Automatic CNC Laser Cutters, Engravers, Cleaning Systems, Welding Machines

Throughout the last few years, automatic CNC laser machining has become widespread, expanding from hobby shops to small businesses, schools, as well as strictly industrial manufacturers. Increased competition on the market also means that choosing the right CNC laser machine for cutting, engraving, marking, etching, cleaning and welding will be harder than ever. Most guys have no idea where to start. STYLECNC would like to assist you throughout the selection process, not by suggesting any specific CNC laser kit, but rather by guiding you to make your own decision, in accordance with your needs and budget. There's a lot to know before you can find the right CNC laser cutter, engraver, marker, etcher, cleaner and welder to start or grow your business. In order to help you get the right information, here are some of the CNC & laser basics you need to know. This guide will discuss what you need to consider when determining which CNC laser machine is the best kit for your business.

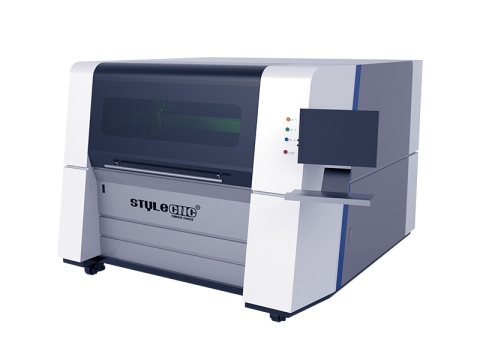

Cheap CO2 Laser Engraver 60W, 80W, 100W, 130W, 150W, 180W

2025 Best Entry Level Small Laser Engraver for Beginners

Budget-Friendly Small Desktop Laser Engraver Cutter Machine

Hobby Laser Engraver for Plastic, Acrylic, Glass, Polymer

2025 Top Rated Laser Wood Engraving Machine for Sale

Affordable Laser Engraver for Leather, Fabric, Paper, Jeans

2026 Best 3D Laser Crystal Engraving Machine for Sale

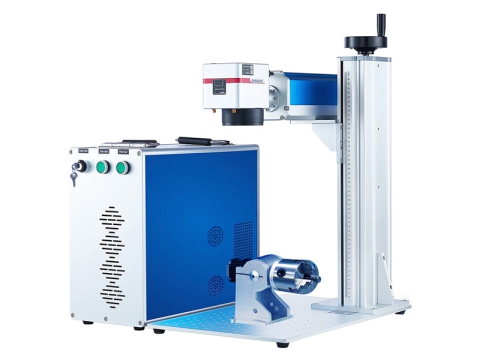

50W Fiber Laser Deep Engraving Machine for Metal

2026 Best Laser Engraver for Gun Stippling & Grip Texturing

Laser Marking Machine with CCD Visual Positioning System

Mini Handheld Fiber Laser Marking Machine 20W, 30W, 50W

Affordable Fiber Laser Engraving Machine for Color Marking

3D Fiber Laser Marking Machine for Metal Texturing

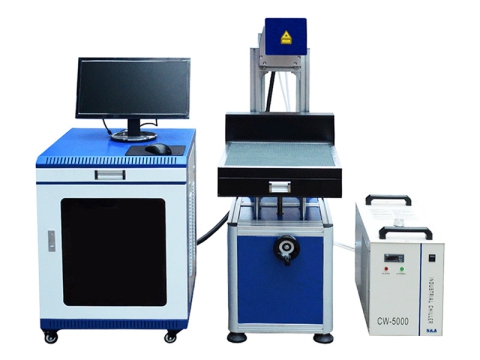

CO2 Laser Marking Machine for Glass, Acrylic, Plastic

Low Cost CO2 Laser Marking Machine for Leather & Fabric

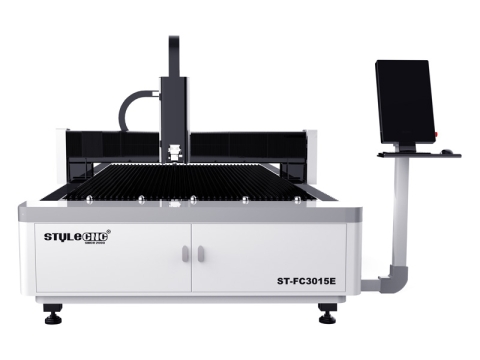

