Find & Buy Automatic CNC Router with Tool Changer for Woodworking

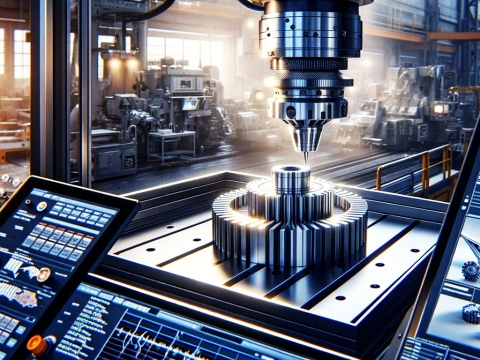

An ATC CNC router is a professional CNC machining center with a tool changer that can automatically change the router bits in the tool magazine without manual operation, thus meeting various finishing business needs for manufacturing cabinets, wardrobes, closets, doors and windows, furniture, crafts, decorations, musical instruments, signs, tables and chairs, as well as other industrial woodworking projects. The spindle usually comes with a tool magazine containing 4 to 12 router bits, which can be automatically switched to handle different designs to improve productivity, save materials and reduce labor costs. The most popular ATC CNC router machines come in linear ATC CNC kits, drum ATC CNC kits (rotary ATC CNC kits) and chain ATC CNC kits. In 2025, STYLECNC has picked three categories of mostly used ATC CNC machines for every budget and need, ranging from entry-level small ATC kits for hobbyists, home shops and small business owners, to professional ATC CNC routers for medium-to-large manufacturers, and industrial ATC CNC machines for 3D modeling and furniture production lines.

