I purchased the STO1625A two months ago and to my surprise it showed up at my door less than 30 days after I placed the order. It took me about 2 hours from start to finish, but once it was done, I felt a great sense of accomplishment. I had a few software issues with the first boot, but I called Mike and he was able to help me out quickly. I have been using this oscillating knife to cut fiberglass and fabric and I am very happy with the results I get. I've never used an automatic CNC cutter like this before, but now it keeps my creative juices flowing.

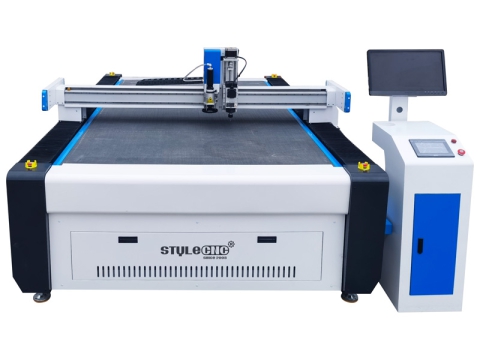

2026 Top Rated CNC Oscillating Knife Cutter for Sale

2026 top rated CNC oscillating knife cutter is a professional CNC digital cutting system for fiberglass, fabric, leather, cardboard, plastic, paper, rubber, cloth, foam, flexible polymer with hobby projects or industrial plans. Now the best CNC oscillating knife cutting machine for sale at affordable price.

- Brand - STYLECNC

- Model - STO1625A

- Maker - Jinan Style Machinery Co., Ltd.

- Category - CNC Digital Knife Cutting Machine

- 360 Units in Stock Available for Sale Every Month

- Meeting CE Standards in Terms of Quality & Safety

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- 30-Day Money Back Guarantee for Your Purchase

- Free Lifetime Technical Support for End-Users & Dealers

- Online (PayPal, Alibaba) / Offline (T/T, Debit & Credit Cards)

- Global Logistics and International Shipping To Anywhere

A CNC oscillating knife cutter is a high-precision cutting machine fitted with a motorized blade that rapidly moves up and down to slice through materials. Unlike rotary cutting tools, the oscillating knife provides clean cuts with no heat buildup, ideal for soft and semi-rigid materials. Controlled by computer software, it follows programmed paths with accuracy for intricate designs.

These machines find their very useful applications in several industries such as packaging, textiles, leather, and signage. These machines work with different materials like foam, rubber, cardboard, fabric, and plastic. The ability to cut without tearing or deforming the material is a key advantage.

CNC oscillating knife cutters work wonders in terms of efficiency, speed, and versatility. They reduce material wastage and labor costs, hence finding their perfect application in industries requiring precision and steadfast repetition.

Materials Suitable for CNC Oscillating Knife Cutting Machines

The soft, flexible, or semi-rigid material is the perfect field to deal with CNC oscillating knife-cutting machines. Applications involving material that can get damaged or deformed by traditional cutting methods can effectively utilize such machines. Below are key materials for those machines:

1. Foam: CNC oscillating knife cutters can handle a variety of foam types, including EVA, polyethylene, and polyurethane. These materials are generally used in packaging, insulation, and upholstery. Because of the accurate movement of the blade, the edges will be clean without compressing the foam.

2. Rubber: Soft rubber sheets used in seals and gaskets can be easily cut using these machines. The oscillating knife ensures smooth, accurate cuts without creating rough edges or heat-induced damage.

3. Fabric and Textiles: From cutting natural fabrics such as cotton to synthetic materials like polyester, these machines work just perfectly. They find wide applications in garment productions, upholstery, and custom textile designs.

4. Leather and Synthetic Leather: These oscillating knife cutters provide clean and consistent cuts for industries like footwear and automotive interiors that involve such materials. They minimize material wastage, ensuring efficiency in high-volume production.

