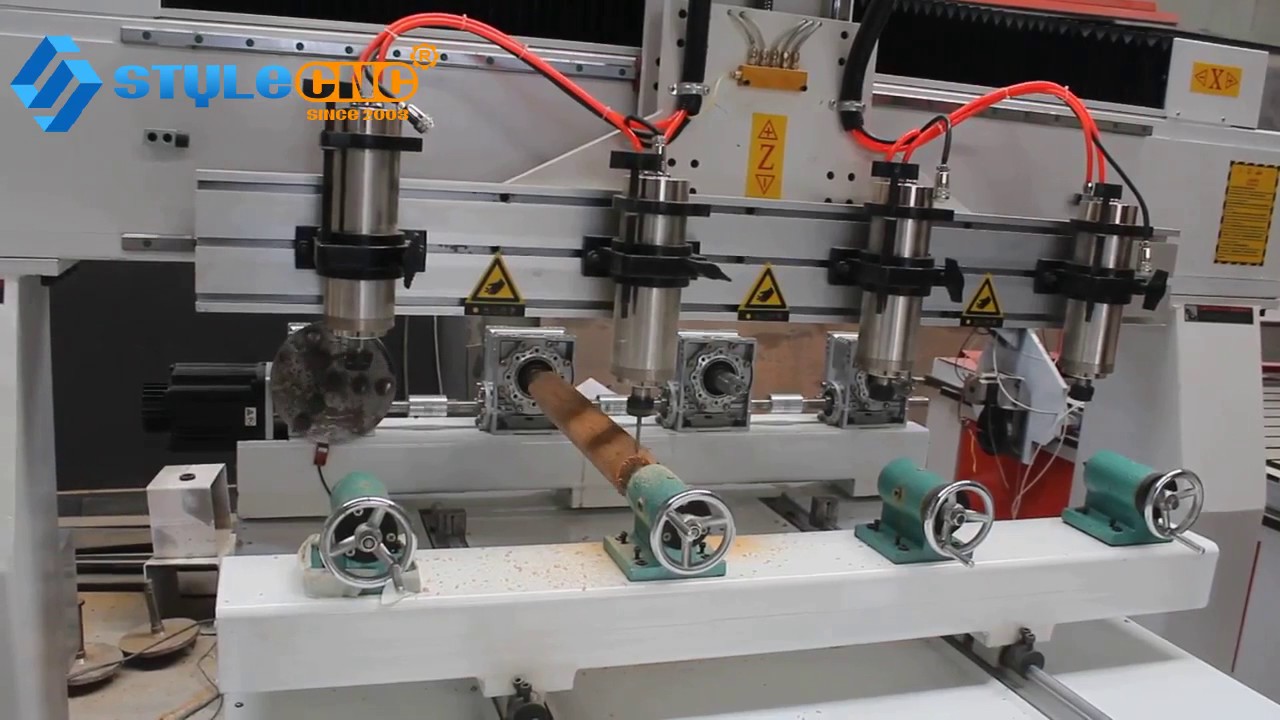

I've always wanted a full-size CNC machine to make custom 3D wooden pillars for a while, but it was too expensive and out of my budget (my furniture store is just starting out). I was on the fence until my wife told me that I could buy a budget-friendly 3D CNC router from China at a low price that I could afford, even with shipping costs. After almost a month of exploration and research, I finally decided to give the STM1325-4 from STYLECNC a try (during which I sent my wood blanks for trial machining and got satisfactory carvings and cuts). The machine arrived about three weeks later in perfect condition. I finally let go of my hanging heart. After all, this was my first cross-border shopping. All that's left is how to play with it. I had no trouble getting it up and running since I am a CNC machinist. I tried milling four stair posts at a time, resulting in smooth and clean carvings, but the only drawback was the somewhat slow speed. Overall, this was a perfect shopping experience. I look forward to it creating more personalized woodworking projects and making my shop prosper.

