Affordable Laser Cutting Machines for Every Budget

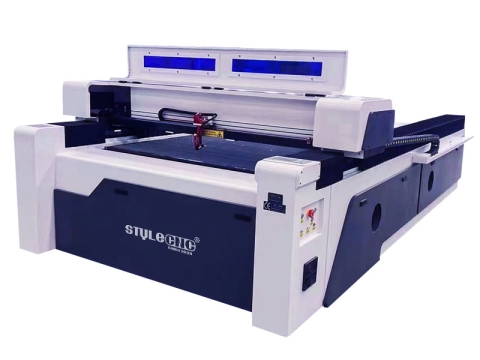

A laser cutting machine is an automatic slitting tool that uses a DSP or CNC controller kit in conjunction with CAM software to instruct a CO2 or FIBER laser beam to cut through metals, metalloids and nonmetals along tool paths created by CAD software, as well as cut custom shapes, contours, and holes out of sheets, tubes and profiles to create precision parts, signs, tags, decorations, arts, crafts, gifts, jewelries, lamps and puzzles for both hobby and industrial commercial use. At home, outdoors, in stores, offices, studios, workshops or manufacturing plants, you can find laser-cut projects everywhere in your life. From advertising letters to street signs, from crafts to artworks, from decorations to clothing, from storage to packaging, from 3D puzzles to auto parts, from plywood to acrylic, from brass to stainless steel, from straight to curved edge cuts, from bevels to chamfers, from 2D sheets to special-shaped pipes, as well as custom graphics and personalized designs, laser cutters can handle almost everything with ease. Creating personalized wood cuts with an affordable CO2 laser cutter is every DIYer's dream. Shaping precision metal parts with an automatic CNC fiber laser cutting machine is what every industrial manufacturer wants. However, how to get your own laser machine with ease? If you are an experienced laser man, you can buy all the required parts and accessories to build it yourself. If you are new to laser, you can purchase a pre-assembled laser kit (new or used) to start cutting right away, and you can enjoy the immediate gratification of playing with a prebuild. So, where can you buy the best laser cutter to match your needs and budget? Look no further, here is the right place to buy top of the line for both beginners and professionals alike. At STYLECNC, you can find various most popular laser cutting machines for every budget and need, ranging from entry-level cutters to professional cutting kits, hobby types to industrial types, home use models to commercial use models, handheld laser cutting guns to automatic CNC cutting systems, flatbed laser cutting tables to 3D laser cutting robots, portable cutting tools to gantry CNC laser cutter machines, low-power to medium-power as well as high-power options. Whether you're cutting soft leather and fabric, or hard stainless steel, there's something for everyone. Moreover, every laser is user friendly and esay to use, all picks are top-notch and budget friendly for small business owner and industrial manufacturer, just compare features and costs, and easily buy what you need.

A CO2 laser cutter is an automatic engraving & cutting tool kit that works with a CNC or DSP controller to drive the carbon dioxide gas laser tube to emit a 1064μm laser beam for etching and cutting nonmetals and metalloids. CO2 lasers can handle precision cuts from soft fabrics to hard plastics, from simple acrylic letters to complex 3D wood puzzles, as well as fine engravings on glass, crystal, stone and ceramics. User-friendly, easy to use and environmentally friendly make it your best partner in life and work. Whether you are new to lasers or an experienced professional, you'll find the perfect match at STYLECNC. Most popular models and types of CO2 lasers available here, ranging from low powers to high powers, entry-level to professional, hobby to industrial applications, home to commercial use, small compact cutter kits to large full-size 4x8 cutting tables. Affordable prices range from as low as $2,800 to as high as $20,000 to match any budget.

