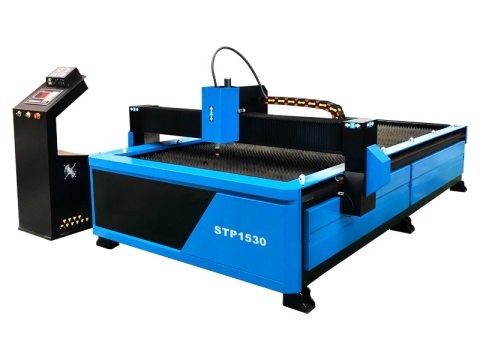

I've used quite a few manual plasma cutters in the past, but this was the first time playing with a CNC so was a little overwhelmed. One of the metalworking forums I belong to had many recommendations for STYLECNC. Did a little research and decided to go with the STP1530R at less than 1/2 the cost of the fiber laser cutter with similar capabilities, capable of cutting both sheet metal and tubing (while plasma cutting is not as precise as laser cutting, it is more than adequate for my business). Arrived in 20 days, initial impression is good, the heavy-duty 5x10 full-size plasma table is sturdy enough, the rotary attachment accommodates a wide range of tubing, and the CNC controller looks very user-friendly. So far, I think it's a good buy, 100% worth the price. I will update the review with further use.

5x10 Hypertherm Plasma Cutter for Sheet Metal & Tube

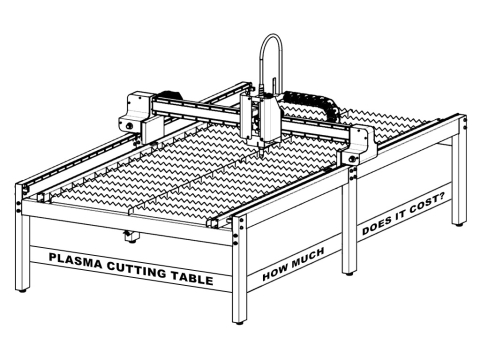

5x10 Hypertherm plasma cutter table with CNC controller is designed to cut both sheet metals and metal pipes with 4th rotary axis, the best 5x10 plasma table adopts Hypertherm Powermax to get a fine cutting of metals, and add a rotary device to cut metal tubes. Now the affordable Hypertherm industrial plasma cutting machine for sale at cost price.

- Brand - STYLECNC

- Model - STP1530R

- Maker - Jinan Style Machinery Co., Ltd.

- Category - CNC Plasma Cutter

- 360 Units in Stock Available for Sale Every Month

- Meeting CE Standards in Terms of Quality & Safety

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- 30-Day Money Back Guarantee for Your Purchase

- Free Lifetime Technical Support for End-Users & Dealers

- Online (PayPal, Alibaba) / Offline (T/T, Debit & Credit Cards)

- Global Logistics and International Shipping To Anywhere

Why Choose a Hypertherm Plasma Pipe Cutter for Your Fabrication Shop?

Metal fabrication shops handling pipe and tube work face a critical decision when selecting cutting equipment. A Hypertherm plasma pipe cutter combines industry-leading plasma technology with precision CNC control to deliver clean, accurate cuts on round, square, and rectangular tubing. This combination addresses the growing demand for faster turnaround times and tighter tolerances in structural steel, HVAC, shipbuilding, and pipeline industries.

Hypertherm plasma systems are renowned for their consumable longevity and cut quality consistency. When integrated into a dedicated pipe cutting machine, these advantages translate directly to lower operating costs and reduced rework. The True Hole technology produces bolt-ready holes in mild steel without secondary operations, while the automatic gas control adjusts parameters in real-time based on material thickness and type.

Modern Hypertherm plasma pipe cutters handle materials ranging from thin-wall tubing under 1mm to heavy-wall pipe exceeding 25mm thickness. The rotary chuck system positions the workpiece with sub-millimeter accuracy, enabling complex bevel cuts, saddle cuts, and intersection profiles that manual methods simply cannot achieve. For shops currently relying on band saws, oxy-fuel torches, or manual plasma cutting, upgrading to a CNC Hypertherm system typically reduces cutting time by 60-75% while improving dimensional accuracy.

