Find & Buy Professional 5-Axis CNC Routers for Commercial Use

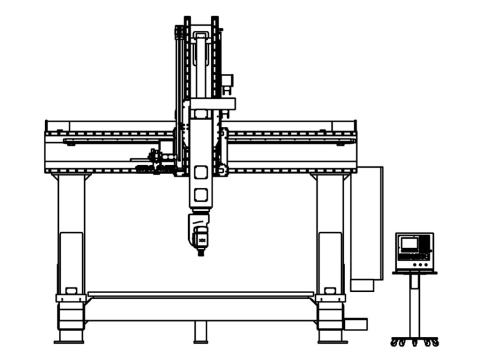

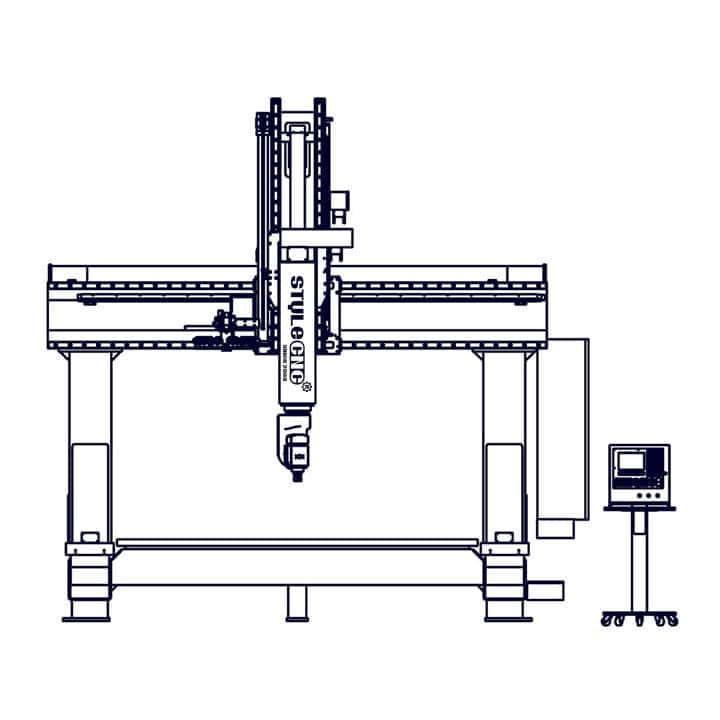

A 5 axis CNC router machine refers to an automatic multi-axis machine tool that adds two additional axes to form a five-axis linkage machining on the basis of three coordinate axes. Unlike 3D printers, five-axis machining requires at least three linear coordinate axes and two rotating coordinate axes, which are simultaneously coordinated and processed under the control of the computer numerical control system. The 5 axis CNC machine is composed of Z-axis box body, gantry beam, gantry column, gantry under-frame support, work table, linear ball guide rail, double-turn electric spindle, servo motor and other components. It adopts advanced gantry type table moving structure and has perfect milling technical characteristics. When it works, the five axes move to the tool in the spindle to process around the part to achieve five-axis linkage 3D machining. It is used to cut & mill wood, plastic, foam, resin, gypsum, aluminum, copper, brass, carbonized mixed materials in aviation parts, auto parts, mold making, and model making.

2024 Top Rated 5 Axis CNC Router Machine for Sale

Industrial 5 Axis CNC Router Machine for 3D Milling

Large Gantry 5 Axis CNC Machine for 3D Machining

Small 5 Axis CNC Machining Center for 3D Woodworking

Mini 5 Axis CNC Milling Machine for 3D Modeling & Cutting

- Showing 5 Results On 1 Page

Free & Profitable Relevant Project Ideas

Most Popular Relevant Videos You Should Watch

Top Relevant Stories & Articles Worth Reading

Pick Your 5 Axis CNC Machine for 3D Modeling and Rapid Prototyping

Five-axis CNC machines have been an indispensable automatic tool for machining continuous, smooth, and complex surfaces in recent years. Once you encounter unsolvable problems in designing and manufacturing complex curved surfaces, you will turn into five-axis machining technology for help.

