Most Popular 4 Axis CNC Routers You Can Pick In 2025

Are you looking for free DIY ideas to build your own 4th axis CNC router kit for rotary machining with wood, MDF, plywood, aluminum, copper, brass, stone, foam, plastic, acrylic, and glass? Are you planning to buy affordable 4 axis CNC router tables online with sizes including 2x2, 2x3, 2x4, 4x4, 4x6, 4x8, 5x10, 6x12 instead of DIY (Do It Yourself) for your home shop, small business, hobbyists, training, school education, commercial use, and industrial manufacturing? Are you picking up the best budget rotary CNC kit in the top rated manufacturer, supplier, dealer, seller, maker, or brand with 24/7 free service & support in stores? Review the best buying guide in 2025 for makers, DIYers, homeowners, shop owners, beginners, operators, machinists, merchants, brokers, distributors, agents, commercial users, wholesalers, industrial manufacturers, carpenters, artisans, builders, woodworkers, metal fabricators, foam fabricators, stone workers with styles & types of mini, small, tabletop, benchtop, desktop, portable, handheld (DSP controller), gantry, and large format. STYLECNC will be the best store & shop that can offer you the top rated new & used 4 axis CNC machines on sale at cost price in 2025 within your budget with free expert customer service to fit your 2D/3D personalized cutting, carving, drilling, grooving, turning, milling projects and solutions.