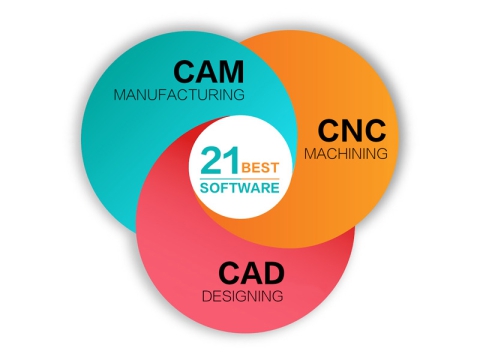

Integration with CAD/CAM software streamlines the workflow from design to finished part. Operators import 3D models, and the nesting software automatically generates optimized cutting paths that minimize material waste and maximize throughput. This level of automation positions fabrication shops to compete for contracts requiring certified cut quality and documented traceability.

Hypertherm is a well-known American brand that makes Powermax plasma, plasma systems, consumables, CNC motion and height controllers for handheld and CNC plasma cutters & table kits. Hypertherm is trusted for high speed and accurate metal cutting performance and reliability, helping thousands of businesses to improve production efficiency and profitability. Hypertherm makes plasma cutting more precise, more economical, safer, and easier to use.

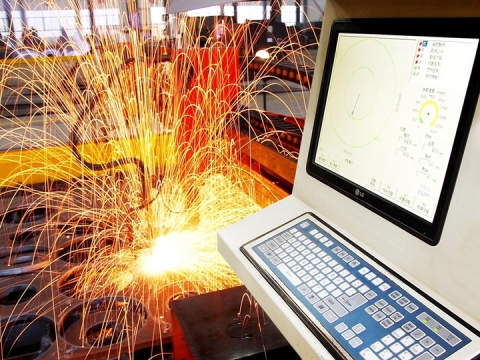

Hypertherm plasma cutter is a multifunctional automatic thermal metal cutting tool with high efficiency, high precision, and high reliability, which combines computer control, compact mechanical transmission, oxygen gas cutting, or plasma cutting technology. It is used for high-precision metal thermal cutting in shipbuilding, steel structure, electric power, boiler, rolling stock, petrochemical, and other manufacturing industries.

Hypertherm plasma table is an automatic metal cutter table kit that uses the high temperature generated by the plasma arc to melt and vaporize metal and blow away the molten metal to form a precision cut with high speed. It is a better choice for thick metal fabrication than a fiber laser cutting machine. The thicker the metal, the higher the power required for the fiber laser cutter, and the cost of investment will also increase significantly. Therefore, in the process of thick metal fabrication, considering the comprehensive investment cost, efficiency, and effect, Hypertherm is an ideal choice.

STYLECNC is a professional Hypertherm CNC plasma table manufacturer for hobbyists and industrial manufacturing, we have different types of CNC plasma cutting tables for options, such as 4x4 Hypertherm plasma table, 4x8 Hypertherm plasma tables, 5x10 Hypertherm plasma table or other customized table tops with any budget.

Technical Parameters of 5x10 Hypertherm Plasma Cutter for Sheet Metal and Metal Pipe with 4th Rotary Axis

| Model | STP1530R |

| Table Size | 1500x3000mm (5x10) |

| Max Cutting Thickness | 40mm |

| Pipe Cutting Size | Diameter from 200mm to 600mm, Length up to 3000mm or 6000mm |

