Top Rated CNC Plasma Cutting Machines for Beginners & Pros

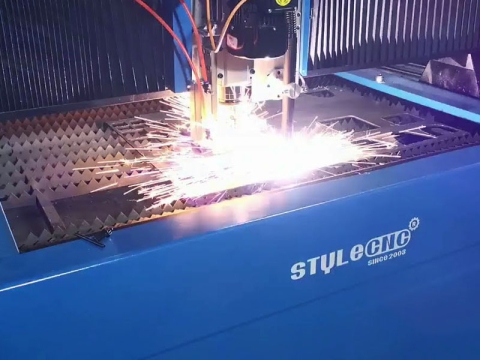

A CNC plasma cutter is an automatic metal cutting system that uses a computer numerical controller to drive the ionized gas torch to move forward, backward, left, and right along the tool path to cut through metals to create personalized contours and shapes, which is professional to cut mild steel, stainless steel, carbon steel, galvanized steel, hot rolled steel, cold rolled steel, iron, brass, copper, aluminum, bronze, titanium and a variety of alloys for automotive manufacturing, welding, repair and restoration, shipbuilding, industrial machinery, commercial construction, aerospace, as well as scrap and salvage operations. Here you can find the most popular CNC plasma table kits with 4x4, 4x8, 5x10 and 6x12 to handle cutting of various sizes of sheet metals, tubes, rods, straps and profiles, which are an upgraded version of handheld plasma cutters. Here you can buy your perfect plasma cutting machine with fully automatic CNC control system for every need and budget, whether you're a small business owner or a large industrial manufacturer. Just compare features and costs, making your choice easy for both beginners and experts.

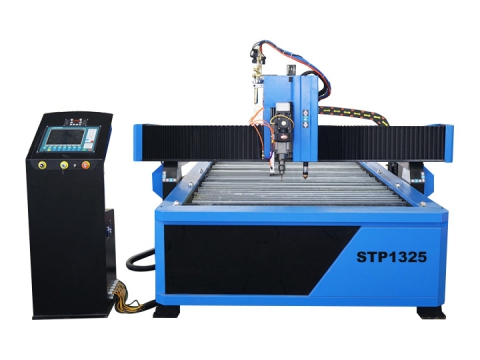

2024 Top Rated 4x8 CNC Plasma Cutting Table for Sale

2024 Best Entry Level 4x4 Hobby CNC Plasma Table for Sale

5x10 Hypertherm Plasma Cutter for Sheet Metal & Tube

High Definition CNC Plasma Cutter for Metal Fabrication

Portable CNC Flame Cutting Machine with Plasma Torch

2024 Best Budget 4x8 CNC Plasma Sheet Metal Cutting Machine

Square & Round Tube CNC Plasma Cutting Machine for Sale

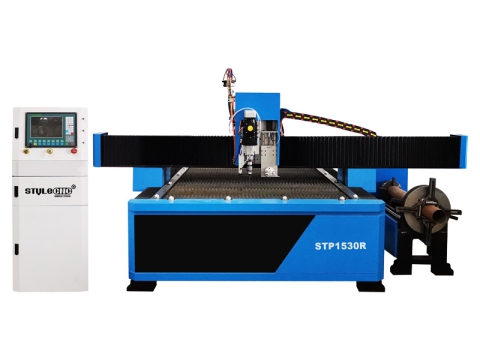

Profitable 4x8 CNC Plasma Table Kit with Rotary Tube Cutter

2024 Affordable CNC Plasma Cutting Drilling System for Sale

Industrial Large Gantry Plasma Cutting Machine for Sale

- Showing 10 Results On 1 Page

Free & Profitable Relevant Project Ideas

Most Popular Relevant Videos You Should Watch

Top Relevant Stories & Articles Worth Reading

Boost Your Business with Automatic CNC Plasma Cutting Tables

A CNC plasma machine can elevate your capability to such an extent that you will be amazed to see the progress you are making once you have the prototype. It's always a huge time saver and the accuracy that such a machine provides always makes it a desirable item to have.

With one of these machines, it is always easy to start up your own business. It is indeed true that a plasma cutter can be an authentic source of print money, but choosing the right one for your desired need might not be that easy.

