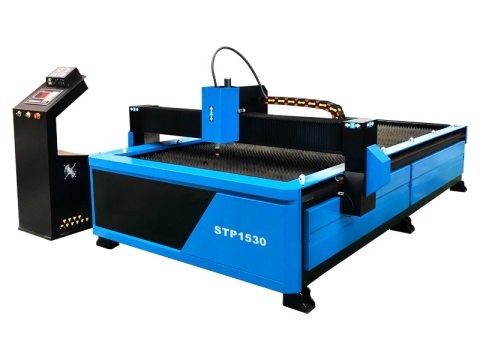

Portable CNC Flame Cutting Machine with Plasma Torch

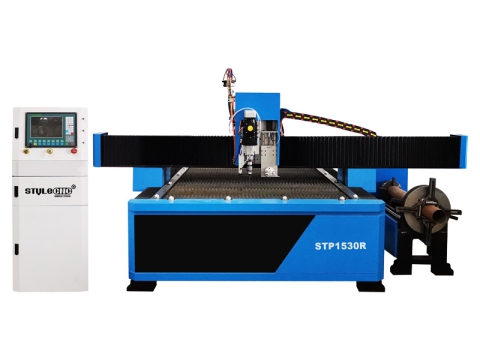

Portable CNC flame cutting machine with plasma torch is type of portable CNC plasma cutter designed for heavy sheet metal fabrication with oxy-fuel gas, the portable CNC oxy-fuel gas and plasma cutter machine adopts gantry structure with double-driven system, now the cheap portable CNC plasma/flame cutting machine for sale at affordable price within your budget.

- Brand - STYLECNC

- Model - STP1325

- Maker - Jinan Style Machinery Co., Ltd.

- Category - CNC Plasma Cutter

- 360 Units in Stock Available for Sale Every Month

- Meeting CE Standards in Terms of Quality & Safety

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- 30-Day Money Back Guarantee for Your Purchase

- Free Lifetime Technical Support for End-Users & Dealers

- Online (PayPal, Alibaba) / Offline (T/T, Debit & Credit Cards)

