The Future of Laser Metal Cutter

The future of laser metal cutting technology is an exciting and rapidly evolving field that promises to revolutionize the manufacturing industry. As new innovations in laser technology emerge, metal laser cutters will continue to become faster, more accurate, and more versatile. Some of the developments that we can expect to see in the future include more powerful laser sources, improved automation and control systems, and the integration of artificial intelligence and machine learning technologies.

What Is Metal Laser Cutter?

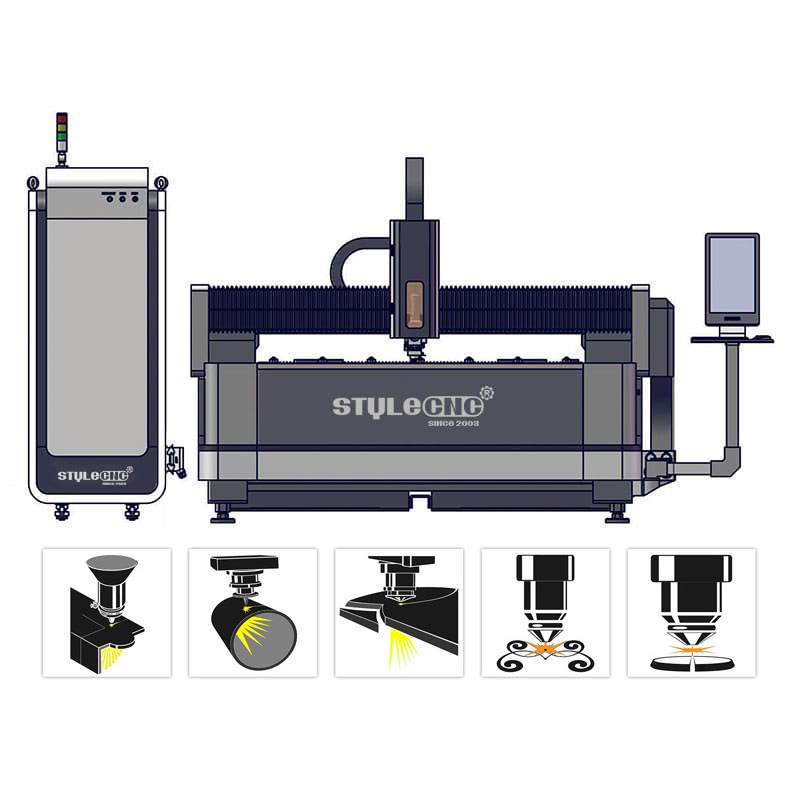

A metal laser cutter is an automatic CNC metal cutting machine that uses a laser beam to cut specified shapes and contours out of metal sheets, plates, bars, panels, profiles, straps, tubes and pipes, which is the best metal cutting solution for hobbyists and industrial manufacturers.

A laser metal cutting machine is an eco-friendly precision cutting tool kit that comes with a CNC controller for automatic sheet metal and tube fabrication to create individual shapes and outlines, as well as perform various roughing and finishing for metal strips, rods and profiles, which consists of bed frame, power supply, generator, reflection path, cutting head, chiller, control panel and software.

How Does A Laser Cut Through Metal?

A metal laser cutting machine works with a CNC controller to drive a fiber or CO2 laser beam to cut in any direction, angle, bevel and slope according to the designed layout file, and create the shapes and contours you want.

The energy of the laser is concentrated into a high-density beam in the form of light. The beam is transmitted to the work surface, generating enough heat to melt the material, and the high-pressure gas coaxial with the beam directly removes the fused metal to achieve the purpose of metal cutting. This shows that laser metal cutting is essentially different from CNC machining.

It uses the laser beam emitted from the generator to focus on the beam irradiation condition of high power density through the external circuit system. The heat is absorbed by the metal part material and the part temperature rises sharply. After reaching the boiling point, the material begins to vaporize and form holes, as the relative position of the beam and the part moves, will eventually form a slit in the material. The technological parameters (cutting speed, power supply, gas pressure) and movement trajectory during slitting are controlled by the CNC system, and the slag at the slit is blown off by the auxiliary gas with a certain pressure.

During laser-cut metal, auxiliary gas suitable for the material to be cut is also added. When cutting steel, oxygen must be used as an auxiliary gas to produce an exothermic chemical reaction with the molten metal to oxidize the material, while helping to blow away the slag in the slit. For metal parts with high processing accuracy, nitrogen can be used as an auxiliary gas in the industry.

