If someone asks you to define the five most important things that you should consider before buying a wood lathe machine, what would you include?

Yes, we know that it's not that easy to do the guesswork. This becomes even harder when you are a beginner in woodturning.

STYLECNC is thus here to deliver the optimum guidelines you should follow before buying your own lathe for woodworking.

Headstock, spindle gearbox, bed, slide box, and carriage are some of the most crucial aspects you may look for the very first time if you have average or little knowledge in this industry.

But these are not the least things that would complete the scene. What else should you know as a woodturner?

Stay tuned until the last with this writing.

What Are The Possibilities With A Woodworking Lathe Kit?

As the lathe machine does the job of woodworking through computerized command, the accuracy rate always meets your desired output. When you have such a tool in your repertoire, you can make almost everything you can think of from lumber.

From sharpening wood to making exciting furniture and designs, a budget-friendly CNC wood lathe will do it all for all wood turners.

What Is A Lathe Machine?

A lathe machine is a type of machine tool working with an electric motor to rotate the spindle through a belt and gear transmission system, which turns the workpiece on the spindle chuck to rotate, and then uses the blade fixed on the tool post to perform turning. A lathe machine is typically used for turning end face, inner and outer diameter, arc, taper, drilling, boring, eccentricity, embossing, cutting, grooving, and turning thread.

Most lathes come with a variety of special tools and blades, which can complete internal and external machining, drilling, threading, cutting grooves, end face machining, turning blanks, turning external circles, drilling center holes, turning holes, reaming, turning tapers, turning forming surfaces, knurling, coiled springs and more processing procedures.

Metal lathe is a type of power metal fabrication tool that uses turning, cutting, grinding or special machining methods to process various metal parts to obtain the required geometric shape, dimensional accuracy and surface quality. The metal type is the most widely used variant and also known as the most powerful one.

Woodworking lathes are the most popular woodworking machine tools that use HSS (high-speed steel) or hard alloy turning tools (spindle gouge, round nose scraper, bowl gouge, parting tool, oval skew chisel, roughing gouge, hollowing tool) to sharp hardwood and cork to complete circles, inner holes, end faces, cones to make stair balusters and spindles, Roman columns, table and chair legs, basins, furniture and decorations, vases, Pillar tables, bedposts, sticks, goblet, bottle cap, suona, cup cover, rolling pin, handle, flute, cello accessories.

There are many classification methods for metal lathes, and the most commonly used classification method is to classify according to the processing nature of the machine and the cutting tools used. In addition, it can be classified according to the degree of versatility, the working accuracy of the power tool, weight and size, the number of main organs of the power tool, and the degree of automation. The asset scale of the metal lathe industry ranks first among all sub-sectors of power tools, which is much higher than that of other sub-sectors.

What Is A Wood Lathe?

A wood lathe is a type of powerful woodworking tool to sharp timber, lumber, wood (Oak, Walnut, Balsa, Pine, Ash, Celtis, Redwood, Beech, Maple, Akasa, Bamboo, Cedar) into cylindrical profiles with various machining operations, including turning, cutting, sanding, broaching, carving, knurling, drilling, deformation or facing with HSS or carbide tools, cutters, blades, knives to create an object with symmetry about an axis of rotation.

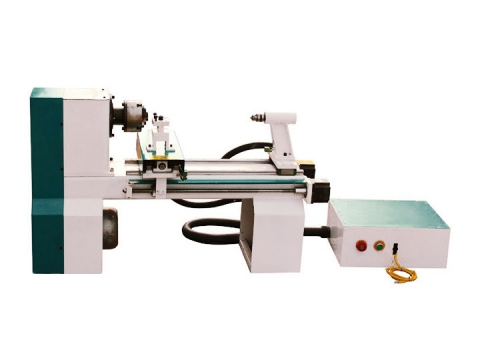

There are two common types of power wood turning lathe machines: fully automatic types and semi-automatic types. Automatic wood turning tools are power tools for woodworking with computer numerical controlled, all the work is automatic from the beginning to the end. The Semi-automatic variant is also quite same as the fully automatic variant except for that the feed work is finished by manually.