With a vast experience in this industry, STYLECNC is thus here to be your savior with perfect guidelines you should follow before having a plasma cutter.

What are the possibilities with a plasma cutter?

Such a tool can help you to customize any design on carbon steel, stainless steel, mild steel, tool steel, iron, aluminum, brass, or copper. One of the reasons why these machines are the best in the industry is because they deliver the highest possible accuracy while bringing out the model in reality.

What Is A Plasma Cutter?

A plasma cutter is a type of thermal metal cutting tool that uses high velocity plasma or ionized gas to cut through metal, and blow away the molten metal with high-speed airflow at the same time to form a narrow plasma cut seams.

It is used to cut various metals, like carbon steel, stainless steel, copper, aluminum, cast iron, and more. It makes it possible to cut through electrically conductive metals with precision. It features with high cutting speed, thin cut seams, low deformation, small heat-affected zone, easy-to-use, and energy saving. With the pilot arc, it will generate a low power plasma arc in the air, which make the cut with lower cost.

It is used for sheet metal fabrication, metal structure making, machinery building, repair shop, drilling, digging, beveling, patching and more metal cutting projects & plans.

What Is A CNC Plasma Table?

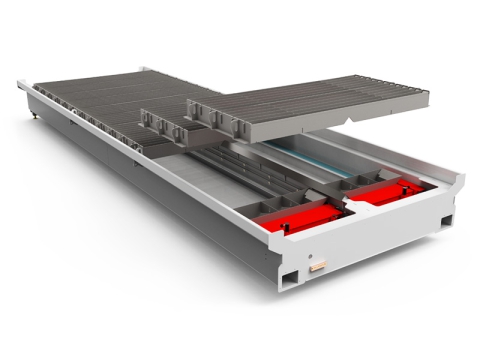

A CNC plasma table is an automated metal cutting tool kit that comes with a custom-sized workbench (4x4, 4x8, 5x10, 6x12) consisting of bed frame, computer numerical controller with CAM software, power supply, cutting torch, blade or sawtooth table, driver, motor, guide rail, ball screw, optional parts and consumable accessories, which is an upgraded version of the handheld plasma cutter to match various sizes of metal fabrications. The CNC controller will make it with a high degree of manufacturing flexibility, high accuracy, stable quality, high productivity, easy to improve working conditions, and are conducive to modernization of production management. Such a tool is a combination of a cutter and controller, which can give play to the greater advantages of gas cutting. In order to realize automatic machining, it must be capable of continuous feeding and automatic feeding, and the torch must be able to move separately or in combination in the horizontal and vertical directions to form the required curve. The various functional parts of the machine must be able to closely cooperate and coordinate to achieve precise continuous cutting. At the same time, various technical parameters can be flexibly adjusted and optimized to meet the cutting requirements of different metals.

How Does A CNC Plasma Cutter Work?

Plasma cutting is a thermal machining method that uses the heat of a high-temperature ionized gas arc to melt at a metal workpiece, and to eliminate the molten metal by high-speed momentum to create a slit. They send an electric arc by using gas like oxygen, nitrogen or compressed air. This turns the gas to plasma, as well as it promptly blasts through metal to cut it with broadband. A flame cutting torch works by adding a blast of oxygen to the flame which oxidizes the metal and turns it into slag. The torch moves along a tool path with height control directed by a computer. The CNC implies that a computer is used to control the motion supported G-code in a program. Compared to handheld devices, plasma CNC cutters realize automatic machining with X, Y, and Z axis.

What Are Plasma CNC Cutters Used For?

A CNC plasma cutter is capable of cutting most metallic materials, including ferrous and non-ferrous metals, such as iron, carbon steel, structural steel, stainless steel, tool steel, brass, copper, bronze, aluminum, titanium and their alloys to shape metal sheets, rods, strips, square and round tubes, as well as manufacturing a variety of metal profiles.

CNC plasma cutting machines are used in a range of metal fabrication industries such as automobile manufacturing and welding workshops, auto repair and restoration shops, machine tool manufacturing, industrial machinery factories, shipbuilding manufacturers, mining machinery workshops, power facilities plants, construction sites, aerospace manufacturing centers.