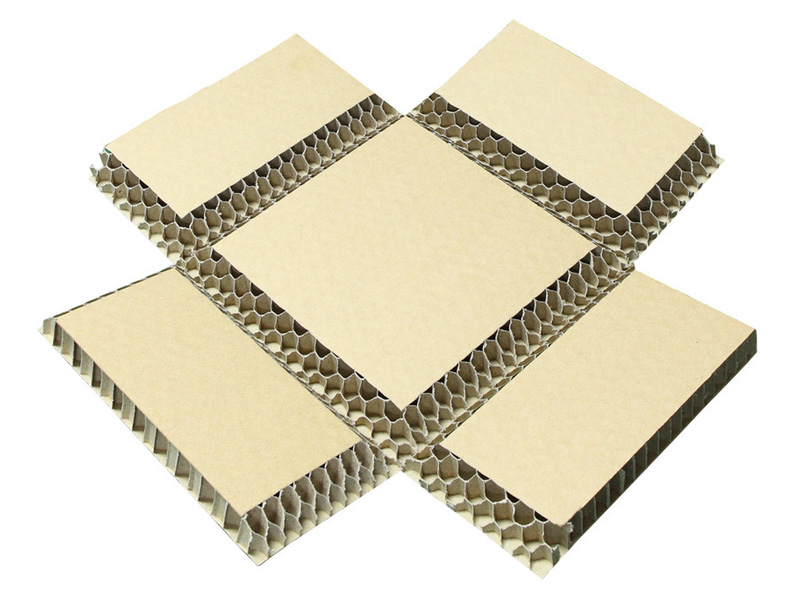

5. Cardboard and Corrugated Board: The machines are perfect for cutting cardboard for packaging prototypes or displays. They deliver sharp, precise cuts, ensuring professional results.

6. Plastic Sheets: Thin, flexible plastics like PVC or polypropylene can be cut without cracks or distortions. These materials are often used in signage, templates, or industrial parts.

Discover the Benefits of CNC Oscillating Knife Cutting Machines

CNC oscillating knife cutters unite speed, precision, and versatility to change how one cuts materials. Ideal for soft and semi-rigid materials, the machines bring forth an increase in productivity, cost efficiency, and faultless results-the dream of any industry with high demands on speed and accuracy.

High Speed and Intelligent Operation

These machines operate at remarkable speeds, significantly reducing production time. Intelligent control systems ensure smooth operation and precise path-following, even for complex designs. This combination boosts productivity and maintains high-quality output.

Precision Cutting

With advanced oscillating blade technology, these machines deliver clean and accurate cuts. They can handle intricate patterns and sharp edges without damaging materials. This makes them ideal for industries requiring flawless detailing.

Ease of Use

CNC oscillating knife cutters are user-friendly, with intuitive software for programming and operation. Minimal manual intervention is required, making them accessible to operators with varying skill levels. Training new users is straightforward, reducing learning curves.

Material Versatility

The machines can cut a wide range of soft and semi-rigid materials, from foam and rubber to textiles and leather. This flexibility makes them suitable for diverse applications. They adapt seamlessly to different projects without compromising precision.

Cost Efficiency

By reducing material waste and labor effort, these machines lower operational costs. Their ability to handle multiple tasks further enhances cost-effectiveness. Over time, they help businesses maximize their return on investment.

Low Maintenance

Unlike rotary cutters, oscillating knives experience less wear and tear. This minimizes downtime and ensures consistent performance over time. The reduced maintenance needs also save long-term operational costs.

Applications of CNC Oscillating Knife Cutter

The CNC oscillating knife cutter, such as the STO1625A series, is designed for precision in material handling, from corrugated board to chipboard, foam board, plastic board, thin wood, leather, and fabric. This makes it so valuable in several spheres of business.

In packaging and protection, it ensures clean cuts for custom boxes, protective layers, and inserts, enhancing product safety and presentation. For advertising displays, it delivers flawless cuts for signage, banners, and promotional materials, enabling sharp and professional finishes.

The machine is widely used in thermal insulation applications, cutting materials like foam boards for construction and energy-saving projects. It is also ideal for model and mock-up making, supporting architects and designers in creating detailed prototypes. Additionally, industries producing puzzles and patterns benefit from its precision in crafting intricate shapes.

Whether for industrial-scale projects or creative applications, the CNC oscillating knife cutter provides unparalleled efficiency and versatility.

Technical Parameters of CNC Oscillating Knife Cutter

| Model | STO1625A |

| Maximum working dimensions | 1600mm*2500mm |

| Cutting speed | Maximum 2000mm/s (set according to different cutting materials) |

| Cutting thickness | according to different materials |

| Repeated positioning accuracy | Maximum 0.01mm |

| Mechanical Precision | Maximum 0.02mm |

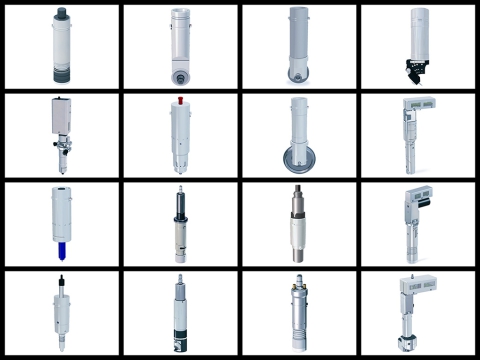

| Multi-function cutting head | Oscillating knife, 45-degree knife, kiss-cut knife, round knife, V-cut knife and various kinds of tools |

