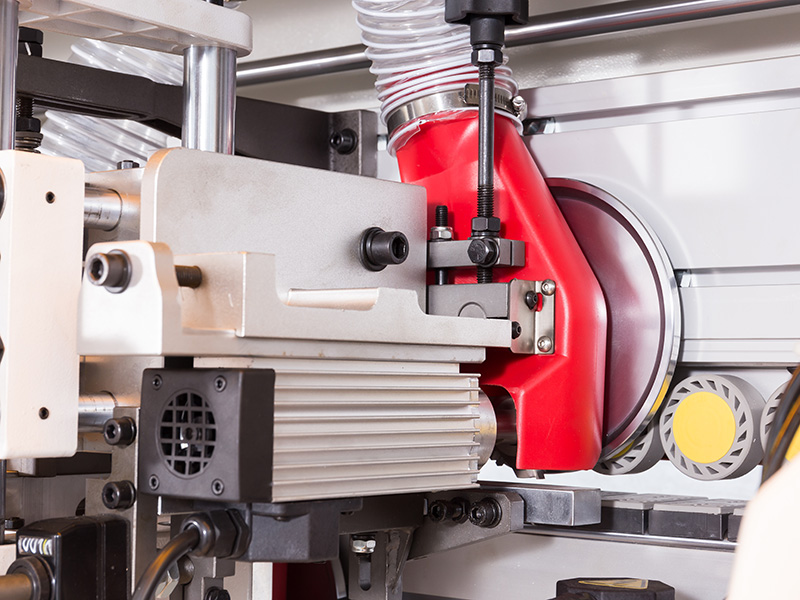

4. Special polishing structure, the motor angle can be adjusted universally, so that the edge grinding and polishing of PVC/acrylic/ABS/veneer can achieve the best effect.

5. Independent lifting system, simple and convenient.

6. Precise encoder control, high-speed edge sealing.

7. Pneumatic clamping bar, easier operation when the edge thickness change.

8. It adopts devices such as sound insulation, dust collection port, and anti-overload.

9. All the parts are made with fine processing of high-precision CNC machining center, and this ensures the stable and high efficiency operation.