Five-axis linkage is the most difficult and widely used in CNC technology. It integrates computer control, high-performance servo drive and precision machining technology, and is applied to efficient, precise and automatic machining of complex curved surfaces. It is a symbol of the automation technology level of a country's manufacturing equipment. Due to its special status, it has an important influence on aviation, aerospace, and military industries.

A lot of people don't know what to do when it comes time to buy a 5 axis machine tool. In fact, buying a new high-end CNC machine can be an exciting experience. And tips on sample trail making test, negotiation, and payment are valuable. But it can also come with significant financial stress, with CNC market reports estimating that the average price of a new five axis machine tool is close to $100,000. The more you know about the maker, the easier you'll get started. For example, if it has a warranty, what are the payment options, and what to do if you have a problem after the order is done, if you can get free service and support.

If you want to land the right CNC machine for the best possible price, here is the right place. Whether you're doing research on your options or comparing machine prices, feel free to use this guide. If you're ready to buy today, compare STYLECNC's selection of the top rated 5 axis CNC router machines listed below this guide, find and buy the right one for your business.

Definition

5 axis CNC router machine is a type of multi axis 3D machining center with CNC controller, which is different from 3D printer, it is somewhat like the 3 axis and 4 axis CNC machine, but five axis CNC machine has two additional axis they can move along. These additional axis will allow for shorter project time due to their capability of cutting five edges of the material simultaneously. However, due to the fact that these five axis machines have a longer X-axis, which makes for less stability and accuracy-potentially requiring more of your attention than a 3 axis or 4 axis CNC router.

Working Principle

First, let's learn something about "axis":

X-axis: front to back.

Y-axis: left to right.

Z-axis: up and down.

A, B or C axis is corresponding to the rotation axis of X, Y and Z axes.

Five axis: X-Y-Z-A-B, X-Y-Z-A-C, X-Y-Z-B-C (The spindle can be rotated left and right with 180 degrees around.)

Five axis CNC machines move a part or tool on five different axis at the same time via CNC programming. 3 axis CNC machines move a part in two directions with X axis and Y axis, and the tool moves up and down with Z axis. Five axis CNC machines can rotate on two additional rotary axis (A aixs and B axis) which will help the tool to approach the part from all directions.

Five-axis linkage machining technology refers to the processing technology that a complex shape surface needs to use 5 independent axes to perform numerical control interpolation movement together to obtain a smooth and smooth surface. The number of axes for five-axis simultaneous machining refers to the number of axes that need to move independently when processing the same surface, rather than the number of controllable axes owned by the CNC. Although theoretically any complex surface can be expressed by X, Y, Z three-axis coordinates, the actual machining tool is not a point, but an entity with a certain size, in order to avoid the occurrence of tool and processing when processing the space distorted surface The interference between the surfaces and to ensure the consistency of the cutting conditions at each point on the surface require adjustment of the angle between the tool axis and the surface normal in the 2D direction. Compared with the three-axis linkage, the five-axis linkage can reduce the machining error and surface roughness to 1/3~1/6.

Types

There are 8 most common types of 5 axis computer numerical controlled machine tools: five-axis linkage machining center, five-axis CNC machining center, five-axis precision machining center, five-axis high-speed machining center, small five-axis machining center, high-precision five-axis machining center, five-axis CNC router machine, vertical five-axis machining center.

Applications

5 axis CNC machine is designed to deliver high speed and highquality cuts for a wide range of materials, including but are not limited to wood, plastics, non ferrous metals and other composites. The CNC machine will provide various new applications including:

1. Edge trimming of molded plastic, thermoformed plastic, and composite parts.

The flexibility of the 5-axis machine creates the ability to provide high quality finishing and edge trimming on many manufactured plastic items.

2. Deep cavity mold making.

On three-axis machines deep cavity mold making requires that you have longer tools to be able to reach deep enough. Having longer tools results in the user having to reduce cutting speed to prevent breakage. With the added movement provide by 5 axis machining, shorter tools can be used, and your cutting speed can be increased.

3. Molded plywood chairs and decorative furniture parts.

The machine allows for unique shaping and molding of various materials, allowing you to make your creative and dynamic designs a reality.

4. Detailed 3D carvings.

The increase in movement of the cutting tool on the machine allows it to carve intricate designs into a piece of material. It allows you to capture the fine details of your design in the job you are cutting.