| Tool configuration | Various tool holders |

| Security configuration | High-sensitivity infrared ray interaction |

| Cutting material | Corrugated paper, PVC expansion sheet, kt sheet, thick foam, grey board, paperboard, car sticker, adhesive Sticker, etc. |

| Material fixing method | High-power vacuum absorption and intellectual partition |

| Drive system | Rack and pinion, AC servo motor, linear guideway |

| Control system | Kinco |

| Operating mode | operation platform + data output control software (operation platform can be divided into connected and separated parts) |

| Display mode | Chinese and English liquid touchscreen |

| Data transmission method | Ethernet |

| Instruction system | HPGL compatible format |

| Buffer capacity | Standard 4GB |

| Rated power | 12KW |

| Rated voltage | 380V or 220V |

Features of CNC Oscillating Knife Cutter

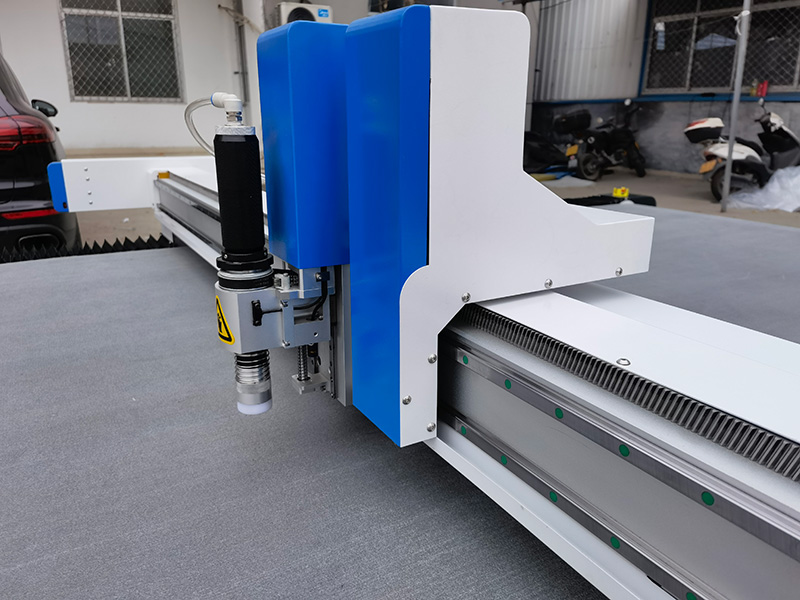

• The platform detection device regulates the knife pressure automatically, enabling a level platform and perfect cutting.

• The high-precision CNC oscillating knife cutter can induce drafts separately and easily cut small pieces.

• The anti-collision and the built-in autosensing device ensure the security of the CNC oscillating knife cutter.

• High efficiency can be realized without making a high-cost knife model.

• The high-precision CNC oscillating knife cutter is designed for production with small quantities and can save on costs while maintaining speed and accuracy.

• The CNC machine cuts by knife, with no burning, and no pollution gases generated.