Such a machine consists of a bed and a tailstock installed at the end of the guide rail of the bed, a tool holder installed at the middle of the guide rail of the bed, a headstock installed at the head of the bed, a main spindle installed on the headstock, and the chuck on it, the motor installed on the headstock, and the variable speed transmission device installed on the motor spindle.

Such a tool is also known as a wood-turning machine, wood-turning lathe, wood-turning tool, woodworking lathe, or a lathe machine for wood.

What Is An Automatic Wood Lathe?

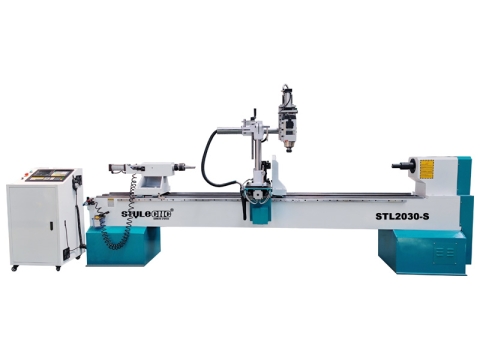

An automatic wood lathe is a type of CNC woodworking tool with computer numerical controller for rough and fine turning blanks of outer circle, inner hole, end face, tapered surface, grooving, and cutting to realize fully automated machining operation for one-time finished woodworking projects making.

An automatic wood turner can finish the manufacturing process of a piece of wood without human intervention according to the CNC programming. After the program instructions are input into the memory of the computer control system, they are compiled and calculated by the computer, and the information is transmitted to the driver to drive the motor through the CNC controller to turn lumber with the designed files.

It is also known as CNC (as well as automated, computerized, computer numerical controlled, computer-controlled, and digital) wood turning machine or turning center.

What Is A Wood Lathe Used For?

The manual and semi-automatic wood lathes are designed for craftsmen, hobbyists, home stores and small businesses to shape wood into personalized bowls, cylinders, rings, spheres.

The fully automatic CNC wood lathes are ideal for commercial use and industrial manufacturing to cut, mill and turn hardwood and softwood into wooden bowls, rolling pins, vases, drawer pulls, candle holders, magic wands, pool cues, cue stickers, billiard cues, baseball bats, chess pieces, trivets, keepsake boxes, egg cups, beads, barrels, round boxes, drumsticks, wooden plates, wine cups, succulent planters, spurtles, stair balusters and spindles, christmas ornaments, salt and pepper shakers or mills, goblets, lamps, pens, bottle stoppers, lidded boxes, wooden flashlights, christmas trees, honey dippers, spatulas, spoons, ice cream scoops, gourd pendants, Buddha heads, magnifying glasses, mortars and pestles, antique pepper mills, furniture legs (chair legs, table legs, ottoman legs and sofa legs), ring shapes (bracelets and bangles), wooden tools and toys, pizza cutter handles, pigtail flipper handles, coffee scoop handles, and handles for anything and everything.

In addition, all lathes are suitable for teaching, training and research by school students and teachers.

How Does A CNC Wood Lathe Machine Work?

CNC wood turning is a form of computer numerical controlled woodworking process that is used to create woodturning objects with blades. It is different from most of automatic woodworking forms in that the workpiece is moving while a stationary blade is used to cut and shape it. Many intricate shapes and designs can be made by CNC turning machines.

In the process of automatic woodturning, the numerical control device is a special computer numerical control system that controls the computer-controlled turning tool and completes the automatic machining of the parts. It receives digital parts patterns, process requirements and other information, and performs interpolation machining operations according to a certain mathematical model. As a result, the speed and position of each movement coordinate are controlled in real time to complete the machining of the parts.

The working principle is mainly divided into the following four steps:

Step 1. When turning blanks, first of all, according to the pattern and process plan of the processed parts, write a program list in the format specified by the computer-controlled system used, and record it on the program carrier.

Step 2. Input the program on the program carrier into the numerical control device through the input device.

Step 3. After the numerical control device processes the input program, it sends a command to the servo system of each coordinate.

Step 4. According to the signal sent by the controller, the servo system drives the moving parts of the machine tool through the servo actuator through the transmission device, so that it works in accordance with the prescribed action sequence, speed and displacement, so as to produce the parts in accordance with the drawing.

How Much Does A Wood Lathe Cost?