| Plasma Cutting Speed | 0-6500mm/min |

| Plasma Power Supply | Powermax 45A, 65A, 85A, 125A, 200A |

| Machine Frame | Welded Structure |

| Machine Structure | Rack and Pinion Drive, Hiwin Rail Linear Bearings |

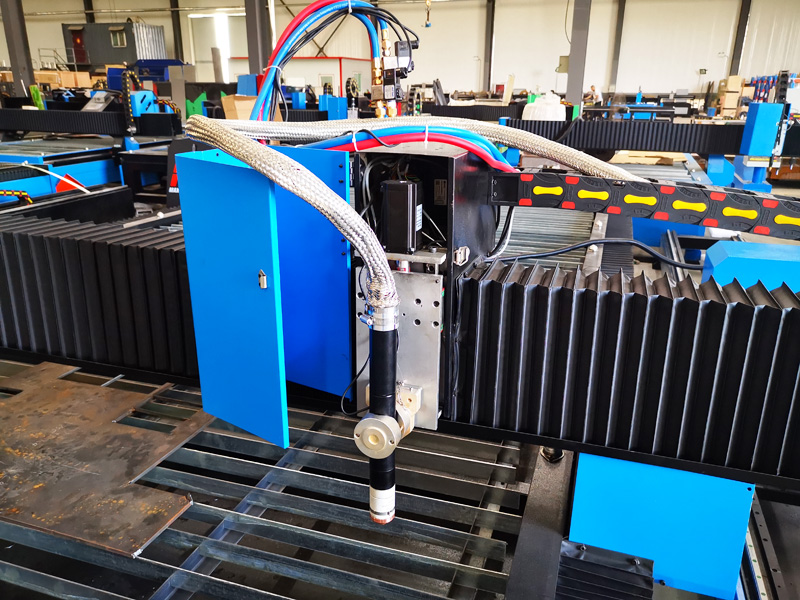

| Height Controller | HYD Torch Height Controller |

| Working Voltage | 380V/3PH |

| Control System | BEIJING STARFIRE CNC |

| Moving Precision | 0.01mm Per Step |

| Document Transmission Form | USB Interface |

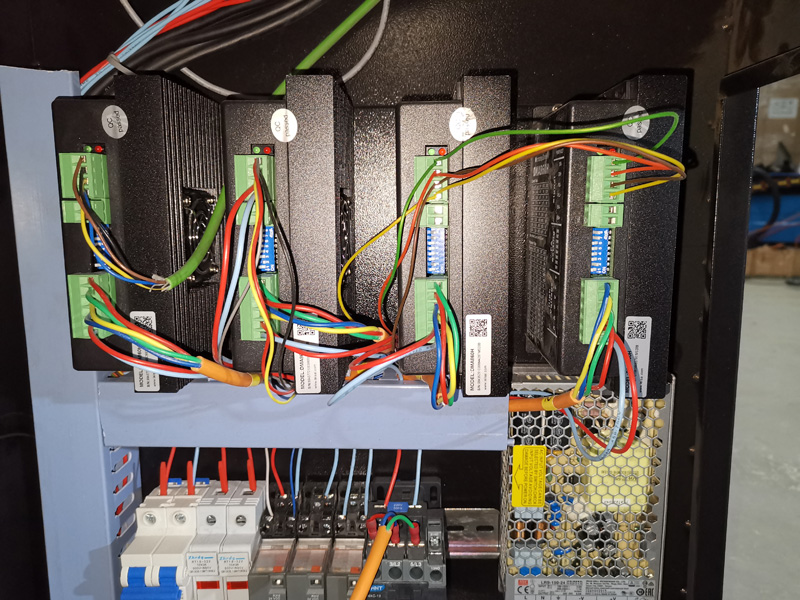

| Drive Motors | Stepper Motor and Leadshine Driver |

| G.W. | 1500KGS |

| Packing Size | 4.17*2.25*1.65m |

Hypertherm Plasma Cutter Cutting Capacity of Plasma Power Supply

| Power Supply | Cutting Thickness | Power Supply | Cutting Thickness |

| China Huayuan Brand | USA Hypertherm Brand | ||

| 63A | 8mm | Powermax 45A | 8mm |

| 100A | 15mm | Powermax 65A | 10mm |

| 120A | 20mm | Powermax 85A | 12mm |

| 160A | 30mm | Powermax 105A | 18mm |

| 200A | 40mm | Powermax 125A | 25mm |

| Powermax 200A | 30mm | ||

Features of 5x10 Hypertherm Plasma Table for Sheet Metal and Metal Pipe with 4th Rotary Axis

The whole machine adopts a square tube welding structure, which has the characteristics of good rigidity, high precision, lightweight, and small inertia. All welded parts are subjected to vibration aging stress relief treatment, which effectively prevents structural deformation; vertical and horizontal drives: all adopt precision rack and pinion transmission. The horizontal guide rail adopts high-quality linear guide rail, and the longitudinal guide rail is made of precision-processed special steel rail, which ensures the machine runs smoothly, with high precision, and is durable, clean, and beautiful. The deceleration adopts the top brand planetary gear reducer, which can perfectly guarantee the precision and balance of the movement.