What Are The Types of Plasma Cutters?

The most common types of plasma cutters include the handheld and CNC variant (hobby types and industrial types). The most common power supplies include Huayuan power supply and Hypertherm power supply.

According to the working methods, the kits can be divided into air kits, dry kits, semi-dry kits and underwater kits.

According to the cutting quality and precision, you will meet the types of ordinary, fine, laser-like, and so on.

According to the appearances, the three types are listed bellow:

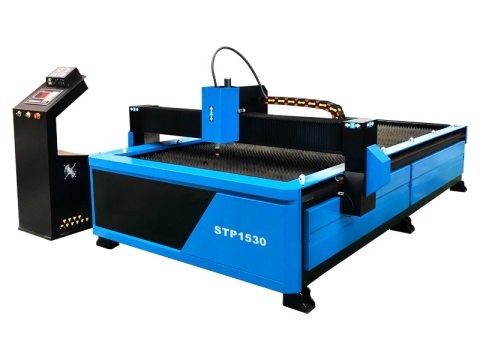

Portable CNC Kits

The machine is portable, easy to setup, compact in structure, small in space and low in manufacturing cost. However, due to the limitation of the cantilever structure, the stress conditions are poor, the transverse deformation is prone to occur, the transverse cutting width is limited, and the rigidity is poor during high-speed machining.

Gantry CNC Kits

The gantry-type supporting method is bidirectionally supported, the force is more uniform, the equipment has good rigidity, and can achieve a large lateral span, usually up to 3 to 10m. However, the equipment installation requirements are high, the structure is relatively large, and it takes up more plant area. The driving mode is divided into unilateral driving and bilateral driving. Unilateral drive and bilateral drive each have their own characteristics and applications. The unilateral drive avoids the high-precision synchronous control and complicated structure of the bilateral drive. However, due to the offset of the center of mass and the driving force does not pass through the center of mass, asymmetric inertial force will be generated during operation, which is prone to vibration, deformation and tilt. Therefore, it can only be used in a small span. The double-sided drive structure is relatively complicated and requires high-precision synchronous control on both sides, which can be used for a larger span and more stable movement.

CNC Table Kits

The cutting part and the machine are integrated, which is convenient to move in place, but the movement range of the cutting torch is relatively small, and the cutting width is subject to certain restrictions.

How Many Types of CNC Plasma Tables?

CNC plasma tables come in four mostly used types including 4x4, 4x8, 5x10 and 6x12 in feet, which are also known as 48" x 48", 48" x 96", 60" x 120", 72" x 144" in inches, as well as 1212, 1325, 1530, 2040 in millimeters (mm). You can also customize the table size according to your actual metalworking dimensions.

What Are The Advantages of Plasma Cutting?

It is an efficient metal cutting method for sheet metal and metal tubes, which has made it to be widely used in many different industries.

You can get benefits from 10 best advantages with fast cuts, ease of use, lower cost, safe to use, multi-tasking, expanded versatility, wide range of material and thickness, eliminated plate warping, raised inside piercing speed, and diminished dross.

Compared with traditional manual & semi-automatic metal cutter, automatic computer-controlled metal cutting system is an integration of quality improvement and cost-efficiency. CNC metal cutters include computerized numerically controlled plasma, flame, water plasma and laser cutting machine. It performs automatic, full-time, high-quality, high-utilization and efficient cutting according to the CNC nesting software.

In industrial production, metal thermal cutting generally includes gas, plasma, and laser cutting. Compared with gas cut, plasma cut has a wider cutting range and higher efficiency. The fine plasma cut system is close to the quality of laser system, but the cost is much lower than that of laser.

It has shown great advantages in saving materials and improving labor productivity. This has promoted it from manual or semi-automatic to numerical control, and has become one of the main directions of the development of numerical control cutting technology.

1. It can cut thicker metals, such as stainless steel, aluminum and its alloys, copper and its alloys, cast iron and other metal materials. You can also use cutting torch to cut insulating materials and non-metallic materials with thickness of more than 150mm.

2. The speed is fast, and the production efficiency is high, especially when working with thin metals with high power, the production efficiency is improved more significantly.

