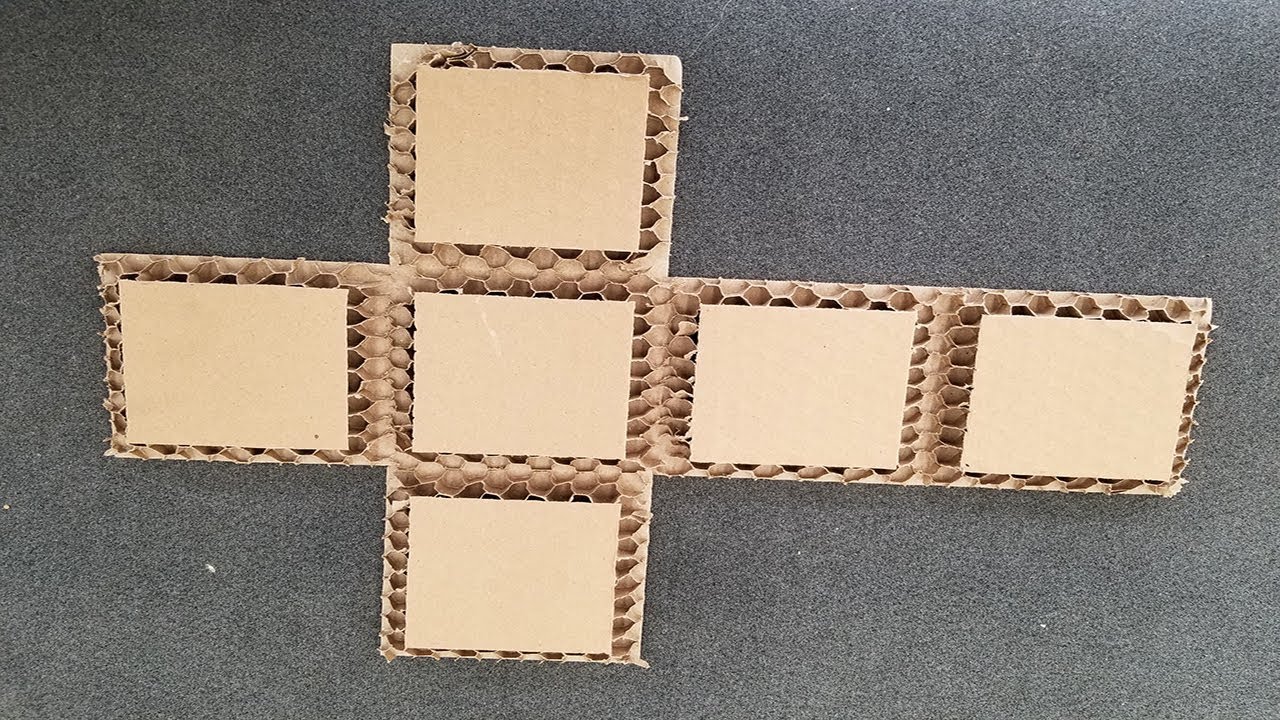

I purchased this automatic CNC cutter to make corrugated cardboard boxes for my custom packaging business. This machine is well designed to cut flat materials quickly with little effort. It is easy to setup and use, and cuts through cardboard like butter. In addition, the blade is replaceable to cut different materials. Overall, an excellent digital cutting tool for flexible materials. I recommend it for fine cuts where exact precision is needed.

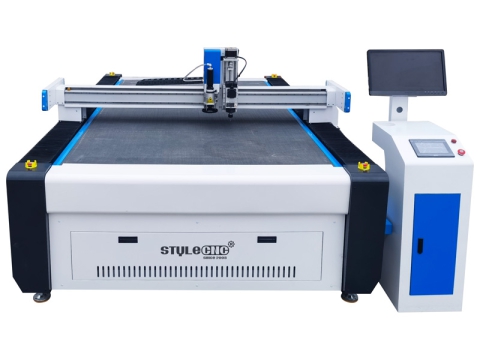

2026 Best Automatic CNC Cardboard Cutting Machine for Sale

CNC cardboard cutting machine with oscillating tangential knife is the best industrial automatic carton box maker of 2026 for packaging with varied knife tools and blades to cut paperboard, hardboard, carton box, corrugated box, corrugated cardboard box, corrugated fiberboard, paperboard, mat board, and chipboard. Now the best automatic cardboard cutter for sale at an affordable price.