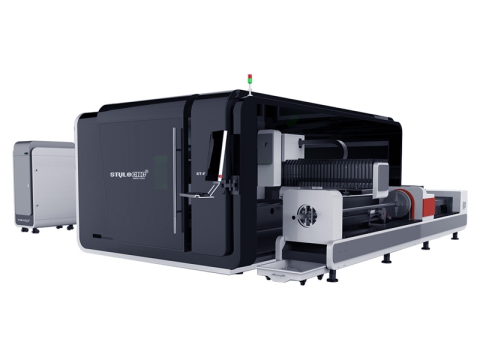

2026 Best Sheet Metal Laser Cutter for Sale (1500W - 6000W)

2026 Top Rated Fiber Laser Cutting Machine for Sale - 2000W

Mini Laser Metal Jewelry Cutter for Silver, Gold, Copper

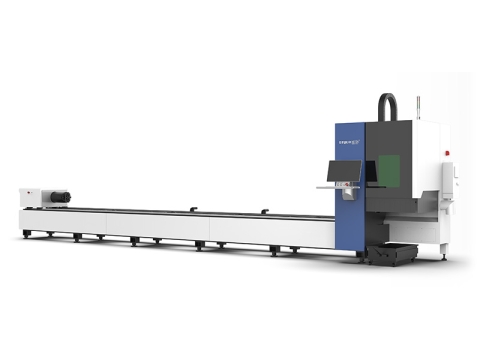

2025 Top Rated Fiber Laser Tube Cutting Machine for Sale

2025 Cheapest 4x8 Fiber Laser Stainless Steel Cutter 1500W

Industrial 3D Robotic Fiber Laser Cutting Machine for Metal

Entry Level Small Metal Laser Cutter for Beginners

Dual-Purpose 6KW Fiber Laser Cutter for Metal Sheet & Tube

5x10 Industrial Fiber Laser Metal Cutting Machine for Sale

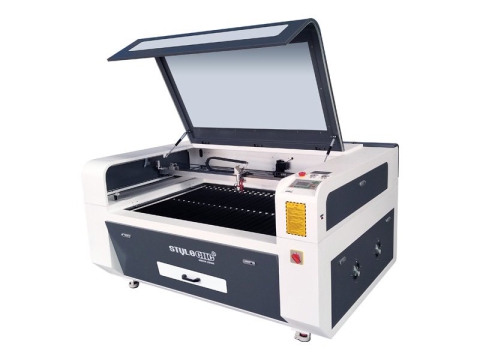

2025 Best CO2 Laser Cutter for Small Business and Home Use

Entry Level CO2 Hobby Laser Cutter Machine for Beginners

100W Laser Wood Cutter Engraving Machine for Woodworking

2025 Best Acrylic Laser Cutting Machine for Sale

2025 Best Industrial Fabric Laser Cutting Machine for Sale

CNC Laser Cutter With CCD Camera Visual Recognition System

Dual-Head CO2 Laser Cutter for Paper and Cardboard

2025 Best-Selling 4x8 Laser Cutter for Plywood & MDF

2025 Best Industrial Laser Foam Cutting Machine for Sale

Metal & Nonmetal Laser Cutter with 300W CO2 Laser Tube

Fiber & CO2 Combo Laser Cutting System for Metal & Nonmetal

4x8 Flatbed Laser CNC Engraving Cutting Machine for Sale

2025 Best Metal & Nonmetal Laser Cutting Machine for Sale

Profitable Mixed CNC Laser Cutter Hybrid Cutting Machine

Mixed CNC Laser Cutter Engraving Machine for Wood & Metal

2026 Best Handheld Fiber Laser Cleaning Machine for Sale

3-In-1 Handheld Laser Welding, Cleaning, Cutting Machine

2026 Best Portable Handheld Laser Welding Machine for Sale

2026 Best Handheld Laser Rust Removal Machine for Sale

Hi-Precision Automatic CNC Laser Welding Machine for Sale

Automatic Smart 3D Industrial Laser Welding Robot for Sale

Feature Stories & Articles That Interest You

Find & Buy Your First CNC Laser Machines In 2025

Definition

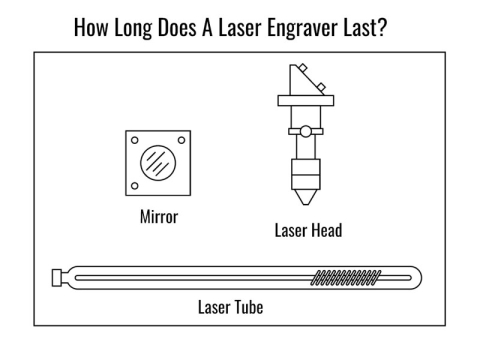

