Looking to buy an affordable stone CNC machine to carve personalized relief sculptures for you custom business, or create 3D Buddha head statues using a rotary attachment as works of art? Having an idea to get an automatic stone carving machine to make headstones & gravestones in memory of your family and friends, or start a new tombstone business? Need to purchase a 3 axis, 4 axis or 5 axis CNC bridge saw to custom kitchen countertops and bathroom vanity tops to upgrade your home improvement business? Here is the right place for your needs and budget. STYLECNC is the most trusted manufacturer & maker to provide all types hobby & industrial CNC machines for stone carving, engraving, cutting and polishing. You'll get a cost price for your machine tools and free expert customer service & support from STYLECNC. Let's start understanding the super practical buying guide to all stone fabricators.

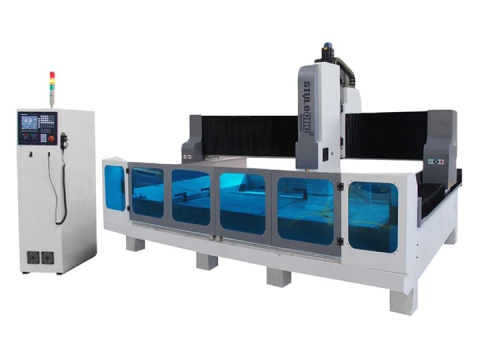

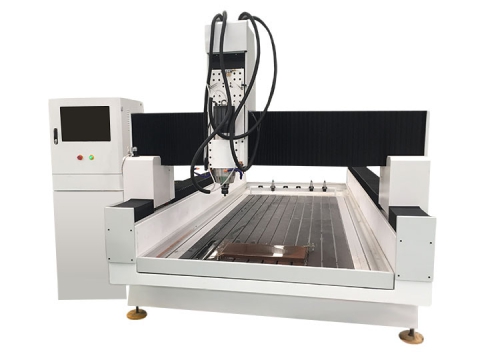

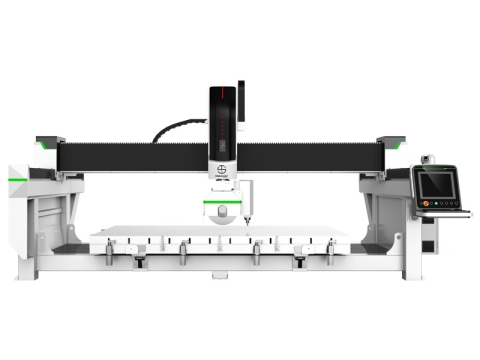

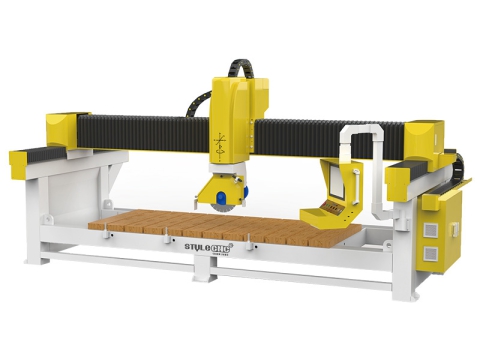

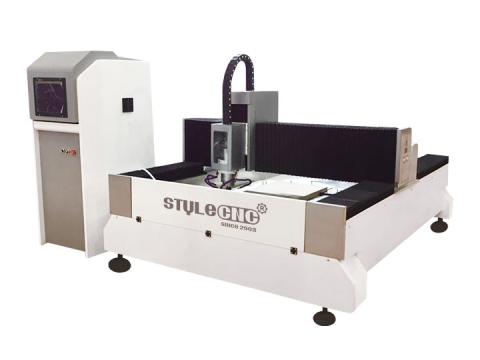

A stone CNC router machine is a specialized CNC machine manufactured for carving, engraving, and cutting stone materials and polishing them. Stone CNC router machines are made to shape different types of stones like marble, granite, ceramics, ink-stone, jade, headstone, tombstone, artificial stone, glass, quartz, blue stone, natural stone, etc. to make cabinets, arts, crafts, inscription and many more.

The machine comes with a robust construction and is compatible with CAD/CAM software, which allows shaping any stone according to the digital designs for customized production lines.

These machines are equipped with high-power spindles that provide extra torque and cutting force to efficiently carve and engrave stone. Equipped with professional router bits and a bidirectional tool cooling system, which can effectively improve tool lifespan.

Definition

A stone CNC machine is an automatic power tool with computer numerical controller for hobbyists and industrial manufacturer to make custom stone machining for artwork, decorations, souvenirs, gifts, crafts, tombstones and home improvement. It is capable of carving, engraving, cutting, polishing for basalt, granite, quartzite, limestone, marble, onyx, jade, travertine, alabaster, sandstone, slate, soapstone.