- Brand - STYLECNC

- Model - STO1630

- Maker - Jinan Style Machinery Co., Ltd.

- Category - CNC Digital Knife Cutting Machine

- 360 Units in Stock Available for Sale Every Month

- Meeting CE Standards in Terms of Quality & Safety

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- 30-Day Money Back Guarantee for Your Purchase

- Free Lifetime Technical Support for End-Users & Dealers

- Online (PayPal, Alibaba) / Offline (T/T, Debit & Credit Cards)

- Global Logistics and International Shipping To Anywhere

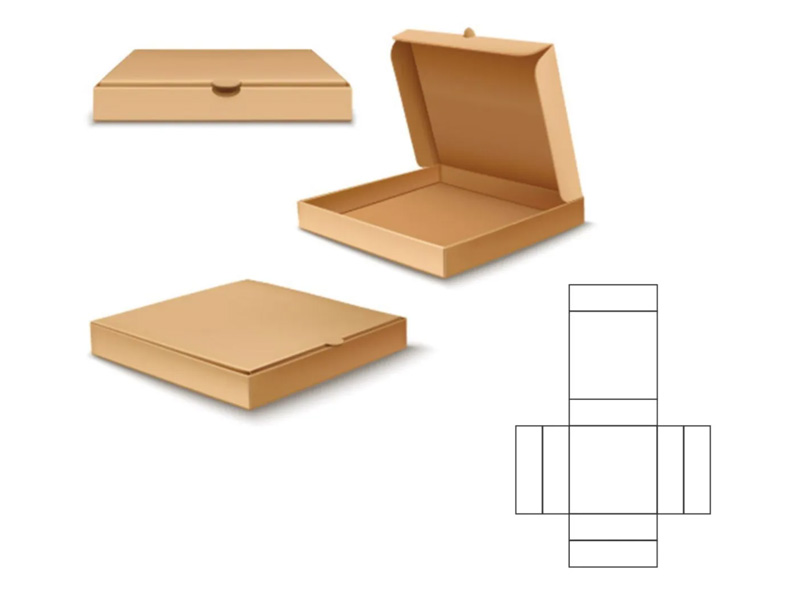

CNC oscillating tangential knife cutting machine is a type of high-precision CNC cardboard box-making machine (CNC carton box-making machine) with varied knife tools and blades for Paperboard Boxes (Bakers' Boxes, Cereal & Food boxes, Drug & Toiletry package boxes, Gift boxes & Shirt Boxes), Corrugated Boxes (Anti-Static Corrugated Boxes, Mailing Boxes, Moving Boxes, Pizza Boxes), Wax Impregnated Boxes, and Cardboard Stock in packaging industry. With the right configuration, the CNC cardboard cutting system can meet different functions, such as cutting, plotting, drawing, routing, punching, and more. CNC oscillating tangential knife cutting system can be used for every flexible or soft material with excellent cutting performance. The CNC cardboard cutting table has the advantages of high speed, high intelligence, highly precise cutting, and easy operation. The CNC carton cutting machine can connect with other software well with data converting software. CNC cardboard box-cutting machines will help the packaging industry upgrade from traditional manual sampling to advanced high-speed and precision production mode.

Cardboard includes corrugated fiberboard, paperboard, and mat board.

Paperboard includes solid bleached sulfate (SBS), solid unbleached sulfate (SUS), and coated recycled board (CRB).

Carton (Paperboard Box) is the most widely used packaging product. According to different materials, there are corrugated boxes, single-layer cardboard boxes, etc., with various specifications and models. There are three and five layers commonly used in cartons. Seven layers are used less frequently. Each layer is divided into lining paper, corrugated paper, core paper, and face paper. The lining and face paper are teaboard paper and kraft paper, and the core paper is corrugated paper. The color and feel of various papers are different, and the paper (color, feel) produced by different manufacturers is also different.