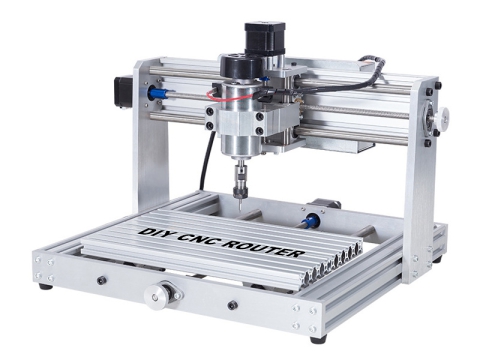

Entry-Level 4th Axis CNC Router Kits

Entry Level Desktop CNC Router with 4th Axis Rotary Table

4th Rotary Axis Hobby CNC Router for Sign Making

Affordable 3D CNC Router Machine with Multi 4th Rotary Axes

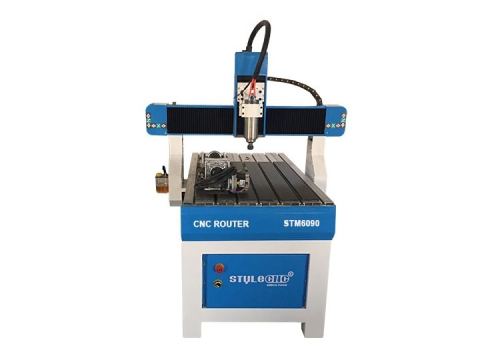

Professional 4th Axis CNC Router Tables

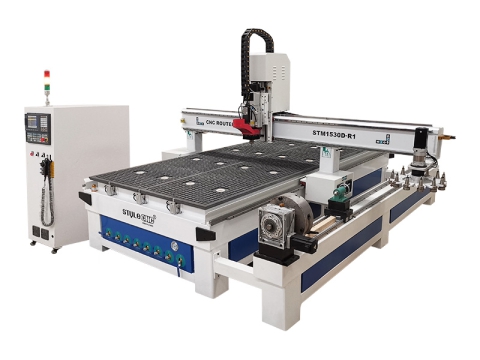

Top Rated 4 Axis CNC Router 1325 with 4x8 Rotary Table

2026 Best 4x8 Wood CNC Router Machine for Sale

2025 Best CNC Router Lathe Machine with 4th Rotary Axis

2025 Best Multi-Head CNC Router Machine with Multi-Spindle

5x10 CNC Wood Machining Center with 4th Rotary Axis on Sale

Professional CNC Wood Carving Machine for Furniture Making

Multi-Head 3D 4 Axis Rotary CNC Wood Carving Machine

3D CNC Router for Woodworking with Rotary Table and 8 Heads

Industrial 3D CNC Machine with 4x8 Table Top for Sale

Industrial 4 Axis CNC Router Machines

Industrial 4 Axis CNC Wood Router with Drum ATC Spindle Kit

2025 Best 4 Axis CNC Foam Router Cutting Machine for Sale

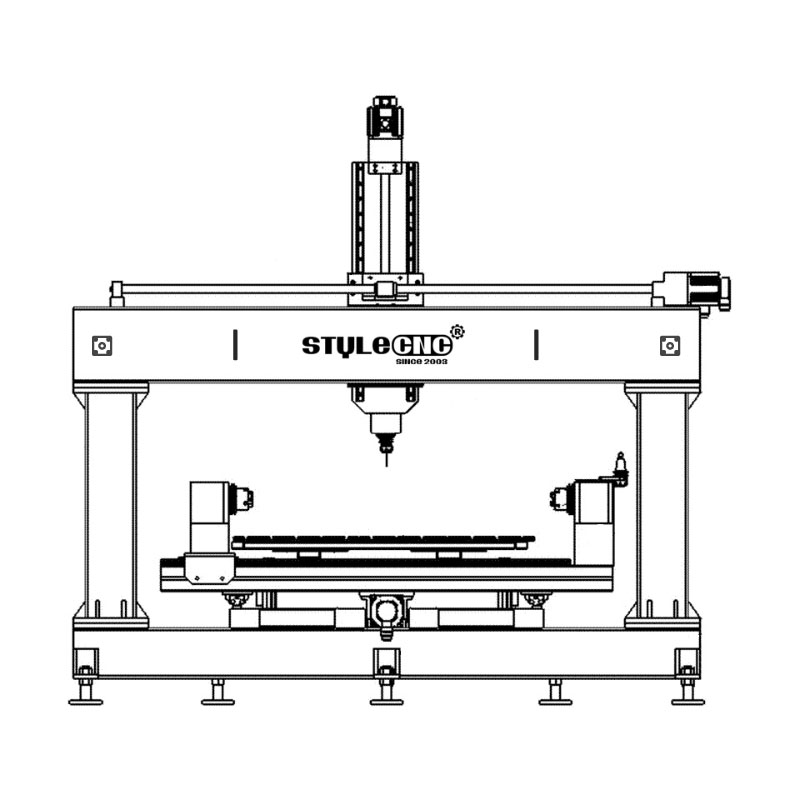

2025 Best 4 Axis CNC Router for 3D Curved Surface Carvings

Feature Stories & Articles That Interest You

Find & Buy Your First Four-Axis CNC Router for 2025

Definition

4 axis CNC router is an automatic computer-controlled machine tool whose spindle rotates 180° along the X-axis or the Y-axis to do 3D arc milling and cutting, which is based on the ordinary 3 axis machine tool.

4th axis CNC router is an automated machine tool kit with computer numerical controller for relief carving and sheet cutting, as well as adding the fourth axis (rotary axis) for 3D cylinders milling.

In addition, the 4-axis CNC machine is divided into four-axis three-linkage and four-linkagel, not to say that the rotation is added, it is a four-axis linkage machine tool, and a computer-controlled system with a rotating axis and a four-axis linkage can be called as a real 4 axis CNC machine. Because of the rotation movement of the 4th rotary axis, 3D machining of cylindrical, arc, and circular surfaces is realized. A real 4-axis machine tool can cut wood, foam, stone, white marble, human body, Buddha statues, sculptures, handicrafts, furniture. 4-axis is refer to X-Y-Z-A, X-Y-Z-B or X-Y-Z-C, 4 axis are linked, the four axis can work at the same time. If the machine has only three feed axes (X, Y, Z), the Y-axis can be manually replaced with a rotating axis, and it can only be three-axis linkage at most. This is a 4th axis CNC machine, and it is also the usual fake four axis. In terms of use, it can process planes, reliefs, and cylinders. If the machine has four feed axes (X, Y, Z, A), it can be processed with four-axis linkage, and can process planes, reliefs, cylinders, non-standard three-dimensional patterns, and corners of 3D patterns.

Applications

• Carpentry: relief and hollow carving of hardwood furniture.

• Furnitures: wooden doors, cabinets, panel, office furniture, solid wood furniture, doors and windows of tables and chairs,

• Advertising: advertising signs, logo production, acrylic cutting, plastic molding, and various materials for advertising decorations.

• Woodworking: audio, game cabinets, computer tables, sewing machines, musical instruments.

• Panel Processing: insulation parts, plasticized workpieces, PCB, bowling track, stairs, anti-fold special board, epoxy resin, ABS, PP, PE, and other carbon mixtures.

• 4-axis CNC machine is applied to aluminum cutting industry, aluminum plate, aluminum plastic plate, aluminum honeycomb plate, aluminum profile, 3D machining process, wave board production, special-shaped artificial sheet cutting, LED, neon slotted literal cutting, plastic suction light box mold production, acrylic, copper sheet, PVC sheet, artificial stone, MDF and plywood sheet cutting & milling.

Features

• Support A/C code format and special M code control.

• Customizable and editable I/O interface, providing users with a wide range of development platforms.

• Intelligent processing memory function, support breakpoint continuous cutting.