Professional ATC CNC Router Tables

2026 Best 5x10 CNC Router with Tool Changer for Woodworking

4x8 Linear ATC CNC Wood Router for Woodworking on Sale

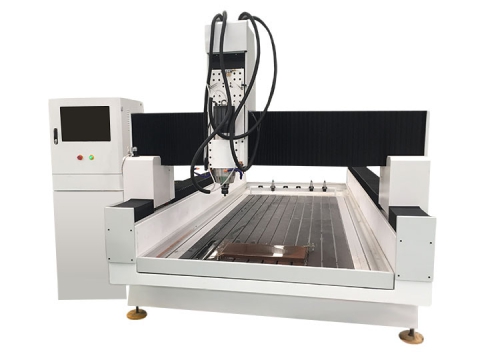

Linear ATC Stone CNC Carving Machine for Sale

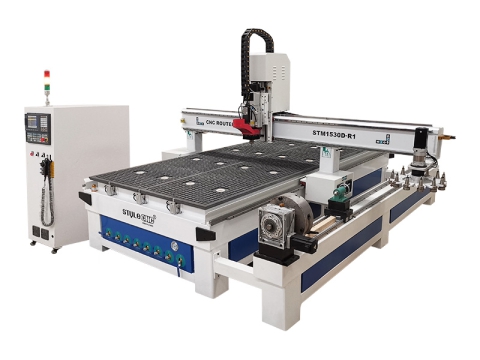

4x8 ATC CNC Router with Automatic Tool Changer Kit for Sale

5x10 CNC Wood Machining Center with 4th Rotary Axis on Sale

ATC 3D CNC Woodworking Router with 4th Axis Rotary Table

Automatic 4x8 CNC Machine with Tool Changer for Woodworking

Heavy Duty 4x8 CNC Router for Aluminum with Tapping Head

Industrial 5x10 CNC Woodworking Machine with Dual ATC Kits

ATC CNC Wood Router Table Kit with HSD C Axis and Aggregate

Automatic Tool Changer CNC Machining Center for Woodworking

4x8 ATC CNC Wood Carving Machine with Tool Changer for Sale

Industrial ATC CNC Router Machines

2025 Top Rated 5 Axis CNC Router Machine for Sale

Smart Nesting CNC Router Machine for Custom Cabinet Making

Industrial 4 Axis CNC Wood Router with Drum ATC Spindle Kit

2025 Best ATC CNC Router with Oscillating Knife Cutter

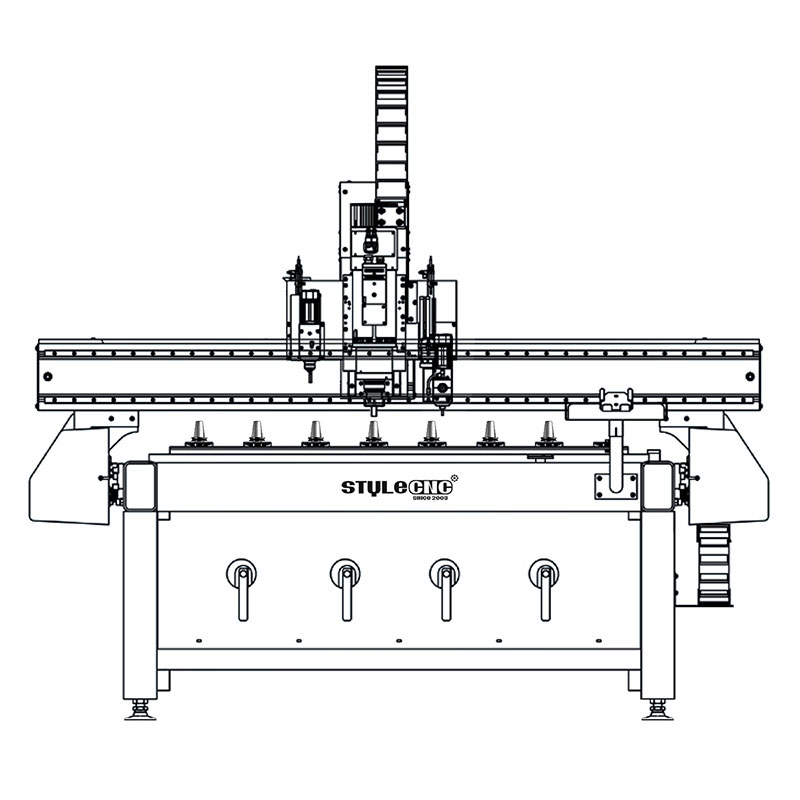

Industrial ATC CNC Router Machine with 4 Spindles for Sale

Moving Table CNC Router with Rotary Automatic Tool Changer

Entry-Level ATC CNC Router Kits

Small Desktop CNC Router with Tool Changer for Home Use

4x4 CNC Router Table Kit with Tool Changer for Beginners

Small CNC Router Machine with Automatic Tool Changer (ATC)

Feature Stories & Articles That Interest You

Upgrading Your Ordinary CNC Router with Automatic Tool Changer

Are you planning to DIY a CNC automatic tool changer kit or buy affordable ATC CNC routers with automated tool changer kits for wood, MDF, aluminum, brass, copper, foam, stone, plastic with routing, cutting, carving, milling, drilling, and grooving? Review this comprehensive and practical buyer's guide for machinists, fabricators, operators and beginners, we'll offer you the best CNC routers with ATC kits of 2025 at cost price with custom service to fit your business plans, projects and ideas. In order to complete multiple processing procedures in one clamping of the workpiece, shorten the auxiliary time, and reduce the error caused by multiple installations of the workpiece, your ordinary CNC machine should come with an automatic tool changer, which can meet the basic requirements of short tool change time, high tool repeat positioning accuracy, sufficient tool storage, small tool magazine footprint, safety and reliability.

Definition

Automatic Tool Changer is a device for transferring, loading and unloading tools between the spindle and the tool magazine. Automatic Tool Changer is the full name of ATC in CNC machining.

Automatic tool changer kits drive the CNC machine with continuous working, that is, after each process is completed, the new tool used in the next process is automatically changed to the spindle, and the spindle picks up the tool, the exchange of tools is generally completed by the coordinated action of the manipulator, magazine and spindle.

Compared with multi spindle CNC routers, ATC only needs one spindle in the headstock, the spindle components have sufficient rigidity to meet the requirements of various precision machining. In addition, the tool magazine can store a large number of tools for multi-step machining of complex parts, which can significantly improve the adaptability and machining efficiency of the machine tools. The ATC system consists of two parts: a tool magazine and an automatic tool change device. It has two major advantages: the first is that only one spindle is reserved, which is beneficial to simplify the structure of the spindle and improve the rigidity of the spindle; the second is that a large number of router bits with different types and functions can be stored in the library, which is convenient complete various complex and multi-step processing procedures.

Automated tool changer kit is composed of tool magazine, tool selection system, tool exchange mechanism and other parts, and the structure is more complicated. It is responsible for transferring the bit between the magazine and the spindle, pushing the bit to be used to the spindle, and then sending the replaced bit back to the magazine inside. Although this changing method is not as straightforward as the previous one, it avoids the magazine and spindle from moving for tool change, and is replaced by an automated tool changer. In this way, the movement range of the mechanical components is reduced, the changing is completed faster, and the design layout is also more flexible.