Features

5 axis CNC machine features with high efficiency and high precision, and complex machining can be completed in one clamping of the workpiece. It can be adapted to the processing of modern molds such as auto parts and aircraft structural parts. There is a big difference between a five-axis machining center and a five-sided machining center. Many people don't know this and mistake the pentahedral machining center as a five-axis machining center. The five-axis machining center has five axes X, Y, Z, A, C. X, Y, Z axis and A, C axis form a five-axis linkage processing, good at space surface processing, special-shaped processing, hollow processing, punching, oblique Holes, bevel cuts, etc. The "pentahedral machining center" is similar to a three-axis machining center, except that it can do five faces at the same time, but it cannot do special-shaped machining, beveled holes, cut bevels, etc.

Speaking of the features of the five-axis CNC machine tool, it is necessary to compare with the traditional three-axis CNC machines. 3 axis CNC machine is relatively common in manufacturing, and there are several forms such as vertical, horizontal and gantry. Common machining methods include end milling and side cutting of end mills. The profiling of ball-end knives and so on. However, no matter which form and method have a common feature, the direction of the tool axis remains unchanged during the machining process, and the machine tool can only realize the rectangular coordinates of the tool through the interpolation of the three linear axes of X, Y, and Z Movement in the department. Therefore, in the face of the following products, the disadvantages of the low efficiency of the three-axis machine tool, the poor quality of the processed surface, and even the inability to process are exposed.

Specifications

| Brand | STYLECNC |

| Spindle | HSD |

| Servo System | YASKAVA |

| Inverter | Delta |

| Tool Magzine | Linear/Carousel |

| Capability | 2D/2.5D/3D Machining |

| Control System | SYNTEC/OSAI |

| Price Range | $80,000.00 - $150,000.00 |

Pricing Guide

If you have an idea to buy or DIY 5 axis CNC router kits, you may wonder how much does it cost? how to get a final price? According to different machine features and models, you will get a price range from $80,000.00 to $150,000.00. If you want to buy overseas, the fee of customs clearance, tax, and shipping costs should be included in the final price.

Pick Up Your Budget

| Models | Minimum Price | Maximum Price | Average Price |

| STM1212E-5A | $80,000.00 | $90,000.00 | $85,000.00 |

| STM1212E2-5A | $90,000.00 | $120,000.00 | $105,000.00 |

| STM1325-5A | $100,000.00 | $110,000.00 | $100,500.00 |

| STM2040-5A | $100,000.00 | $150,000.00 | $12,500.00 |

Pros & Cons

Pros

The advantage of automatic 5 axis machine tool is that it can process free-form surfaces that can not be processed by ordinary 3 axis machine tools or that it cannot be processed at one time. For example, the blades of aircraft engines and steam turbines, the propellers of ships, and other complex molds with special curved surfaces. Since the tools and angles of the five-axis machining center can be adjusted at any time during the machining process, other tools can be avoided and all machining can be completed at one time.

Five-axis CNC milling machinie can also achieve the machining accuracy and quality of free-form surfaces under the premise of high effects. For example, when a three-axis machine tool is used to process complex curved surfaces, a ball-end milling cutter is used. Its cutting efficiency is low, and the angle of the tool cannot be adjusted freely, so it is difficult to ensure the smoothness of the processed surface. However, with a five-axis machining center machine tool, because the angle of the tool can be adjusted freely, the above situation can be avoided, so that higher cutting efficiency and high-quality surface quality can be obtained.

When the five-axis machining center is processing deeper and steeper cavities, the additional rotation and swing of the workpiece or spindle head can create the best process conditions for the processing of end mills, and avoid cutting tools, tool holders, and cavity walls. Collision occurs, reducing the jitter of the tool during machining and the risk of tool damage, thereby helping to improve the surface quality of the mold, the machining efficiency and the durability of the tool.

The five-axis machining center can complete the processing of the entire part at one time by using a shorter tool. It does not need to re-install the card or use the longer tool required in the same type of 3-axis machining, and it can be delivered in a shorter time. The surface quality is also ideal.

The technology of the five-axis machining center eliminates the need to reposition the workpiece at complex angles for multiple debugging and clamping. This not only saves time, but also greatly reduces the error, and saves the expensive cost of fixtures and fixtures required to install the workpiece in place.