3. The cutting quality is high, the slit is smooth and flat, the incision is narrow, and the heat-affected zone and deformation are smaller than other tools.

4. Low cost, due to the high speed, the use of cheap gas such as nitrogen requires less raw materials and labor than other methods to cut the same material.

How Much Does A CNC Plasma Cutter Cost?

According to different requirements and configurations for power supply, plasma torch, cutting table, motor, driver, computerized control system software, machine frame, guide rail, ball screw, optional and consumble parts, CNC plasma cutters come at affordable prices ranging from $5,060 to $21,300 for every budget. An entry level plasma cutter starts at around $3,980, while a professional CNC plasma cutting machine costs anywhere from $5,600 to $17,800, and industrial CNC plasma tables are priced from $6,980 to $20,800, overall, the average cost is around $7,200 in 2024. If you buy from local shop, you can get free shipping cost, while the sale price is higher. If you want to buy cheap CNC plasma cutting table kits overseas, the fee of shipping costs, tax, and customs clearance should be included in the final price.

Pricing Guide

| Model | Minimum Price | Maximum Price | Average Price |

|---|---|---|---|

| STP1212 | $4,280 | $5,800 | $5,020 |

| STP1325 | $4,680 | $6,560 | $5,680 |

| STP1325R | $6,060 | $12,060 | $8,020 |

| STP1530 | $4,880 | $7,180 | $6,080 |

| STP1530R | $6,080 | $18,000 | $9,150 |

| STP3000-G | $6,800 | $15,600 | $10,180 |

Specifications

| Brand | STYLECNC |

| Model | STP1212, STP1325, STP1325R, STP1530, STP1530R, STP3000-G |

| Table Sizes | 4'x4', 4'x8', 5'x10', 6'x12' |

| CNC Controller | Starfire, FireControl, Mach3 CNC Controller |

| CAM Software | FastCAM, SheetCAM, Autodesk Fusion 360 |

| Cutting Modes | Plasma Cutting | Flame Cutting |

| Power Supply | Huayuan | Hypertherm |

| Cutting Speed | 0-10000mm/min |

| Price Range | $4,280 - $18,000 |

Plasma Power Supply & Cutting Thickness

Chinese Huayuan Power Supply

| Power | Thickness |

|---|---|

| 63A | 0-8mm |

| 100A | 0-15mm |

| 160A | 0-20mm |

| 200A | 0-30mm |

USA Hypertherm Power Supply

| Power | Thickness |

|---|---|

| 65A | 0-12mm |

| 85A | 0-16mm |

| 105A | 0-18mm |

| 130A | 0-20mm |

| 200A | 0-30mm |

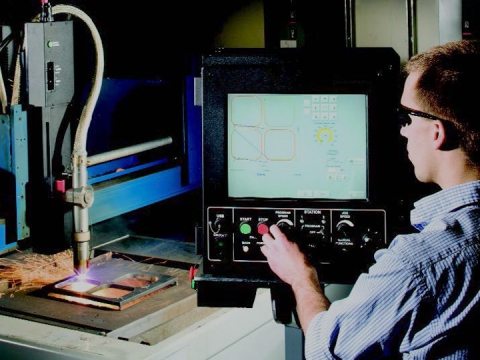

How To Use A CNC Plasma Cutter & Cutting Table?

For people who have never used a gas cutter or plasma table with computer-controlled controller. This is an easy-to-follow guide with software installation, setting, debugging, parts assembly, setup, and operation.

Manual Non-Contact Cutting.

Step 1. Touch the torch roller to the workpiece, and adjust the distance between the nozzle and the plane of the workpiece to 3-5mm. (When the machine cuts, the "Cut Thickness Selection" switch is upscale).

Step 2. Turn on the torch switch to ignite the plasma arc. After cutting through the workpiece, move to the cutting direction at an even speed. The speed is based on the premise of cutting through. Too slow will affect the quality of the incision and even break the arc.

Step 3. After working, turn off the torch switch and the arc goes out. At this time, compressed air is sprayed out at a delay to cool the torch. After a few seconds, the ejection stops automatically. Remove the torch to complete the entire process.