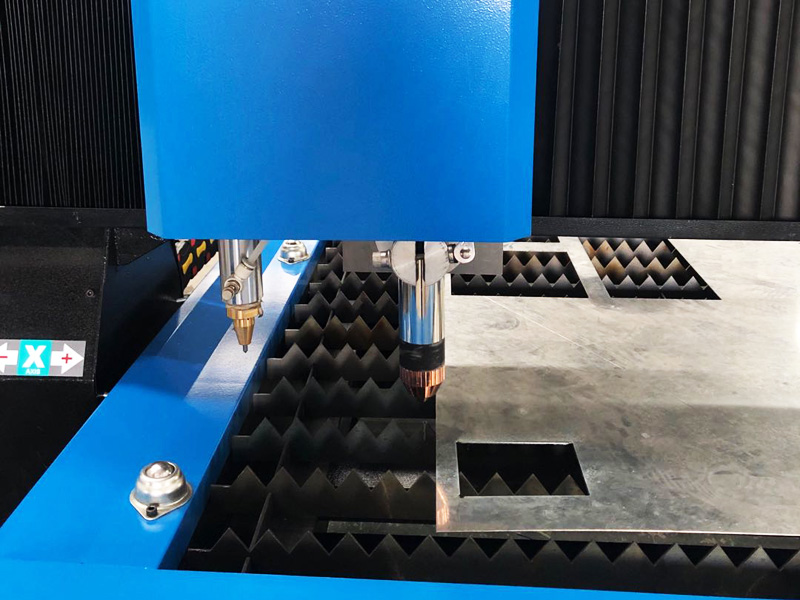

✔ The Hypertherm CNC plasma table size is 5x10ft, and the rotary device with diameter of 300mm and 3000mm in length. Other sizes are optional based on your cutting plan.

✔ The plasma power supply can be equipped with the USA Hypertherm brand or the Chinese Huayuan brand.

Hypertherm

Huayuan

✔ Hypertherm 5x10 plasma table adopts STARFIRE numerical control system disposes of high, the automatic striking arc, the performance is stable.

✔ The 5x10 CNC plasma table adopts a lubrication system, an auto-fume extraction system, and dust proof.

✔ The Y axis uses a dual-motor driven system, X, Y, and Z axes all use Taiwan Hiwin square rails which make the machine drive smoothly with high precision.

✔ High quality control cabinet with motor driver system.

✔ STYLECNC identification plate for STP1530R.

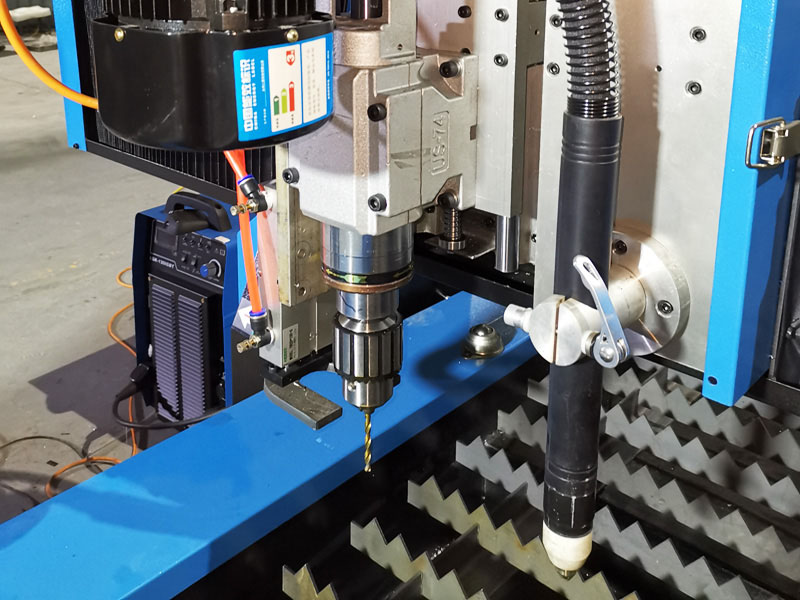

✔ Plasma cutter torch is professional for cutting sheet metals and tubes.