• Stronger anti-interference ability and passed a number of CE tests.

• With parameter backup and recovery functions, it effectively prevents the loss of important parameters.

• Easy to handle complex projects such as cylinders, prisms, and polyhedrons.

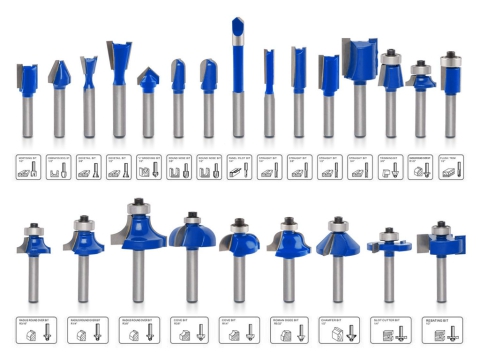

• Professional in 3D jade carvings, 3D stone carvings, Buddha statues, stair pillars, sofas, table legs, stair balusters, spindles.

Specifications

| Brand | STYLECNC |

| Table Sizes | 2' x 3', 2' x 4', 4' x 4', 4' x 6', 4' x 8', 5' x 10', 6' x 12' |

| Axis | 4 Axis, 4th Axis |

| Capability | 2D Machining, 2.5D Machining, 3D Machining |

| Materials | Wood, Aluminium, Copper, Brass, Metal, Stone, Foam, Plastic |

| Types | Hobby Types for Home Use and Industrial Types for Commercial Use |

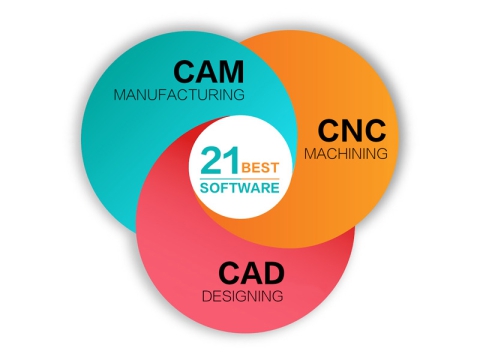

| Software | ArtCAM, Type3, Cabinet Vision, CorelDraw, UG, Solidworks, MeshCAM, AlphaCAM, UcanCAM, MasterCAM, CASmate, PowerMILL, Fusion360, Aspire, AutoCAD, Autodesk Inventor, Alibre, Rhinoceros 3D |

| Controller | Mach3, Mach4, Ncstudio, OSAI, Siemens, Syntec, LNC, FANUC |

| Price Range | $2,580.00 - $38,000.00 |

| OEM Service | X, Y, Z Axis Working Area |

| Optional Parts | Rotary Device, Dust Collector, Vacuum Pump, Cooling System, Servo Motors, Colombo Spindle |

Costs

The cost of a 4 axis CNC router kit (including rotary 4th-axis types) can vary significantly depending on table size, brand, features, and capabilities, typically ranging from about $5,280 to $36,800. Entry-level models for hobbyists start at the lower end, while industrial-grade machines with advanced features can be at the higher end of the spectrum.

In 2025, the average cost of a rotary 4th-axis CNC router table is around $5,680, while a 3D 4-axis CNC router machine can cost you anywhere at least $12,000. Should you choose a 4th-axis for rotary carving and cutting, or a 4-axis for 3D surface milling? You have to understand what you are buying it for, and plan your budget, then decide how much you can spend to meet your business needs.

Pros & Cons

• Calculate the rotating cutting path without unfolding the surface.

• No need to rotate the workpiece repeatedly, and complete the tool path calculation at one time.

• Reduce the finishing allowance, and the tool path can be roughed in layers.

• Realize partial rotation processing, can set the angle range and length range.

• Affected by the accuracy of the fixture, the machining of irregularly rotating workpieces usually adopts multi-face rotation positioning machining, and there are always joints between different machining directions.

• Rotary carving without positioning joints adopts the integral method of rotating spindle, and the machine generates an automatically closed rotary cutting path.

3 Axis vs. 4 Axis

3 axis CNC machine has only three coordinate axes, X, Y, and Z, while the 4 axis kit has one more indexing head than the 3 axis kit. The indexing head is a common accessory used for machining complex products. The best auxiliary tool, controlled by the operating system, can realize linkage with other axes. It is mainly used for indexing and positioning machining of workpieces. The indexing device is generally located on the spindle of the machine tool. Under normal circumstances, the machine has three basic axes, X, Y, and Z. The other rotation and feed axes are the fourth axis. The latter can realize the positioning of the tool magazine, the rotary positioning of the rotary table and the indexing head, and more advanced The system can also perform interpolation operations with the basic axis to realize four and five axis linkage.