Compared with 3 axis machining centers, 5-axis machining center s has the following advantages:

1. Maintain the optimal cutting state of the tool and improve the cutting conditions.

In the three-axis cutting mode, when the cutting tool moves to the tip or the edge of the workpiece, the cutting state gradually deteriorates. To maintain the best cutting condition here, you need to rotate the table. And if we want to completely process an irregular plane, we must rotate the table multiple times in different directions. It can be seen that the five-axis machine tool can also avoid the situation that the linear velocity of the center point of the ball head mill is 0, and obtain better surface quality.

2. Effectively avoid tool interference.

For the impellers, blades and integral discs used in the aerospace field, the three-axis machine tool cannot meet the process requirements due to interference. The five-axis machine tool can be satisfied. At the same time, the machine tool can also use shorter tools for processing, improve the rigidity of the system, reduce the number of tools, and avoid the generation of special tools.

3. Reduce the number of clampings and complete five-sided machining in one clamping.

The five-axis machining center can also reduce reference conversion and improve machining accuracy. In actual processing, only one clamping is required, and the processing accuracy is more easily guaranteed. At the same time, due to the shortening of the process chain and the reduction of the number of equipment in the five-axis machining center, the number of tooling fixtures, the floor space of the workshop and the maintenance cost of the equipment are also reduced. This means that you can use less fixtures, less plant area and maintenance costs to complete more efficient and higher quality processing.

4. Improve processing quality and efficiency.

The machine tool can be cut with the side edge of the tool, which is more efficient.

5. Shorten the production process chain and simplify production management.

The complete processing of the five-axis machine tool greatly shortens the production process chain, which can simplify production management and scheduling. The more complex the work piece, the more obvious its advantages over traditional production methods with dispersed processes.

6. Shorten the development cycle of new products.

For companies in the aerospace, automotive, and other fields, some new product parts and molding dies have complex shapes and high precision requirements. Therefore, five-axis CNC machining centers with high flexibility, high precision, high integration, and complete processing capabilities can It solves the problem of precision and cycle of complex parts processing in the development of new products, greatly shortens the development cycle and improves the success rate of new products.

In addition, the five-axis machining center can also enable the machine tool to process complex parts, which is impossible with other methods, including drilling, cavity recesses and taper machining usually required on complex surfaces.

Cons

Five-axis CNC programming is abstract and difficult to operate

This is a headache for every traditional NC programmer. Three-axis machine tools only have linear coordinate axes, while five-axis CNC machine tools have various structures. The same piece of NC code can achieve the same processing effect on different three-axis CNC machine tools, but the NC code of a certain five-axis machine tool cannot be applied to all types of five-axis machine tools. In addition to linear motion, NC programming also needs to coordinate calculations related to rotary motion, such as rotation angle stroke inspection, nonlinear error check, tool rotary motion calculation, etc. The amount of information to be processed is very large, and NC programming is extremely abstract.

The operation and programming skills of five-axis CNC machining are closely related. If the user adds special functions to the machine tool, the programming and operation will be more complicated. Only by repeated practice can programming and operators master the necessary knowledge and skills. The lack of experienced programming and operators is a major obstacle to the popularization of five-axis CNC technology.

Very strict requirements on NC interpolation controller and servo drive system

The movement of the five-axis machine tool is the synthesis of the movements of the five coordinate axes. The addition of rotating coordinates not only increases the burden of interpolation calculations, but also the small errors of rotating coordinates will greatly reduce the machining accuracy. Therefore, the controller is required to have higher operation precision.

The kinematic characteristics of the five-axis machine tool require the servo drive system to have good dynamic characteristics and a large speed range.

NC program verification of five-axis CNC is particularly important

In order to improve the efficiency of machining, it is urgent to eliminate the traditional "trial cutting method" calibration method. In five-axis CNC machining, the verification of NC programs has also become very important, because the workpieces usually processed by five-axis CNC machine tools are very expensive, and collision is a common problem in five-axis CNC machining: the tool cuts into the workpiece; Collision to the workpiece at a very high speed; collision between the tool and the machine tool, fixture and other equipment in the processing range; collision between the moving part on the machine tool and the fixed part or the workpiece. In five-axis CNC, the collision is difficult to predict, and the calibration program must conduct a comprehensive analysis of the kinematics of the machine tool and the control system.