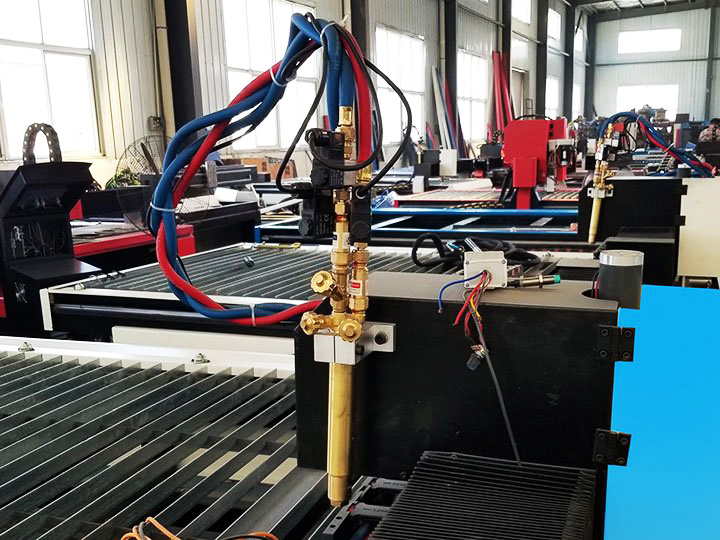

✔ Flame cutter torch is the best option for cutting metals thicker than 30mm.

✔ The CNC drill torch is ideal for drilling holes in metal.

✔ Plasma cutter torch with pen plotter to draw lines to mark out folds for sheet metal cutting.

Applications and Industries Served by Hypertherm Plasma Pipe Cutting Systems

The versatility of Hypertherm plasma pipe cutters makes them indispensable across multiple industries where precision tube processing determines project success. Structural steel fabricators rely on these machines to produce complex node connections for architectural frameworks, stadium structures, and industrial facilities. The ability to cut accurate cope joints and miter angles eliminates grinding and fitting time during assembly.

Oil and gas pipeline contractors use Hypertherm plasma systems for preparing pipe ends with precise bevel angles required for certified welds. The automated bevel cutting capability produces consistent J-bevels, V-bevels, and compound angles that meet API and ASME welding specifications. This consistency is critical when pipe joints undergo radiographic inspection and pressure testing.

HVAC and mechanical contractors benefit from the rapid processing of ductwork transitions, branch connections, and equipment mounting brackets. The speed advantage over manual methods allows smaller crews to handle larger project volumes. Shipyards and marine fabricators process structural tubing for vessel frameworks, railings, and equipment supports where salt-water exposure demands perfect fit-up to prevent corrosion traps.

Furniture manufacturers and artistic metalworkers explore creative applications, including custom railings, sculptural elements, and architectural features. The precision cutting enables designs that would be impractical with traditional methods. For production environments handling repetitive parts like round tube cutting projects or square tube profiles, automated loading and unloading options increase throughput while reducing operator fatigue.