Working Principle

In the automatic tool changing system, the device that realizes the transfer and loading and unloading of the tool between the magazine and the spindle is called the tool changer. There are two ways to exchange tools: the relative movement of the magazine and the spindle, and the manipulator. The device that uses the relative movement of the magazine and the spindle to realize the tool exchange must first return the used tool to the magazine when changing the tool, and then take out the new tool from the magazine. The two actions cannot be performed at the same time, and the tool change time longer.

However, the manipulator tool changer can grab and load and unload the bits in the spindle and the magazine at the same time during changing, so the changing time is further shortened. The method of tool exchange using a robot is the most widely used. This is because the manipulator is flexible in changing, fast in action, and simple in structure. The manipulator can complete a series of actions such as grasping - drawing - turning - inserting - returning. In order to prevent the bit from falling, the movable claw of the manipulator is equipped with a self-locking mechanism.

Features & Advantages

The high-power automatic tool changer spindle is adopted, with good starting performance and large torque, which can give full play to the advantages of the machine's high speed and higher efficiency. It adopts high-torque servo motor made in Japan, which has the advantages of low noise, high speed and high positioning accuracy. Equipped with a unique tool magazine, you can exchange the required router bits at will. The tool change time only takes a few seconds. The standard tool magazine comes with 8 tools, and a larger capacity tool magazine can be customized.

Costs

The cost of an ATC (Automatic Tool Changer) CNC router machine can vary widely based on the machine's specifications, size, features, and brand, typically ranging from around $10,800 to over $100,000. Entry-level hobby ATC CNC router kits cost an average of $12,000, while some higher-end industrial ATC CNC router tables with advanced capabilities, larger working areas, and additional features tend to be more expensive. All in all, the average cost of purchasing an ATC CNC router with tool changer is about $16,000. It's advisable to consult specific manufacturers or suppliers for precise pricing based on your needs.

Most woodworkers are eager to own an ATC CNC router, but some of them have no idea how much it costs to upgrade an ordinary CNC machine with an automatic tool changer kit. According to the 2025 industrial CNC market report, you will have to spend an additional $3,000 to $8,000 on top of a regular machine if you want to DIY.

Specifications

| Brand | STYLECNC |

| Table Sizes | 4' x 4', 4' x 6', 4' x 8', 5' x 10', 6' x 12' |

| Axis | 3 Axis, 4th Axis, 4 Axis, 5 Axis |

| Capability | 2D Machining, 2.5D Machining, 3D Machining |

| Materials | Wood, Metal, Aluminium, Copper, Brass, Stone, Foam, Plastic |

| Types | Hobby Types for Home Use and Industrial Types for Commercial Use |

| Software | ArtCAM, Type3, Cabinet Vision, CorelDraw, UG, Solidworks, MeshCAM, AlphaCAM, UcanCAM, MasterCAM, CASmate, PowerMILL, Fusion360, Aspire, AutoCAD, Autodesk Inventor, Alibre, Rhinoceros 3D |

| Controller | OSAI, Syntec, LNC |

| Price Range | $6,000.00 - $110,000.00 |

| OEM Service | X, Y, Z Axis Working Area |

| Optional Parts | Dust Collector, Rotary Device, Vacuum Pump, Servo Motors, Cooling System, Colombo Spindle |

Types

Automatic tool changers are divided into three common types: linear type, drum type, and chain type, we will introduce them one by one.

Linear Type

This is a type of in-line changer, which used for magazines with 4 to 12 tools. It is featured by fast tool change and easy to use.

Drum Type

This is a type of rotary changer, which is also known as CTM type ATC and disc type ATC. It is used for magazines with 8 to 20 tools.

Chain Type

It is used for vertical CNC machines with lower tool changing speed. It is designed for magazines with more than 30 tools, which has the best tool carrying capacity.

How To Change Tool in CNC Machining?

Rotary Tool Holder

Rotary tool post is one of the simplest changers, commonly used in CNC lathes. It can be designed into various forms such as square, hexagonal or disc type axial tool rest. Four, six or more tools are respectively installed on the rotary holder, and the bits are changed according to the instructions of the numerical control device. The rotary tool holder must have good strength and rigidity in structure to withstand the cutting resistance during rough machining. Since the turning machining accuracy largely depends on the position of the tool tip, for computer numerical control lathes, the tool position is not adjusted manually during the machining process, so it is more necessary to choose a reliable positioning scheme and a reasonable positioning structure to ensure the rotary tool. After each indexing, the rack has the highest possible repeat positioning accuracy (usually 0.001-0.005mm). Under normal circumstances, the change action of the rotary holder includes the holder lifting, the holder indexing and the holder pressing.