3 axis machine tool cannot process many surfaces even if it is horizontally rotated through the table. 4 axis is better than 3 axis in this respect. In terms of programming, the difference between 3 and 4 axis is basically the same. The operator who can operate the 3 axis machine tool can quickly get started with the operation of the 4 axis CNC machine, and the operation difference will not be much worse.

4 Axis vs. 5 Axis

Four-axis linkage and five-axis linkage generally refer to the number of linkage control axes of the control system. Four-axis linkage must first have four controllable axes, and the four axes can be interpolated motion control at the same time, that is, the four axes can achieve simultaneous linkage control. The motion speed during simultaneous linkage is the composite speed, and It is not separate motion control. It is a point in space that moves through four axes at the same time to reach another point in space. It moves from the starting point at the same time to the end point and stops at the same time. The motion speed of each axis in the middle is the motion interpolation of the controller according to the programmed speed. The speed of each axis is synthesized internally by the algorithm. For a four-axis machining center, it is X, Y, Z axis plus a rotation axis A (also can be B or C, the definition of A, B and C is corresponding to the rotation around X, Y and Z respectively axis, generally the fourth axis is the A axis that rotates around the X or B axis that rotates around the Y axis. This depends on the installation position of the fourth axis on the actual machine tool), and this fourth axis is not only It can move independently and can also be linked with another axis or two axes or these four axes at the same time. Some machine tools have four axes, but they can only move independently. They can only be used as indexing axes, that is, they will be stopped and locked after rotating to an angle. This axis does not participate in the cutting process. It is only used for indexing. The only type can only be called Four-axis three linkage. Similarly, the total number of axes of a four-axis linkage machine tool can be more than 4 axes, it can have five axes or more, but its maximum number of linkage axes is four axes.

5 axis machining means that there are at least five coordinate axes (three linear coordinates and two rotating coordinates) on a machine tool, and it can be processed simultaneously under the control of a computer numerical control system. Linkage means that the axes reach a certain set point at a certain speed at the same time. Five-axis linkage is all five axes. The 5 axis machine tool is a high-tech, high-precision machine tool specially used for processing complex curved surfaces. This machine tool system is useful for a country’s aviation, aerospace, military, scientific research, precision equipment, high-precision medical equipment and other industries.

What Is 4th Axis (Rotary Axis)?

The 4th axis is also called as the CNC indexing head, which is a machine tool accessory that clamps the workpiece on the chuck or between the two centers, and makes it rotate, index and position. The advantage of adding the 4th axis to the machine is that it can make the plane of the tool machining more extensive, and can reduce the repeated clamping of the workpiece, improve the overall processing accuracy of the workpiece, and help simplify the process and improve the production efficiency.

Specifically, the 4th axis can complete the tasks that the 3 axis CNC machine cannot complete at one time. It can realize multi-sided processing of the product through rotation, which greatly improves the machining efficiency and reduces the number of clamping, shorten production time.

• The rotation angle can process multiple surfaces at the same time, which improves the overall machining accuracy of the workpiece, which is beneficial to simplify the process and improve the production efficiency.

• The three axes are X, Y, Z three linear moving coordinates, and the 4th axis is generally a rotating axis, which can cause an angular offset between the tool and the workpiece, that is, the tool axis and the surface normal of the workpiece form an angle. One can expand the machining range, and the other can make the machining conditions better.

How To Use Rotary Axis (4th Axis)?

Step 1. Put it directly on the platform, so that the gantry needs to be heightened, and the platform size will not be affected when the plane is carved. The rotating shaft can be put on and taken down at any time.

Step 2. Put the side of the platform, the diameter of the rotating shaft affects whether the gantry is heightened. If the diameter is large, the gantry needs to be heightened. If the diameter is 10cm, it is not necessary. .

Step 3. The table top sinks, the table top sinks as a whole, put the rotary axis under the platform, if you carve the plane, put the platform on the rotary axis for carving.

What Our Customers Say?

Don't take our words as everything. Find out what customers say about our 4-axis CNC router machines they have owned or experienced. Why is STYLECNC considered a credible brand and manufacturer to buy a new 4-axis CNC router machine? We can talk all day about our quality products, 24/7 excellent customer service and support, as well our 30-day return and refund policy. But wouldn't it be more helpful and relevant for newbies and professionals alike to hear real-life customers experience what it's like to purchase and operate an automatic computer-controlled machine tool from us? We think so too, which is why we've collected tons of genuine feedback to help bring transparency to our unique buying process in-depth. STYLECNC guarantees that all customer reviews are real evaluations from those who have purchased and used our products or services.