Hard to make up my mind when I ordered this lathe for woodworking at STYLECNC. After all, I had been working with manual lathes for the past few years, and was a little apprehensive about getting started with CNC. My hanging heart relaxed at the moment of unpacking.

PROs:

• Basically all in one, no trouble with assembly.

• Well made with heavy-duty bed structure.

• Full-sized to handle most woodturning projects.

• Easy to get started and fun to play, with instructional documents and videos.

CONs:

• Creating CAD files is hard for CNC beginners like me.

• Controller software compatibility is limited, no other options except what comes with it.

Conclusion

More features remain to be tested in the future time. Overall, so far so good and great value for money.

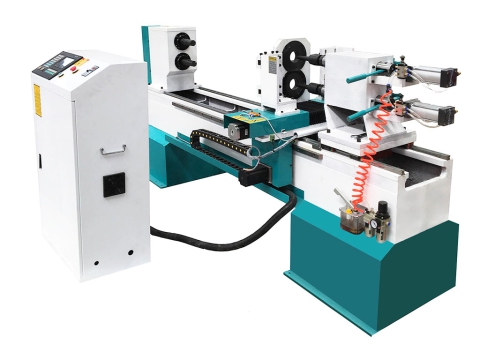

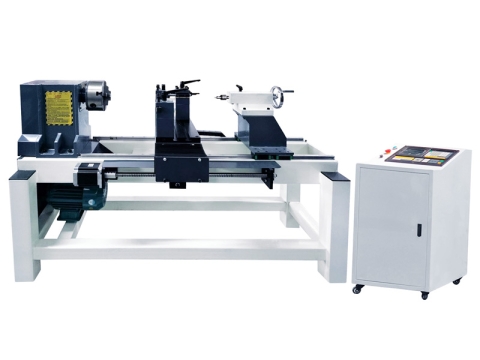

Top Rated Self-Feeding CNC Lathe Machine for Woodworking

2025 best self-feeding CNC lathe machine is used for batch wood turning of identical designs or templates, which can automatically load raw timber, center and turn according to the CNC program, saving time and labor to improve the working efficiency.

- Brand - STYLECNC

- Model - STL1530-A

- Maker - Jinan Style Machinery Co., Ltd.

- Category - CNC Wood Turning Lathe Machine

- 360 Units in Stock Available for Sale Every Month

- Meeting CE Standards in Terms of Quality & Safety

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- 30-Day Money Back Guarantee for Your Purchase

- Free Lifetime Technical Support for End-Users & Dealers

- Online (PayPal, Alibaba) / Offline (T/T, Debit & Credit Cards)

- Global Logistics and International Shipping To Anywhere

A self-feed wood lathe CNC is an advanced woodworking device that automates turning procedures of wood into intricate forms. Unlike traditional lathes, which require the material to be hand-fed on the cutting tool, this machine auto-feeds, therefore considerably increasing efficiency through less human efforts. Such machines have found their use in furniture-making industries, decorative craftsmanship, and mass production of components made of wood.

The machine works on a pre-programmed CNC system that guides it with precision. A user can upload designs into the system, specifying details like dimensions, patterns, and speed. Once the material, such as a wood blank, is loaded, the self-feeding mechanism ensures continuous feeding of the workpiece, allowing the cutting tools to create consistent and accurate results.

Some of the key features include automatic feeding, thus limiting human interference to a minimum; variable cutting speeds to suit different types of wood and designs. This self-feeding function saves not only time but also minimizes the chances of an error; hence, it is ideal for repetition work and intricate designs.

This combination of precision, automation, and efficiency makes self-feed CNC lathe machines a worthy investment for both small-scale woodworkers and large production facilities. Be it table legs, wooden spindles, or any other artistic craft, this machine simplifies the process while maintaining high quality.

Features of Top Rated Self-Feeding CNC Lathe Machine for Woodworking

1. Heavy cast iron lathe bed. Avoid shaking when the motor rotates fast for a big-size workpiece process, and the turning speed can be adjusted through the frequency converter.

2. STL1530-A comes with one chuck and one backlash for fixed materials, the max working dimension is 300mm*1500mm.

3. STL1530-A adopts the Taiwan Hiwin square guide, high precision and durable.

4. Autocad software, it easier for drawing designs.

5. LCD control system, it show the working process.

6. With a fully automatic feeding device, automatic loading of raw timber, automatic centering, and automatic turning according to the program, save time and labor to improve the working efficiency.