STYLECNC creates revolutionary CNC carton box-cutting plans for the printing and packaging industry. Scribing, drawing, text annotation, indentation, half-knife cutting, full-knife cutting, all in one go. It is used in corrugated board cutting, carton proofing, color box proofing, plastic box proofing, POP paper display rack paper shelf proofing, and small batch production. Instead of the traditional manual development design and proofing of cartons, color boxes, and paper display racks. CNC carton-cutting machines will shorten the corresponding research and development time to meet the production goal of fewer batches, more orders, and more styles.

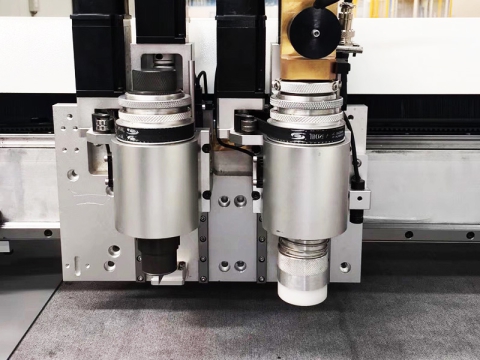

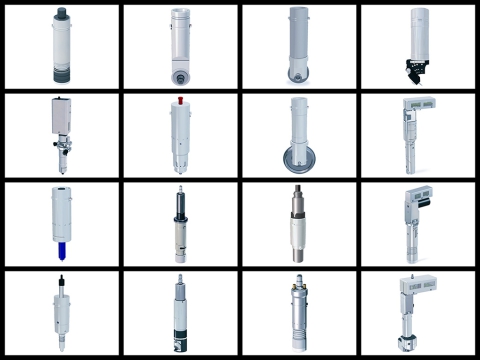

Features of Automatic CNC Cardboard Cutting Machine with Oscillating Tangential Knife