2025 Best CO2 Laser Cutter for Small Business and Home Use

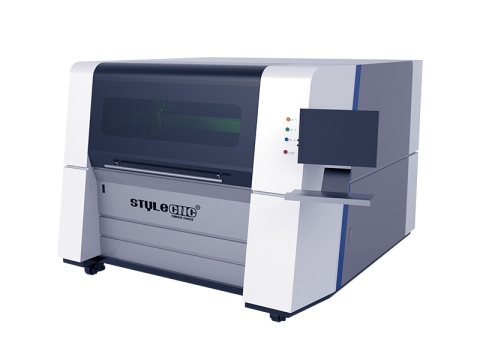

Entry Level CO2 Hobby Laser Cutter Machine for Beginners

100W Laser Wood Cutter Engraving Machine for Woodworking

2025 Best Acrylic Laser Cutting Machine for Sale

2025 Best Industrial Fabric Laser Cutting Machine for Sale

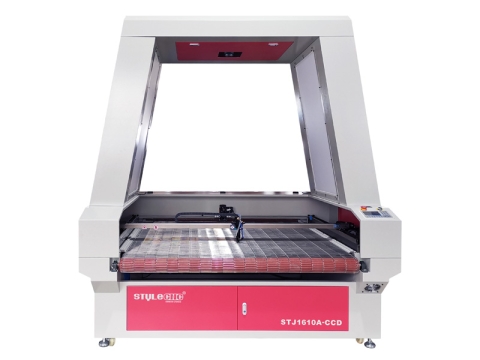

CNC Laser Cutter With CCD Camera Visual Recognition System

Dual-Head CO2 Laser Cutter for Paper and Cardboard

2025 Best-Selling 4x8 Laser Cutter for Plywood & MDF

Budget-Friendly Small Desktop Laser Engraver Cutter Machine

2025 Best Industrial Laser Foam Cutting Machine for Sale

Affordable 4x8 Laser Leather Cutting Machine for Sale

Fabric Laser Cutter for Sublimation Printing Sportswear

A fiber laser cutting machine is an automated metal cutter that uses a CNC controller with CAM software to direct a 1064nm laser beam to cut shapes and contours on metal sheets, tubes, bars and strips according to layout files designed by CAD software to complete metal fabrication projects. It is a fine precision cutting tool for both sheet metals and tubes, as well as flat and beveled metal profiles. With a robotic arm, personalized 3D metal cuts are easily created. Non-contact cutting will not damage the substrate with smaller thermal influence of spot irradiation area. Fiber lasers are capable of cutting metals as thin as 1 mm and as thick as 200 mm, with powers ranging from 1,500 watts to 60,000 watts, and a maximum speed of more than 120 meters per minute. Fiber lasers can handle everything from hard metals (such as stainless steel, mild steel, carbon steel, spring steel, silicon steel, titanium, nickel, chromium, molybdenum, iron and alloy) to highly reflective metals (such as aluminum, gold, silver, copper and brass), which make them popular for both home and commercial use.