Technical Parameters of Top Rated Self-Feeding CNC Lathe Machine for Woodworking

| Model | STL1530-A |

| Max turning length | 100mm-1500mm |

| Max turning diameter | 20mm-300mm |

| Axis & Blade | Single axis, single blade or double blades |

| Maximum feed rate | 200cm/min |

| Spindle speed | 0-3000r/min |

| Minimum setting unit | 0.01cm |

| Control system | PLC |

| Driving system | Stepper motor |

| Power supply | AC380v/50HZ or AC220v/50HZ/60HZ |

| Weight | 1800kgs |

Details of Top Rated Self-Feeding CNC Lathe Machine for Woodworking

Full Automatic Feeding Device

Penumatic Full Automatic Feeding Device

Applications of Self-Feeding CNC Lathes in Woodworking Projects

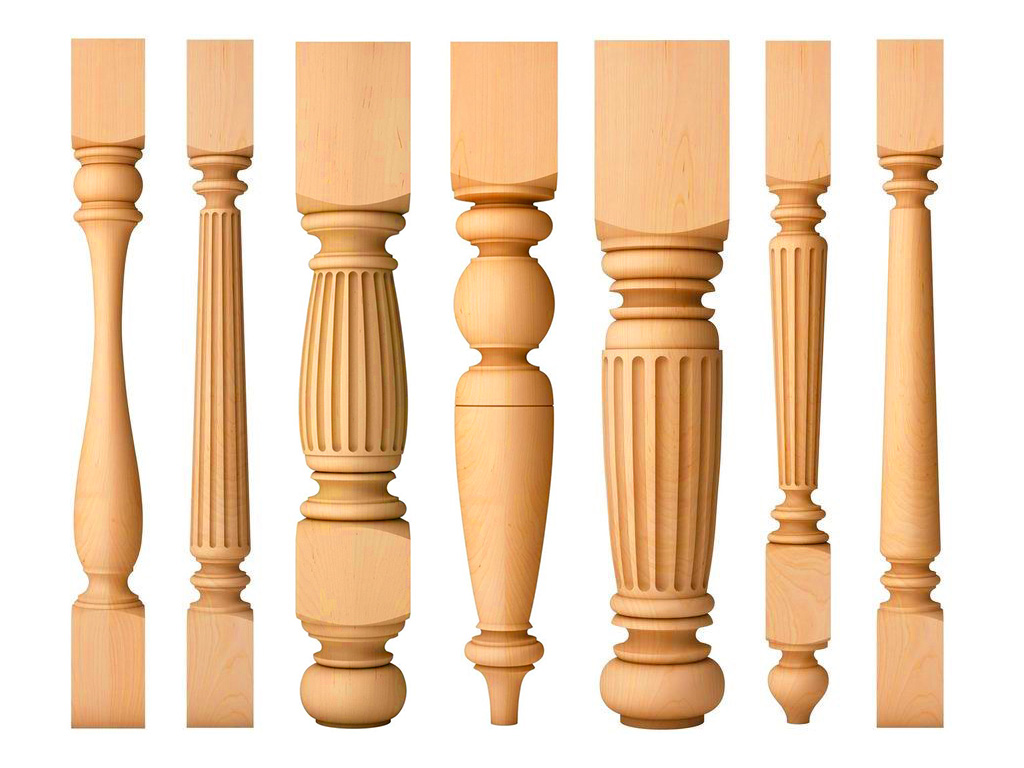

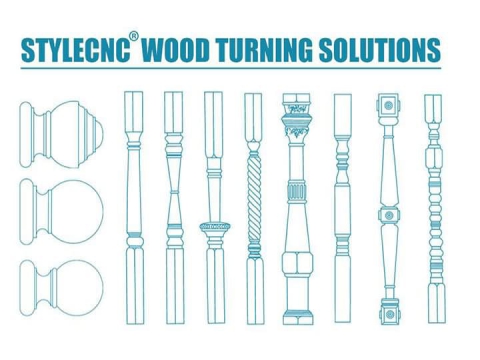

Self-feeding CNC lathes are versatile machines that have revolutionized woodworking, making intricate designs and mass production more efficient. These machines are ideal for crafting a wide range of cylindrical and decorative wood items with precision. Here’s an overview of their key applications:

Crafting Cylindrical Workpieces

Self-feeding CNC lathes are widely used for turning cylindrical wood items such as baseball bats, chair stretchers, and bed rails. The precision of these machines ensures consistent dimensions and smooth finishes, which are essential for quality and durability.