A CNC laser machine is an automatic computer numerical controlled laser machining system that adopts FIBER/CO2/UV laser beam to mark, etch, engrave, cut metallic and nonmetallic materials, and weld pieces of metal together by melting and fusing, as well as clean pollutant layer, remove rust, strip paint and coating. It is composed of bed frame, controller, power supply, generator, tube, head, mirror, lens, water chiller, stepper motor or servo motor, air compressor, gas cylinder, gas storage tank, dust extractor, air cooling filer, dryer, software and system. It is mostly used in industrial manufacturing applications, school education, small businesses, home business, small shop, home shop, advertising, arts, crafts, gifts, toys, packaging industry, printing industry, leather processing industry, clothing industry, automotive industry, musical instruments, architecture, label production, medical industry and more.

Applications

CNC laser machines are used for marking, etching, stippling, engraving, and cutting variety of metal & nonmetal materials:

Metal Materials: Carbon steel, stainless steel, tool steel, spring steel, galvanized steel, aluminum, copper, gold, silver, alloy, titanium, iron, brass, manganese, chromium, nickel, cobalt, lead.

Nonmetal Materials: Wood, MDF, plywood, chipboard, acrylic, plastic, PMMA, leather, fabric, cardboard, paper, rubber, depron foam, EPM, gator foam, polyester (PES), polyethylene (PE), polyurethane (PUR), neoprene, textile, bamboo, ivory, carbon fibers, polyvinyl chloride (PVC), polyvinyl butyrale (PVB), polytetrafluoroethylenes (PTFE /Teflon), beryllium oxide, and any materials containing halogens (chlorine, fluorine, iodine, astatine and bromine), phenolic or epoxy resins.

Types

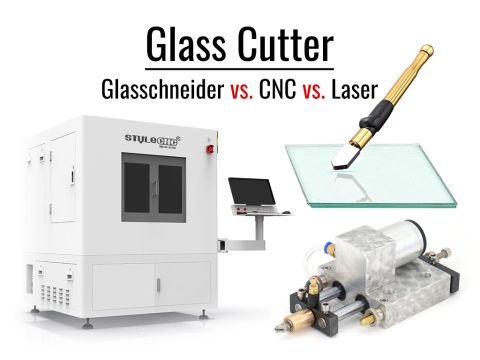

CNC laser machines are divided into cutting, engraving, marking, cleaning, welding machine,

Cutters are divided into fiber, CO2 and hybrid laser cutters,

Engravers are divided into fiber, UV and CO2 laser engraver.

Markers are divided into fiber, CO2 and UV laser marking machine.

Welders are divided into handheld and automatic laser welding machine.