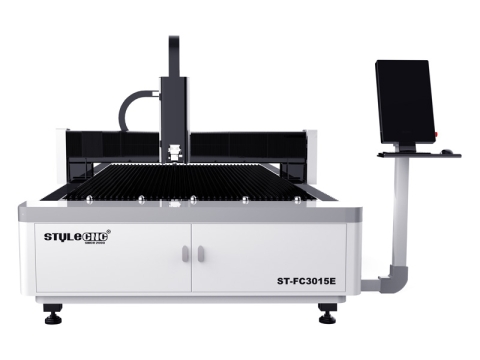

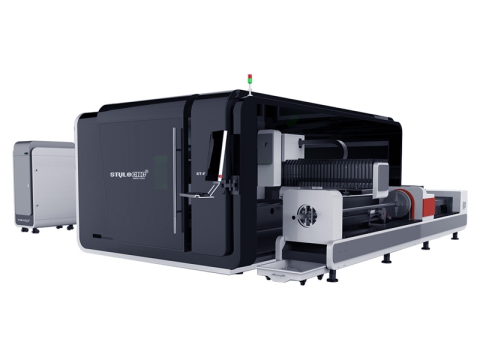

2026 Best Sheet Metal Laser Cutter for Sale (1500W - 6000W)

3-In-1 Handheld Laser Welding, Cleaning, Cutting Machine

2026 Top Rated Fiber Laser Cutting Machine for Sale - 2000W

Mini Laser Metal Jewelry Cutter for Silver, Gold, Copper

2025 Top Rated Fiber Laser Tube Cutting Machine for Sale

High Speed 12KW IPG Fiber Laser Cutter for Sheet Metal

2025 Cheapest 4x8 Fiber Laser Stainless Steel Cutter 1500W

High-Power 6000W Fiber Laser Metal Cutting Machine for Sale

Industrial 3D Robotic Fiber Laser Cutting Machine for Metal

Entry Level Small Metal Laser Cutter for Beginners

Dual-Purpose 6KW Fiber Laser Cutter for Metal Sheet & Tube

5x10 Fiber Laser Cutter with Fully Enclosed Cover for Metal

Ultra-Large Fiber Laser Sheet Metal Cutting Table 30000W

5x10 Industrial Fiber Laser Metal Cutting Machine for Sale

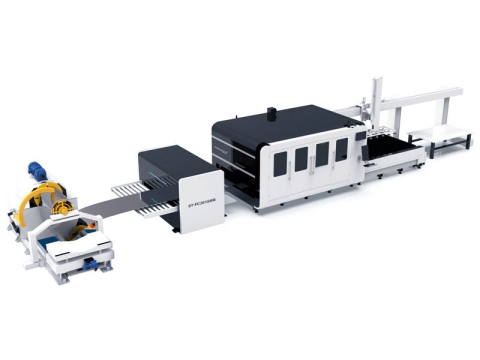

Automatic Coil Fed Laser Blanking Line & Cutting System

20000W Ultra High Power Fiber Laser Metal Cutter for Sale

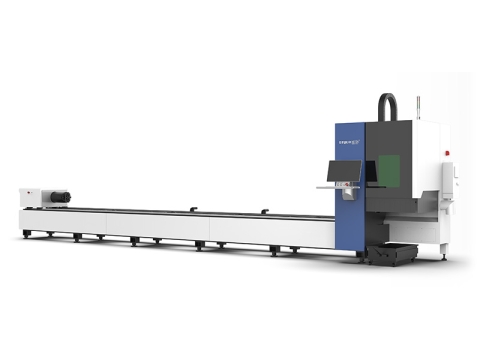

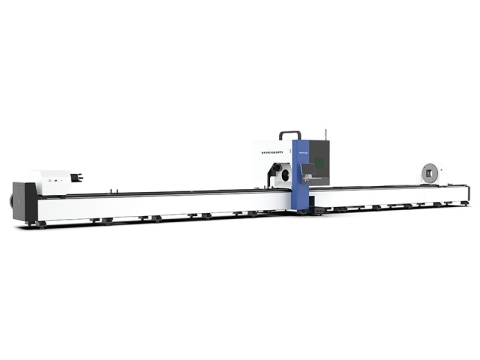

Industrial Tube Laser Cutter for Metal Pipes & Profiles

3D Tube Laser Bevel Cutting Machine with Automatic Feeder

A hybrid laser cutter is an affordable combined cutting system with fiber and CO2 laser generator all in one machine. With fiber lasers, it can cut thicker metals, with CO2 lasers, it is capable of cutting thick nonmetals and thin metals. A hybrid laser cutting machine also refers to an automated cutter kit that uses a high-power CO2 sealed laser tube with combining beam for cutting thin metals such as steel, aluminum, brass, copper, titanium, iron, silver, gold and alloy, as well as cutting nonmetals such as plywood, wood, MDF, acrylic, plastic, fabric and leather. The hybrid laser cutting table fits 2x3, 4x4, 4x8, 5x10, and 6x12, which can be customized as your business needs. It's the best budget cutting tool for both hobby use and industrial manufacturing.

Metal & Nonmetal Laser Cutter with 300W CO2 Laser Tube

Fiber & CO2 Combo Laser Cutting System for Metal & Nonmetal

4x8 Flatbed Laser CNC Engraving Cutting Machine for Sale

2025 Best Metal & Nonmetal Laser Cutting Machine for Sale

Hobby Hybrid CO2 Laser Cutter for Metal & Nonmetal

Profitable Mixed CNC Laser Cutter Hybrid Cutting Machine

Feature Stories On Laser Cutting

Pick Your First Laser Cutter Machine for Home & Industrial Use

You do not need to own a big company to grab your next laser cutter. In recent years, there are many affordable options available that will allow you to grab your next cutting solution without breaking your bank. But at the same time, it is essential that you become careful about the purchase as quality matters at the end of the day. Look for a precise, reliable machine with high-quality components, and make sure you get proper training and support. Consider your specific needs and budget when selecting an automatic cutting tool kit, and choose the one that best fits your requirements. With the right smart cutting system, you can achieve your production goals without overspending. In addition, with the continuous innovation and development of Industry 4.0 and artificial intelligence, laser cutting technology will be combined with industrial robots to achieve automated and digital cutting, improving the cutting speed, thickness, accuracy and quality. In case you are looking for a trusted manufacturer and brand to purchase your next laser cutting machine at an affordable price, STYLECNC can be an excellent place to rely your trust on.

Definition & Meaning

A laser cutter is an automated cutting tool kit that uses a laser beam together with a smart digital cutting system to cut out patterns on metals (steel, copper, brass, aluminum, titanium, gold, silver, alloy, iron), acrylic, rubber, wood, plywood, MDF, plastic, leather, paper, foam, textile and fabric. A laser cutting kit consists of machine base and frame, CNC controller, generator, power supply, tube, head, lens, mirror, water chiller, stepper motor or servo motor, gas cylinder, air compressor, gas storage tank, air cooling filer, dust extractor, dryer and software.

A laser cutting system is an organized collection of parts that are integrated to accomplish precision cuts for industrial manufacturing, commercial use, education, training, small business, home business, small shop, and home shop. It is a flexible cutting system compared to manual and mechanical cutting tools. It can cut a variety of materials in varying thicknesses and there is no limit to the shapes you can get. It is fast to program and any changes can be applied at any stage of manufacturing at almost no additional cost and time. It features with high precision, excellent trimming quality and no deformation of parts. It is the best solution for modularization and automation in the manufacturing cycle.

How It Works

Laser beam is a type of light from the transition of atoms (molecules or ions). However, it is different from ordinary light in that it depends on spontaneous radiation only for a very short period of time. The subsequent process is completely determined by the excitation radiation, so it has a very pure color, almost no divergence direction, and extremely high luminous intensity, and high coherence.

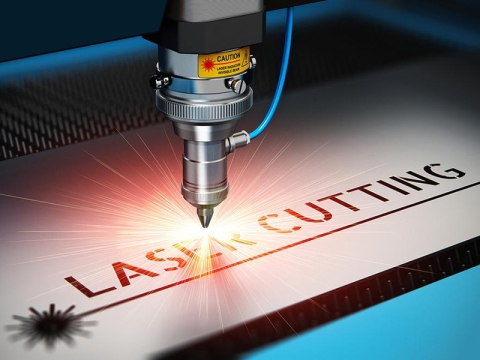

Laser cutting is an automated process that uses high-power and high-density energy from a focused light beam to melt and vaporize metal, wood, acrylic, plastic, fabric, leather, foam, and other materials, resulting in a precision kerf.