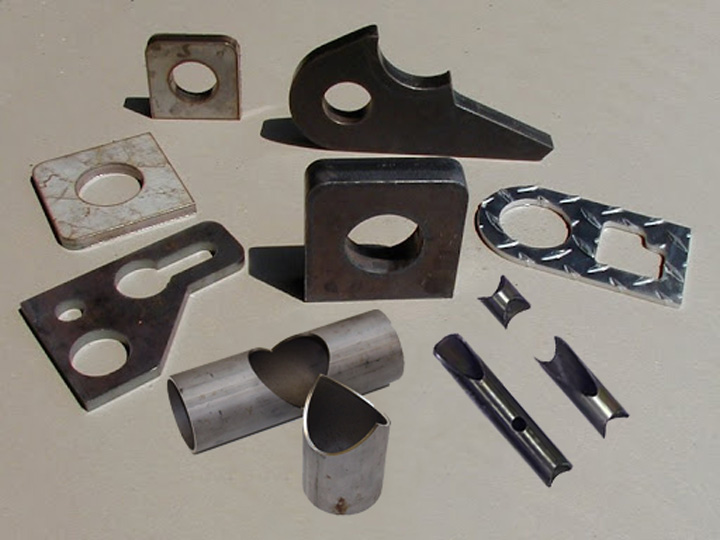

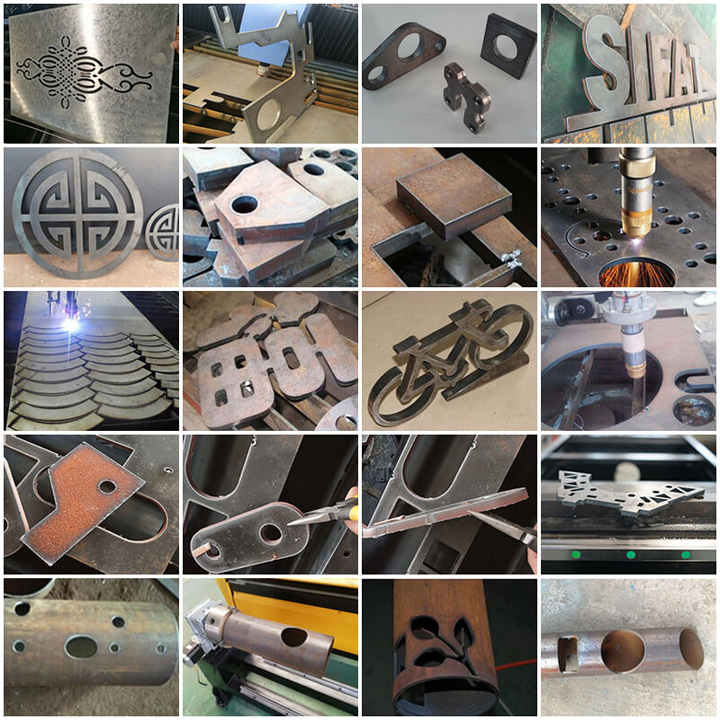

Hypertherm 5x10 CNC Plasma Cutter Applications & Projects

Compared with mechanical cutting, plasma cutting is much faster and easier to cut metal. Its unique features of high speed, high efficiency, high kerf finish, and wide applicable cutting range make it easy to fast-cut carbon steel, mild steel, tool steel, stainless steel, silicon steel, aluminum, titanium, copper, brass, alloy, pickled sheet, galvanized sheet, iron, and more metal materials.

It is used in sheet metal & tube processing, aviation, electronics, shipbuilding, aerospace, elevators, subway parts & accessories, auto parts, machinery manufacturing, precision accessories, metallurgical equipment, tool making, household appliances, arts, crafts, gifts, advertising and decorations, and is gradually replacing the dominant position of flame cutting in some fields.

Pros & Advantages

Hypertherm integrates many new technologies and realizes the practical application. Even compared with the previous generation of high-precision plasma systems, it is also very different. When cutting low-carbon steel, the traditional plasma cutting technology can basically achieve the range of ISO, the high-precision plasma cutting technology can basically achieve the range of 3-4, while Hypertherm can basically achieve the range of 2-3. Another difference is that Hypertherm can extend the service life of vulnerable parts, and the effect is much better than previous generations of systems.

When 125A or higher current is used to cut materials with thickness greater than 12mm, the cutting quality of XPR in the life cycle of vulnerable parts can almost reach the cutting quality of range 3. When the thinner material is less than 10mm by the low current process, the cutting quality of Hypertherm series products can reach ISO range 2.

When cutting thinner materials less than 10mm, more than 1100 times of cutting tests in 20 seconds of the Hypertherm plasma cutting process were stable within the cutting quality of ISO range 2, and then it changed to the cutting quality of range 3. This is a comparison with the cutting quality of the previous generation of high-precision plasma cutting systems in ranges 3 and 4.

In comparison with fiber laser cutting, we found that the cutting quality of Hypertherm is not inferior to laser cutting in many thicknesses. In two examples of cutting 6mm and 12mm plates, the cutting speed of this Hypertherm process combines quality and production efficiency (rather than focusing only on cutting quality). When cutting a 6mm plate, the average angle deviation of the cutting edge is smaller, and the deviation fluctuation will be minimized after 1000 arc strikes. The effect of cutting 12mm low carbon steel is similar.

✔ Consumable parts have the longest life in the industry.

✔ Pilot arc circuit increases pilot arc current precisely when needed, significantly reducing nozzle wear.

✔ The Hypertherm quick-disconnect torch assembly provides easy switching between hand torch and machine torch, and it also features a stress-relief design for durability.

✔ Ease of Use - Easy and convenient gas regulation and current regulation.

✔ Very safe to use When the wearing parts are removed, the interlock device will prevent the machine from starting.

✔ With a special voltage fluctuation compensation device, there is no need to worry about the impact of voltage fluctuations on the machine.

✔ All equipment is equipped with a standard CNC/automatic machine interface, enabling automatic control and quick transfer to machine operation.

✔ New "fan on demand" function minimizes dust inhalation.

✔ Torch lead sheath made of AC chemistry resists jet and cut-through capabilities of molten metal.

✔ Accurate fault alarm indicator light makes it easier for you to operate and maintain.

✔ Auto-voltage™ automatic voltage regulation capability, which can automatically adapt to various input power sources of 200V-600V and three-phase.

