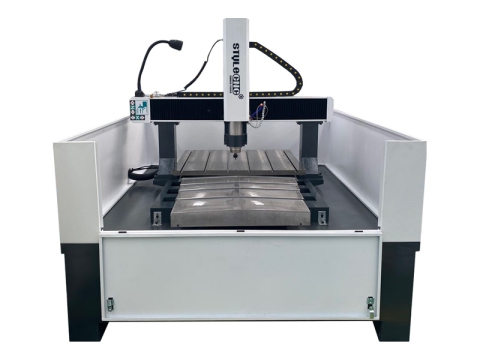

Definition

A CNC mill is an automatic milling machine with CNC (Computer Numerical Controlled) controller to cut 2D/3D shapes or mill patterns on various materials. CNC milling is a computer numerical controlled machining method similar to engraving, cutting, boring, and drilling, and able to achieve many of the operations performed by CNC router machines and boring machines. A computer-controlled mill uses a rotating cylindrical tool, which is able to move along multiple axis, and can create a variety of shapes, slots and holes. In addition, the workpiece is often moved across the milling tool in different directions.

A CNC milling machine is a high-precision machining tool kit that works with a computer numerical controller to drive a milling cutter to move along the tool path to cut out CAD/CAM designed shapes or contours, which is upgraded on the basis of a handheld mill. A CNC mill can perform drilling, boring, tapping, 2D and 3D milling. The most popular milling machines include vertical mill and horizontal mill, which can complete 3-axis, 4-axis or 5-axis linkage to cut and mill aluminum, brass, copper, iron, and steel with high-power spindle motor and servo motor to ensure the spindle to run with high speed to improve the machining accuracy, precision, and tolerance of the metal parts. A computer-controlled milling machine is used for aviation parts, auto parts, mold making, machinery parts, train parts, and shipbuilding parts. A automatic computer-controlled mill with tool changer is also known as a CNC machining center.

Principle

CNC milling machines are grouped by the number of axis on which they operate, which are labeled with various letters. X and Y designate horizontal movement of the workpiece (forward-and-back and side-to-side on flat surfaces). Z represents vertical, or up-and-down, movement, while W represents diagonal movement across a vertical plane. Most large format and small size mini mills offer from 3 to 5 axis, providing performance along at least the X, Y and Z axis. High end automatic milling machines, such as 5 axis CNC mills, require computer numerical controlled programming for optimal performance due to the incredibly complex geometries involved in the automatic milling process. These equipments are extremely useful because they are able to produce shapes that would be nearly impossible using manual tooling methods. Computer-controlled mills also integrate a machine tool for cutting fluid pump to the tool during machining.

Computer numerical controlled mills are used to generate a variety of components, and tooling costs involved have continued to become more affordable. Generally, large manufacturing runs requiring relatively simple designs are better served by other methods, although CNC machining can accommodate a wide range of manufacturing needs. CNC mills are ideal solutions to everything ranging from prototyping and short-run production of complex parts to the fabrication of unique precision components.

Basically remove material that can be sculpted or cut can be machined by an automatic mill, although a lot of the work done is performed in metal. As with engraving and cutting, the right mills must be selected for every type of material in order to avert possible issues. The hardness of the material, as well as the rotation of the mill must all be factored before start machining process.

Types

CNC mills come in vertical and horizontal types depending on the axis of the spindle. These machines are also classified as ram types, knee types, planer types, and manufacturing or bed types. Most automated mills have complete computer numerical controller, variable spindles, electric drive motors, coolant systems, and poweroperated table feeds. CNC mills are divided into vertical milling machines, horizontal milling machines, turret mills, bed mills, multi-axis (3 axis, 4 axis, 5 axis) mills.

Applications

CNC mills are used for engraving, carving, milling, cutting and drilling most metal materials, including copper, aluminum, steel, iron, brass, as well as nonmetal milling includes wood, foam, and plastics. It is widely used in injection mould, ironware mould, metal molds, shoe mold, drop mold, clock parts, zinc electrodes, copper electrodes, automotive, metal electrodes, metal crafts, jade, metal arts, jewelry, dental crown, and other molding industries. It is especially designed for batch milling molds, watch, eyeglasses, panel, brand, badge, outside surface's sleeking, 3D graphics and words, It’s easy for this mill to form 2D or 3D relieves on a wide range of materials.