Decorative Furniture Components

These machines excel in producing intricate components like stairway balusters, newel posts, and Roman columns. Whether for modern or classical designs, CNC lathes deliver finely detailed results that elevate the aesthetic appeal of furniture and home decor.

Custom Wooden Furniture

From dining table legs to sofa and bun feet, self-feeding CNC lathes are invaluable for creating furniture pieces with complex shapes. Their ability to replicate designs ensures uniformity across multiple items, making them perfect for custom furniture production.

Artistic and Functional Crafts

Beyond furniture, these machines are used for crafting items like wooden vases, lamp posts, and car wooden accessories. Their flexibility allows woodworkers to experiment with unique designs while maintaining high precision.

Specialized Projects

For projects like washstands, stair columns, and children’s bed columns, self-feeding CNC lathes offer the accuracy and repeatability needed to meet exacting specifications. They’re also used in producing decorative bowl and tubular shapes, adding versatility to their capabilities.

Self-Feeding CNC Lathe Machine for WoodTurning Projects

Comparison: Manual vs. Self-Feeding CNC Lathe Machines

When choosing between manual and self-feeding CNC lathe machines, it's important to understand the key differences to determine which is best suited for your woodworking needs. Here’s a side-by-side comparison of both options:

| Feature | Manual CNC Lathe | Self-Feeding CNC Lathe |

|---|---|---|

| Automation | Requires manual feeding of the workpiece. | Automatically feeds the material into the lathe. |

| Precision | High precision but depends on operator skill. | Provides consistent precision with minimal operator involvement. |

| Efficiency | Slower process, as feeding and adjustments are manual. | Faster and more efficient with continuous feeding. |

| Complexity | Requires more skill and experience to operate. | Easier to operate with minimal training needed. |

| Customization | More flexibility for custom, small batch projects. | Ideal for large, repetitive projects or mass production. |

| Labor Involvement | Requires more hands-on work from the operator. | Less labor-intensive with automated feeding. |

| Cost | Typically less expensive than self-feeding models. | Higher initial cost due to automation but more cost-effective in the long term. |

| Maintenance | Regular maintenance and adjustments required. | Requires less maintenance, but proper care is needed for the feeding mechanism. |

| Suitable For | Small-scale, custom, and detailed work. | Large-scale, mass production, and uniform designs. |

Tips for Optimizing Self-Feeding CNC Lathe Machines for Efficiency

Optimizing your self-feeding CNC lathe machine can significantly enhance production speed, precision, and reduce waste. Here are some practical tips to get the most out of your machine:

• Regular Maintenance and Cleaning: Clean your machine regularly to prevent dust and debris from affecting its performance. Proper maintenance ensures smooth operation and extends the lifespan of the machine.

• Use Quality Materials: Using high-quality wood or materials ensures the machine operates smoothly and produces consistent results. Inferior materials can cause issues like uneven cuts or tool wear.

• Fine-Tune Cutting Parameters: Adjust the cutting speed, feed rate, and depth of cut according to the material being worked on. Fine-tuning these settings reduces energy consumption while maintaining precision.

• Monitor Tool Wear: Regularly inspect tools for signs of wear and replace them when necessary. Sharp tools reduce the load on the machine and improve the quality of cuts.

• Optimize the Tool Path: Using efficient tool paths minimizes unnecessary movements, saving time. Proper software settings can optimize the tool path for faster and more accurate results.

• Automate Loading and Unloading: Invest in an automated system for loading and unloading materials. This reduces operator downtime and increases overall machine productivity.

• Train Operators Well: Well-trained operators can quickly identify and resolve issues, ensuring smooth operation. Regular training helps maximize the machine’s potential and reduces costly mistakes.

Roy Hubbard

Julio A Erickson

Paul

An auto feeding machine is exactly what I need. I would like to recommend it to my friends too.