If you have an idea to buy a cheap lathe machine for woodworking, you may wonder how much does it cost? how to get a fair price? Tell it realistically, the final cost depends on the machine's configurations, including axis, spindles, turning tools, blades, cutters, power supply, control system, driving system, other hardware and software.

An entry-level mini wood lathe starts at $200 for hobby and home use, a midi-lathe is typically priced from $1,200 to $3,600 for small business, a primary automatic CNC wood lathe machine costs anywhere from $2,800 to $11,180 for commercial use, while some professional full-size lathes are as expensive as $13,000 for industrial manufacturing, depending on the machine's features and capabilities.

If you want to buy from overseas, additional tax fee, customs clearance fee, and shipping costs will be added to the total budget.

Wood Lathe Types

Centre Types

Centre lathe machine is the most common type. The old transmission was driven by a belt-conducted tower wheel, but now, it has been changed to a gearbox transmission. The advantage of the gearbox is that it can accurately control the speed of the spindle without excessively high spindle speed range, belt friction, or slippage. Because the spindle is placed horizontally, it is also known as a horizontal type. If the bed surface is notched, it is a Gap type.

Bench Top Types

Benchtop are also known as desktop or tabletop. Their type and structure are similar to centre types. They are usually installed on a work table and get their name. They are suitable for the production of precision measuring tools, instruments and small parts.

Vertical Types

The main spindle of the vertical turning machine is installed vertically, the bed is horizontal, and the workpiece is placed on the rotatable bed. It is especially suitable for turning large diameter but short length workpieces.

Turret Types

Turret woodworking turning machines are also known as hexagonal lathes, which are designed to replace the tailstock of ordinary lathes with a hexagonal rotating turret. Especially suitable for processing a large number of workpieces in a variety of processing procedures (such as drilling, reaming, boring), and suitable for mass production.

Automatic Types

The automatic one can automatically turn the workpiece according to the processing order. After the turning is completed, it will automatically retract the tool, feed the material, and perform the turning of the next finished product, which is suitable for mass production of smaller diameter workpieces.

Copying Types

It is also known as profiling or imitation turning lathe, which uses the stylus to move in accordance with the shape of the model or template, and the turning tool also moves the turning work accordingly, so it can turn the workpiece exactly as the model.

CNC Types

It is suitable for processing workpieces with large quantities, complex designs and high precision requirements. High-end CNC tools are also known as CNC turning centers.

Specifications

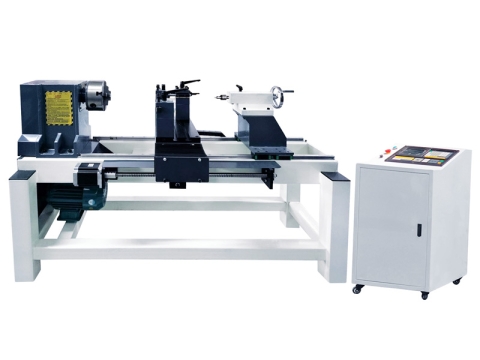

| Brand | STYLECNC |

| Model | STL0410, STL0810, STL1512, STL1516, STL1530, STL2030, STL2530 |

| Max Turning Length | 3000mm |

| Max Turning Diameter | 300mm |

| Maximum Feed Rate | 2000mm/min |

| Minimum Setting Unit | 0.1mm |

| Air Pressure | 0.6-0.8Mpa |

| Price Range | $2,800 - $11,180 |

| Speed Range | 0-3000r/min |

| Transimission Type | Ballscrew for X/Z axis, Gear for Y axis |

Lathe Machine Parts

Head Stock

The headstock, also known as the drive center, is located on the left side. It consists of a transmission mechanism (belt-conducted tower wheel transmission and gear transmission) and a hollow spindle with Morse taper. The rear part of the spindle is equipped with a gear, which is connected with the tower wheel or gear of the transmission mechanism to drive the spindle to run. The front part of the spindle can be equipped with chuck, face plate and other fixtures to clamp the workpiece. (The advantage of the hollow spindle is that it reduces the weight of the spindle and can hold long workpieces. It can also be used with cutting tools to realize automatic loading and unloading.)