Pricing

In terms of prices, the hobby CNC mill lineup starts as low as $3,600 for the 3 axis and tops off at $80,000 for the industrial CNC milling machine with the 5 axis. We have listed the various models, their working table size, the number of axis they have, their style and their current list price, which for some mills includes a $3,000 additional fee if you add an automatic tool changer kit at the time of purchase. And if you're looking for the best CNC mill deals, we have you covered there too.

Machines with different features have different costs. Machines from different makers and brands have different service and support, which will lead to different price.

Machines from different countries have different different customs, tax rates, different shipping costs. All of these factors will result in the final price.

If you want to buy one overseas, and get the final price, please contact us to get a free quotation, we'll calculate the final price of your required mill.

Specifications

| Brand | STYLECNC |

| Controller | NC Studio, SYNTEC |

| Types | Horizontal and Vertical |

| Software | Type3, UcanCAM, ArtCAM |

| Driver | Yaskawa Servo Motor, Stepper Motor |

| Capability | 2D Milling, 3D Milling |

| Milling Speed | 6000mm/min |

| Milling Accuracy | 0.1μm |

| Price Range | $3,000.00 - $120,000.00 |

Features & Advantages

CNC mills feature with high precision, user friendly, high cost effectiveness, stable and reliable machining quality, which can mill complex and 3D curved parts. It can perform drilling, reaming, boring, tapping, milling, grooving for box parts.

High Reliability

As the integration density of the summary line is increased, the hard connection of the components of the numerical control and the driving device is reduced, and the welding points, the connection points and the exterior are continuously reduced, thereby greatly reducing the failure rate.

High Flexibility

Since the computer numerical controlled system hardware is universal and standardized, for the control requirements of different machines, it is only necessary to change the system control program in the programmable read-only memory. At the same time, due to the modular structure, it is also convenient for the expansion of system functions.

High Adaptability

The adaptive part, so-called flexibility, is the adaptability of the exponentially controlled machine to change with the production object. Product processing is carried out on computer-controlled equipment. When the product changes, only the input mill program can be changed to meet the production needs of the new product. There is no need to change the hardware of the mechanical part and the control part, and the production process is automatically completed. This feature not only satisfies the market competition needs for fast product updates, but also solves the problem of automated production of single-piece, small-batch, and variable products. Strong adaptability is the most prominent advantage of computer-controlled equipment, and it is also the main reason for the emergence and rapid development of computer-controlled equipment.

Mechatronics

After the use of VLSI, the size of the cabinet box is reduced, the programmable interface is used, and the logic circuits of S, M, T (spindle transfer control, auxiliary function and tool parameters) and other sequential control parts are combined with the Nc device. Therefore, all the control boxes are entered into the machine, which reduces the floor space and facilitates the management of the equipment.

Things To Consider

Basic Considerations

1. In automatic milling machine operations, wear work clothes, tie the big cuffs tightly, and tie the shirt under the trousers. Female students should wear hard hats and put the braids in the hat. It is not allowed to wear sandals, slippers, high heels, vests, skirts and scarves to enter the workshop;

2. Be careful not to move or damage the warning signs installed on the machine;

3. Be careful not to place obstacles around the automatic mill, and the working space should be large enough;

4. If two or more people are required to complete a certain task, they should pay attention to mutual coordination;

5. It is not allowed to use compressed air to clean mills, electrical cabinets and NC units;

6. Internships should be carried out on designated machines and computers. Without permission, other machines, tools, or electrical switches shall not be arbitrarily moved.

Preparations

1. Before operation, you must be familiar with the general performance, structure, transmission principle and control program of the automatic mill, and master the functions and operating procedures of the operating buttons and indicator lights. Do not operate and adjust the automatic mill until you understand the entire operation process.

2. Before starting the machine, check whether the electrical control system of the machine is normal, whether the lubrication system is unblocked, whether the oil quality is good, and add enough lubricating oil according to the specified requirements, whether the operating handles are correct, and whether the workpieces, fixtures and tools are firmly clamped , Check whether the coolant is sufficient, and then drive a slow car idling for 3 to 5 minutes, check whether the transmission parts are normal, and confirm that there is no fault before it can be used normally.