What Are Laser Metal Cutting Machines Used For?

A laser metal cutting system is applied in industrial manufacturing, school education, small business, home use, small shop and home store for sheet metal fabrication, aviation, spaceflight, electronics, electrical appliances, kitchenware, auto parts, office supplies, furniture kitchen dining, subway parts, automobile, machinery, precision components, ships, metallurgical equipment, elevator, household appliances, metal signs, logos, tags, profiles, letters, words, arts, crafts, gifts, tool fabrication, foils, adornment, advertising and other metalworking industries.

Most organic and inorganic materials can be cut by laser. In the metal fabrication industry, which occupies a heavy weight in industrial manufacturing, many metals, regardless of their hardness, can be cut without deformation. Of course, for high-reflectivity materials such as gold, silver, copper and aluminum alloys, they are also good heat transfer conductors, so laser cutting is difficult or even impossible to cut (some difficult materials can be cut using pulsed laser beams, due to the extremely high peak power of the pulse wave, the absorption coefficient of the material to the beam will increase sharply instantly).

They can cut stainless steel, carbon steel, tool steel, galvanized steel, spring steel, alloy, iron, aluminum, copper, brass, silver, gold, titanium, nickel, manganese, cobalt, chromium, lead and other metals in hobby use, home business, small shop, commercial use, and industrial manufacturing.

Stainless Steel

For the manufacturing industry dominated by stainless steel sheets, the laser metal cutter is an effective cutting tool. When the heat input is strictly controlled, the width of the heat affected zone of the trimming edge can be limited, thereby ensuring good stainless steel The corrosion-resistant type. Laser cut of stainless steel uses the energy released when the beam is irradiated to the surface of the steel plate to melt and evaporate the stainless steel. For the manufacturing industry that uses stainless steel sheets as the main component, laser cut of stainless steel is a fast and effective cutting method. The important process parameters that affect the cutting quality of stainless steel are cutting speed, power supply, air pressure and so on.

Carbon Steel

The thickness of the laser cut of carbon steel plate can reach 70mm, the slit of carbon steel cut by oxidation flux cutting mechanism can be controlled within a satisfactory width range, and the slit of thin plate can be narrowed to about 0.1mm.

Copper & Alloys

Pure copper (purple copper) is too high reflectivity, laser cut of brass (copper alloy) should use higher power, auxiliary gas using air or oxygen, can cut thinner plates. Pure copper and brass has high reflectivity and very good thermal conductivity. Pure copper and brass can only be cut when a "reflective absorption" device is installed on the system, otherwise the reflection will destroy the optical components.

Aluminum & Alloys

The cut of aluminum plates is easy to do with fiber lasers, which have high performance whether it is cutting aluminum or aluminum alloy.

Nickel & Alloys

They are also known as high-temperature alloys with many types, most of them can be laser oxidized and flux-cutting with good cuts.

Titanium & Alloys

Pure titanium can be well coupled with the heat energy converted by the focused beam. When the auxiliary gas uses oxygen, the chemical reaction is violent and the cutting speed is fast, but it is easy to form an oxide layer at the cutting edge, which may also cause over-burning. Therefore, the use of air as an auxiliary gas can ensure the cutting quality. Laser cut of titanium alloys is commonly used in aircraft manufacturing. Titanium plates are cut with nitrogen and nitrogen as working gases.

How Many Types of Laser Cutters for Metal?