Spindle Gearbox

The main motor drives the spindle to rotate through the transmission chain including the intermediate gear rod and the spindle high and low speed conversion rod. the spindle drives the Ball Screw or Feed Rod under the control of the tumbler gear and the gearbox to realize the linkage between the spindle rotation and the feed of the tool post.

Ball Screw is called a screw, and Feed Rod is called a smooth screw, both of which are named after its thread (screw) and smooth surface.

The lead screw is used for thread turning. The rotation of the spindle drives the lead screw through the set of gear transmission pairs in the gearbox to drive the screw at a determined speed ratio. A nut that is cut in half is installed in the tool post, which can be fastened on the thread of the screw when closed, and then drives the tool post to move at a certain speed (one revolution of the spindle, how long the tool post moves) to cut the thread.

Smooth bars are used for turning smooth outer surfaces (or knurling). A keyway is cut on it, and a sliding gear in the tool holder is sleeved on the light bar to receive the movement. At this time, the knife is moved by a rack mounted under the bed. The difference with the lead screw is that the speed ratio of the spindle and the smooth rod is not fixed, and the transmission chain of the fast feed motor can be connected through the clutch, so that the smooth rod rotates quickly to drive the tool post to quickly approach the workpiece and save processing time.

The tool post movement power switch is a four-to-five-position (that can be moved on a cross-shaped track) handle. It can be moved up and down to change the rotation direction of the light bar. The middle position cuts off the transmission chain from the spindle, stops the rotation of the light bar and prevents Movement interference, and then pull left and right to turn on the fast feed motor to implement fast feed. There are also some types of machines, the handle can only be moved up and down (two directions and three positions), and the fast cutting tool is a separate handle installed on the carriage box.

If the built-in gear of the gearbox cannot meet the processing requirements, you can open the cover of the change gear cover, hang a gear with a specific number of teeth on the shaft, and move the handle to select the change gear to move according to the set transmission ratio of the change gear. Knife.

Lathe Bed

The bed is a large basic part made of cast iron construction that has undergone quaternization. There are two high-precision V-shaped guide rails and rectangular guide rails, the guide rails are generally made by high-frequency hardening treatment. The guide rail is divided into two parts to guide the carriage and tail stock to move. A lead screw is installed under the bed. The screw will match the rotation speed of the spindle and can cooperate with the automatic feed mechanism of the tool seat to perform threading and workpiece knurling (or embossing).

The cross-sectional shape of the bed has different design styles according to the manufacturing plant, and it can be roughly divided into two types: British and American lathe.

The bed base includes a bed rail and a bed frame, the lower part is the bed frame, and the upper part is the bed rail.

Slide Box

The slide box is framed on the bed, and the hanging part on the side is equipped with a transmission mechanism to receive movement from the lead screw and the smooth rod, and drive the tool holder mounted above to cut.

Carriage (Tool Holder)

The carriage includes a compound carriage and an automatic feed mechanism. The compound carriage can operate horizontal and longitudinal feed. (The transverse feed direction mentioned here is kept perpendicular to the bed, and the longitudinal feed direction is parallel to the bed, that is, from the perspective of the spindle rather than the operator.) Generally speaking, the longitudinal feed is carried by the slide plate. The large hand wheel (feed hand wheel) on the box is operated and the horizontal feed is operated by the hand wheel on the tool holder. The principle of automatic feed mechanism for threading and workpiece hobbing is to use the workpiece to run at a constant speed, and the tool in the carriage is used for turning blanks at a constant speed and linear movement.

A wood turning tool is clamped on the square tool holder. This part of some machines can hold four turning tools at the same time, and one turning tool is selected for processing with a handle that rotates 90° each time, saving the trouble of frequent tool changes.

The upper seat of the compound tool post can be rotated on the index plate to change the horizontal feed into an oblique feed for machining inclined surfaces.

When the thread/smooth surface cutting control rod is turned to the thread position, the two half nuts in the slide box are buckled on the lead screw, and the transmission chain from the sliding gear on the smooth rod to the rack of the bed is disconnected, and the lead screw drives the thread turning. On the contrary, the smooth screw cooperates with the bed rack to drive the outer circle cutting.

The vertical and horizontal feed control lever controls whether the upper seat of the compound tool post or the horizontal sliding plate is linked with the light bar, that is, whether the tool blade feeds automatically.