Manual Contact Cutting.

Step 1. The "Cut Thickness Selection" switch is at the low level, and it is used when cutting thinner metal plates by a single machine.

Step 2. Place the torch nozzle at the starting point of the workpiece to be cut, turn on the torch switch, ignite the arc, cut through the workpiece, and then move uniformly along the cutting direction.

Step 3. After working, open and close the torch switch. At this time, the compressed air is still spraying out. After a few seconds, the spraying will stop automatically. Remove the torch to complete the entire process.

Automatic Cutting.

Step 1. Automatic cutting is mainly suitable for cutting thick workpieces. Select the "Cut Thickness Selection" switch position.

Step 2. After removing the torch roller, the torch and the semi-automatic machine tool are firmly connected, and the attachment is provided in the random accessories.

Step 3. Connect the power of the semi-automatic cutting system, and install the radius rod or guide rail according to the shape of the project (if you need to cut arc or circle, a radius rod is required).

Step 4. If the torch switch plug is turned off, replace the remote switch plug (prepared in the accessories).

Step 5. Adjust the appropriate walking speed according to the thickness of the workpiece. And set the "up" and "down" switches on the semi-automatic cutter to the cutting direction.

Step 6. Adjust the distance between the nozzle and the workpiece to 3-8mm, and adjust the center position of the nozzle to the starting strip of the workpiece slit.

Step 7. Turn on the remote control switch. After cutting through the workpiece, turn on the power switch of the semi-automatic machine to cut. In the initial stage, pay attention to the seam at any time and adjust to a suitable speed. And pay attention to whether the two machines work normally at any time.

Step 8. After cutting, turn off the remote control switch and the power switch. At this point, the entire process is completed.

Manual Cutting Circle.

According to the material and thickness of the part, choose the single or parallel cutting method, and choose the corresponding cutting method. Tighten the cross bar in the random attachment to the screw hole on the torch holder. To the required radius and tighten, then adjust the distance from the tip to the torch nozzle according to the length of the workpiece radius (the width of the slit must be considered). After adjustment, tighten the center fastening screws to prevent loosening, and loosen the cage to tighten the knurled screws. At this point, you can cut the workpiece.

What Is The Voltage of Plasma CNC Cutter?

When it is working, the CNC plasma torch will control the mechanical precision and the kerf quality with the power supply. It can be said that a good power supply has the fine cutting quality. In the actual use and operation of the computer-controlled cutter system, the cutting quality and stability are related to the power supply's brand & maker, power, cutting torch, nozzle, as well as the metal thickness and the cutting parameters.

The power supply of manual cutter must have a high enough no-load voltage to easily start the arc and make the arc burn stably. The no-load voltage is generally 120-600V, and the arc column voltage is generally half of the no-load voltage. Increasing the arc column voltage can significantly increase the power of the arc, thereby increasing the speed and cutting higher thickness sheet metals. The arc column voltage usually can not be achieved by increasing the internal contraction of the electrode and adjusting the gas flow rate, but the arc column voltage should be less than 65% of the no-load voltage, if not, it will lead to the instability of the arc.

How Thick Can Plasma Cut?

According to the size of the configured power supply, the cutting thickness is generally within 0.5-100mm, and the high power supply can cut to more than 100mm; CNC flame cutting ability: Ordinary flame cutting torch 6-180mm (maximum 250mm), special flame cutting torch generally does not exceed 300mm, of course, it can also be customized to be higher.

How To Choose A Dust Collector for CNC Plasma Cutting Table?

A material receiving and dust removal device for a plasma CNC cutting machine includes a workbench composed of a bracket and a grid-like work surface fixed on the top of the bracket. The bracket is provided with a material receiving plate that can move horizontally relative to the workbench and is located in the bottom of the grid-shaped work surface, and the material receiving plate is a steel wire mesh plate, the bottom of the workbench directly below the material receiving plate is provided with a dust removal water tank, and the bottom of the dust removal water tank is provided with wheels. The material receiving and dust removal device enables the workpieces and wastes cut by the machine and dropped below the working table to be easily taken out, and at the same time, it can greatly reduce the metal dust pollution generated when cutting the workpiece.