10. The strict and elaborate assembly process to ensure each equipment gets to its perfect performance.

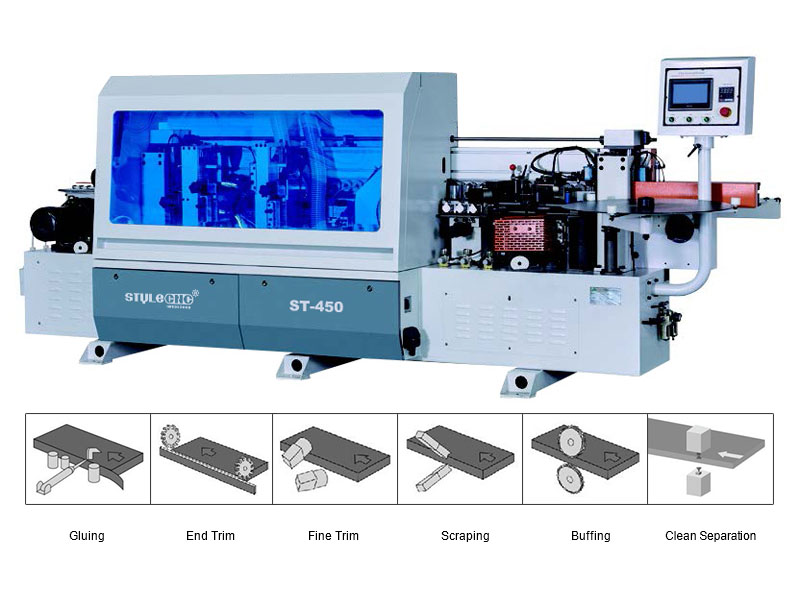

ST-450

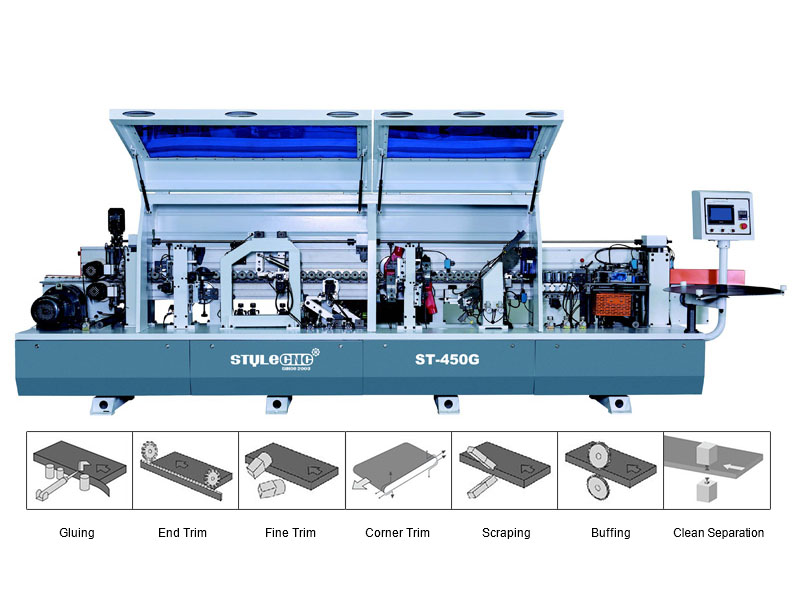

ST-450G

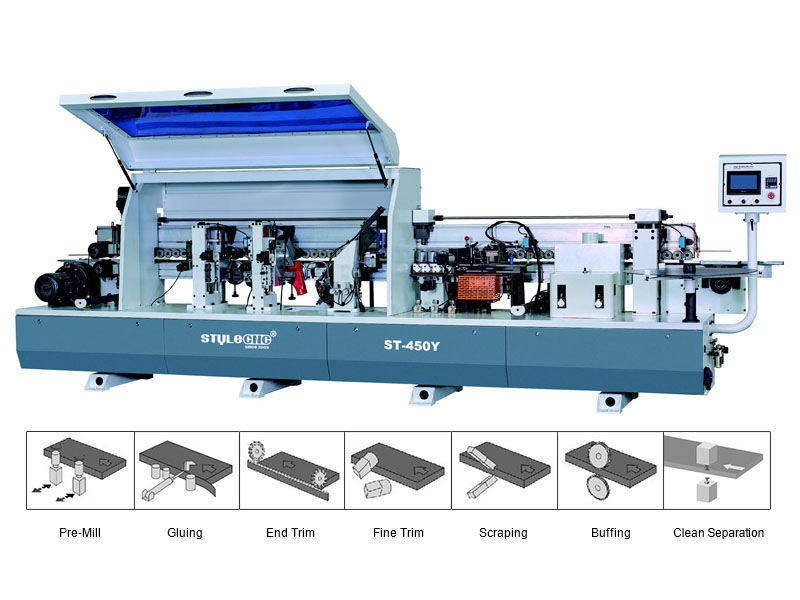

ST-450Y

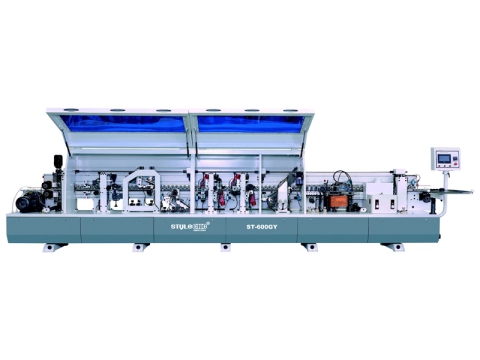

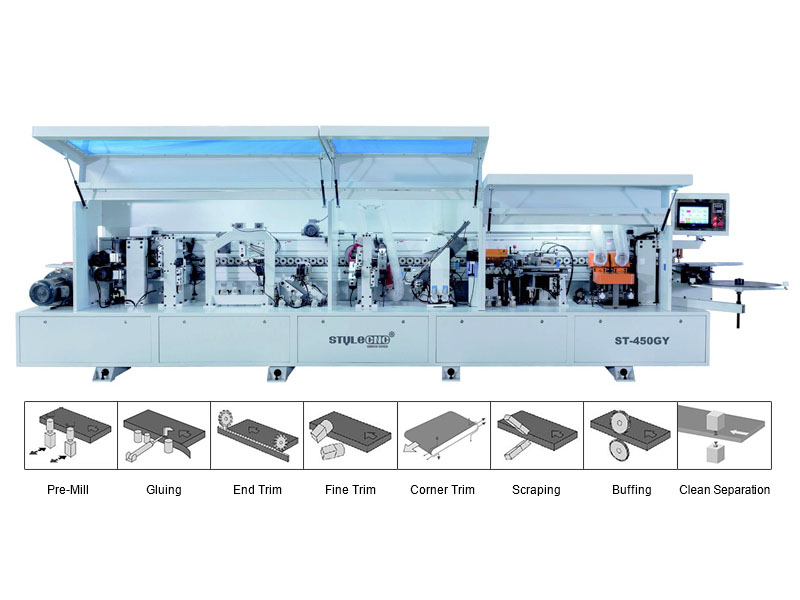

ST-450GY

2026 Best Automatic Edge Bander Machine Technical Parameters

| MODEL | ST-450 | ST-450G | ST-450Y | ST-450GY |

| Total power | 8KW | 9.5KW | 12.5KW | 13.9KW |

| Dimension | 3980x1000*1600mm | 5125x1000*1600mm | 4975x1000*1600mm | 6125x1000×1600mm |

| Feed speed | 12-17-20m/min | 12-17-20m/min | 12-17-20m/min | 12-17-20m/min |

| Board Thickness | 10~60mm | 10~60mm | 10~60mm | 10~60mm |

| Edge thickness | 0.3~3mm | 0.3~3mm | 0.3~3mm | 0.3~3mm |

| Board width | ≥80mm | ≥80mm | ≥80mm | ≥80mm |

| Board length | ≥120mm | ≥120mm | ≥120mm | ≥120mm |

| Working pressure | 0.6MPa | 0.6MPa | 0.6MPa | 0.6MPa |