If the CAM system detects an error, the tool path can be processed immediately; but if an NC program error is found during machining, the tool path cannot be directly modified like in three-axis CNC. On a three-axis machine tool, the machine operator can directly modify parameters such as tool radius. In five-axis machining, the situation is not so simple, because changes in tool size and position have a direct impact on the subsequent rotational motion trajectory.

Tool Radius Compensation

In the five-axis linkage NC program, the tool length compensation function is still valid, but the tool radius compensation is invalid. When contact forming milling is performed with a cylindrical milling cutter, different programs need to be compiled for different diameter cutters. None of the current popular CNC systems can complete tool radius compensation, because the ISO file does not provide enough data to recalculate the tool position. The user needs to change the tool frequently or adjust the exact size of the tool during CNC machining. According to the normal processing procedure, the tool path should be sent back to the CAM system for recalculation. As a result, the efficiency of the entire processing process is very low.

In response to this problem, Norwegian researchers are developing a temporary solution called LCOPS (Low Cost Optimized Production Strategy, Low Cost Optimized Production Strategy). The data required for toolpath correction is transferred from the CNC application to the CAM system, and the calculated toolpath is sent directly to the controller. LCOPS requires a third party to provide CAM software that can be connected directly to the CNC machine, where CAM system files are transferred instead of ISO codes. The ultimate solution to this problem depends on the introduction of a new generation of CNC control systems that can recognize workpiece model files in common formats (such as STEP, etc.) or CAD system files.

Post Processor

The difference between a five-axis machine tool and a three-axis machine tool is that it has two rotating coordinates. The tool position is converted from the workpiece coordinate system to the machine tool coordinate system, and several coordinate transformations are required in the middle. Using the popular post-processor generator on the market, only the basic parameters of the machine tool can be input to generate the post-processor of the three-axis CNC machine tool. For five-axis CNC machine tools, there are currently only some improved post-processors. The post processor of the five-axis CNC machine tool has yet to be further developed.

When the three axes are linked, the position of the origin of the workpiece on the machine table does not need to be considered in the tool trajectory, and the post-processor can automatically handle the relationship between the workpiece coordinate system and the machine tool coordinate system. For five-axis linkage, for example, when machining on a horizontal milling machine with X, Y, Z, B, and C five-axis linkage, the position size of the workpiece on the C turntable and the position dimensions between the B and C turntables, when generating the tool path must be considered. Workers usually spend a lot of time dealing with these positional relationships when clamping workpieces. If the post-processor can process these data, the installation of the workpiece and the processing of the tool path will be greatly simplified; just clamp the workpiece on the table, measure the position and orientation of the workpiece coordinate system, and input these data into the post-processing After processing the tool path, the appropriate NC program can be obtained.

Nonlinear Errors and Singularity Problems

Due to the introduction of rotating coordinates, the kinematics of a five-axis CNC machine tool is much more complicated than that of a three-axis machine tool. The first problem related to rotation is nonlinear error. The nonlinear error should be attributed to the programming error, which can be controlled by reducing the step distance. In the pre-calculation stage, the programmer cannot know the size of the nonlinear error, and the nonlinear error can be calculated only after the machine tool program is generated by the post-processor. Tool path linearization can solve this problem. Some control systems are capable of linearizing the toolpath while machining, but usually this is done in a post-processor.

Another problem caused by the axis of rotation is singularity. If the singularity is at the extreme position of the rotation axis, a small oscillation near the singularity will result in a 180° flip of the rotation axis, which is quite dangerous.

Requirements for CAD/CAM systems

For the operation of pentahedron processing, the user must rely on a mature CAD/CAM system, and must have experienced programmers to operate the CAD/CAM system.

Substantial investment in the purchase of machine tools

There used to be a huge price gap between five-axis machines and three-axis machines. Now, adding a rotary axis to a three-axis machine tool is basically the price of an ordinary three-axis machine tool, which can realize the functions of a multi-axis machine tool. At the same time, the price of five-axis machine tools is only 30% to 50% higher than that of three-axis machine tools.

In addition to the investment in the machine tool itself, the CAD/CAM system software and post-processor must also be upgraded to meet the requirements of five-axis machining. The calibration program had to be upgraded so that it could simulate the entire machine tool.