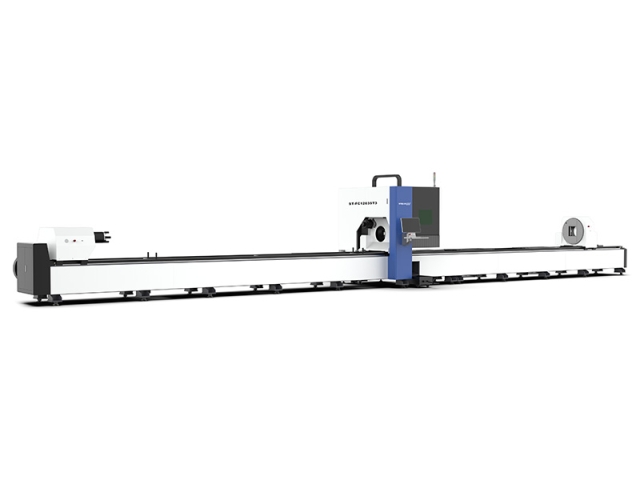

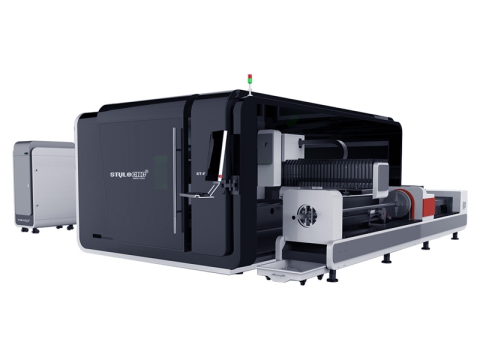

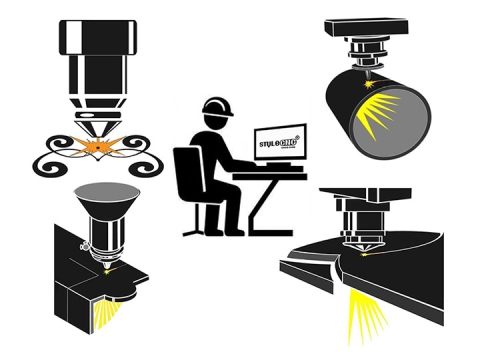

Metal laser cutting machines come in all features, from sheet metal cutters to tube cutters, dual-function 2-in-1 sheet metal & tube cutting systems, as well as all-in-one 5-axis 3D metal laser cutting robots that will fit your multiple purposes.

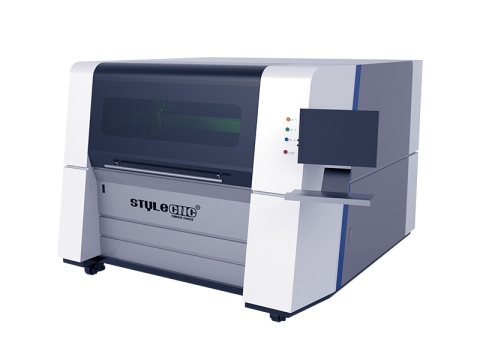

By the laser source definition, metal laser cutters should be classified as CO2 lasers, fiber lasers, and hybrid laser metal cutting systems.

Laser metal cutting tables are available in sizes ranging from small (compact) to large (full-size). You can get them with 300mm x 300mm, 400mm x 600mm, 600mm x 900mm (2x3), 900mm x 1300mm, 1000mm x 1600mm, 1300mm x 2500mm (4x8), 1500mm x 3000mm (5x10), 2000mm x 4000mm (6x12), 2500mm x 6000mm.

In addition, laser metal cutters are also available in different power options from 150W to 60000W. Pricing ranges from as little as about $6,500 for a low-power cutter to well over $1000,000 for ultra-high power laser metal cutting machines.

How To Choose The Best Laser Cutter for Metal?

If you are working for the metal fabrication business, you may need a laser metal cutter, review the four types of automatic metal cutting tools to fit your needs & budget:

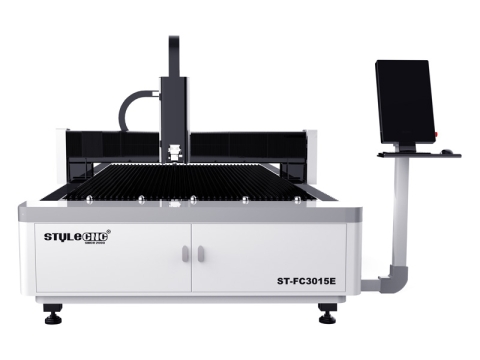

1. Sheet metal laser cutters.

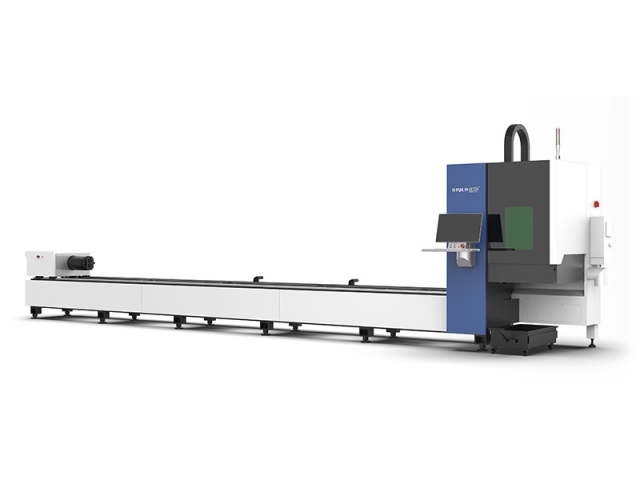

2. Automatic Laser tube cutters.

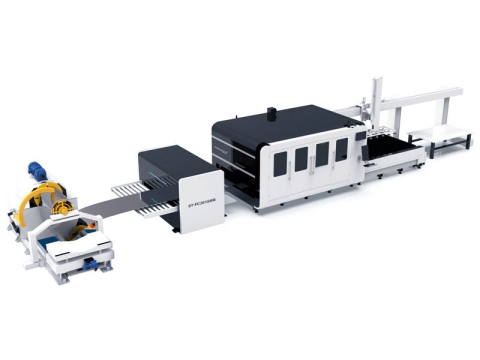

3. Dual-purpose metal laser cutting systems for sheets and tubes.

4. All-in-one 3D metal laser cutting robots for special profiles.

Technical Parameters - Specifications

| Brand | STYLECNC |

| Model | ST-FC3030, ST-FC6040, ST-FC1390, ST-FC1325, ST-FC3015, ST-FC4020, ST-FC6025, ST-FC60M, ST-FC12025, STJ1325M, STJ1390M, STJ1610M, ST-18R |

| Laser Type | Fiber Laser, CO2 Laser |

| Laser Generator | Yongli, Raycus, MAX, RECI, IPG |

| Laser Power | 180W, 300W, 1500W, 2000W, 3000W, 4000W, 6000W, 8000W, 10000W, 12000W, 15000W, 20000W, 30000W, 40000W, 60000W |

| Table Sizes | 2' x 3', 2' x 4', 4' x 4', 4' x 8', 5' x 10', 6' x 12' |

| Laser Wavelength | 10.6 μm, 1064 nm |

| Cooling System | Water Chiller |

| Max Cutting Thickness | 200mm |

| Max Cutting Speed | 120m/min |

| Applications | Metal Sheets, Tubes and Profiles of Mild Steel, Carbon Steel, Stainless Steel, Tool Steel, Galvanized Steel, Spring Steel, Aluminum, Copper, Brass, Iron, Gold, Silver, Lead, Nickel, Cobalt, Chromium, Titanium, Manganese, Alloy |

| Price Range | $6,500 - $1000,000 |

| Warranty | 3 years |

How Much Does A Metal Laser Cutter Cost?

Once you have an idea to buy a cheap laser cutter for metal from local store, you may wonder how to get a fair price? According to different sources, powers, software, driving system, control system, spare parts, other hardware and software.

The average cost of buying a new metal laser cutter in 2025 is around $12,800.00 based on the data from Amazon, eBay, Google Shopping, and STYLECNC.

The least expensive fiber laser metal cutting machine in 2025 starts at a respectable $11,800, while some high-power industrial models can cost as high as $1000,000 with IPG fiber lasers. The average cost of purchasing a budget-friendly CO2 laser metal cutter in 2025 is around $9,620. The starting cost of the most affordable hobby models is priced under $6,780, without considering any additional options. However, in the case of the most expensive commercial models, the final sale price can reach upwards of $20,000.

Most entry-level sheet metal laser cutters are priced anywhere from $6,500.00 with lower-power Yongli 180W and 300W CO2 laser tube for hobbyist, enthusiast, home use, and small business, while the high-end precision sheet metal cutting machines can be as expensive as $278,000.00 with high-power 12000W IPG fiber laser source for commercial use. In addition, the 30000W extra-high power enterprise-level lasers cost over $500,000, and the 60000W ultra-high power industrial lasers can reach 1 million US dollars for thicker sheet metal fabrication. A professional automatic laser metal tube cutter starts around $50,000 with 1500W, 2000W, 3000W fiber laser power supply for most types of tubing. All-in-one tube and sheet metal laser cutting systems range in price from $40,800 to $108,000 for dual-purpose metal fabrication with CNC controller in industrial manufacturing. The price of a multifunctional laser metal cutting robot ranges from $42,000 to $76,000 for 3D metal cuts with multiple angles, directions and dimensions.