- Global Logistics and International Shipping To Anywhere

Overview

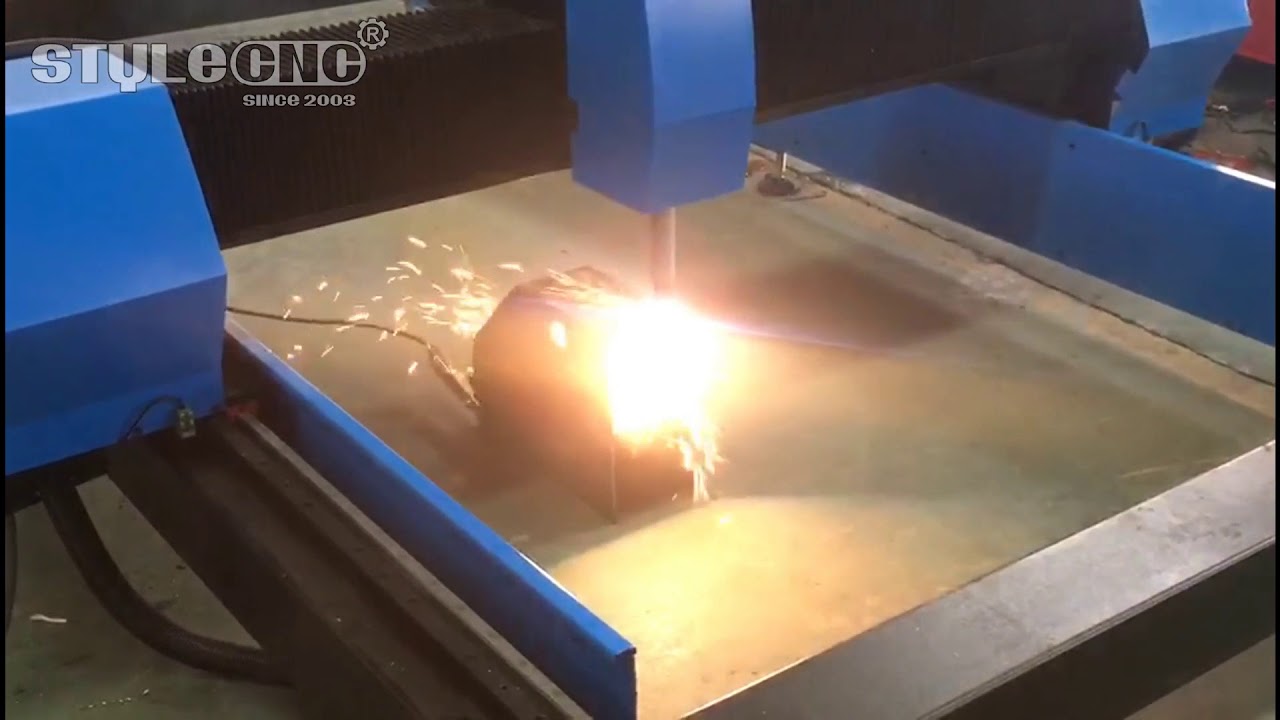

CNC flame cutting machine is a type of CNC metal cutter that uses fuel gas with oxygen or gasoline with oxygen to cut metal materials, and CNC plasma cutting machine is a type of CNC metal cutting system that uses the heat of a high-temperature plasma arc to melt and evaporate the metal part or part of the incision of the workpiece, and uses the momentum of the high-speed plasma to remove the molten metal to form the incision. The CNC plasma flame cutting machine is to ionize the material to produce a high temperature of 6000 degrees Celsius to 8000 degrees Celsius to quickly melt the object. In the energy center of the plasma arc, the gas can completely form an ion state to reach a high temperature of 15,000 to 30,000 degrees Celsius, and quickly merge metals to achieve rapid cutting. The purpose is to melt the metal through the plasma arc when working, and then use the attached airflow to blow the melted metal away to achieve the purpose of cutting.

CNC flame cutting machine with plasma torch is a type of portable plasma cutter with CNC controller, which can cut metals up to 200mm. It's also known as CNC oxy-fuel gas and plasma cutting machine, CNC plasma and flame cutting machine, CNC oxy fuel cutting machine, CNC plasma & oxy-fuel cutting machine.

Portable CNC Flame/Plasma Cutting Machine Features

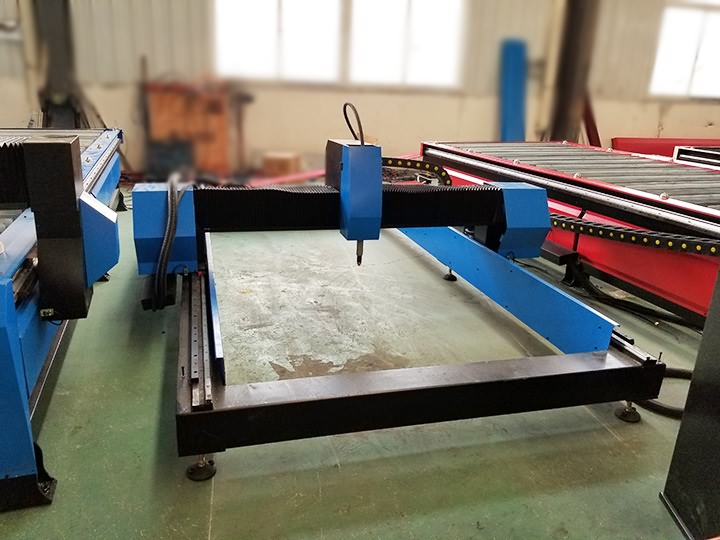

1. The portable plasma cutter can cut large and small metal parts. The working size is 1300*2500mm and we also can customize the working size according to your requirements, like the Y axis, we can make it up to 8-10m.