✔ Coaxial-assist™ technology increases cutting speed.

✔ The Boost Conditioner™ input voltage compensation circuit compensates for fluctuations in the input voltage, which improves the performance of low-voltage lines, motor generators, and input power (fluctuations).

✔ Design for reliability improves downtime and greatly reduces investment.

✔ CNC interface and Easy Torch Removal (ETR™) are versatile for both handheld and machine use.

Cons

✔ Higher price than ordinary plasma power supply.

✔ Compared with the fiber laser cutting machine, the plasma cutting gap is larger, the cutting end surface is rougher and not smooth enough, and the cutting precision is lower.

Safety Considerations

Safety measurements are very important steps while working with plasma cutters. Plasma cutting involves high-temperature electrical currents which come with significant safety hazards. Proper safety measures are a must to avoid any unwanted exploration.

A few probable hazards that can occur due to the lack of safety considerations are,

⇲ Risk of high voltage electric shock

⇲ A densely heated plasma arc can cause fire and eventually potential to burn

⇲ Hazardous gases and fumes can cause severe health issues

⇲ Risk of eye injury from UV radiation

Now the 5x10 Hypertherm Plasma Cutter is equipped with various safety features. To minimize risk and ensure safe operation several features are added. Such as,

⇲ Thermal overload protection

⇲ Emergency stop button

⇲ Machine Guarding

⇲ Voltage monitoring system and

⇲ Safety interlocks

Proper training and availability of safety equipment including PPI and Glasses are recommended before start using the plasma cutter.

Environmental Impact

Like any industrial process plasma cutting can impact the environment to a great extent. It is necessary to consider the environmental impact of plasma cutting to minimize the chances of affecting our environment badly.

Plasma cutting can result in several environmental changes including,

⇲ Air pollution due to excessive fume, smoke, and bi-product

⇲ Uncontrolled usage will affect excessive power consumption

⇲ Off-cuts and scrap materials can be responsible for polluting the environment directly

⇲ Additional water usage as coolant and the chemical bots mixed within water particles can contaminate it to a greater extent

It is a matter of hope that the advanced technology of the Hypertherm plasma cutter utilizes electricity consumption. Implementing strategies to minimize wastage and emissions can help save the environment from pollution. Optimizing the machine parameters will also make a helpful impact on overall environmental detoxification.

Related FAQs

What is the maximum pipe diameter a Hypertherm plasma pipe cutter can handle?

Standard Hypertherm plasma pipe cutters handle diameters from 20mm to 600mm (24 inches). Heavy-duty industrial models extend capacity to 1000mm (40 inches) for oil and gas, shipbuilding, and large structural fabrication applications.

Is plasma cutting better than laser cutting for metal pipes and tubes?

Plasma excels for pipes thicker than 6mm with lower costs and faster speeds. Laser cutting offers superior edge quality on thin-wall tubing under 6mm. Many fabricators use both technologies for different applications.

How much does a Hypertherm plasma pipe cutter cost?

Prices range from $35,000 to $250,000+, depending on configuration. Entry-level systems start at $35,000-$55,000, mid-range production machines cost $75,000-$150,000, and fully automated systems exceed $200,000. Contact us for a customized quote.

Can a Hypertherm plasma pipe cutter perform bevel cuts and saddle cuts?

Yes, advanced systems perform bevel cuts (0° to 45°), saddle cuts, miter cuts, and intersection profiles. Cutting paths are programmed directly from 3D CAD models, eliminating manual grinding and reducing assembly time by 40-60%.

What maintenance does a Hypertherm plasma pipe cutter require?

Daily maintenance includes inspecting consumables and checking gas pressures. Weekly tasks involve lubricating guides and bearings. Monthly procedures cover axis alignment and electrical inspections. View our complete maintenance guide for detailed procedures.

Malushzik

Collin Cheah

The 5x10 plasma table with Hypertherm Powermax 125 arrived on site in good condition. We were able to set up the machine with minimum experience. Just ensuring the flatness and square the machine. It arrived with in-house software installed and fortunately no startup bug. A good value machine.

Frederick

Stevens

Lachlan D Webster

Leonora V Pimentel

Richard

Excellent service, thanks Nick for answering my questions in time. This plasma cutter came with all the things that had been agreed upon. Hooked it all up in 1hr, it has been working great, and doesn't let me down.