If you want to buy overseas, the fee of tax, customs clearance and shipping costs should be included in the final price.

Pick Up Your Budget

| Laser Powers | Minimum Price | Maximum Price | Average Price |

|---|---|---|---|

| 180W | $7,000 | $15,800 | $10,760 |

| 300W | $11,000 | $20,000 | $14,630 |

| 1500W | $13,000 | $34,000 | $17,210 |

| 2000W | $15,000 | $42,000 | $21,320 |

| 3000W | $20,000 | $60,000 | $26,010 |

| 4000W | $36,000 | $70,000 | $45,300 |

| 6000W | $37,000 | $80,000 | $50,100 |

| 12000W | $85,000 | $190,000 | $112,600 |

| 20000W | $120,000 | $300,000 | $165,100 |

| 30000W | $200,000 | $400,000 | $252,300 |

| 40000W | $320,000 | $600,000 | $391,800 |

| 60000W | $500,000 | $1000,000 | $721,900 |

How Thick of Metal Can You Cut with A Laser?

A metal laser cutter is easy to cut various thicknesses of different types of metals and alloys. Every type of laser source features with its own unique pros and cons to cut metals and alloys. In the case of the same source, different power supplies will result in different maximum metal cutting thicknesses. In terms of the same power, different brands of generators have different performances in metal cutting thickness, precision, and speed.

• The cheapest 300W CO2 laser metal cutters can cut stainless steel up to 3mm thick and carbon steel up to 4mm thick at speeds of up to 6m/min.

• The entry-level 1.5KW (1000W) low-power fiber laser metal cutters are typically used to cut stainless steel up to 6mm, carbon steel up to 16mm thick, aluminum and copper up to 5mm thick, at maximum speeds in excess of 35m/min.

• The 2KW (2000W) fiber laser metal cutting tables have the ability to cut carbon steel up to 16mm thick, maximum 8mm stainless steel and aluminum, and maximum 6mm brass and copper at speeds of up to 40m/min.

• The most popular 3KW (3000W) fiber lasers have great applicability for cutting carbon steel up to 20mm thick, stainless steel and aluminum up to 10mm, brass and copper up to 8mm at maximum speeds of over 45m/min.

• The professional 4KW (4000W) mid-power laser metal cutting machines have the power to cut stainless steel up to 12mm, carbon steel up to 22mm thick, aluminum up to 14mm, copper and brass up to 10mm at speeds of up to 50m/min.

• The commercial 6KW (6000W) medium-power fiber lasers can release enough heat energy to cut carbon steel up to 25mm thick, stainless steel and aluminum up to 16mm, copper and brass up to 10mm at max speeds in excess of 60m/min.

• The industrial 8KW (8000W) high-power fiber lasers are capable of cutting stainless steel and aluminum up to 25mm, carbon steel up to 30mm thick, brass and copper up to 12mm at speeds of up to 70m/min.

• The 12KW (12000W) hi-power lasers are ideal for cutting carbon steel, stainless steel and aluminum up to 50mm thick, copper and brass up to 20mm thick at maximum speeds of more than 80m/min.

• The 15KW (15000W) power supplies are applicable for carbon steel and stainless steel up to 60mm thick, maximum 50mm aluminum, and maximum 30mm copper and brass at max speeds in excess of 90m/min.

• The 20KW (20000W) high power lasers can easily cut carbon steel up to 70mm thick, maximum 80mm stainless steel, maximum 80mm aluminum, maximum 70mm brass and copper at maximum speeds in excess of 100m/min.

• The 30KW (30000W) extremely high power lasers come with the precision metal cutting capabilities of stainless steel thickness ranges up to 100+ millimeters, and maximum 80mm thick carbon steel, aluminum, brass and copper at max speeds of over 110m/min.

• The 40KW (40000W) extra-high power fiber lasers are typically used to cut carbon steel, stainless steel, aluminum, brass and copper up to 120+ millimeters thick at speeds of up to 120m/min.

• The 60KW (60000W) ultra-high power fiber laser metal cutting systems are powerful enough for precise cutting stainless steels and carbon steels from 16mm to 200mm at speeds from 0.05m/min to 15m/min.

NOTE: The 1000W fiber laser power option is discontinued and no longer available, replaced by free upgrade to 1500W.

