With so many laser tools available in the market, nowadays it has become a bit confusing regarding the choice one should make. Undoubtedly, laser engraver is one of the most versatile engraving solutions available that can engrave precisely on a variety of materials. From small to large business fields and from professional to passionate hobbyists, such a engraving machine always creates appeal. Now, what would allow you to choose your perfect engraving tool? Well, a lot of things can be mentioned, especially laser power, engraving area, and seamless software compatibility are always worth mentioning. But there are always more. In this buying guide, we are here to explore them all. If you are interested, let's get started.

Why Laser Engravers Are Better Than Traditional Engraving Tools?

One of the primary reasons why you should shift to a laser engraver is that these tools are extremely precise than most other traditional engraving tools. When it comes to creating high-end markings with a high level of detail, a light beam engraving tool can be the next wonder. With software-based commands and computerized automatic action, the chances of making any mistakes will always be down to zero. Laser engraving is also faster and more efficient than manual engraving, with the ability to create complex designs quickly and easily. Overall, laser engraving is a versatile and efficient tool that offers a wide range of benefits for both personal and professional use.

Meaning & Definition

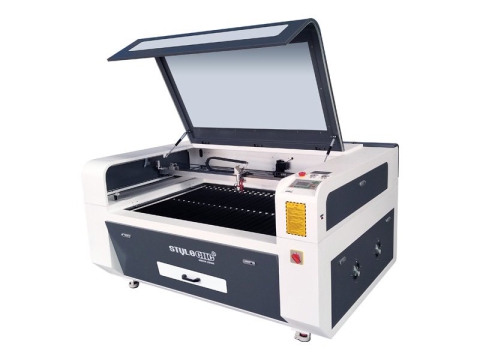

A laser engraver machine is a professional fine engraving tool that uses a handheld DSP controller or an automatic CNC controller to direct a laser beam to vaporize materials into fumes to create permanent graphics or text on surfaces of different materials.

A laser engraving system is a set of hardware units and software programs working together as parts of a mechanism to perform precise and repeatable engravings on surfaces of metal, wood, glass, fabric, acrylic, and plastic.

A laser engraver kit is an organized collection of parts and components (bed frame, generator, power supply, engraving head, tube, lens, mirror, servo motor or stepper motor, gas cylinder, gas storage tank, air compressor, dust extractor, air cooling filer, dryer, water chiller, laser software and controller) that are integrated to create 2D/2.5D/3D text or graphics on metals, metalloids and nonmetals in home store, small business, commercial use, industrial manufacturing, school education and skills training.

A laser engraving machine is also known as laser etching machine, etcher, ablator, ablation kit, burner, burning machine, texturing tool, patterning kit, stippler, stippling machine, branding machine, printer, printing machine, marker, marking machine.

Working Principle

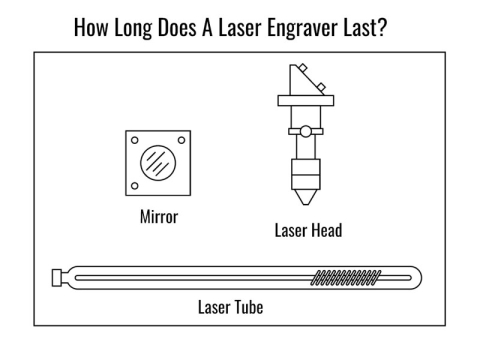

Laser engraving is based on computer numerical control technology. First, you need to make a design of file, then, open the file through software, and start CNC programing, the engraver will start working after the control system received the control command. The laser beam is reflected through mirrors, the focal point downward through lens, where the heat is most intense. Thus, the beam starts impinging on the material, the material will burn or evaporate, and the color will change as well, and make a contrast. After a while, a complete engraved project will be finished.