Parts & Accessories

1. Basic components. It is the basic structure of the machining center, which is composed of a bed, a column, and a table. They mainly bear the static load of the machining center and the cutting load generated during machining, so they must have sufficient rigidity. These large parts can be cast iron parts or welded steel structural parts. They are the largest volume and weight parts in the machining center. AKIRA-SEIKI castings are made of high-grade Meehanite castings, which have high stability after heat treatment.

2. Spindle parts. It is composed of main shaft box, main shaft motor, main shaft and main shaft bearing. The spindle's start, stop and speed change are all controlled by the numerical control system, and participate in the cutting movement through the tool mounted on the spindle, which is the power output part of the cutting process. It is the key component of the machining center, which determines the machining accuracy and stability of the machining center.

3. Numerical control system. The numerical control part of the machining center is composed of CNC device, programmable controller PLC, servo drive device and operation panel.

4. Automatic tool change system. It is composed of tool magazine, manipulator drive mechanism and other components. When the tool needs to be changed, the CNC system issues an instruction, and the manipulator (or through other means) takes the tool out of the tool magazine and loads it into the spindle hole. It solves the task of automatic storage, selection, transportation and exchange of tools between processes in the continuous processing of multiple processes after the workpiece is clamped once. The tool magazine (cutter head) is a device that stores all the tools used in the machining process. The tool magazine has a disc chain type and the capacity ranges from a few to a few hundred. The structure of the tool arm also has various forms according to the relative position and structure of the tool magazine and the spindle, such as single-arm type, double-arm type, and so on. Some machining centers do not use the tool arm but directly use the movement of the headstock or tool magazine to change the tool.

5. Auxiliary device. Including lubrication, cooling, chip removal, protection, hydraulics, pneumatics, and detection systems. Although these devices do not directly participate in the cutting movement, they play a role in guaranteeing the machining efficiency, machining accuracy and reliability of the machining center, so they are also an indispensable part of the machining center.

6. APC automatic pallet change system. In order to realize unmanned advancement or further shorten non-processing time, some machining centers adopt multiple automatic exchange worktables to store workpieces. While one workpiece is installed on the worktable for processing, the other one or several worktables You can also load and unload other parts. When the parts on a workbench are processed, the workbenches are automatically exchanged to process new parts, which can reduce auxiliary time and improve processing efficiency.

Buyer's Guide

When you are considering to purchase a new or used 5-axis CNC machine online, you need to make all the critical steps in your online buying process from the researching & shopping process. Here are 10 easy-to-follow steps on how to buy it online.

Step 1. Plan Your Budget.

Before you shop an machine tool online or in any way, you should make a budget plan. It's hard to make your choice if you have no idea on what you can afford.

Step 2. Do Your Research.

After you plan your budget, you need to understand what is the right machine tool for yourself? What will you use it to do? Once you assess your needs, you can compare different dealers and models by checking expert reviews online.

Step 3. Request A Consult.

You can consult with our sales manager online, and we will recommend the most suitable machine tool to you after being informed by your requirements.

Step 4. Get Free Quotation.

We will offer you with our detail quotation based on your consulted machine tool. You will get the best specifications and the affordable price within your budget.

Step 5. Sign A Contract.

Both sides carefully evaluate and discuss all the details (technical parameters, specifications and business terms) of the order to exclude any misunderstanding. If you have no doubt, we will send you the PI (Proforma Invoice), and then we will sign a contract with you.

Step 6. Build Your Machine.

We will arrange the machine making as soon as receiving your signed sales contract and deposit. The latest news about building will be updated and informed to the buyer during the manufacturing.

Step 7. Inspection.

The whole production procedure will be under regular inspection and strict quality control. The complete machine will be inspected to make sure they can work very well before out of factory.

Step 8. Shipping.

Shipping will start as the terms in the contract after your confirmation. You can ask for transport information at any time.

Step 9. Custom Clearance.

We will supply and deliver all the necessary shipping documents to the buyer and ensure a smooth customs clearance.

Step 10. Support & Service.

We will offer professional technical support and free customer service by Phone, Email, Skype, WhatsApp, Online Live Chat, Remote Service. We also offer door-to-door service in some areas.