What Is A Stone CNC Router Machine?

A CNC stone router machine is a fully automatic computer-controlled machine tool capable of carving and cutting marble, granite, ceramics, ink-stone, jade, headstone, tombstone, artificial stone, glass, quartz, blue stone, natural stone to make cabinets, arts, crafts, inscription, Buddhas statues & sculptures.

To achieve a precised production a machine must fill all requirements. Starting with the machine setup to reach final production a series of actions is done.

A CNC stone router machine is built rigidly with steel or cast iron. The robust frame holds the overall stability while in production. At the heart of the machine, there’s a cutting tool, held by a spindle. A software control system does the rest. However, monitoring, precision, and material handling need attention to detail by an expert.

How Does A Stone CNC Router Works?

It is compatible with a variety of CAD/CAM design software. It is equipped with professional router bits and a bidirectional tool cooling system to effectively improve tool lifespan. It adopts a computer numerical control system to realize a 3D dynamic simulation display.

A CNC stone router machine can do stone lettering, relief carving, shadow carving, line carving, stone cutting, and stone hollowing in home improvement, advertising, and industrial decorations.

Starting with design the machine uses CAD software to make a 2D model. After that CAM programming defines the parameters with the help of an expert. Material preparation, tool setup, and machine setup are done sequentially. Once the setup is done, execution and monitoring are the two steps to find a précised final product.

These machines are equipped with a High-Power Spindle that gives the machines extra torque and cutting force to effectively carve and engrave a stone. They are equipped with professional router bits and a bidirectional tool cooling system to effectively improve tool lifespan.

Applications

Stone Industry

Granite, marble, quartzite, slate, sandstone, alabaster, basalt, jade, limestone, travertine, artificial stone, tombstone, headstone, cemetery, and memorial.

Kitchenware

Slate countertops, artificial quartz countertops, artificial marble table top, ceramic tile, and kitchen decorations for sink, oven, cooktop.

Decorations

Stone crafts, gifts, jewelry, wall decoration, building decoration, portrait, Buddha statue, and some exquisite stone arts.

Woodworking

Chair, door, window, bed, cabinet, kitchenware, redwood classical and antique furniture, exquisite european furniture, sculpture.

Mold Making

Copper, aluminum, building models, shoes, badge, embossed mould, biscuit, candy, chocolate mould, artificial marble, plastic, PVC, wood, foam.

Advertising

Billboard, signage, badges, logo, company plate, signs, emblem, badge, display panels, fair signs, building numbers, decoration, 3D character.

Specifications

| Brand | STYLECNC |

| Model | STS4040, STS6090, STS1318, STS1325, STS1330, STS1420, STS1530, STS2513, STS3113 |

| Table Size | 2' x 4', 4' x 4', 4' x 8', 5' x 10' |

| Materials | All types of stones |

| Axis | 3 axis, 4 axis, 4th axis, 5 axis |

| Capability | 2D Machining, 2.5D Machining, 3D Machining |

| Control Software | Type3, UcanCAM, ArtCAM, AlphaCAM |

| Operating System | Mach3, Nc-studio, Syntec, DSP, Siemens, Nk200, Nk260, NK300 |

| Price Range | $2,800.00 - $34,800.00 |

How To Use A Stone CNC Router?

Proper and accurate operation of a CNC router machine ensures a greater outcome. Therefore, it is compulsory to use and monitor the machine once in a while. Follow the given steps to maximize your stone CNC router’s efficiency.

Step-1. Before turning it on, we need to check whether the machine tool is connected to the computer normally, turn on the power and the computer, start the program, and enter the operating system.

Step-2. Select the menu of returning to the origin in the control system to correct the origin coordinates.

Step-3. Load the required processing program, select the open menu, and a standard file operation dialog box will pop up, from which you can select the drive, path, and file name where the file to be opened is located. After clicking the open button, the processing program is loaded into the system.

Step-4. Determine the origin of the workpiece, manually move the X and Y axes to the predetermined position on the workpiece, select the menu of setting the current point as the origin of the workpiece, or clear the coordinate value of the current position in the coordinate window. In this way, when executing the processing program, it will start processing with the current position as the starting point.

3D Stone CNC Router Machine

A 3D stone CNC router machine is another technological advancement in the industry. Of course, it is compatible with the similar CAD/CAM software. What extra does a 3D stone CNC router offer?

⇲ Three Dimensional Machining.

⇲ Multi-Axis Motion Control.

⇲ Specialized Cutting Tools.

⇲ Versatile Applications.

⇲ High Precision Machining.