Uses & Applications

Laser engravers are the mostly used engraving tools, which are used in various industries of embroidery, brand processing, packaging and printing, custom credit cards, advertisement decoration, architectural models, metal fabrication, woodworking, custom smartphones & laptops, molds, crafts, leathers, shoes, toys, fablabs & education, medical technology, rubber stamps, watches, architectural models, packaging design, automotive industry, mechanical engineering, awards & trophies, signs & displays, signage, giveaways, electronics industry, data plates, personalized jewelry maker, ball bearing, barcode serial numbers, and more. With the laser beam engraving system, you can engrave different designs on different substrates. The laser beam will make the surface to vaporize. It is ideal for someone who wants to customize or personalize something.

Cost & Pricing

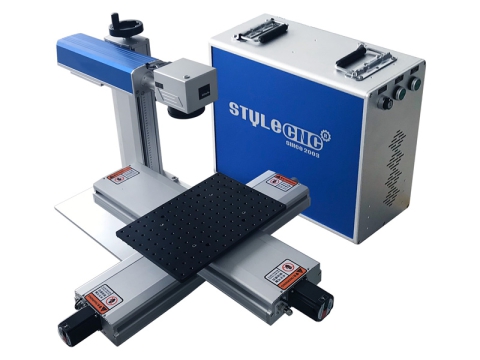

If you have an idea to buy the best budget laser engravers for hobby or commercial use, you may wonder how much does it cost? how to get a fair price or final price in your area? STYLECNC can tell you what you should expect to pay for your next laser engraving machine.

A new laser engraver costs an average of $5,280 for entry-level and high-end models in 2025. However, that figure varies depending on your laser power and engraving table size, you may spend more or less than that. The small hobby laser engraver kits are cheaper than the average, costing roughly $2,760, while the professional industrial CNC laser engraving machines average $7,800. Prices can also go up if you need personalized customization since manufacturers can charge anywhere from $200 to $1,000 for new designs.

Laser engraving systems come in three basic types. The average cost of affordable fiber laser engravers is around $5,060, slightly lower than its $5,510 average price last year. The budget-friendly CO2 laser engraving machine's average price in 2024 was over $3,960 and decreased to $3,680 in 2025. Purchasing brand-new UV laser etching machines can set you back $5,780 - around 20% less than the average price in the previous year ($7,120).

The used laser engravers are relatively cheaper, ranging from $1,280 to $5,600. However, this will bring about the troubles of insufficient laser service life and inability to provide after-sales technical support.

Specifications

| Brand | STYLECNC |

| Laser Power | 20W, 30W, 50W, 60W, 80W, 100W, 130W, 150W, 180W, 200W, 280W, 300W |

| Laser Type | CO2 Laser/Fiber Laser/UV Laser |

| Table Size | 2' x 3', 2' x 4', 4' x 4', 4' x 8', 5' x 10' |

| Price Range | $2,400 - $70,000 |

| Applications | Industrial Manufacturing, School Education, Hobby, Small Business, Home Use, Craftsman. |

| Engraving Software | Laser GRBL, LightBurn, Inkscape, EzGraver, EZCAD, LaserWeb, SolveSpace, Adobe Illustrator, AutoCAD, Corel Draw, Archicad. |

| Engraving Materials | Metals (Copper, Gold, Silver, Aluminum, Alloy, Iron, Brass, Steel), Wood, Stone, Glass, Acrylic, Plastic, Rubber, Leather, Fabric, Textile, Paper. |

Pros & Cons

Unlike laser printers, laser engraving is the application of CNC laser technology to make text or pattern on the object. While engraving, the surface of the object is still smooth, and the writing will not wear. The laser beam does not touch the surface of the material, is not affected by mechanical motion, and the surface does not deform, generally no need to be fixed. Laser etching is not affected by the elasticity and flexibility of the material, and is convenient for all types of metal, metalloid, and nonmetal materials. Overall it has its own pros and cons listed below.

Pros

• The precision workbench can be used for fine micromachining.