Troubleshooting

1. The working air pressure is too low.

When the plasma CNC cutter is working, if the working pressure is far lower than the pressure required by the instructions, this means that the ejection speed of the arc is weakened, and the input airflow is less than the required value. At this time, a high-energy, high-speed arc cannot be formed. As a result, the incision is of poor quality, imperviousness, and incision buildup.

The reasons for insufficient air pressure are: insufficient air input from the air compressor. The pressure adjustment of the air regulating valve of the CNC cutting machine is too low, there is oil in the solenoid valve, and the air path is not smooth. Therefore, it is necessary to check these aspects one by one, and find the problems and improve them in time.

2. The working air pressure is too high.

If the input air pressure is too high, after the arc is formed, the excessive airflow will blow away the concentrated arc column, disperse the arc column energy, and weaken the cutting strength of the arc. The main reasons are: improper input air adjustment, over-adjustment of the air filter pressure reducing valve, or failure of the air filter pressure reducing valve.

3. Improper installation of wearing parts such as electrode nozzles.

The electrode nozzle is threaded and needs to be tightened in place. Due to improper installation of the nozzle, such as the thread is not tightened, or the vortex ring is installed improperly, the cutting will be unstable and the vulnerable parts will be damaged too quickly.

4. The input AC voltage is too low.

Before commissioning, check whether the power grid connected to the CNC plasma cutting torch has sufficient carrying capacity and whether the power cord specifications meet the requirements. The installation location of the computer-controlled cutting torch should be far away from large-scale electrical equipment and places with frequent electrical interference.

5. The ground wire is in poor contact with the workpiece.

Grounding is an essential preparation before cutting. If no dedicated grounding tool is used, insulation on the surface of the workpiece, and long-term use of a ground wire with serious aging, etc., will cause poor contact between the ground wire and the workpiece.

6. The cutting speed and verticality of torch clamping.

The speed should be fast or slow according to the different material and thickness, and the current size. Too fast or too slow will cause uneven cutting surface and dross on the upper and lower edges. In addition, the cutting torch is not held vertically, and the sprayed arc is also sprayed obliquely, which will also cause the surface to have a slope.

Plasma CNC Controller & Software

The most common controller and software combination is Starfire control system and FastCAM nesting software. Of course, you can choose Mach3 and FireControl, Sheetcam CAM software and Autodesk Fusion 360 CAM software.

Starfire CNC Controller

Starfire is designed with plasma interference, lightning protection, high reliability, and surge capacity. It has features of automatic breakpoint memory. It is suitable for all types of plasma & flame cutting machines. Optional wireless remote control can be used to realize long-distance operation.

FastCAM CAM Software

FastCAM is a fully automatic common edge continuous cutting nesting software. The software is aimed at CNC cutting machines, including flame, plasma, laser and waterjet cutting machines, used for drawing, programming, nesting, verification and automatic cutting of arbitrary shape parts. Using FastCAM can increase the rate of steel nesting and effectively save steel, improve the efficiency of programming, nesting and cutting, and effectively improve the efficiency of production.

The automatic co-edge nesting function is to realize rectangular parts and non-rectangular parts in the automatic nesting process, that is, the automatic co-edge of any part with different side lengths, without manual editing, and automatically process the co-edge and continuous cutting of different parts, in order to prevent And to avoid thermal cutting deformation, automatically process the cutting direction and the position of the perforation point, and use the cut edge to directly preheat the cutting to avoid perforation.

Plasma Cutter VS Plasma Welder

Plasma cutter comes from welder, which is a unique type of welding system. It uses ionized gas to fuse two metals together. By increasing the arc discharge, the welding system can be transformed into a cutting system.

At this stage, most of the thermal cutting and welding businesses are from plasma. Among them, a cutter has developed portable, cantilever, gantry, desktop, tube cutting machine and other forms of cutting equipment, while welder is divided into manual welding machine and robotic welding machine.

Gas cutter uses an arc to generate high temperature to melt the material to be cut. At the same time, it uses compressed gas to blow away the material to be cut into slits to complete the final cutting projects. It has the advantages of good cut quality, narrow cut width, high precision, fast cutting, safety, and cleanliness. It is an advanced metal cutter.