| Weight | 1270kgs | 1750kgs | 1750kgs | 1900kgs |

| Thickness adjust | Manual | Automatic | Automatic | Automatic |

| Pre-milling | × | × | √ | √ |

| Gluing | √ | √ | √ | √ |

| End cutting | √ | √ | √ | √ |

| Fine Trimming | √ | √ | √ | √ |

| Corner rounding | × | √ | × | √ |

| Scrapping | √ | √ | √ | √ |

| Sprayer cleaning | √ | √ | √ | √ |

| Buffing | √ | √ | √ | √ |

What Can An Automatic Edge Banding Machine Do?

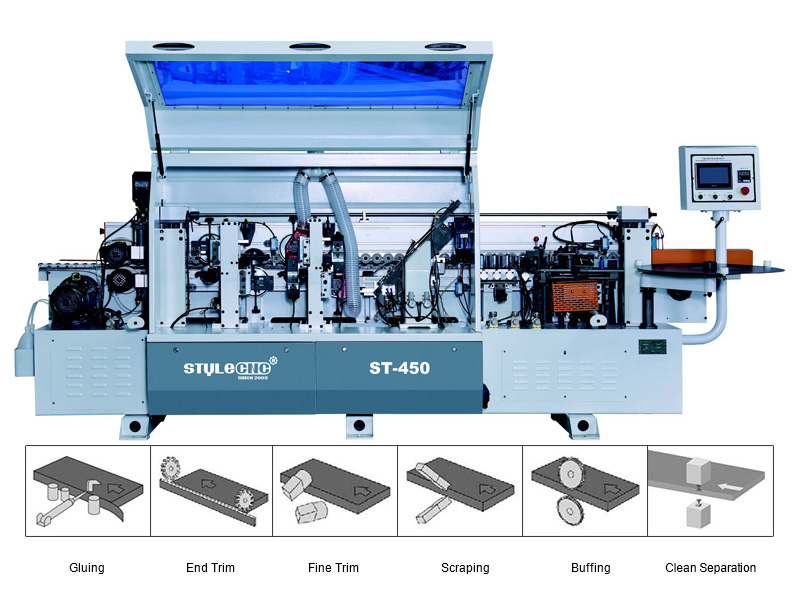

An automatic edge bander is used to pre-mill, bond the edge banner to the substrate, trim the leading & trailing edges, and corner edges, trim top and bottom flush with the substrate, scrape any surplus, and polish the finished edge.

This automatic edge banding machine is applied in panel furniture, office furniture, customized furniture, kitchen cabinet, wardrobe, solid wood furniture, tables, chairs, doors , woodworking, and decorations.