With the CNC controller, the generator outputs a high-frequency to make a beam with a certain frequency and pulse width. The beam is transmitted and reflected through the optical path and focused by the focusing lens group. A tiny, high-energy-density light spot is formed on the surface of the part, the focal point is located near the surface to be cut, and the material melts or vaporizes at an instant high temperature. Each pulse shoots a small hole in the substrate. With the computer numerical controller, the head and the substrate perform continuous relative movement and dotting according to the designed file, so as to cut the substrate into the desired shape. The technological parameters (cutting speed, power, gas pressure) and movement trajectory during slitting are controlled by the CNC system, and the slag at the slit is blown off by the auxiliary gas with a certain pressure. The beam emitted by the generator is focused by the optical path system into a beam of high-power density. The beam is irradiated onto the surface of the part to bring the part to a melting point or boiling point, while the high-pressure gas coaxial with the beam blows away the molten or vaporized material. As the beam moves relative to the part, the material is slit finally, thereby achieving the purpose of cutting. Different powers can cut different projects with different thickness. Generally speaking, higher power for thicker part. You should make the appropriate choice according to your requirements.

Applications & Uses

Lasers are versatile cutting tools used in a wide range of applications, inlcluding personalization (customization), digital printing, medical technology, fab labs, education, architectural models, smart phones and laptops, computers & electronics, toys, watches, arts & crafts, awards, trophies, rubber stamps, packaging design, die cut, mold making, signs making, displays making, giveaways, electronics industry, automotive industry, signage, mechanical engineering, ball bearing, jewelry making, fashion & apparel fabrics, stencils, paper cards, car floor mats & liners, textile and garment industry, bar code serial numbers, watches, machining industry, data plates industry, packaging industry.

Laser Cuttable Materials

Laser cutters can easily cut through a wide range of materials, including metals, nonmetals and metalloids, as well as some composites.

Fiber lasers are capable of cutting a variety of metal materials, including carbon steel, stainless steel, mild steel, tool steel, spring steel, galvanized steel, aluminum, copper, gold, silver, alloy, titanium, iron, brass, manganese, chromium, nickel, cobalt, lead, and more metals to create shapes and outlines for sheet metals, metal tubes, metal profiles, 3D curved metals, and irregular metals.

CO2 lasers have the ability to cut most thin metals and non-metals, metalloids, and composites, including wood, MDF, plywood, chipboard, acrylic, plastic, PMMA, leather, fabric, cardboard, paper, rubber, depron foam, woodleather, wood paper, EPM, gator foam, polyester (PES), polyethylene (PE), polyurethane (PUR), neoprene, textile, bamboo, ivory, carbon fibers, beryllium oxide, polyvinyl chloride (PVC), polyvinyl butyrale (PVB), polytetrafluoroethylenes (PTFE / Teflon), phenolic or epoxy resins, and any materials with halogens (fluorine, astatine, iodine, chlorine, bromine).

Specifications

| Brand | STYLECNC |

| Types | Fiber Lasers, CO2 Lasers |

| Laser Wavelength | 10.6 μm, 1064 nm |

| Powers | 80W, 100W, 130W, 150W, 180W, 300W, 1500W, 2000W, 3000W, 4000W, 6000W, 10000W, 12000W, 15000W, 20000W, 30000W, 40000W, 60000W |

| Table Sizes | 2' x 3', 2' x 4', 4' x 4', 4' x 8', 5' x 10', 6' x 12' |

| Axis | 3 Axis, 4th Axis (Rotary Axis), 4 Axis, 5 Axis |

| Cutting Materials | Metals (Stainless Steel, Carbon Steel, Tool Steel, Galvanized Steel, Spring Steel, Copper, Brass, Aluminum, Gold, Silver, Iron, Titanium, Chromium, Alloy, Manganese, Cobalt, Nickel, Lead), Wood, MDF, Plywood, Chipboard, Acrylic, Plastic, Fabric, Leather, Jeans, Paper, Cardborad, ABS, PE, EPM, PES, PVB, PUR, PVC, PTFE, PMMA. |

| Cutting Software | LaserCut, CypCut, RDWorks, LaserWeb, EZCAD, CypOne, Laser GRBL, EzGraver, SolveSpace, Inkscape, LightBurn, Corel Draw, Adobe Illustrator, Archicad, AutoCAD. |

| Applications | Industrial Manufacturing, School Education, Small Businesses, Home Business, Small Shop, Home Shop, Hobbyists. |

| Price Range | $2,600 - $1,000,000 |

Cost & Pricing

If you're looking to start your business with a used or new laser cutting tool to make money, you might be wondering how much it will cost? and what is the standard cost on the market? According to big data analysis, the cheapest laser cutters cost around $2,600, with the most expensive costing up to $300,000, excluding the price of shipping, tax rates, customs clearance, service, and technical support. The actual costs depend on the brand, type, model and power, as well as whether you want any extra features, including personalized design, custom table size, generator and power, rotary attachment, controller, software, parts, accessories, upgrades, setup, debugging, and other special features. Here are the average costs list in 2025.

A fiber laser cutting machine typically costs anywhere from $14,000 to 1,000,000. The prices for CO2 laser cutters vary between $2,600 and 20,000 on average. A mixed hybrid laser cutting system starts at $6,800 and climb as high as $32,500. You can purchase a variety of options and add-ons appropriate for your business, starting at around $10 for consumable parts and accessories, and going up to $36,000 for high-power fiber laser generators.