Spindle Head Changing

Spindle head tool change is a relatively simple tool change method for CNC machines with rotating tools. This spindle head is actually a turret tool magazine. There are two types of spindle heads: horizontal and vertical. Usually, the turret indexing is used to replace the spindle head to realize automatic tool change. On each spindle of the turret, the rotary tools required for each process are pre-installed. When a tool change command is issued, each spindle head turns to the processing position in turn, and the main motion is turned on, so that the corresponding spindle drives the bit to rotate. Other spindles in non-machining positions are disconnected from the main motion. The spindle tool changing device saves a series of complicated operations such as automatic loosening, clamping, unloading, loading and unloading, thereby shortening the changing time and improving the reliability of the changing. However, due to the limitation of space position, the structural size of the spindle components cannot be too large, thus affecting the rigidity of the spindle system. In order to ensure the rigidity of the spindle, the number of the spindle must be limited, otherwise the structure size will be increased. Therefore, the turret spindle head is usually only suitable for machines with few processes and low precision requirements, such as computer numerical control drilling and milling machines.

Automatic Tool Changing System

Since the rotary tool rest and turret head type changer can not accommodate too many bits, they cannot meet the processing needs of complex parts. Therefore, ATC CNC machines mostly use automatic changers with tool magazines. The device with a tool magazine consists of a magazine and a tool changing mechanism, and the changing process is more complicated. First of all, all the bits used in the machining process should be installed on the standard holder, and after pre-adjusting the size outside the machine, put them into the magazine in a certain way. When changing, first select the bit in the magazine, and then the changer will take out the bit from the magazine or the spindle for exchange, put the new bit into the spindle, and put the old bit back into the magazine. The magazine has a large capacity and can be mounted on the side or above the headstock. Since there is only one spindle in the headstock of the machine with the automatic tool changing magazine, the rigidity of the spindle components should be high to meet the requirements of precision machining. In addition, the number of bits in the magazine is large, so multi-process processing of complex parts can be carried out, which greatly improves the adaptability and processing efficiency of the machine. The ATC system with magazine is suitable for drilling centers and machining centers.

How To Choose Magazine And Tool?

Tool Magazine Type

The tool magazine is used to reserve a certain number of router bits, which can be exchanged with the bits on the spindle through the manipulator. There are various types of magazines, such as disc type magazines and chain type magazines. The form and capacity of the magazines should be determined according to the technological scope of the machine. In the disc tool magazine, the direction of the router bit is in the same direction as the spindle. When changing the bit, the spindle box rises to a certain position, so that the bit on the spindle is aligned with the bottom position of the magazine, and the router bit is clamped, the spindle is under the control of computer, release the handle, the disc tool magazine moves forward, pulls out the router bit on the spindle, and then the magazine rotates the bit used in the next process to the position aligned with the spindle, the magazine backward, insert the new bit into the spindle hole, the spindle clamps the holder, the spindle box is lowered to the working position, the tool change task is completed, and the next process is starting to work. The advantages of this tool changing device are simple in structure, low cost, and good changing reliability. The disadvantage is that the changing time is long, and it is suitable for machining centers with small magazine capacity. For machining centers that require a large magazine capacity, a chain tool magazine will be used. The magazine has a compact structure and a large magazine capacity. The shape of the chain ring can be made into various types according to the layout of the machine. Shape, the change position can also be protruded to facilitate change. When the number of router bits needs to be increased, it is only necessary to increase the length of the chain, which brings convenience to the design and manufacture of the magazine.

Tool Selection Method

There are many bits stored in the magazine. Before each changing, the bit must be selected. The commonly used tool selection methods include sequential method and arbitrary method. The tools are inserted into the holders of the magazine in turn according to the process requirements. The processing is to adjust the bits in sequence. When processing different workpieces, the order of the bits in the magazine must be re-adjusted. The advantage is that the drive and control of the magazine are relatively simple. Therefore, this method is suitable for automatic tool change of small and medium-sized computer numerical control machines with large processing batches and small number of workpiece varieties. With the development of numerical control system, most numerical control systems adopt the method of arbitrary tool selection, which is divided into three types of tool holder coding, tool coding and memory type.