What Are The Advantages of Laser Metal Cutting Machine?

You can get benefits of excellent beam quality, high efficiency, high speed, easy operations, low cost, low maintenance, stable running, super flexible optical effects for laser metal cutters, which are easy to flexible industrial manufacturing requirements.

• High precision and best stability: The use of heavy duty bed frame, high precision ball screw transmission mechanism, optimized CNC system control, which can meet the processing of precision parts, and the dynamic performance is stable, and it can work for a long time.

• The cutting section is of high quality: The mechanical follow-up cutting head system is adopted, the cutting head follows the height of the plate, and the position of the cutting point is always maintained, so that the cutting seam is smooth.

• High performance: For thin sheet metal cutting, it can replace CO2 laser machine, CNC punching machine and shearing machine, the cost of the whole laser metal cutting machine is equivalent to 1/4 of CO2 laser machine and 1/2 of CNC punching machine.

• Low cost of use and high cutting speed. No consumables, environmental protection, long service life.

• Easy to use: Whether you are a beginner or a professional, whether you are a young adult or an old man, you can easily operate it.

How To Buy An Affordable Laser Cutter for Metal?

How to purchase a budget-friendly laser metal cutter with local pickup or global shipping? This is an annoyance you have to face after browsing and researching. You can do the majority of your shopping online by following the 8 buying steps below. Let's walk you through each step of the buying process.

Step 1. Request A Consult.

You can have a free pre-sales consultation with our sales manager, stating the type of metal you would like to cut, its size and thickness, as well as the shape and profile you require. You can find everything from CO2 to fiber lasers, sheet metal cutters to metal tube cutters, and all-in-one cutting machines at STYLECNC. We will suggest you the budget-friendly model with fast speed, high precision, good quality, and professionalism to match your specific needs.

Step 2. Get Free Quotation.

We will offer you with our detail quotation based on your consulted laser machine. You will get the best machine specifications and the affordable price within your budget.

Step 3. Sign A Contract.

You need to review the purchase agreement to ensure that it accurately reflects your needs and the details of the laser metal cutting machine you specified, including payment information, terms and conditions, and then sign a contract to stipulate the responsibilities of both parties to ensure the completion of the buying process.

Step 4. Build Your Machine.

We will place a production order with the manufacturing plant and start the machine building process as soon as receiving your signed sales contract and deposit. During the manufacturing process, we will keep you updated with the latest news about your machine in the form of pictures or videos.

Step 5. Inspection.

The entire manufacturing process is subject to regular inspections and strict quality control. Your machine is inspected before leaving our factory to ensure it is free of defects and can cut metals as you expect.

Step 6. Shipping & Transportation.

After you confirm that the machine meets your requirements, we will start shipping to the agreed address according to the terms of the contract. You can ask for transport information at any time.

Step 7. Custom Clearance.

Customs clearance is an essential step in cross-border transactions. We will provide you with all the documents required for customs clearance at any time.

Step 8. Support & Service.

We can provide professional technical support and free customer service by phone, email, Skype, WhatsApp, online live chat, remote service. We also provide door-to-door service for all types of metal laser cutting machines in some areas.

How To Use A Laser To Cut Metal?

Using laser to cut metal is not a one-step job, requiring professional software operation experience, precise cutting parameter setting and optimization, proficient operation process, and basic safety protection. Here are 5 easy-to-follow operation steps for beginners.

Step 1. Fix Metal Sheet or Tube.

Fix the sheet metal flat on the cutting table, or fix the metal pipe to the rotary attachment to ensure the stability of the material placement to avoid shaking during the cutting process, resulting in insufficient cutting accuracy.

Step 2. Choose Auxiliary Working Gas.

Choose auxiliary gas based on the metal properties, and adjust the gas pressure according to the metal thickness to ensure that the cutting can be stopped when the gas pressure is lower than a certain value, so as to avoid scrapping the cut parts and damaging the focusing lens.

Step 3. Import Cutting File.

Open the CNC controller software, import the designed layout file, set cutting parameters such as metal thickness, adjust the laser cutting head to the appropriate focus position, and center the nozzle.

Step 4. Start Chiller.

Start the chiller with voltage stabilizer, set the normal water temperature and pressure to match the laser generator requirements.

Step 5. Turn On Laser Generator and Machine for Cutting.