From entry-level to high-end or eco-friendly types, the costs vary depending on the features and powers you choose.

Most inexpensive entry-level laser cutter kits range in price from $2,600 to $5,600, starting with an 80W CO2 glass tube for beginners, hobbyists and enthusiasts, home users and small business owners, while some high-end laser cutting machines are as expensive as $1000,000 with 60000W ultra-high-power IPG fiber lasers for industrial thicker metal cuts.

A budget-friendly home laser cutting system is priced from $3,000 to $10,800 with CO2 laser power options of 80 watts, 100 watts, 130 watts, 150 watts, 180 watts for plywood, MDF, bamboo, fabric, leather, acrylic, fabric, and foam.

The most affordable industrial laser sheet metal cutter of 2025 starts at $6,800 with 300W CO2 laser tube, while some precision models range from $14,000 to $1000,000 with fiber laser power options of 1500 watts, 2000 watts, 3000 watts, 4000 watts, 6000 watts, 10000 watts, 12000 watts, 15000 watts, 20000 watts, 30000 watts, 40000 watts, and 60000 watts.

A professional laser tube cutting machine comes with a price tag of at least $50,000 with CNC controller for any types of metal tubing.

You'll have to spend $42,500 to $116,000 to purchase an all-in-one laser sheet metal and tube cutter with automation for dual-purpose commercial use.

An automatic 5 axis laser cutting robot ranges from $49,000 to $83,500 for flexible 3D dynamic metal cuts of multi-angle and multi-dimensional in industrial manufacturing.

NOTE: The 1000W laser power option is discontinued and no longer available, replaced by free upgrade to 1500W.

Pick Up Your Budget

| Types | Minimum Price | Maximum Price | Average Price |

|---|---|---|---|

| Entry Level | $2,600 | $5,200 | $3,980 |

| Hobby | $3,280 | $7,500 | $5,210 |

| Enthusiast | $3,960 | $8,800 | $6,380 |

| Professional | $5,900 | $16,800 | $9,120 |

| Commercial | $7,800 | $23,200 | $12,300 |

| Industrial | $9,600 | $61,500 | $15,600 |

| Enterprise | $12,700 | $300,000 | $18,900 |

| CO2 | $2,800 | $20,000 | $6,720 |

| Fiber | $14,000 | $1000,000 | $32,600 |

| Wood | $3,200 | $18,000 | $5,180 |

| Acrylic | $3,800 | $8,000 | $5,600 |

| Fabric | $6,500 | $12,000 | $8,100 |

| Foam | $5,200 | $10,800 | $6,900 |

| Metal | $6,500 | $1,000,000 | $10,250 |

Types & Categories

Laser cutting machines include fiber lasers and CO2 lasers based on different laser sources. Laser cutters come in handheld, portable, mini, small, desktop and gantry types according to different styles and appearances. Laser cutting tables are available in 2x3, 2x4, 4x4, 4x8, 5x10 and 6x12 depending on the workbench size (work area). Before purchasing, please measure your workshop space to ensure an exact fit and find the right table kit. Laser cutting systems are divided into 3-axis, 4th-axis (rotation axis), 4-axis, 5-axis and multi-axis 3D robots to cope with cutting in different directions and angles. You can meet flatbed cutting tables, tube cutters, home cutting tools, hobby cutting kits, die cutters, profile cutting systems, and industrial cutting machines in a variety of practical applications. As far as cutting materials are concerned, you can call them laser cutters for metal, wood, fabric, leather, paper, acrylic, plastic, foam, paper, and more.

DIY Guidelines

As a DIYer, when you have an idea to build & make a laser kit, you should first understand its structural composition. A complete kit consists of core components such as generator, cutting head, beam transmission components, working table, CNC controller, and cooling system.

Laser Generator

It is a component that generates a beam. Fiber is professional for all types of sheet metals and metal tubes. CO2 is economical for wood, plastic, acrylic, fabric, leather, foam, and thin metals.

Cutting Head

It is composed of a nozzle, a focusing lens and a focusing tracking system.

Cutting Nozzle

There are three common types of nozzles in the market, including parallel, converging, and conical.

Focusing Lens

Focus the energy of the beam and form a high energy density spot. The medium and long focusing lens is suitable for thick plate, and has low requirements on the spacing stability of the tracking system. The short focusing lens is only suitable for thin sheet, which requires high spacing stability of the tracking system and greatly reduces the output power requirements.

Focus Tracking System

The focus tracking system is composed of an auto focus cutting head and a tracking sensor system. The cutting head is composed of mechanical adjustment parts, air blowing system, light guide system, and water-cooling system. The sensor consists of amplification control part and sensing element. There are two types of tracking systems, one is an inductive sensor tracking system (also known as a contact tracking system), the other is the capacitive sensor tracking system (also known as the non-contact tracking system).

Beam Delivery Components

The main component of the beam delivery assembly is the refractive mirror, which is used to direct the beam in the desired direction. The reflector is usually protected by a protective cover, and a clean positive pressure protective gas is introduced to protect the lens from contamination.

Cutting Table

The table is composed of the bed frame and the driving part, which is used to realize the mechanical part of the X, Y, Z axis movement.