Technical Parameters - Specifications

| Brand | STYLECNC |

| Laser Power | 20 Watts - 60000 Watts |

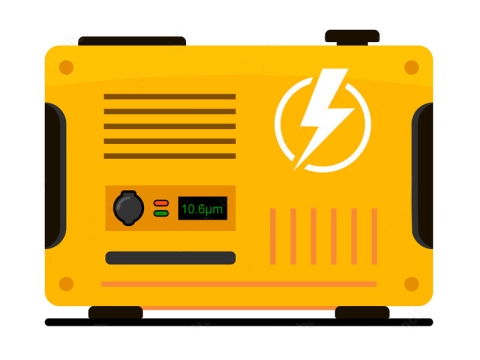

| Laser Wavelength | 10.6 μm, 1064 nm, 355 nm |

| Laser Type | Fiber, CO2 and UV laser |

| Capability | Cutting, Engraving, Etching, Marking, Cleaning, Welding |

| Price Range | $2,400 - $260,000 |

Cost & Pricing

The cost of a CNC laser machine is composed of spare parts (CNC controller, power supply, generator, head, laser tube, lens, mirror, bed frame, water chiller, stepper motor or servo motor, dust extractor, air compressor, gas cylinder, gas storage tank, air cooling filer, dryer), software and control system, shipping costs, tax rates, customs clearance, service and technical support.

A CNC laser cutter ranges from $2,600 to $300,000. A CNC laser engraving machine starts at $2,400 and up to $70,000. A CNC laser marking machine is priced from $3,000 to $70,000. A CNC laser welding machine costs anywhere from $16,800 to $28,000. All in all, you'll have to spend around $6,000 on average for a CNC laser machine in 2025.

Benefits and Advantages

As a new technological method in recent years, the CNC laser machine can irradiate a beam with a high energy density to the workpiece to be processed, so that it is locally heated and melted, and then use high-pressure gas to blow off the slag to cut shapes & profiles or engrave texts & patterns.

• Narrow kerf, high precision, good kerf roughness, no need for further processing after cutting.

• It has a high degree of automation, can be completely enclosed for processing, has no pollution, and has low noise, which greatly improves the working environment of the operator.

• The processing cost is low. The one-time investment in equipment is more expensive, but continuous and large-scale processing will eventually reduce the processing cost of each part.

• It is non-contact processing, with low inertia and fast processing speed. It is time-saving and convenient, and the overall efficiency is high with the CAD/CAM software programming of the CNC system.

• The high energy density is enough to melt any metal, and it is especially suitable for processing some materials that are difficult to process with high hardness, high brittleness, and high melting point.

• The action time is short, the heat affected zone is small, the thermal deformation is small, and the thermal stress is small. In addition, it is non-mechanical contact processing, which has no mechanical stress on the workpiece and is suitable for precision processing.

• The CNC laser system itself is a set of computer systems, which can be conveniently arranged and modified, and is suitable for personalized processing, especially for some sheet metal parts with complex contours and shapes. The batches are large and the batches are not large, and the product life cycle is not long. From the perspective of technology, economic cost and time, manufacturing molds is not cost-effective, and engraving & cutting is particularly advantageous.

The CNC laser machine is not a consumer product. It is a weapon to help you make money. The purpose of buying it is to increase production capacity, improve production efficiency, reduce production costs, improve the level of technology, so it is very important to choose the right machine.

How To Use?

Step 1. Determine the production plan according to the arrangement, and distribute the processing drawings to the entire equipment operation group.

Step 2. According to the plan, the drawing staff will analyze the drawings, and draw them with CAD according to the requirements of the drawings.

Step 3. The quality inspector confirms the correctness of the drawing drawn by the draftsman.

Step 4. According to the drawn electronic file drawings, the production supervisor calculates the processing completion time and prepares the materials required for processing and the cutting auxiliary gas used.

Step 5. Programmers use programming software to prepare files in the format of NC operation.

Step 6. The supervisor issues a task list to the equipment operator (the task list contains the following contents: the program name of the workpiece, the type of material, the thickness of the material, the maximum length and width of the workpiece to be processed, and the number of workpieces required.)

Step 7. Trial cut the first piece and send it to the quality inspector for inspection. After confirming that the size is qualified, the first piece is archived.

Step 8. Start batch processing

Step 8. Number the processed workpiece.

Precautions

Startup Precautions

• Check whether there are obstacles on the machine table that affect the zero return of the X, Y, and Z axes of the machine tool, and remove them if necessary.

• Prepare various gases required for cutting, and adjust the pressure to an appropriate value as required; for example, the pressure of oxygen used for cutting should be adjusted to 0.4-0.5 MP, and the pressure of nitrogen gas should be adjusted to 1.8-2.2 MP (Note : According to the thickness of the cutting plate, the pressure should be changed, and the thin plate should use a small air pressure, and the thick plate should use a high air pressure).