Tool Coding Method

The tool code or holder code needs to be identified by installing a code bar on the tool or holder, which is generally coded according to the principle of binary coding. The selection method adopts a special tool holder structure, and each bit has its own code, so the bit can be reused in different processes, and the replaced bit does not need to be put back into the original holder. The large-capacity magazine can be reduced accordingly. However, each bit has a special coding ring, the length is lengthened, it is difficult to manufacture, and the structure of the magazine and the manipulator becomes complicated. The coding method of the holder is that one knife corresponds to one holder. Tools removed from one holder must be put back on the same holder. Pick and place bits are cumbersome and take a long time to change. At present, the memory method is widely used in machining centers. In this way, the number and position of the holder in the magazine can be stored in the PLC of the CNC system accordingly. Tool information is always stored in the PLC, regardless of which fixture the tool is placed in. The magazine is equipped with a position detection device, which can obtain the position information of each holder. This way the tool can be taken out and returned at will. There is also a mechanical origin on the magazine, so that every time a knife is selected, the nearest knife will be selected.

Applications

ATC CNC router machines can be used in a wide range of industries, such as furniture and home improvement, wooden crafts, cabinets, screens, advertising, musical instruments or precision instrument shell processing industries. And the materials that can be processed mainly include various non-metallic materials such as wood, glass, stone, plastic, acrylic, and insulating materials.

Woodworking

Home doors, 3D wave board machining, cabinet doors, solid wood doors, craft wooden doors, paint-free doors, screens, craft window making, shoe polishers, game machine cabinets and panels, computer tables and panel furniture making.

Mold Making

It can make metal molds such as copper, aluminum, iron and more, as well as non-metal molds such as wood, stone, plastic, PVC, and more.

Advertising & Hobbyists

Sign making, logo making, lettering, acrylic cutting, blister molding, and decorations.

Indsutrial Manufacturing

It can make all kinds of shadow sculptures and relief sculptures, which are widely used in the crafts and gifts industries.

Troubleshooting

CNC router with ATC is the most powerful classification of computer numerical control machines. Although the machining strength and speed are incomparable to other computer numerical control machines, as a fully automated mechanical equipment, daily inspection and maintenance are also very necessary. A CNC router with tool changer is completely different from the detection and fault diagnosis methods of ordinary computer numerical control machines.

Machine Operation Inspection Method

The operation inspection method is a method of observing and monitoring the actual operation of the machine to determine the position of the malfunction and thus to trace the root cause of the fault. Generally speaking, computer numerical control machine kits adopt hydraulic and pneumatic control parts, such as automated tool changer, exchange table device, fixture and transmission device, etc., which can be used to determine the cause of the fault through motion diagnosis.

State Analysis Method

The CNC system can not only display fault diagnosis information, but also provide various states of diagnosis in the form of diagnosis address and diagnosis data. For example, when the system returns to the reference point incorrectly, you can check the status value of the relevant parameter to determine the cause of the failure.

CNC Programming Check Method

The CNC programming check method is also called the program function test method. It is a method to confirm the cause of the failure by compiling a special test program segment. You can use the manual programming method to compile a function test program for the system functions (such as linear positioning, circular interpolation, thread cutting, canned cycles, user macro programs, etc.), and run the test program to check The accuracy and reliability of the machine to perform these functions, and then determine the cause of the failure. Usually a test program is written with instructions for repairing the machine, and the program is run when a fault occurs to determine what the fault is.

Instrument Inspection Method

Instrument inspection method refers to the use of conventional electrical instruments to measure the voltage of each group of AC and DC power supplies, phase DC and pulse signals, etc., to find faults.

Numerical Control System Self-Diagnosis Method

The self-diagnosis of the numerical control system is a diagnostic method that uses the internal self-diagnosis program or special diagnostic software of the system to self-diagnose and test the key hardware inside the system and the control software of the system. It mainly includes power-on self-diagnosis, online monitoring and offline testing. The CNC machine uses the system's self-diagnosis function, which can easily display the interface signal status between the system and each part, and find out the general location of the fault. It is the most commonly used method in the fault diagnosis process.

What Our Customers Say?

Don't take our words as everything. Find out what customers say about our ATC CNC router machines they have owned or experienced. Why is STYLECNC considered a credible brand and manufacturer to buy a new ATC CNC router machine? We can talk all day about our quality products, 24/7 excellent customer service and support, as well our 30-day return and refund policy. But wouldn't it be more helpful and relevant for newbies and professionals alike to hear real-life customers experience what it's like to purchase and operate an automatic computer-controlled machine tool from us? We think so too, which is why we've collected tons of genuine feedback to help bring transparency to our unique buying process in-depth. STYLECNC guarantees that all customer reviews are real evaluations from those who have purchased and used our products or services.