Start the laser generator, turn on the machine for cutting, observe the cutting status at any time, suspend cutting with any problem, and continue cutting after the danger is eliminated.

These five steps are brief descriptions. Operators need to spend a lot of time practicing in the actual operation process to master the details of each operation step.

After using the metal laser cutter machine, you should shut down all equipment in sequence to reduce the failure of the laser generator and extent the service life of the machine. The specific operation steps are as follows.

Step 1. Turn off the laser generator.

Step 2. Turn off the water chiller.

Step 3. Turn off the gas cylinder and discharge the remaining gas in the pipeline.

Step 4. Turn off the CNC controller (lift the Z axis to a safe height) and seal the nozzle with tape to prevent dust from contaminating the lens.

Expert Skills

When using a laser metal cutting machine, it is necessary to pay attention to some small details and precautions. Only by mastering the use skills can the machine cutting efficiency be higher.

Corner Melting

When decelerating to cut the corners of thin sheets, the laser can overheat and melt the corners. A small radius is generated at the corner to maintain the high-speed cutting and avoid the phenomenon of overheating and melting of the steel plate when cutting the corner, so as to achieve good cutting quality, reduce cutting time and improve manufacturing force.

Part Spacing

Usually, when cutting thick plates and hot plates, the distance between parts should be large. Because the heat of the thick plates and hot plates is greatly affected, it is easy to burn edges when cutting sharp corners and small graphics, which will affect the cutting quality.

Lead Settings

In the process of cutting thicker plates, in order to make the slits well connected and prevent burns at the beginning and end points, a transition line is often drawn at the beginning and end of the cutting, which are called lead and tail lines respectively. The lead and tail lines are important to the workpiece itself. It is useless, so it should be placed outside the category of workpieces, and at the same time, be careful not to set the leads at sharp corners and other places that are not easy to dissipate heat. The connection between the lead wire and the slit adopts a circular arc transition as much as possible to make the mechanical movement stable and avoid burns caused by corner stop.

Co-Edging

Two or more parts are co-edged into a combination, and a large number of regular graphics are co-edged as much as possible. Co-edging cutting can greatly shorten the cutting time and save raw materials.

Part Collision

In order to increase production efficiency, some metal laser cutters work 24 hours a day, and use unmanned automatic loading and unloading devices to hit the overturned parts after cutting, causing damage to the cutting head and interruption of manufacturing, causing great losses. When you need to sort, pay attention to the following three points:

• Choose a suitable cutting path, avoid the cut parts, and reduce collisions.

• Plan the cutting route reasonably to reduce the cutting time.

• Automatically or manually combine multiple small parts with micro-connections. After cutting, the removed parts can easily disconnect the micro-connections.

Safety Rules & Precautions

While enjoying the high-efficiency and beauty of laser metal cutting, how to do a good job of safety protection during use, so that the machine can perform better and reduce the radiation to the human body?

Check Before Operation

Whether the main controller casing, power supply casing, switching power supply casing, motor driver casing, data line casing, machine tool guide rail, motor casing, exhaust fan casing, and the main grounding point are well connected. Poor grounding will shorten the life span. High voltage discharge will damage the control circuit and even threaten life safety.

Be Careful When Handling

Light Path: When cutting and debugging the light path, please be careful not to let any part of the body touch the light path to avoid injury.

Energy: The magnitude of the laser current determines the magnitude of the energy, but when the current is greater than the allowable value, the energy will drop, and if the current exceeds the allowable value for a long time, it will greatly affect the service life.

Ambient Temperature: When the ambient temperature is higher than the maximum allowable value, the equipment will not get sufficient heat dissipation, which will reduce the operating stability of the equipment. When the ambient temperature is lower than the minimum allowable value, it may cause the water to freeze.

Cooling water temperature: When the cooling water temperature is greater than the maximum allowable value, the laser energy efficiency will drop rapidly. When the cooling water temperature is lower than the minimum allowable value, it will cause the water to freeze.

Ambient Humidity: Excessive humidity will cause high-voltage discharge, endangering personal safety, and will also cause damage to the power supply.

Power Supply: The fluctuation of the power supply voltage will cause the equipment to work unstable. If the voltage is too high, it will cause permanent damage to the power supply system of the equipment. In order to avoid the electrical appliances and circuits of the machine from being burned out due to excessive voltage, please install a power regulator of more than 2000W.