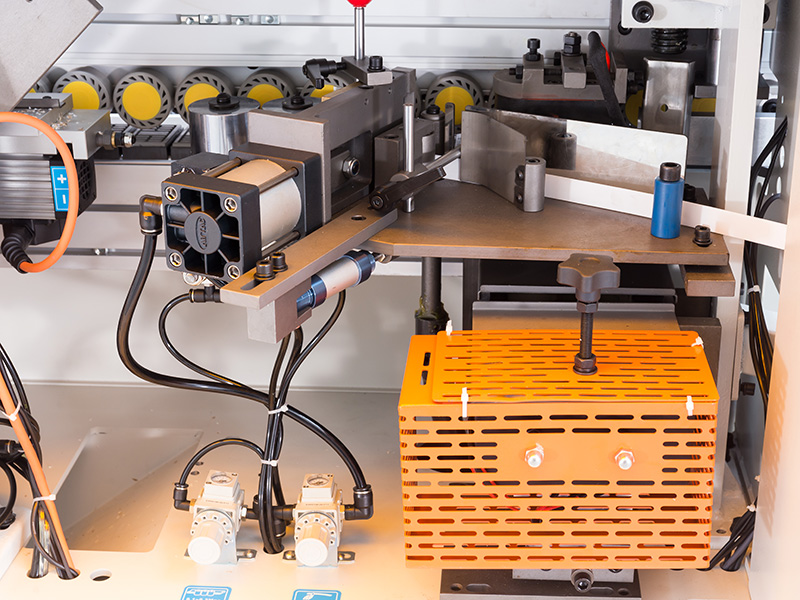

Automatic Gluing

Hot melt adhesive is added through the glue pot, and the spiral structure is adopted to feed the adhesive, so that the sheet material and the sealing material can be coated evenly.

Pressing

Inclined small pressing roller to stick the tape on the bevel side of panel.

End Cutting

It adopts normal high matching technology structure, through precise linear guide movement, adopt automatic tracking by mould and fast cutting structure of high frequency and high speed motor, ensure smooth cutting surface.

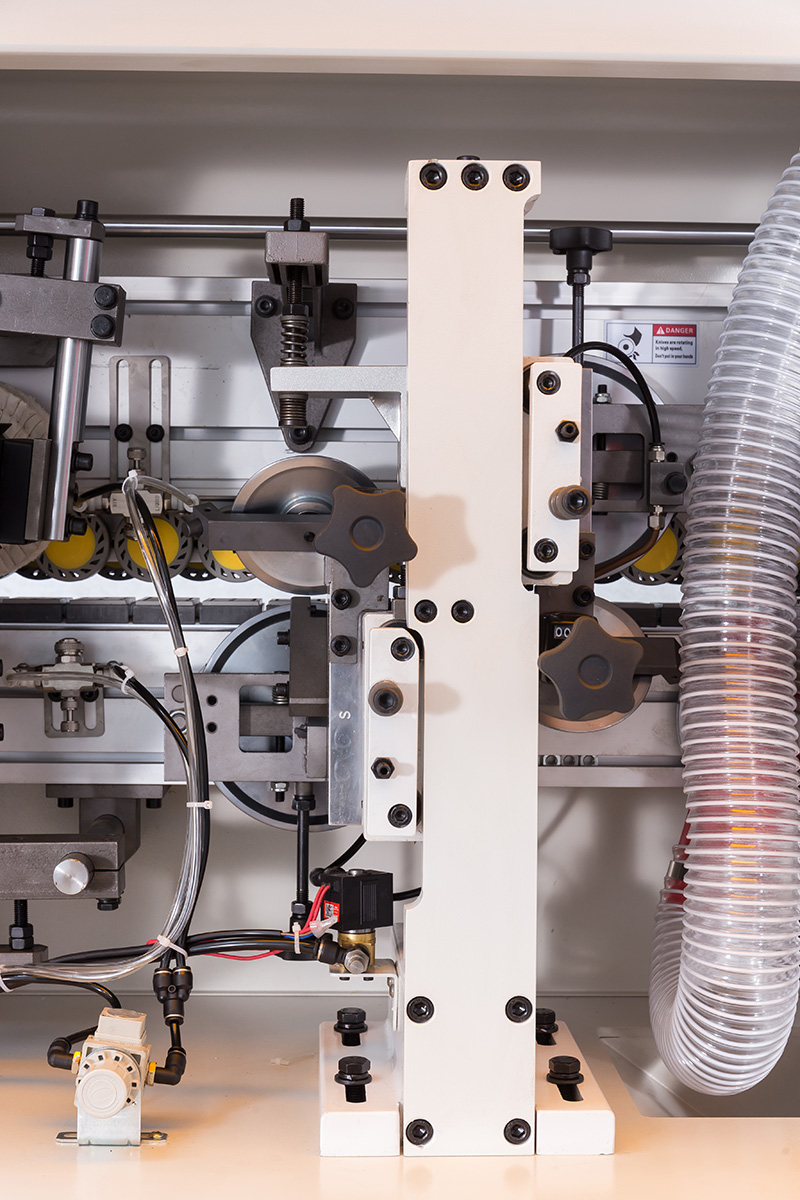

Fine Trimming Part with Double Saw

Eliminate the redundant tape in the top and bottom sides of board.