• Open the drain valve of the air storage tank of the air compressor to drain the sewage in the air tank, then close the drain valve to start the air compressor (the loading and unloading pressure of the air compressor should be set to 0.8MP and 1MP).

• Start the voltage regulator (the voltage regulator value is set to 380~400V).

• Start the condenser (function: to cool the gas generated by the air compressor, dry it and send it to each reflector).

• Start the chiller to check whether its water level and water pressure are normal, and turn on the cooling water and normal temperature water. The cooling water pressure should be set to about 0.5MP, and the upper limit temperature should be set to 20 degrees. The water pressure at room temperature is around 0.3MP, the upper limit temperature is set to 30 degrees in summer and 25 degrees in other seasons.

• Turn on the pressure of high-purity nitrogen (purity ≥99.999℅) is greater than 0.4MP, the pressure of high-purity carbon dioxide (purity ≥99.999℅) is greater than 0.4MP, and the pressure of high-purity helium (purity ≥99.999℅) Greater than 0.4MP.

• Turn on the laser generator.

• Turn on the machine, enter the OPERATOR system (password: user), release the emergency stop button and reset the alarm, return to the reference point (SET ZERO), light up the CLC button, light up the start button (LASER ON), and observe the laser after the word (HV READY) appears on the panel of the electric cabinet, the high voltage on button (HV ON) on the numerical control panel can be lighted.

• According to the task plan, input the program to be processed into the CNC for processing and production.

Shutdown Precautions

• Return the X, Y, and Z axes to the reference point.

• Turn off the high voltage button (HV ON).

• Turn off the power supply (LASER OFF).

• Press the emergency stop button to close the CNC panel. (The power supply of the CNC panel cannot be forcibly turned off. Forcibly shutting down may easily cause system data loss)

• Cut off the power supply of the electric control cabinet of the machine.

• Stop the chiller and disconnect its power source.

• Cut off the power supply of the electric control cabinet.

• Stop the air compressor and cut off the power.

• Stop the condenser and disconnect the power supply.

• Close each auxiliary air valve.

• Clean the CNC laser machine.

Precautions During Operation

• Protection against anti-slag from drilling (protective lens).

• When cutting stainless steel, galvanized sheet, aluminum sheet and other materials, it is easy to cause slag and contaminate the focusing mirror. In order to avoid such consequences due to improper parameter setting, customers are required taking note of the following items.

• The punching height is set to 2~5 mm, and the height increases with the increase of material thickness.

• For materials with a thickness greater than or equal to 2.5 mm, it is required to turn on the option of “cut small hole after piercing” and set the radius of the small hole to 0.5-1 mm.

• For stainless steel with a thickness of 3 mm or less, nitrogen drilling must be used.

• Stainless steel thicker than 3 mm can be perforated with nitrogen or oxygen.

• For aluminum or galvanized panels, oxygen perforation must be used.

• When drilling holes with oxygen, it is required to turn on the "Wait for oxygen and nitrogen conversion" option, and set the time to 1 to 3 seconds.

• During the cutting process, the customer is required paying heed to the deformation of the plate. If the plate jumps, the customer is required to press the plate before cutting, so as to avoid the occurrence of impermeable cutting and slag due to the beating of the plate.

Personal Safety Tips

• Check the nature of the material to be cut, learn whether it will produce toxic gas when cutting, and ensure that there is a proper smoking system. (Note: the operators must wear protective equipment)

• Focus on the instructions in the equipment operating manual.

Machine Tool Safety Tips

• When starting a cutting job, attend to the following: check the properties of the material to be cut, understand its reflection of the beam, and ensure its absorption of light to prevent damage to the laser after reflection.

• Pay attention to electricity and laser damage during the use.

Electricity Safety

The machine is powered by 390-400V AC, and then converted to a high voltage of more than 10 kV through a high-voltage transformer to provide excitation energy.

• When it is powered on, do not open the electrical cabinet and laser head protection door to avoid electric shock.