It's Prohibited To Use In The Following Cases

Do not turn on the machine during severe weather such as thunder and lightning.

Untrained operators are not allowed to operate the machine alone.

Harm To Human Body And Protective Measures

Respiratory Tract Protection

The high temperature generated by the laser cooperates with the gas to complete various processing. At the same time, it also produces a large amount of dust, especially when processing some special metal materials. The generated dust contains some chemical components, which will cause harm to the human body if inhaled.

Therefore, when operating a metal laser cutter, attention should be paid to the protection of the respiratory tract. Install the supporting dust removal device, try to operate in an environment with unobstructed air, and wear a mask as much as possible. Do not touch the cut parts immediately to avoid scalding by residual heat.

Eye Protection

A laser metal cutter will cause damage to the retina or cornea of the eye when it is working. When arranging the cutting site, the following measures can be taken to reduce the reflection or radiation of ultraviolet rays:

• Darken the wall finish at the job site to reduce radiation.

• Install protective screens or curtains to reduce UV radiation.

• Wear protective dark-tinted eyes or goggles, or a welding cap to protect the eyes from the glare of the flame, ultraviolet and infrared rays from the plasma arc.

• Others in the working area should not look directly at the arc or flame during cutting.

Skin Protection

Laser cutting has certain damage to skin tissue, which can be repaired by itself. It should be noted that long-term exposure to laser beam may cause skin burns or leave scars. Therefore, when working with a laser metal cutter, the protection of the skin must also be given great attention.

For safety reasons, it is recommended that the operator wear long-sleeved clothes to prevent skin burns caused by direct laser radiation and prevent scalding caused by molten slag splashing on the skin. Do not touch the cut parts immediately, and wear gloves to avoid burns due to residual heat.

Care & Maintenance

In order to achieve a better operating state of the metal laser cutter, regular maintenance is also essential, and the following points should be paid attention to in maintenance:

• Daily cleaning is required to keep it clean and tidy.

• After the machine stops working, check whether the X, Y, and Z axes of the machine tool can return to the origin. If not, check whether the position of the origin switch is offset.

• The daily slag discharge drag chain needs to be cleaned.

• Clean up the sticky matter on the filter screen of the air outlet in time to ensure the smooth flow of the ventilation duct.

• The cutting nozzle needs to be cleaned every 1 hour of operation, and replaced every 2-3 months.

• Clean the focusing lens, keep the lens surface free of residue, and replace it every 2-3 months.

• Check the temperature of the cooling water, the temperature of the water inlet of the generator should be kept between 19°C and 22°C.

• Clean up the dust on the cooling fins of the water cooler and freeze dryer. To ensure the heat dissipation efficiency, the dust should be removed.

• Frequently inspect the working status of the voltage regulator to monitor whether the input and output voltages are normal.

• Monitor and check whether the switch of the mechanical shutter is normal.

• Auxiliary gas is output high-pressure gas, pay attention to the surrounding environment and personal safety when using the gas.

• Switching sequence:

Start-up

Open air, water-cooled unit, cold dryer, air compressor, main engine, and generator should be baked for 10 minutes if conditions permit.

Shutdown

First press the high pressure, then the low pressure, and turn off the generator after the turbine stops rotating without sound. Followed by the water-cooled unit, air compressor, gas, cold dryer, machine power off can be left behind, and finally turn off the voltage stabilizer cabinet.

Buyer's Guide

A laser metal cutter can come with a price from a few thousand to as much as ten thousand dollars. Therefore, it is never going to be an affordable option to pick up. To save your budget, you may think about picking up an affordable option, but do it only when you have enough knowledge about which one will be a good option and which one will not. In that case, choosing from a trusted manufacturer that will ensure good after-purchase support will be a better option to buy from. In case you face any difficulties after making the purchase, you will have the option to ask for help or support.

At the same time, check for all the technical issues that will allow the machine to work functionally well. In that case, the software should be compatible with the devices to which you will connect the machine.

Last but not the least, always choose a user-friendly interface so that you do not have to face any issues with the machine.

STYLECNC Will Be A Good Option

Yes, we are talking about our own brand and it is because we trust in ourselves. With tremendous and excellent customer support and after-purchase response, we work at making our customers happy to all extent. Choose your next metal laser cutter from STYLECNC and we can bet you will thank yourself later.