• Use a microscope or camera system to observe or monitor the condition of the engraved surface.

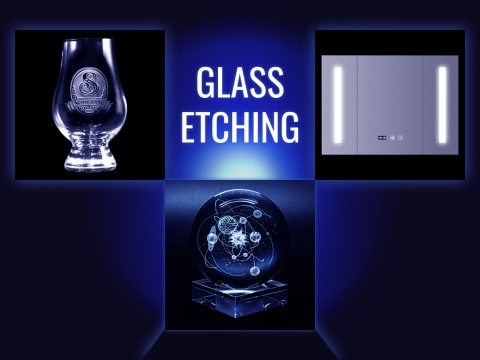

• It can pass through light-transmitting materials (such as quartz, glass) to engrave its internal parts.

• It can process most metal or non-metal materials.

• The laser beam is very thin, so that the consumption of the engraved material is small.

• During etching, X-rays will not be generated like electron beam bombardment and other engraving methods, and will not be interfered by electric and magnetic fields.

• It can mark the surface of "millimeter-level" parts.

• The laser uses non-mechanical "tools" for engraving, which does not produce mechanical extrusion or mechanical stress on the material, has no "tool" wear marks, is non-toxic, and rarely causes environmental pollution.

• The prism and mirror system can be used to focus the beam on the inner surface or inclined surface of the workpiece for etching.

• The operation is simple, the use of numerical control technology can realize automatic engraving, can be used for high-speed and high-efficiency engraving of parts on the production line, and can be used as a part of the flexible system.

Cons

• Lasers are easy to cause damage to the human eye due to the short wavelength, however, users can wear special protective glasses to reduce damage.

• Due to the CO2 laser tube for engraving is made of glass, improper use can cause it to break.

Types

Laser engraving machines are classified as laser wood burning machine, metal engraving machines, leather ablation machines, stone engraving machines, fabric marking machines, plastic engraver kits, rubber branding kits, paper printing tools, glass etching machines, acrylic engraving tools based on the materials.