CNC Controller

A CNC controller is used to control the movement of X, Y and Z axes, and set cutting parameters such as power and speed.

Cooling System

A cooling system refers to a water chiller, which is used to cool the machine. For example, the electro-optical conversion rate is 33%, and about 67% of the electric energy is converted into heat energy. In order to ensure the normal operation of the equipment, the chiller needs to be cooled by water to reduce the temperature of the whole machine.

Assemble

After researching and buying the parts and accessories, the rest job is to assemble the kit and debug the software and hardware. The operation and cutting quality of the machine are directly related to the material, generator, gas, air pressure and the parameters you set. Please set the parameters carefully according to your process requirements. Improper parameter setting and operation may result in reduced effect, damage to the cutting head or other machine parts, or even personal injury.

Operating Instructions

Laser cutting is a non-contact subtractive manufacturing technology used to cut materials in small businesses and industrial manufacturing applications. The laser outputs a high-power focused beam that melts the material and leaves the edge with a high-quality surface finish. With its outstanding technical advantages, ultra-low power consumption, maintenance-free, reduced operating costs and repeatable and precise positioning performance, the laser beam cutting system has established a new benchmark for complex cutting and a new standard for process quality inspection.

Before starting, you should do the following preparations:

First, we should check that all connections to the machine (including power, PC, and exhaust system) are correct and plugged in correctly. Visually check the condition of the machine. Make sure that all mechanisms move freely and check that there is no material under the processing table. Make sure that the work area and optical components are clean and clean them if necessary. For more information on this issue, please read the "General Maintenance" section of the operating manual. Check the exhaust system and start the cooling system if necessary. Check that the filters and activated carbon of the exhaust system are installed according to the instructions, and cover the protective case after checking.

Next, press the main switch to turn on the machine. If all covers with safety circuit breakers are closed, the system will start to chime after startup. After turning on the machine, the table will move all the way down, while the cutting head moves to the zero position (located in the upper left corner). When there is a sound and the LED light flashes slowly and steadily, the chime process has been completed correctly and the machine is ready to start running.

After all preparations are completed, please follow the 15 easy-to-follow operating steps:

Step 1. Fix the material steadily on the cutting table.

Step 2. Adjust the cutting parameters of the laser controller according to the type and thickness of the material.

Step 3. Assemble the matching nozzle and lens, and check whether their appearance and cleanliness are intact.

Step 4. Debug and move the focus of the cutting head to the appropriate position.

Step 5. Center the nozzle.

Step 6. Calibrate the sensor.

Step 7. Choose the correct working gas according to your work needs.

Step 8. Test cut the material and observe whether the cutting edge is smooth and the cutting is accurate. If there is any deviation, adjust the cutting parameters accordingly until it meets your requirements.

Step 9. Draw and layout graphic files, and import them into the cutting control system.

Step 10. After all preparations are ready, you can start working.

Step 11. During the operation, the staff needs to observe the operation of the equipment on site. If there is an emergency, press the stop button as soon as possible.

Step 12. When the machine stops working, you should clean the guide rails frequently, wipe the equipment frame, and apply lubricating oil to the guide rails frequently to ensure that there is no debris.

Step 13. Clean the motor ring frequently to ensure the normal operation of the machine and accurate cutting to ensure quality.

Step 14. The staff must use a vacuum cleaner to remove dust and debris from the machine every week to ensure the cleanliness of the equipment.

Step 15. The staff needs to check the straightness and verticality of the track every six months to ensure the service life of the machine. If any abnormality is found, it must be maintained and debugged in time.

Pick Your Own

When you have the idea of buying a laser cutting machine, there are many things to consider. Let's make a detailed purchasing plan for you.

Planning Your Laser-cut

First of all, you need to consider some factors such as the scale of your business, what materials you need to cut, how thick the materials are, and then confirm the power supply and the size of the workbench according to your own needs. Currently, the laser powers in the market range from 80 watts to 40,000 watts, and the table size can be customized according to your requirements.

Researching Manufacturers & Makers

If you confirm your needs, you can go to do research on it. Maybe you can learn from your peers, and understand the machine functions and basic parameters. Select a few powerful manufacturers with favorable prices to conduct preliminary exchanges and proofing, and then conduct on-site investigations in the later stage, and conduct more detailed discussions on prices, online and offline training, and after-sales services.

Generator Selection

If you need to cut sheet metal and metal tubes, a fiber laser generator is the best choice, which includes some well-renowned brands such as IPG, JPT, Raycus, and MAX. If you want to engrave and cut wood, acrylic, leather, fabric, A CO2 glass laser tube is the right solution, which includes some world famous brands such as RECI and YONGLI.

Power Requirements

When researching the cutting ability, you need to consider the watts of the power supply. If you cut thin sheets, you can choose a lower power supply to meet your cut. The material with higher thickness need to consider higher power supply, which is beneficial for enterprises to control costs.

Choosing Parts & Accessories

You should pay special attention to the major parts in purchasing, such as the laser generator, controller, cutting head, motor, water chiller, air compressor, gas cylinder, gas storage tank, cold dryer, filter, dust extractor, slag discharger. The quality of these components is related to the cutting speed and accuracy.