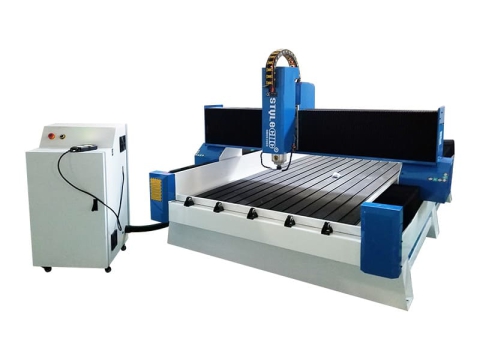

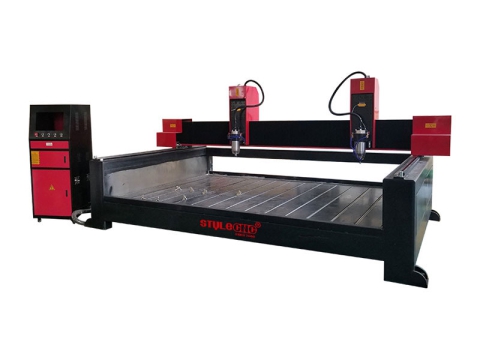

Types of Stone CNC Router

You will find different stone CNC router machines in the market each made for different applications and requirements. A few common types are,

⇲ Flatbed CNC Router.

⇲ Bridge Style CNC Router.

⇲ Rotary Axis CNC Router.

⇲ Multi-Head CNC Router.

⇲ 5-Axis CNC Router.

⇲ Hybrid CNC Router.

Each type has its advantages and limitations. To achieve efficient and high-quality machining results choosing the right kind of Stone CNC Router is a must. Now this depends on a few factors that one must follow.

Buyer's Guide

Buying a Stone CNC Router Machine can be a profitable business if it is compatible with the product requirements. Therefore, it is necessary to select your brand and item based on your business type and requirements. Some key factors are given below that will help you pick the best on your terms. Let's take a look at them.

⇲ Specific application requirements

⇲ Material properties

⇲ Desired machining capabilities and

⇲ Budget constraints

Step 1. Consult:

We will recommend the most suitable stone CNC machine to you after being informed by your requirements. You should tell us the material you want to carve, the max size of the stone (Length x Width x Thickness).

Step 2. Quotation:

We will offer you with our detail quotation according to the consulted CNC stone router. You will get the most suitable specifications, the best accessories and the affordable price.

Step 3. Process Evaluation:

Both sides carefully evaluate the details (including technical parameters, specifications and business terms) of the order to exclude any misunderstanding.

Step 4. Placing Order:

If you have no doubts, we will send you the PI (Proforma Invoice). Then we will sign a contract with you.

Step 5. Production:

We will arrange the CNC stone cutting machine production as soon as receiving your signed sales contract and deposit. The latest news about production will be updated and informed to you during the production.

Step 6. Quality Control:

The whole production procedure will be under regular inspection and strict quality control. The complete CNC stone cutting machine will be tested to make sure they can work well before out of factory.

Step 7. Delivery:

We will arrange the delivery as the terms in the contract after the confirmation by the CNC stone carving and cutting machine buyer.

Step 8. Custom Clearance:

We will supply all the necessary shipping documents to the buyer and ensure a smooth customs clearance.

Step 9. Support and Service:

We will offer professional technical support and service by Phone, Email, Skype, WhatsApp, Online Live Chat, Remote Service. We also have door-to-door service in some areas.

Precautions

⇲ Before using the machine, be sure to check the lubrication of the accessories and whether the protection device can meet the processing requirements.

⇲ During the operation, be sure to observe whether there are signs of looseness in the accessories. If signs of looseness are found, the machine should stop running immediately to prevent damage during the stone processing process and bring unnecessary losses to the business.

⇲ After the speed of the machine reaches a certain height, attention should be paid to the surrounding environment to prevent unnecessary collisions.

⇲ Stop working immediately after encountering abnormal noise from the machine, and check whether it is caused by itself.

⇲ In the process of stone machining, the machine itself cannot stack some tools and workpieces casually, and it is forbidden to touch the rotating accessories when rotating.

⇲ After the operation is completed, wipe the machine carefully, and after cleaning the work site, disconnect the power supply.

⇲ Stone carving usually refers to relief, and the power is generally set higher. If you encounter hard stone, the color of the carved figure may become darker. If you want to make the color of the carved stone lighter, you can properly increase the carving speed and perform the operation several times. Because of the different stone materials, some stones will wear out some oily fume and stick to them when carving, which can be carefully wiped off with a wet rag. If there is no paint on the stone, it may not be wiped clean when wiping. The surface is defaced, affecting sales.

⇲ When cutting stone, the cutting depth is generally not very deep. If cutting very thick stone, you can properly slow down the cutting speed and cut in layers, which may cause the knife to break. During the specific operation, the cutting can be carried out by repeated cutting.