Oscillation Tools Cutting Function

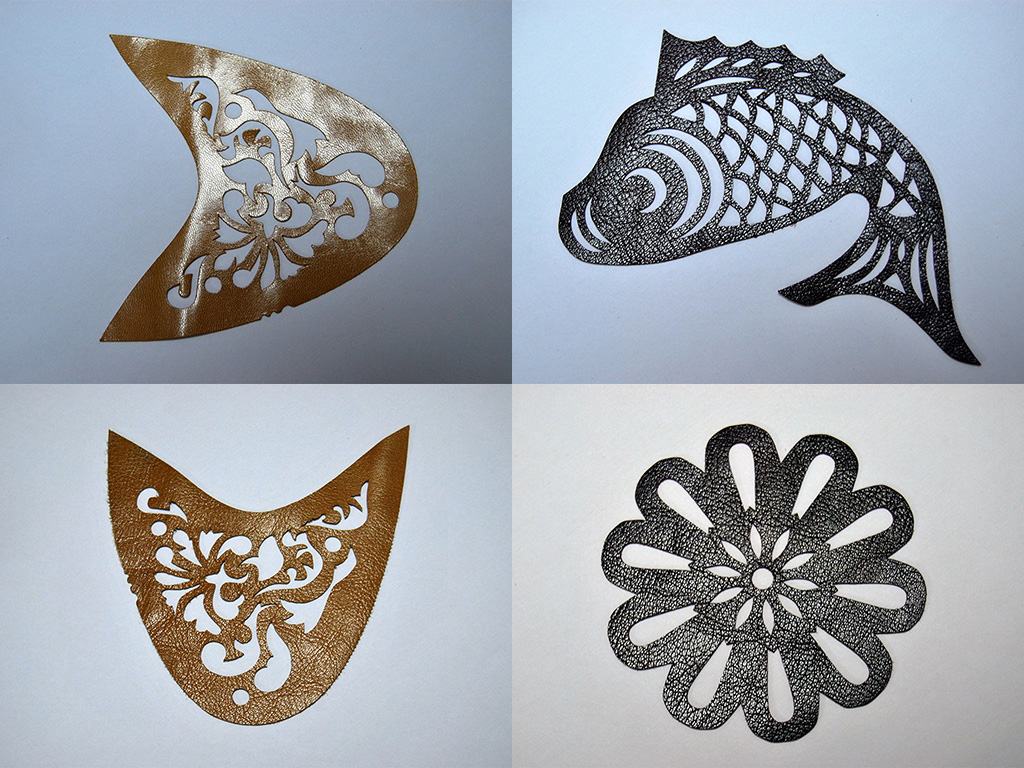

Automatic carton cutting machine can cut different materials (such as a gasket, leather, fabric, carpet, corrugated paper, cardboard, offset paper, grey board, rubber, honeycomb board, PP, PE, and PVC)

Punching Function

An automatic corrugated cardboard cutter can punch holes in material, such as cartons, leather, carpets, PVC, and mats.

Drawing Function

Automatic cardboard box-making machine can draw various high-precision materials, including foam, PVC, corrugated board, styrene, coroplast, magnetic film, Celtic, adhesive vinyl, rubber, fabrics, paper, leather, cardboard, vinyl, polystyrene, magnetic films, and high-intensity reflective films.

Dotted Line Function

An automatic cardboard cutting table is used to fold them after half cutting corrugated paper and grey card paper and to cut dotted lines.

Folding Function

Automatic carton cutter can fold corrugated paper, card paper and offset board into perfect folding lines.

Location Function

Location with camera or projector.

Advantages of Automatic CNC Cardboard Cutter Machine with Oscillating Tangential Knife

High Speed

The max cutting speed is 1200mm/s, which is three to five times higher than traditional manual cutting.

Material Saving

Machines are computerized accurate and material saving.

Compatible

The CNC cardboard cutter supports any CAD/CAM software that can output files in DXF or PLT format with Coreldraw, AutoCAD, AI, and more.

User Friendly

All the sharp turnings can be controlled on the CNC automatic cardboard cutting machine.

Applications of Automatic CNC Carton Cutting Machine with Oscillating Tangential Knife

CNC carton cutter machine is used for cutting, indentation, dotted line, marking, drawing, and other processes in the packing industry, instead of the traditional carton, exhibition frame, and other manual development, design, and proofing, shorten the R&D time, with high proofing speed, and high quality. The CNC box-cutting machine can complete the die-cutting, indentation, and molding of paper, plastic, and other flexible materials without a knife die and die-cutting machine to save a lot of manpower and mold costs.

Materials Can Be Cut with CNC Oscillating Tangential Knife Cutting Machines

Textiles, fabrics, leathers, fiber glasses, rubbers, stickers, films, foam boards, corrugated cardboards, cardboards, plastic boxes, clothes, gasket materials, footwear materials, garment materials, bag materials, rugs, sponges, carpets, PU, PP, PE, PTFE, ETFE, EVA, XPE, PVC and composites.

Technical Parameters of CNC Cardboard Cutter with Oscillating Tangential Knife

| Brand | STYLECNC |

| Model | STO1630 |

| Table Size | 1600mm x 3000mm |

| Cutting Speed | 200-2000mm/s |

| Cutting Thickness | ≤50mm |

| Cutting Materials | Fabric, leather, textile, corrugated cardboard, cardboard, foam board, fiberglass, sticker, plastic box, film, rubber, cloth, garment materials, gasket materials, bag materials, footwear materials, carpets, sponges, rags, EVA, PU, XPE, PP, PE, PVC, ETFE, PTFE, and composites. |

| Multi-Functional Heads | Vibration knife Circular knife Punching knife Oblique knife Pen Punch knife Milling knife |

| Multi-Functional Tools | Vibrating knife full cutting High-power active round knife Camera positioning cutting Edge finding cutting Cursor positioning Drawing line mark |