Tail Stock

The tailstock is located on the right side of the bed. The shaft hole of the tailstock has a morse taper, which can be equipped with drills, reaming cutters and screw taps for inner hole processing. You can also move the tailstock on the guide rail according to the length of the workpiece; at this time, the tailstock can be equipped with the top center to bear the workpiece clamped by the chuck to prevent the workpiece clamped by the chuck from being too long and difficult to clamp .

Wood Lathe Accessories

Chuck

The chuck is a mechanical device used to clamp a workpiece on a lathe machine.

Face Plate

The face plate is a basic fixture accessory, used for the wood or metal variants. It is a round metal (usually cast iron) plate. There are many radial or irregular parallel slender grooves on the face plate, which are used for boring and drilling of larger or irregularly shaped work objects, and work objects that cannot be clamped by other methods.

Finger

It is applied to the hole of the processed work object. The two ends of the mandrel are provided with center holes, so that one end is supported by the center and the other end enters the spindle end.

• Solid finger.

• Expand finger.

• Row finger.

• Screw finger.

• Cone finger.

Center (Tip, Thimble), Retractor (Chuck, Clamp)

The center is used to support the work. It is installed on the spindle end and called the live center, also known as top center or front center.

There are 5 types of lathe centers:

• Ordinary center.

• Center for small pieces.

• Half center for cutting the end face.

• Movable center for high-speed cutting.

• Umbrella center for tubes or hollow cylinders.

Retractor, the hollow part can be used to hold the work.

The heart-shaped retractor is also called a chicken heart chuck, which is usually used to hold round work objects.

Clip-shaped retractor: Clip-shaped retractor is usually used to hold square work objects.

Driven Disc

The driven disc is installed on the spindle, and when it rotates, it rotates the work piece clamped between the two top centers for turning processing.

Collet Chuck

The collet is mainly responsible for clamping the small diameter work object to the spindle end. It's mainly used for hexagonal and automatic lathes.

Steady Rest

It is a stable support which is installed on the tool holder and moves with it to avoid the bending phenomenon of the work.

Angle Plate

It is used as an auxiliary tool that cannot be directly installed on the face plate.

V Clamp Block

It is used to determine the center position of the work.

Wood Turning Tool

It is used for turning the appearance of work objects. We can define it into the following types based on the applications:

Outer circle turning tool: according to the main declination angle - There are 95 degrees (for semi-finishing and finishing of outer circle and end face), 45 degrees (for outer circle and end face, mainly used for rough turning), 75 degrees (mainly used for rough turning of outer circle), 93 degrees (mainly used for profiling finishing), 90 degrees (for rough and fine turning of outer circle).

Grooving Blade - The outer grooving blade is typically used for outer circular grooving and cutting, and the inner grooving tool is typically used for inner groove processing.

Thread Turning Tools include external thread-turning tools and internal thread-turning tools. Among them, external thread-turning tools are typically used for external thread processing, and internal thread-turning tools are typically used for internal thread processing.

Inner Hole Turning Tool is used for inner holing.

We can also classify by the materials of the turning tools:

HSS (High-Speed Steel) Turning Tool is made of high-speed steel, which can be continuously sharpened. It is a general-purpose cutting tool for rough machining and semi-finishing.

Tungsten Carbide Tool is made of hard alloy, which is used for cutting cast iron, non-ferrous metal, plastic, chemical fiber, graphite, glass, stone and ordinary steel, and can also be used for cutting heat-resistant steel, stainless steel, high manganese steel, tool steel and other difficult-to-process materials.

Diamond Blade is inlaid with diamond, which features with extremely high hardness and wear resistance, low friction coefficient, high elastic modulus, high thermal conductivity, low thermal expansion coefficient, and low affinity with non-ferrous metals. It can be used for non-metal brittle Precision machining of hard materials such as graphite, high wear-resistant materials, composite materials, high-silicon aluminum alloys and other tough non-ferrous metal materials.

In addition, we will also meet turning tools made of other materials, such as cubic boron nitride and ceramic blades.