• After it is powered off, do not open the electric cabinet and the laser head protective door, especially the back door of the electric cabinet,

• Because the electricity inside the laser may not be completely discharged, it is easy to cause harm to people.

Laser Safety

Laser is invisible light with high power density, which is easy to cause burns and radiation to the human body. When using it, do not stand in the path of the light to avoid being burned. Do not stare directly at the laser to avoid being burned. It is best to wear protective glasses for work.

Focusing Lenses Precautions

Pay attention to the cleaning of the focusing lens and clean it frequently. It needs to be adjusted once a month if the optical path is found to be off, and the equipment should be maintained regularly according to the maintenance requirements in the operation manual to keep the equipment in the best condition.

Cold Dryer Precautions

• The indoor temperature cannot exceed 35 degrees.

• Discharge sewage every day.

• Clean the vents once a week (just blow with an air gun).

• Clean the filter monthly (soft brush soapy water).

Maintenance & Troubleshooting

Machine Tool Daily Maintenance

• The external optical path is checked 1-2 months. If the copper mirror is found to be polluted, it needs to be cleaned in time (cleaning as required). After cleaning, the external optical path needs to be re-adjusted. After adjusted, don't move it easily.

• The screw and linear guide need to be lubricated and maintained every half a month to a month.

• The entire machine table surface needs to be cleaned once a week.

• Clean the dust on the radiator of the chiller once a week (blow the radiator up and down with air). 5. Check the water level in the water exchanger once a month and replenish the water (note that the water inside should be as clean as possible).

• Check the filter of the cold dryer once every 2-3 months and clean the filter element once (alcohol). Do not wash it too hard. If there is oil stain, clean it with gasoline. If it is damaged, it needs to be replaced.

• The guide rails of the workbench and the lift table are cleaned once a month.

• The chiller should be inspected every month. If the water level is insufficient, replenish water. The pure water should be replaced every 2 months, and the distilled water is replaced every 6 months. If the water quality is not good during the inspection, replace it immediately.

It is recommended to use telephoto lens cutting for carbon steel over 9.6mm and stainless steel over 5mm, which is easy to protect the lens.

• Remember to clean the lens after cutting stainless steel, wood, rubber, plexiglass, and quartz.

• Due to the high temperature in summer, if the CNC laser machine works for a long time, the Z-axis and the Z-axis box may be slightly heated, which is normal. But if the temperature is high or even hot, it is not normal. It is recommended to start checking from the following aspects:

- Check whether the switch of the control external light path on the chiller is turned on.

- Whether the optical path of the Z axis is positive.

- Is the surface of the focusing lens badly damaged (many spots on the surface).

- Whether the Z axis is vertical.

- Whether the two copper mirrors at the proximal end of the Y axis are clean. Any of the above situations will cause the Z-axis and the Z-axis box to heat up, so you should pay more attention to it in the future.

- After changing the mixed gas, tighten the valves of the mixed gas, and then gently close the lid.

• Pay attention to the standard operation. When raising the head (RETRACT) to execute cycle cutting (CYCLE START) and lowering the head (SET TO CUT) to execute cycle cutting (CYCLE START), you must pay attention to the display in the program, and do not move quickly when the cutting head is lowered. (It is easy to crash the cutting head in this way).

• Frequent blasting will occur in the following situations (frequent blasting will damage the lens).

- Due to the unstable working voltage or other reasons, the pulses emitted by the laser are sometimes unstable.

- The light is biased.

- Piercing parameters are not reasonable.

• Every once in a while, use a cotton swab or absorbent cotton to dip some acetone to clean the inside of the Z-axis.

CNC Laser Daily Maintenance

In order for the CNC laser machine to have and maintain good working performance, it is necessary to provide it with good working conditions, that is, to meet its requirements mainly in terms of water, gas and electricity.