Industrial 3D CNC Machine with 4x8 Table Top for Sale

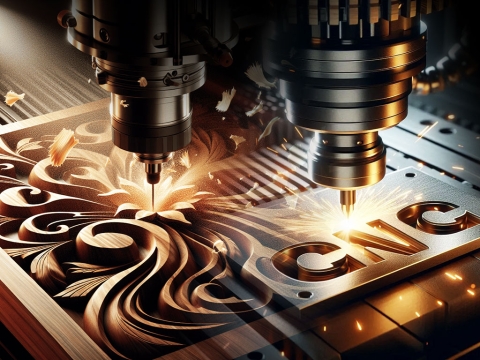

Industrial 3D CNC machine with 4x8 table top and 4th rotary axis is used for 3D CNC machining of staircase handrails, wooden pillars, stool legs, table legs, wood arts, crafts, gifts and toys.

- Brand - STYLECNC

- Model - STM1325-4

- Maker - Jinan Style Machinery Co., Ltd.

- Table Size - 4' x 8' (48" x 96", 1300mm x 2500mm)

- 360 Units in Stock Available for Sale Every Month

- Meeting CE Standards in Terms of Quality & Safety

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- 30-Day Money Back Guarantee for Your Purchase

- Free Lifetime Technical Support for End-Users & Dealers

- Online (PayPal, Alibaba) / Offline (T/T, Debit & Credit Cards)

- Global Logistics and International Shipping To Anywhere

Features of Industrial 3D CNC Machine with 4x8 Table Top

1. Steel gantry, cast Iron uprights, high rigidity.

2. Y axis adopts durable driving by synchronizing wheel consist of belt and gear shaft. High power sub-division motors keep stable moving, improve your working efficacy.

3. Power outages, breakpoint, continued carving. More intelligent. It will start the work automatically at the point from which the power cut off.

4. The 3D cylinder engraving machine adopts high quality sensor switch, improve the working safty.

5. Multi spindle work at the same time, greatly improve the work efficiency.

Applications of Industrial 3D CNC Machine with 4x8 Table Top

1. Furniture decoration industry: large area plate plane carving, wood carving and board type furniture carving. Solid wood art mural, solid wood door, cabinet door sculpture.

2. Wood products processing: sewing machine desktop, electrical counter desktop, sports supplies equipment.

3. Instrument industry: 3d curved surface, shape cutting.

Technical Parameters of Industrial 3D CNC Machine with 4x8 Table Top

| Model | STM1325-4 |

| Working Area | 1300x2500 |

| Table Size | 1450×2780mm |

| Traveling Positioning Accuracy | ±0.03/300mm |

| Repositioning Positioning Accuracy | ±0.05mm |

| Lathe Structure | Welded Structure |

| X, Y Structure | Gear Transmission |

| Z Structure | Taiwan TBI Ball Screw transmission |

| Max. Consume power | 6.5Kw |

| Max Speed | 0-32000mm/min |

| Max Working Speed | 0-20000mm/min |

| Spindle Power Motor | 1.5KW Chinese water-cooling spindle |

| Spindle Speed | 0-24000RPM |

| Working Mode | Hybrid servo |

| Working Voltage | AC220V,single PH,220V/50/60Hz,3PH |

| Command | G Code, *uoo, *mmg, *plt |

| Operating System | RichAuto DSP control system |

| Interface | USB |

| Flash Memory | 128M |

| Collet | ER20 |

| X,Y Working Accuracy | <0.01mm |

| Running Circumstance | Temperature: 0℃~45℃ Relative humidity: 30%~75% |

Details of Industrial 3D CNC Machine with 4x8 Table Top

Projects of Industrial 3D CNC Machine with 4x8 Table Top

Marcus Earl

Zac

Most efficient 3D CNC machine I have ever puchased and the only reason that I got it was to make crafts for my woodshop. It works great for me and I really suggest you guys to have it as well.