Pros & Cons

The high-efficiency and functional "CNC wood lathe" is developed through computer numerical control technology and other mechanical technologies. It can process complex rotary or semi-finished wood products. It is a special power tool developed in accordance with the requirements and the features of the woodworking industry, and the combination of woodworking operation habits. Through CNC technology to control mechanical actions, it is possible to process complex shapes of semi-finished or rotary wood projects such as cylinders, cones, curved surfaces, and spheres. It is especially suitable for the mass production of small and medium-sized woodworking shops. The shape can be flexibly set at any time and the processing style can be quickly changed.

Advantages

• The use of high-reliability computer numerical controller ensures reliable work stability, after-sales service, installation and deployment.

• The operation interface is simple and friendly, with full text prompts and a simple setting method for direct input of the size.

• Driven by a high-precision stepping motor, the accuracy of the processing size is ensured through program calculation.

• Two-axis can process two at the same time, and a single-axis can be equipped with a chuck, which has high efficiency and low energy consumption.

• The learning time is short. It only takes 30 minutes to understand the programming method, operation process and equipment maintenance method respectively, and you can become proficient in operation in one week.

• Fully-enclosed or semi-enclosed guards are adopted for CNC lathe machines, and closed guards are used to prevent chips or cutting fluid from flying out, causing accidental injury to the operator.

• Most lathes with automatic chip removal device adopt a slant bed structure layout, which is convenient for chip removal and easy to adopt automatic chip removal machine.

• The spindle speed is high, and the workpiece clamping is safe and reliable. Most computer-controlled lathes use hydraulic chucks, which are convenient and reliable to adjust the clamping force, and at the same time reduce the labor intensity of the operators.

• All CNC variants for woodworking with tool changer adopt an automatic rotary tool post, which can automatically change the tool blade during the machining process to continuously complete the processing of multiple procedures.

• The main drive and feed drive adopt independent servo motors to make the transmission chain simple and reliable. At the same time, each motor can move independently or realize multi-axis linkage.

Disadvantages

• The sale price is higher, and the first investment in equipment is large.

• Higher technical requirements for operation and maintenance personnel.

• When turning complex shapes of wood projects, manual programming requires a lot of work.

Care & Maintenance

A woodworking lathe is the most common machine tool that features with high working efficiency, high precision and cost saving, which can bring continuous economic benefits to you and your business.

However, in the process of operation, it is necessary to do a good job of care and maintenance to ensure that the machine can successfully finish the work and extend the service life.

• The new machine needs to be inspected once every 10 days to avoid the loosening of the screws during the running-in process, and the loosening should be tightened in time, and regular inspections should be made in the future.

• Use the oil injection pump to refuel and maintain the guide rail and screw rod every day. If the oil passage is found to be blocked, it should be dealt with in time

• The wood powder should be cleaned every 2 hours of work.

• the spindle bearing should be filled with oil once a year. Especially for sliding guide rails, special attention should be paid to refueling on schedule.

• Replenish oil to the bearing of the tool post every 1 month of work.

• Check the lubrication condition of the bearing at the end of the ball screw every 3 months of work and replenish oil in time.

• Check the wear condition of the new V-belt after three months of operation. If the V-belt is too loose, use the motor fixing plate to adjust the tightness of the V-belt.

• The dust cover not only plays the role of dust prevention but also plays a role of ensuring safety, so it should not be removed casually.

• Check whether the spindle motor is buried and covered by sawdust every day, and clean it up in time to avoid fire.

Buyer's Guide

All the aforementioned sections clarified almost everything you need to know about a wood lathe. But when it comes to choosing one from the market, considering some of the facts will always guide you to have the best possible possessions-

First of all, you can either go for a used variant or a completely new one. But if you have enough budget, we recommend going for a new one. This will minimize future risks.

In case you are planning to purchase a used variant, make everything clear about the after-purchase support you will get from the enterprise.

We also recommend asking for quotes from different enterprises so that you always get a clear picture of the pricing that you should spend on a wood-turning tool.

Last but not the least, if you are a first-timer in this industry who are about to make his first purchase, consider grabbing some suggestions from a professional. This will help you to make a better purchase.

Why Should You Choose From STYLECNC?

STYLECNC will be the best store & shop that can offer you the cheapest CNC lathe machines for woodworking in 2025 with 24/7 free custom expert service to fit your personalized woodworking projects, ideas, and plans.

From counseling to showing you the best possible options for your desired demand, STYLECNC is always committed to providing you with the best possible service.