The main function of cooling water is to take away the heat generated during operation and prevent it from working at high temperature. The chiller uses distilled water to take away the heat in the electrical cabinet and resonance cavity through cooling and water circulation, so that the machine can work normally. The water temperature of the cooling water should be kept at 20 degrees. Since the water passes through the pipeline of the chiller and the copper plate in the resonance cavity, it is required that the pH and conductivity of the water meet the requirements, otherwise the laser will be damaged if used for a long time. In order to avoid this situation, anticorrosion inhibitors need to be added to the water, and the conductivity of the water should be measured regularly to ensure that the water quality meets the requirements. The RF generator is cooled with deionized water, and a deionized agent is also required to ensure that the conductivity meets the requirements.

The working gas is divided into two types, one is the mixed gas that provides the medium for the resonator, and the other is high-purity nitrogen. The purity of high-purity nitrogen must reach more than 99.99%, otherwise it will pollute and cause damage to the lens in the inner optical path. Pay attention to the quality of the gas, otherwise the laser will be easily damaged.

Air Compressors Maintenance

• Check the oil level (at the 3/4 position) every day before starting up, and drain the waste water after stopping.

• Clean the cooling nets on both sides (just blow with an air gun) and the air filter every week.

• Clean oil cooler air cooler every 1000 hours.

• Check the belt tension every 1000 hours to adjust.

• Replace air filter oil filter compressor oil every 4000 hours.

• Do not exceed 110 degrees when the machine is running (80~90 degrees when working).

• The number of motor starts must not exceed 20 every hour.

• Do not use the emergency stop for non-emergency situations.

• The fan blades run counterclockwise, indicating that the wires are not reversed.

Safety and Security

Fire Protection

Oxygen is needed for the operation of the CNC laser machine, so smoking should be prohibited in the area around the machine, especially near the oxygen cylinder, to prevent hidden dangers and unnecessary damage. (If conditions permit, fire extinguishers should be provided next to the equipment)

Laser Protection

When hitting the center, one must pay attention to make sure the person's hand is away first, turn off the height control (turn off the CLC) and then light. When adjusting the external light path, it must be ensured that no one is standing in the light path range. The operator should also pay attention to ensure that the light will not hit people before lighting. The lighting power and time should be controlled to a reasonable range (the central power is generally 200 between 0.01 and 0.02S. When adjusting the external optical path, the light output power is generally controlled at about 300W, and the light output time is controlled between 0.2 and 0.5S). After the external optical path is adjusted, all protective covers must be installed before cutting. When exchanging air, remove the high voltage first, and close the door immediately after exchanging air. Do not open the door of the electrical cabinet casually, and do not touch the circuits and electronic components inside.

Trends

The era of intelligence will come in all respects. Whether it is Germany's Industry 4.0 or China's smart manufacturing, the fourth industrial revolution in the industrial field is quietly coming. As a high-precision laser CNC machine, the laser CNC cutting machine or laser CNC engraving machine is bound to keep pace with the times and fly with technology. The development of laser CNC automation has greatly improved the production capacity and automation level of the workshop.

In the future, on this basis, an era of laser CNC engraving & cutting machines combined with intelligent manufacturing is brewing deeply in the fields of network technology, communication technology, and computer software technology. As an intelligent manufacturing pilot demonstration unit, STYLECNC is relying on its own system technology integration capabilities, focusing on the future development direction and technological commanding heights, and joining strategic partners to build a fully intelligent laser CNC machining factory and create a new situation for intelligent laser CNC engraver and laser CNC cutter.

Things To Consider

This is only a small scratch to know about automatic CNC laser machining. However, by having a basic understanding of these helpful concepts, you'll be able to quickly build upon them and grow your knowledge of CNC laser machine choices.

What Our Customers Say?

Don't take our words as everything. Find out what customers say about our CNC laser machines they have owned or experienced. Why is STYLECNC considered a credible brand and manufacturer to buy a new CNC laser machine? We can talk all day about our quality products, 24/7 excellent customer service and support, as well our 30-day return and refund policy. But wouldn't it be more helpful and relevant for newbies and professionals alike to hear real-life customers experience what it's like to purchase and operate an automatic computer-controlled machine tool from us? We think so too, which is why we've collected tons of genuine feedback to help bring transparency to our unique buying process in-depth. STYLECNC guarantees that all customer reviews are real evaluations from those who have purchased and used our products or services.