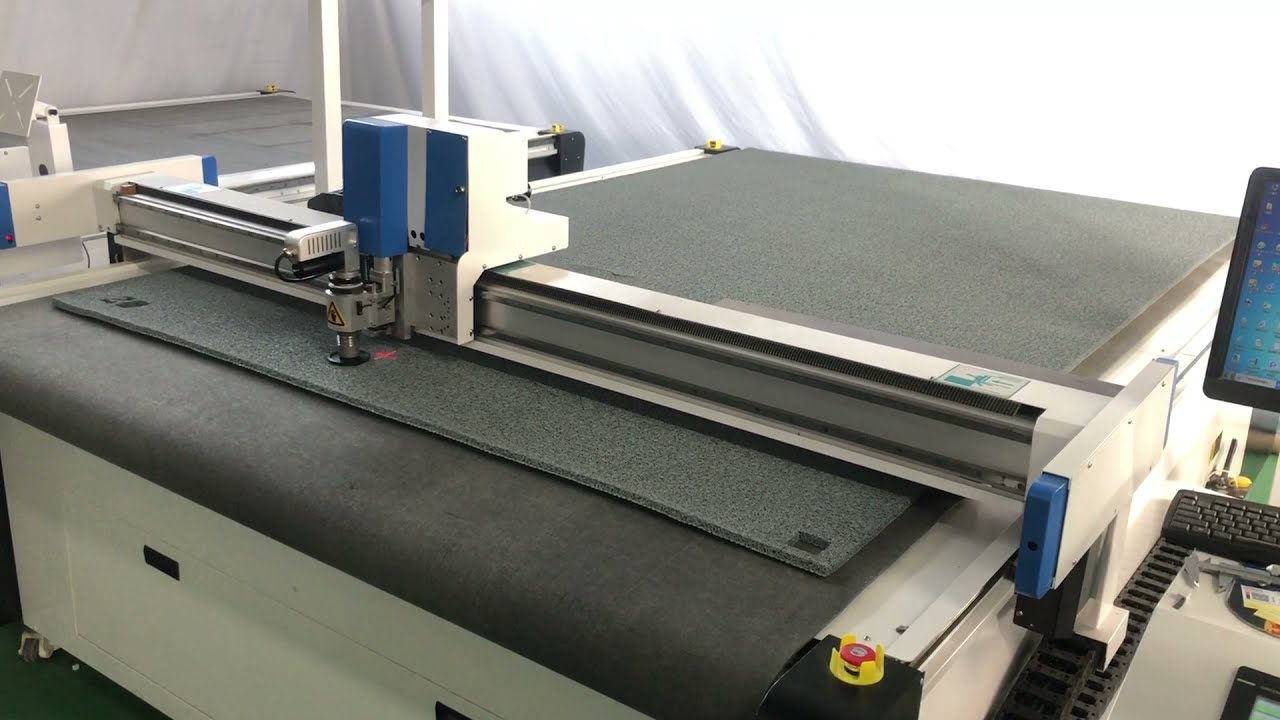

Oscillating Knife Cutting Machine in Factory

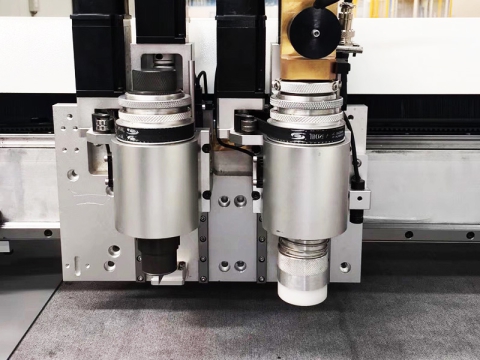

Pneumatic Knife Cutter

High Power Oscillating Knife

CNC Oscillating Knife Cutter Cutting projects

Cardboard cutting projects by CNC oscillating knife cutter andV-cut knife:

Leather cutting projects by CNC oscillating knife cutter and punching knife:

Carpet cutting projects by CNC oscillating knife cutter and round knife:

Dust-proof foot mat cutting project by CNC oscillating knife cutter:

Automotive interior cutting projects by CNC oscillating knife cutter and circular knife:

Maintenance Tips for Maximizing the Lifespan of Your CNC Oscillating Knife Cutter

Proper maintenance will ensure the longevity and peak performance of your CNC oscillating knife cutter. By caring for it regularly, you can prevent breakdowns that are not necessary, cut with precision, and reduce downtimes. Here are some easy maintenance ways to consider in maximizing its lifespan:

• Regular Cleaning: Clean the machine after every use to remove dust, debris, and material residue. This prevents buildup that could affect performance. Use compressed air or a soft brush to clean hard-to-reach areas.

• Blade Inspection: Check the oscillating knife regularly for wear and tear. Replace the blade when it shows signs of dullness or damage. A sharp blade ensures clean, accurate cuts and reduces the strain on the machine.

• Lubrication: Smear friction-reducing oils on the moving parts such as the oscillating mechanism and guide rails. Do this with recommended lubricants to avoid dust formation due to over-greasing.

• Tighten Loose Parts: Make periodic checks for screws and bolts loose in the machine. Tightening helps in giving a good structure that keeps away vibrational effects which can affect accuracy at the point of cut.

• Software Updates: Always keep the machine software updated for both optimized performance and security. Regular checks for software are good for attaining compatibility with new designs and to work more efficiently.

• Routine Calibration: Keep up routine calibration to avoid losing any cutting precision. Calibration ensures the machine movement is exactly aligned with the design specifications.

Feridun ARICI

PAUL LANGLOIS

I received the CNC knife cutting table on time and in good condition. It took me 3 days to get the hang of it and learn how to use this tool properly. So far just doing lots of leather jacket cutting projects. No noise and dust at all. A great automatic leather cutter to work with.