The stable frame design reduces the jitter of the tool during high-speed cutting, which leads to the instability of the trimming quality.

The design of the cutting edge is optimized to make the edge of the workpiece more perfect.

Scraping

It is used to eliminate the wavy marks caused by the cutting process of trimming non-linear motion, so that the upper and lower parts of the plate are more smooth and neat. At the same time, the size of the arc angle can be adjusted to make the sealing effect more perfect.

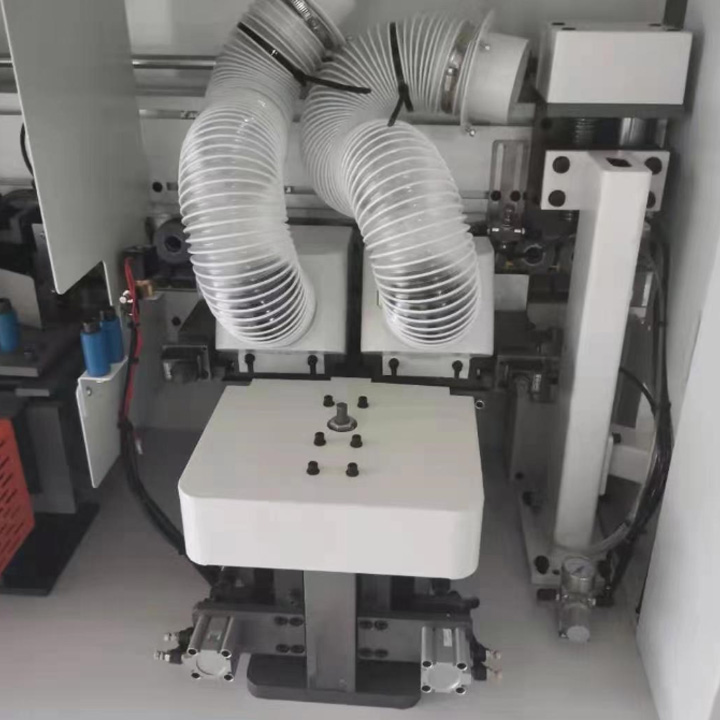

Sprayer Cleaning and Buffing

Clean the finished boards with a cotton polishing wheel. Remove excess glue and smooth the end face of sealing edge by polishing.

Pre-Milling (Optional for ST-450Y and ST-450GY)

Using 2 pcs of high wear-resisting blades, work on the waved effect that is caused by precise panel saw. Ensure the edges of panel are good for banding.

Corner Rounding (Optional for ST-450G and ST-450GY)

Double heads corner rounding, high precision guaranteed perfect look and touch.

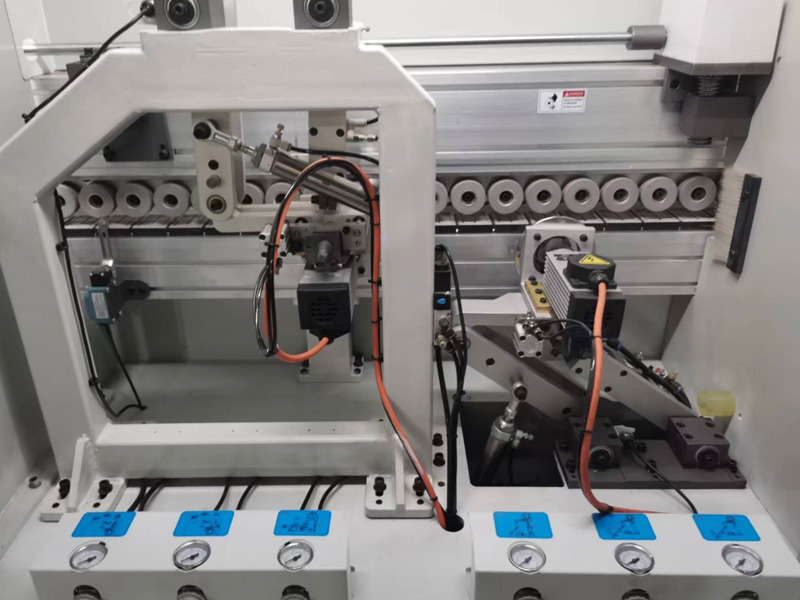

2026 Best Autoamtic Edge Bander Machine Parts & Accessories

Stable Conveyor Motor

Machine feeding speed can be 12m/min.