3. After the machine program is debugged, it must be approved by the instructor to operate according to the steps, and it is not allowed to skip the steps. Without the permission of the instructor, operate or operate in violation of regulations, and the results will be treated as zero points, and those who cause an accident will be punished and compensated for corresponding losses in accordance with relevant regulations.

4. Before machining parts, it is necessary to strictly check whether the machine origin and tool data are normal, and perform a simulation run without cutting trajectory.

Precautions

1. When processing parts, the protective door must be closed, the head and hands are not allowed to enter the protective door, and the protective door is not allowed to be opened during processing;

2. During milling, the operator is not allowed to leave the machine without authorization, and should maintain a high degree of concentration and observe the running state of the machine. In the event of an abnormal phenomenon or accident, the program operation should be terminated immediately, the power supply should be cut off and the instructor should be reported in time, and no other machine operations should be performed;

3. It is strictly forbidden to slap the control panel and touch the display screen hard. It is strictly forbidden to knock on the worktable, indexing head, clamps and guide rails;

4. It is strictly forbidden to open the control cabinet of the computer numerical controlled system to watch and touch without permission;

5. The operator is not allowed to change the internal parameters of the machine at will. Intern students are not allowed to call or modify other programs not compiled by themselves;

6. On the machine control microcomputer, no other machine operations are allowed except for program operation and transmission and program copying;

7. The automated milling machine is a high precision equipment. Except for the tooling and workpieces on the workbench, it is strictly forbidden to stack any tools, clamps, blades, measuring tools, workpieces and other sundries on the machine;

8. It is forbidden to touch the tip of the cutter and iron filings by hand. The iron filings must be cleaned with iron hooks or brushes;

9. It is forbidden to touch the rotating spindle, workpiece or other moving parts by hand or in any other way;

10. It is forbidden to measure the workpiece, manual speed change during processing, and not to wipe the workpiece with cotton thread, nor to clean the machine;

11. It is forbidden to conduct trial machine operations;

12. When using the handwheel or rapid traverse to move the position of each axis, be sure to see the signs in each direction of the machine's X, Y, and Z axis before moving. When moving, turn the hand wheel slowly to observe the direction of movement of the computer-controlled milling machine before speeding up the movement;

13. When the measurement of the workpiece size needs to be suspended during the program operation, the standby bed must be completely stopped and the spindle can be stopped before the measurement can be carried out to avoid personal accidents;

14. If the machine is not used for several days, the NC and CRT parts should be energized for 2-3 hours every other day;

15. When shutting down, wait for the spindle to stop for 3 minutes before shutting down.

Troubleshooting

Each machine will meet troubles in daily use. You can troubleshoot by yourself based on the most common problems and solutions listed below.

1. Spindle motor failure: It will cause different milling depths.

2. The spindle and the table are not perpendicular to the table and need to be corrected (Symptoms: the depth of the cutting and closing positions is different). It will cause the machine to fail.

3. Troubles for spindle stalling.

3.1. Short circuit inside the spindle.

3.2. Current shielding.

3.3. The inverter parameter setting is wrong or its own fault.

3.4. The control card is faulty.

3.5. The main shaft line or the data line is short-circuited.

4. Problems for abnormal sound of spindle rotation.

4.1. The inverter is set incorrectly.

4.2. The spindle does not rotate.

4.3. There is a problem with the spindle itself (damaged bearing).

5. Troubles for the spindle to rotate automatically or fail to stop.

5.1. The control card is faulty.

5.2. The inverter is faulty.

6. Problems why the spindle motor does not rotate or reverse.

6.1. Check the parameter settings of the inverter.

6.2. Whether the signal wire of the inverter is connected reversely.

7. Troubles for the sudden stop or slow rotation of the spindle motor during the working process.

7.1. The working voltage is unstable or overloaded, just add a voltage stabilizer.

7.2. Check whether the middle line is connected well and whether the end of the line is unsoldered.

Understand the listed items above, you will solve the problems according to the causes of these failures, and grow up from a beginner to a professional in CNC milling.