| Safety Device | Infrared Sensing |

| Fixed Mode | Flate table (Automatic feeding table for option) |

| Transmission port | Network port |

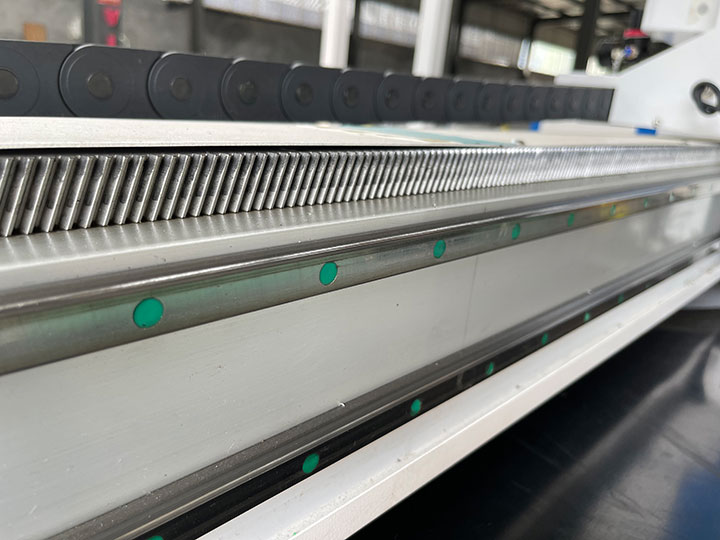

| Transmission System | Panasonic servo motor Linear linear guide rack and pinion transmission |

| Power | 11kw |

| Voltage | 380V±10% (220V±10% for option) |

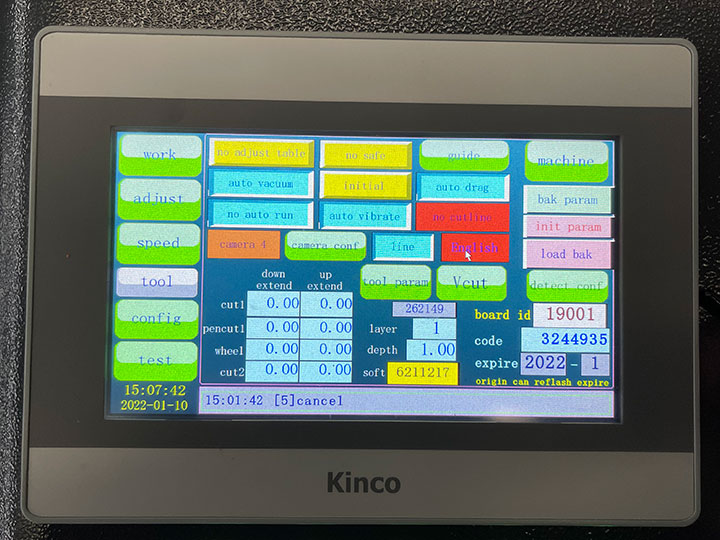

| Control System | Kinco controller |

| Operating Environment | Operating environment temperature 0-40°C humidity 20%-80%RH |

| Optional Software | Automatic nesting software Leather identification Cardboard entry software |