Choosing Software & Controller

In order to make the machine easy to use, an user-friendly controller and powerful CAD/CAM software based on Windows and macOS are indispensable. Some of them are free with simple functions, while paid software is more professional for your business. All depends on your business needs.

Quality & Stability Assurance

Today's products are being updated faster and faster. Due to the short product development cycle, there are more product diversity, sample trial production, and mass production. How to complete customer orders with quality and quantity, enhance corporate competition, and maintain corporate reputation is also every time. Therefore, the purchase of processing equipment with stable functions is the condition and foundation. Try to choose a brand with a high market share, a sound after-sales service system, a large number of after-sales service outlets, and a long-term shopping mall inspection. Greedy to buy low-quality products with low prices and no after-sales service, this will have a great negative impact on the processing of enterprises.

After-Sales Service & Support

Each manufacturer's after-sales service is different, and the warranty period is also intertwined. For hardware and software, there must be a professional training system to help customers get started as soon as possible. No matter how well a machine is made, it will encounter various problems in the process of use. If customers encounter problems that cannot be solved, it is particularly important whether the maker can provide solutions in a timely manner. This is also an important thing to consider when purchasing.

Purchasing Process Flow

The purchasing process typically begins with determining your needs and setting a budget, then researching laser cutter machines, selecting a supplier, creating a purchase order and signing a contract, processing invoices, making payments, building, shipping, receiving and inspecting your machine, and finally finalizing the deal.

Investment & Benefits

A CO2 laser cutter machine is suitable for customers with tight budget, which is priced from $3,000 to $16,000, and features with low investment cost, less consumption of wearing parts and short payback period. However, while considering the price, you should also care about the value it brings. In other words, its capabilities and profitability determine whether it is worth investing in.

A CO2 laser machine is easy to use with CNC automation, which is used to DIY profitable crafts, gifts and artworks. It's a great partner to help you start a customization business at Amazon, or sell personalized laser cuts at Etsy to make money, it's worth buying anyway.

However, is it worth investing in an expensive fiber laser cutting machine? How profitable is it? Most companies or individuals may worry about whether it is worth its price when purchasing. The cheapest fiber laser machine starts at $15,000, and the most expensive cutter costs as much as $1,000,000. How long will it take to recoup its investment cost, and how much profit can it bring to me per year?

If your business volume is sufficient, you can quickly recoup the investment cost, while most companies buy it for their own internal processing, with relatively small volume, and the cost recovery will be slow.

Let's take external processing as an example. At present, the average profit of external laser machining is between 50% and 60%. If the average outsourcing cost is $5,000 per month, the annual cost is $60,000. If you own a fiber laser, excluding 1-month's cost and the same processing volume, the cost is about $2,500. According to this calculation, $30,000 can be saved per year, so a high power 6000W fiber laser can pay for itself.

The service life of fiber laser generators is up to 100000 hours but is limited. It's impossible to keep using it without any cost. You can calculate after-usage and pre-usage costs. Calculate the change in profit after using the machine, after subtracting the investment cost.

Pros & Cons

Laser cutting is one of the thermal cutting methods, which can do vaporization, fusion and oxygen cutting, dicing and controlled fracture. It has replaced the traditional mechanical cutters with invisible beams. It has advantages of high speed, high precision, high quality, low machining cost, automatic typesetting, smooth cut edges for any shapes and designs. It is an upgrade to traditional cutting tools. In addition to the advantages, it also has its own shortcomings and limitations.

Pros

• The mechanical part of the cutting head has no contact with the part, and it will not scratch the surface of the part during operation.

• The cutting speed is fast, the slit is smooth and flat, generally no subsequent cutting is required.

• The heat affected zone is small, the sheet deformation is small, which is used for precision fine cutting.

• Low cost of use without consumables, which is beneficial for makers to reduce manufacturing costs.

• The slit has no mechanical stress, no shear burr. It is high precision, good repeatability, does not damage the surface of the material with smooth cut edge.

• Using a computerized numerical control (CNC) unit that accepts cutting data from a computer-aided design (CAD) workstation.

• Working with CNC programming, which can cut any plan, and the whole large format part without molding.

Cons

• Since it is thermal cutting, in the process of multi-layer cutting, the edge part is easy to stick, which has a great impact on the quality.

• Due to the short wavelength of the laser, it is easy to cause damage to human eyes. Users can choose to wear special protective glasses to reduce injuries.

• Due to the thin incision of the fiber laser, the gas consumption is large (especially when working with nitrogen).

• Since the CO2 laser tube is made of glass, improper handling will cause it to break.

Care & Maintenance

A laser cutting machine should be regularly maintained to ensure the cutting speed, accuracy, and quality, and extend its service life. You should form the seven good work habits listed below.

• Before starting the machine every day, carefully check the pressure of the working gas and cutting gas. If the gas pressure is not enough, it should be replaced in time.

• Check whether the zero points of X axis, Y axis, and Z-axis, laser ready state and other buttons are damaged, and whether the limit switches of each axis are sensitive, and whether the travel block mounting screws are loose.

• Check whether the circulating water level in the chiller is sufficient and fill it up.

• Check whether there is any leakage in the circulating water of the external optical path. Leakage must be dealt with in time, otherwise it will shorten the life of the optical lens.