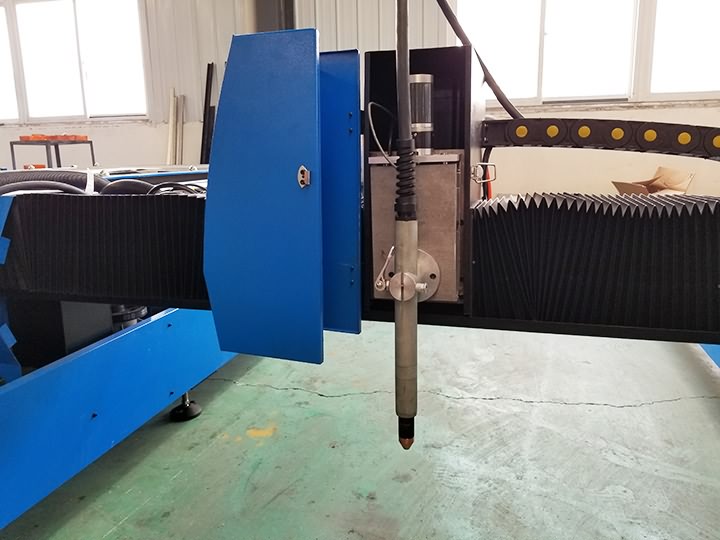

2. The portable CNC plasma cutter has two cutting head, one of them is Hypertherm plasma cutting head and other is independent lift flame cutting head can cutting around 150-200mm metal.

3. Hypertherm power supply can provide a high and stable power when the portable CNC plasma & oxy-fuel cutting machine working.

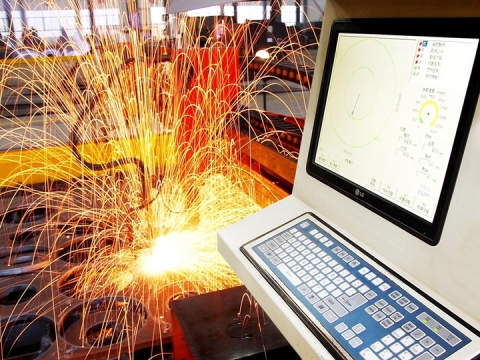

4. STARFIRE control system and with ARC voltage automatic height adjusting device, arcing can protect plasma torch from damage, improve the cutting quality, the success rate is over 99%.

5. Double guide and square rails can keep the portable CNC oxy-fuel gas and plasma cutting table stability.

6. Ultra big torque stepper motor and driver with features of function detecting, high running precision, wide speed range and short speed up time.

7. High-precision HIWIN rail linear guide, smooth movement to ensure that the CNC oxy fuel cutting machine tools with high precision, small cutting gap, no residua.

8. Excellent performance on cutting illuminated letters for advertising and channel letters on sheet metal.

9. Perfectly design, equipped with the best machine accessories to minimize the failure rate preferred.

10. The portable CNC flame cutting machine supports G-code files of ARTCAM, Type3 software. It also supports DXF files of AUTOCAD by transfer software. The control system supports U disk file transfer.

Details of Portable CNC Flame Cutting Machine with Plasma Torch

Hypertherm Powermax Plasma Cutter

Hypertherm Plasma Torch for Portable Plasma Cutter

Professional CNC Control System for Portable Plasma Cutter

CNC Plasma Cutting Nozzle

Applications of Portable CNC Plasma Cutter with Flame Torch

Portable CNC plasma cutting machine with flame torch is widely used in ship, car, boiler pressure vessel, steel structure, plane, engineering machinery and other fields. The portable flame cutter is used to cut thicker metal materials and the portable plasma cutter for thin metal cutting, such as carbon steel, stainless steel, aluminum, copper and other metal plates. It is especially designed for irregular drawing batch cutting.