A welder uses ionized gas arc as a heat source and a certain composition of alloy material (metal wire, alloy powder) as a filler metal.

Arc welding is a high-quality welding method. The depth/width ratio of the weld is large, the heat affected zone is narrow, the deformation of the workpiece is small, and there are many types of weldable materials, especially the development of pulse current plasma welding and molten electrode arc welding. The application range is expanded, and it has the advantages of high construction efficiency and low cost.

Buyer's Guide

A computer-controlled CNC plasma cutter will always be a significant investment because of the higher budget you will have to pay for the machine. Therefore, selecting the right one is crucial to enhance the quality of your work. Some of the key factors that will help you to choose the perfect tool have been discussed below.

The first thing comes first. The cutting capacity is always a crucial factor with such kinds of machines. The tool should have a better capacity to cut the metals with precision. If you are working with thick metals, ensure that the machine you are about to buy can handle that much thickness. Additionally, consider the maximum cutting speed of the machine and how it will affect your productivity. Precision, software, maintenance, maneuverability, and pricing are some of the other factors that should be considered while purchasing such a tool. Last but not the least; consider the level of support and service provided by the manufacturer. Look for a manufacturer that offers excellent customer support, including technical assistance, training, and ongoing maintenance.

The continuous progress of CNC automation and plasma cutting technology has made the types of CNC cutters more and more abundant, and the market's requirements for metal processing quality have also been continuously improved. There are options from 63A to 200A, with large format and small table, precision cutter, pipe cutter, plate and tube integration. They have become a hot-selling metal processing and forming product in recent years.

Should I Buy It?

If your business belongs to the following types of work, you can buy one for a try. It can greatly improve the quality and efficiency of products, liberate your productivity and save costs.

Sheet Metal Fabrication

A large number of production and fabrication requirements, different batches, large batches, and small batches of production requirements, this automatic metal cutting tool can perfectly provide solutions.

Kitchen Utensils

The kitchenware industry has high requirements for metal material processing, and the kitchenware industry uses more metal plates and pipes. Using this CNC machine tool can maximize benefits.

Advertising Decoration / Architectural Hardware

Whether it is advertising sign making, or architectural hardware matching, this type of machine tool can easily cut.

Machinery Manufacturing / Chassis Cabinet

In these industries, there are also a large number of applications of metal materials. Metal sheets and pipes of different thicknesses can be cut using this automated power tool.

How To Buy It?

Whether it is easy to use depends on whether you will buy it or not, and whether you have bought it right. Pay attention to these tips when choosing, so that you can avoid detours and buy an easy-to-use automatic plasma cutter with CNC controller at one time.

Step 1. Brand Selection.

There are many brands on the market, and the quality is uneven. Some brands are only OEM products, and have no technical accumulation. You must choose a brand with a professional CNC background, a product that has undergone long-term iterations, and a mature technology.

Step 2. Hardware & Software Selection.

CNC gas cutter is an organic combination of hardware and software technology. Simply have software technology, the cutting efficiency is low. Similarly, only with hardware technology, the cutting efficiency is not up to standard, so a good machine tool is equally important for hardware and software technology. Here, customers should pay attention to distinguish some low-end fish in troubled waters with only hardware but no advanced control system support.

Step 3. Usability Selection.

The purpose to buy it is to replace manual. Whether it can achieve fast, accurate and stable, whether it needs follow-up maintenance, whether it can minimize manual intervention are the key to judging whether it is easy to use.

Based on the above, whether the CNC plasma cutting machine is easy to operate depends on whether you have bought the right product. Products and experience are closely related. I hope that the purchase precautions summarized by the author can help you practice sharp eyes, choose the most suitable CNC cutter for you, and experience the speed and passion brought by CNC as soon as possible.

Why Should You Trust STYLECNC?

STYLECNC has been a leading enterprise for a long period of time that has been delivering computer-controlled prototypes for most of your precise cutting solutions. The brand not only delivers but also innovates constantly to meet customers' needs. Overall, trusting STYLECNC is about more than just the product itself. It's about trusting our expertise, experience, transparency, accountability, and commitment to quality and innovation.