Rotary Table to Support Edge Sealing Belt

Single table design, heavy load.

Delta Colorful Touch Screen

Easy to operate.

Taiwan Airtec Pneumatic Components

Small space position, light structure, beautiful appearance, can withstand large lateral load.

Taiwan Delta PLC

Taiwan Delta Inverters

Oil Lubrication and Oil-Water Separator

Schneider Electric Parts

Automatic Edge Bander Machine Advantages

The use of the automatic edge banding machine has provided great convenience for the furniture industry, improved the competitiveness of the furniture industry, and made it continue to develop rapidly.

1. No glue leakage: When traditional hand-sealing of furniture is performed, glue leakage often occurs due to improper operation, resulting in a large amount of waste of raw materials and a reduction in the quality of furniture edge sealing. When using the automatic edge banding machine for operation, there will be no glue leakage at all, saving a lot of raw materials.

2. Easy to clean: When traditional hand-sealing furniture, glue is often spilled everywhere for various reasons, and sometimes even the furniture will be stained with a large amount of glue, which is very unfavorable for the beauty of the furniture, and cleaning Difficulties will also be encountered when using the automatic edge banding machine. After using the automatic edge banding machine, the machine can be cleaned regularly, and sometimes the automatic edge banding machine can be cleaned while running, which will not affect the production of the production line.

3. Fewer failures: When traditional hand-sealed furniture is edged, the efficiency of edge-sealing is affected by the edge-sealing operator. Many artificial reasons will lead to the decline of edge-sealing quality and efficiency, which is completely unhelpful to the development of the furniture industry. The use of automatic edge banding machine for furniture edge banding will not be affected by human factors, and the failure of the machine is very small, which greatly improves the efficiency of furniture edge banding.

4. The sol is not easy to age: when the edge is manually sealed, the sol must be sealed while the edge is sealed, so it is easy to cause the aging of the sol because the glue is not taken in time, which affects the quality of furniture edge sealing. However, this kind of trouble will not occur at all when using the automatic edge banding machine for furniture edge banding.

What Are Automatic Edge Bander Machines Used For?

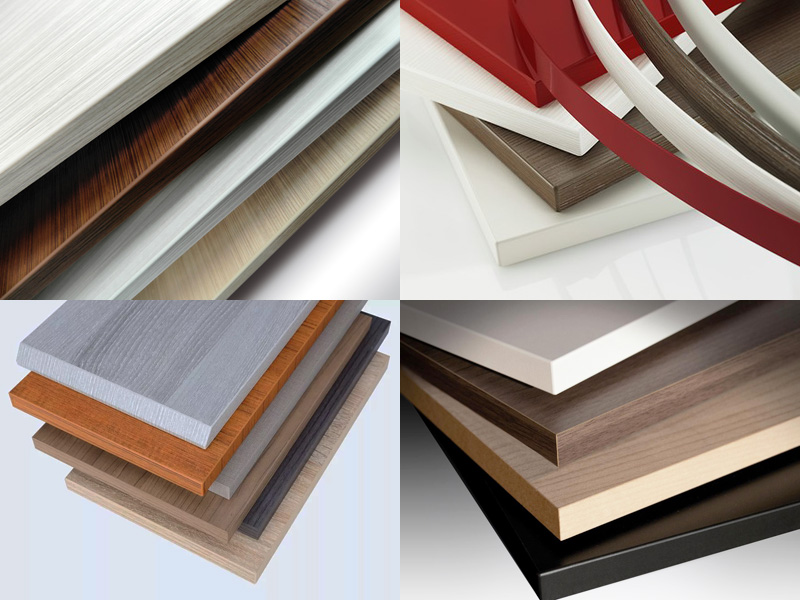

The automatic edge bander machine is suitable for MDF, block board, solid wood board, particle board, polymer door sheets, plywood, aluminum honeycomb panel. It is used for covering the exposed sides of panels and boards such as MDF, plywood, or particle board, creating decorative edges, increasing durability and giving the more valuable appearance.

Automatic Edge Banding Projects