Technical Parameters of Portable CNC Flame Cutting Machine with Plasma Torch

| Model | STP1325 |

| Motor Style | Stepper Motors Dual Drive |

| Effective Cutting Range for each Tool X*Y | 1300*2500mm |

| Cutting Speed | 0 - 4000mm/min |

| Input Power | Single Phase AC 220V |

| Cutting Modes | Plasma Cutting and Flame Cutting |

| Transmission Style | Rack And Gear |

| Working Precision | ± 0.2 mm / meter |

| Plasma Cutting Thickness | Depends on the cutting capacity of the Plasma Generator |

| Flame auto igniter | Including Flame Device |

| Gas Pressure | Acetylene Gas or Propane Gas Max 0.1Mpa |

| Oxygen Pressure | Oxygen Gas Max 0.8Mpa |

CNC Plasma/Flame Cutting Capability

| Plasma power | Cutting thickness |

| Hypertherm 65A | Carbon steel 12mm, stainless steel 8mm |

| Hypertherm 85A | Carbon steel 16mm, stainless steel 12mm |

| Hypertherm 105A | Carbon steel 22mm, stainless steel 18mm |

| Hypertherm 125A | Carbon steel 25mm, stainless steel 20mm |

| Flame cutting head | 1-200mm metals |

Projects of Portable CNC Plasma Cutting Machine with Flame Torch

Flame Cutting VS Plasma Cutting

For the two most common methods of CNC metal cutting machines, different people have different understandings. Some think that plasma cutting machines should be economical, and some think that plasma cutting is cheaper. In fact, each cutting method has its own advantages and disadvantages. You can choose different cutting methods according to the material you actually need to cut. STYLECNC compares plasma cutting and flame cutting for customers to choose.

Metal cutting is a necessary process for most metal fabrication. For example, in sheet metal fabrication, we need to first cut the steel plate into the rough shape we need, and then finish it into the required parts. CNC flame/plasma cutting machine uses a digital motion control system to realize movement by writing processing programs or transferring processing files or graphics in the system, combined with stepping or servo motor drivers, driving stepping or servo motors to control the machining axes of the machine tool It can realize the processing technology of flame/plasma cutting, cutting out the required metal shape through combustible gas or plasma arc.

Pros and Cons

CNC Plasma Cutting

The CNC plasma cutting machine is a machining method in which the CNC machine tool uses the heat of the high-temperature plasma arc to locally melt and evaporate the metal at the incision of the workpiece, and uses the momentum of the high-speed plasma to remove the molten metal to form the incision.

Pros

1. The cutting area is wide, and all metal plates can be cut.

2. The cutting speed is fast, the efficiency is high, and the cutting speed can reach more than 10m/min.

3. The cutting accuracy is higher than flame cutting, underwater cutting has no deformation, and fine plasma cutting has higher accuracy.

Cons

1. It is more difficult to cut steel plates of 20mm or more, and a high-power plasma power supply is required, and the cost is relatively high.

2. When cutting thick plates, the cut is V-shaped.

CNC Flame Cutting (Oxy Fuel Cutting)

CNC flame cutting machine is a cutting method in which a CNC machine tool uses gas and oxygen or gasoline and oxygen to cut metal materials.

Pros

1. It can cut very thick carbon steel, its cutting range is very wide, and it can cut thick steel sheet of 6mm to 200mm.

2. The price of flame cutting machine is relatively low, and the initial investment cost is also low.

Cons

1. The cutting requires long preheating and perforation time, and the cutting speed is slow.

2. The thermal deformation during cutting is large, especially when cutting (0.5-6mm) thin plates, the cutting accuracy is not high.

3. Unable to cut non-ferrous metals such as copper, aluminum and stainless steel.

4. The method of burning fuel has serious environmental pollution and is not environmentally friendly.

Although CNC flame cutting of thin sheet metals (0.5 to 6mm) has been gradually replaced by plasma cutting in the cutting field, CNC flame cutting is still playing an important role in cutting thick and medium plates, and flame cutting has the advantage of its price. It has always occupied a certain market share in cutting.