• After working every day, check the focusing lens for damage, and check whether the external optical path telescopic bellows is burned or damaged.

• The waste should be cleaned up in time, the workplace should be cleaned up, and the workplace should be kept clean and tidy. At the same time, do a good job of cleaning the equipment to ensure that all parts of the equipment are clean and free of stains, and no debris can be placed in each part of the equipment.

• After the daily work is completed, open the drain valve of the air storage tank at the bottom of the air compressor to drain water, and close the drain valve after the waste water is discharged, then shut down the machine and turn off the main power.

Cautions & Warnings

A beginner or professional should operate the laser cutting machine under the guidance of the instructions and the safety tips in the user manual to avoid accidents. You must follow the listed 18 safety rules.

• You should clean the dirt on the bed frame and guide rails every day.

• The user must strictly abide by the safety operation rules.

• The operator must consult all the manuals provided with the machine, be familiar with the structure and performance of the equipment, and master the relevant knowledge of the operating system.

• Wear labor protection equipment as required, and wear protective glasses that meet the regulations near the beam.

• Do not process the material until it is determined whether the material can be irradiated or heated to avoid the potential danger of fumes and vapors.

• When the machine is started, the operator shall not leave the post or be managed by the trustee without authorization.

• Keep the fire extinguisher within easy reach. Turn off the laser or shutter when not working. Do not place paper, cloth or other flammable materials near an unprotected beam.

• If an abnormality is found during the processing, the machine should be stopped immediately, and the fault should be eliminated or reported to the supervisor in time.

• Keep the generator, bed and surrounding sites clean, orderly and free of oil. Workpieces, plates and scraps are stacked according to regulations.

• When using gas cylinders, avoid squeezing wires, water pipes and air pipes to avoid leakage of electricity, water and air. The use and transportation of gas cylinders shall comply with gas cylinder regulations. Do not expose gas cylinders to direct sunlight or near heat sources. When opening the bottle valve, the operator must stand on the side of the bottle mouth.

• Before turning on the power of the chiller, check the water level of the chiller. It is strictly forbidden to turn on the chiller when there is no water or the water level is too low to avoid damage to the water cooling equipment. It is strictly forbidden to squeeze or step on the water inlet and outlet pipes of the chiller to keep the water passages unblocked.

• The beam will cause burns when it irradiates the human skin. Staring into a beam for extended periods of time can cause serious damage to the retina of the eye. Operators must wear goggles.

• The equipment will generate a lot of smoke and dust when cutting certain plates, so the outlet pipe of the fan should be led to the outside, or an air purification device should be installed. In addition, operators should wear dust masks to prevent the occurrence of occupational diseases.

• When the temperature is below 0 °C for a long time, the cooling water in the water cooler, laser and water pipeline should be drained to prevent the cooling water from freezing when the temperature is too low, causing damage to equipment and pipelines.

• Check the protective lens inside the cutting head once a day. When the collimating mirror or focusing mirror needs to be disassembled, record the disassembly process. Pay special attention to the installation direction of the lens and do not install it wrong.

• Turn off the air source and power supply when off work, and the residual air belt in the machine pipeline should be emptied at the same time. If you leave the machine for a long time, please turn off the power to prevent unprofessional operation.

• Pay attention to observe whether there is lubricating oil on the surface of the horizontal and longitudinal guide rails and the frame of the machine, and maintain good lubrication.

• If there is an automatic height adjustment device, check whether it is sensitive and whether to replace the probe.

Buyer's Guide

When buying a laser cutter, it's important to focus on technical features to ensure that the machine meets your needs. Key technical features to consider include power, cutting area, resolution, and software compatibility. Laser power determines the type and thickness of materials the cutter can handle, while the cutting area refers to the size of the working area. Resolution determines the level of detail and precision the cutter can achieve. It's also important to ensure that the cutter is compatible with the software you plan to use. Price is another important factor to consider when buying a laser cutting machine. The cost can vary depending on its technical specifications and the brand. It's important to balance cost with the machine's capabilities and reliability to ensure that you are getting good value for your money. By considering these technical features, you can make an informed decision when choosing a laser cutter kit & cutting system that will meet your specific needs and requirements.

Why STYLECNC?

STYLECNC is a leading manufacturer of high-quality laser cutting machines. With 20+ years of experience in the industry, STYLECNC is committed to delivering cutting-edge technology and innovative solutions to its customers.

Whether you need to cut metal, wood, or other materials, the brand has a machine that can handle the job. In addition to its top-of-the-line machines, the enterprise offers exceptional customer support and service. The company's team of experts is available to answer any questions and provide assistance to ensure that your machine is running at its best.

What Our Customers Say?

What can bring you closer to us than objective ratings and comments from real customers? Through customers' feedback of the pros and cons of STYLECNC's laser cutting machines, the highlights and shortcomings are clear at a glance. Positive reviews encourage us to keep innovating and moving forward, while negative reviews motivate us to stop defects, refine our offerings and better meet your needs. What we want is to build trust with you and achieve a long-term partnership rather than words of praise. Only in this way can STYLECNC stand out among so many popular laser cutter brands and win everyone's approval.