| Support File Formats | PLT, AI, DXF, CDR |

CNC Oscillating Tangential Knife Cutting Projects

CNC Knife Cutting Machine for Cardboard Retail Store Display Fixtures and Racks

Window Packaging Box Cutting Projects

Die Cut Carton Plans

CNC Cardboard Box Making Projects

CNC Knife Cutting Machine for Genuine Leather Cutting

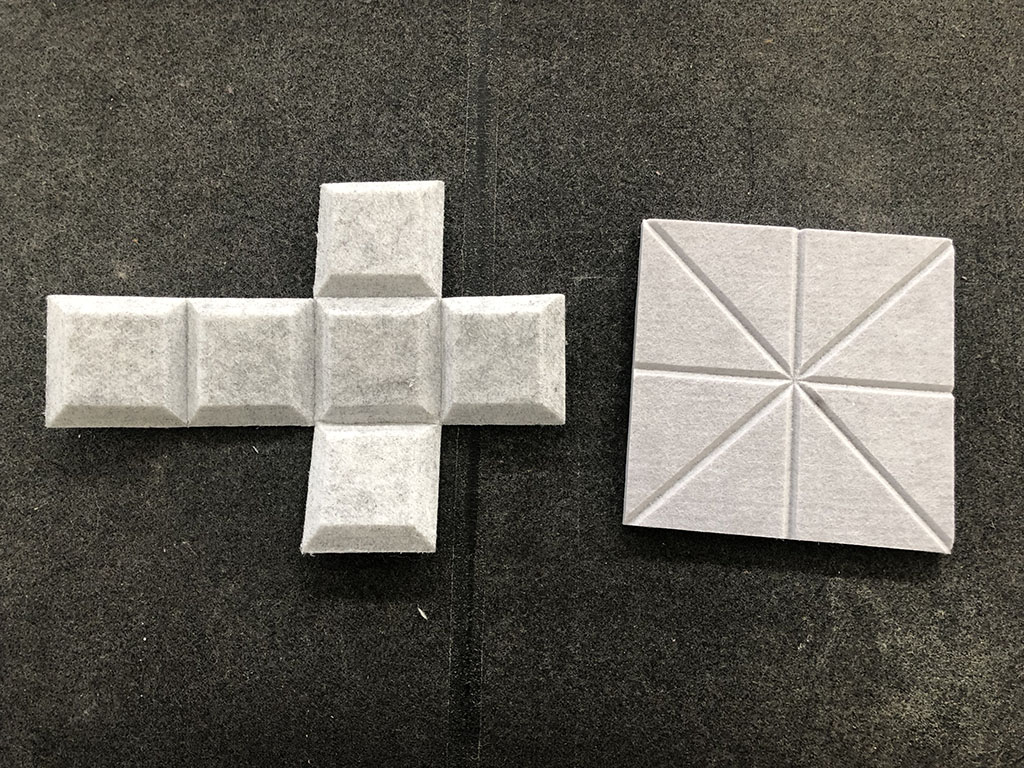

Felt Cutting Projects with CNC Oscillating Knife Cutter

Oscillating Knife Cutting Machine for EVA Foam Tray Projects

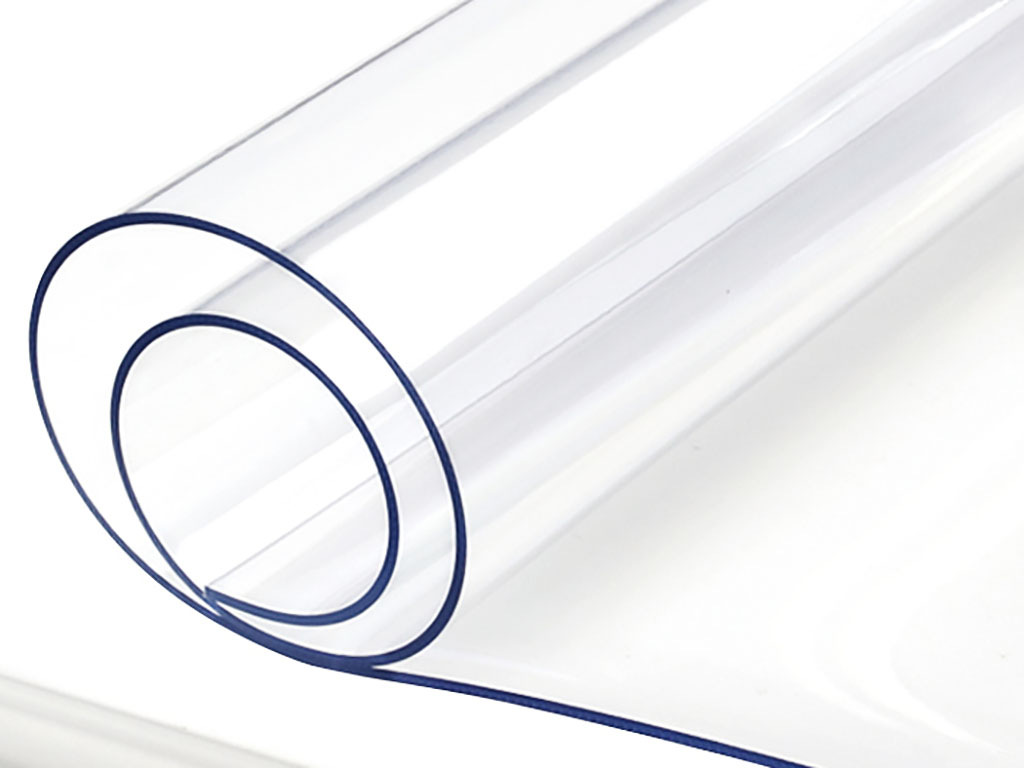

CNC Knife Cutter for PVC Soft Glass

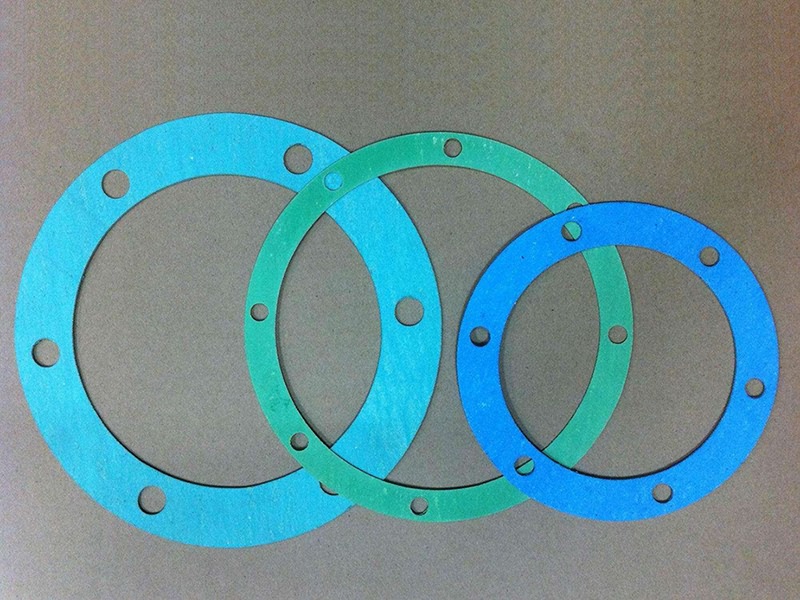

PTFE Impregnated Asbestos Gasket Cutting Samples

You can find more details from:

What is a CNC Knife Cutter used for?

Package of CNC Cardboard Cutting Table with Oscillating Tangential Knife

Service & Support for Automatic Cardboard Box Cutter with Oscillating Tangential Knife

• One-year quality guarantee, the cardboard cutting machine with main parts (excluding the consumables) shall be changed free of charge if there is any problem during the warranty period.

• Lifetime maintenance free of charge.

• Free training course at our plant.

• We will provide the consumable parts at an agency price when you need replacement.

• 24/7 online service each day, free technical support.

• All CNC cardboard cutting machines have been adjusted before delivery.

• Our staff can be sent to your company to install or adjust if necessary.

Maintenance Tips for CNC Cardboard Cutting Machine

Accurate cutting and breakdown prevention are ensured by routine maintenance. Make sure your CNC cardboard cutting machine is in good working order. You can preserve the performance of your computer and increase its lifespan by adhering to these easy instructions. The longevity of your CNC machine can be significantly extended with the help of these simple maintenance advices.

• Clean The Machine Regularly: Debris from cardboard and dust can accumulate over time. To keep everything tidy, clean surfaces and clear away any debris from the cutting area.

• Check The Blades: Check the cutting blades often. To guarantee precise cuts and avoid straining the machine, replace dull or broken blades.

• Lubricate Moving Parts: Apply a thin layer of oil to the machine's moving parts. This maintains everything functioning smoothly by lowering friction.

• Tighten Loose Screws: Inspect for any missing nuts or screws. Tighten them to stop any potential damage and vibrations while the machine is operating.

• Monitor Software Updates: Keep the software on your computer up to date. This guarantees you get the most recent updates for improved functionality and repairs.