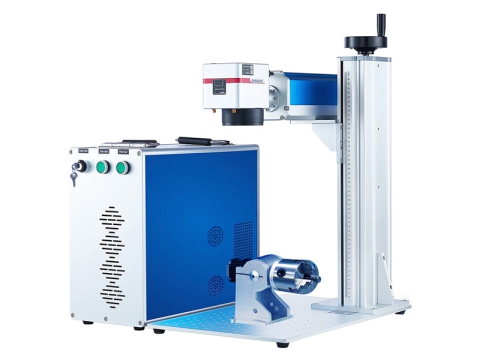

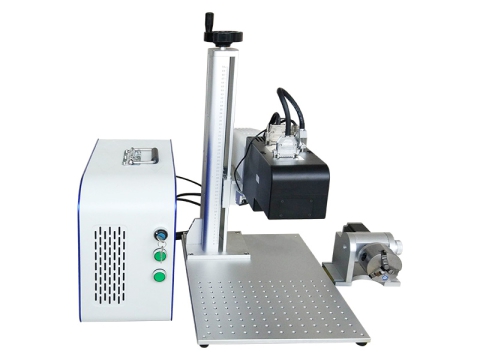

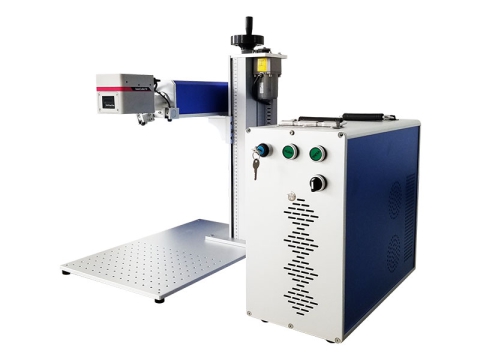

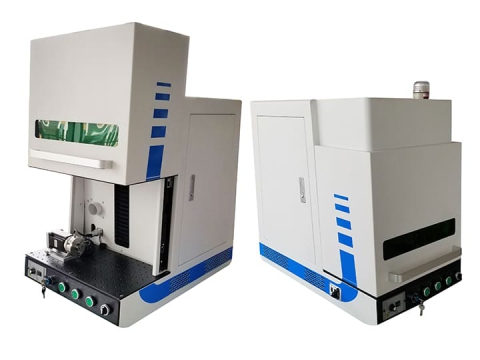

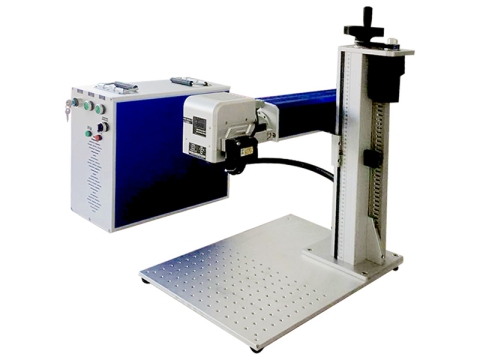

Laser engraving systems are defined as CO2 laser systems, fiber laser systems (the best tool to engrave metal), and UV laser systems (the best tool to etch glass) based on the sources.

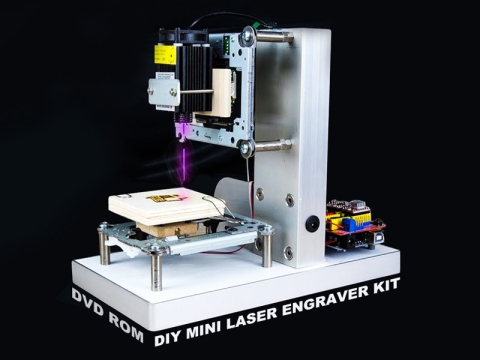

Laser engraving tables are divided into mini types, handheld types, compact types, desktop types, portable types, 2x3 engraving tables, 2x4 engraving tables, 4x4 engraving tables, 4x8 engraving tables, 5x10 engraving tables, large format engraving tables according to the working area.

These kits are classified as home kits, hobby kits, commercial kits, industrial kits based on applications.

These engravers are defined as laser jewelry engravers, pen printers, iPhone engraving tools, gun stippler, ring engraver kits, signage markers, art engraving kits, logo branders, cup etchers based on industries. If you are working for 3D engraving, the rotary engraver kit is the best option.

Setup & Installation

As a novice or DIYer, you should know how to setup, install, and debug a laser engraving machine for use in your business to make money. Here are 8 basic steps to help you to grow professionally.

Step 1. First check whether the tube is damaged and whether any parts are loose.

Step 2. Install the exhaust device, connect the exhaust pipe to the exhaust fan, and install the other end outdoors. The maximum distance between the exhaust fan and the outdoor air outlet is 2 meters. If it is caused by the local environment, if the exhaust pipe extends too long, you need to configure additional exhaust equipment.

Step 3. Connect the ground wire (see the grounding position behind the machine, the grounding resistance should be ≤4 ohms).

Step 4. Check the 220V power supply line for aging of the wireless circuit, loose connectors, poor contact, etc. The 220V AC voltage is normal. If necessary, a special power supply line and a regulated power supply (power ≥3000W) must be used.

Step 5. This machine uses an external submersible pump circulating water supply cooling device. The user must prepare a capped bucket. The height difference between the engraving machine and the submersible pump should not be greater than 0.5 meters. The cooling circulating water must be clean, dust-free, and scale-free.

Step 6. The water temperature of the circulating cooling water should be 5-25 ℃, otherwise it will affect the engraving depth. In the cold area, it should be ensured that there is no ice blockage in the tube, otherwise the tube will burst. It is best to drain the remaining water in the circulating water channel and tube when it stops working at night to prevent frost cracking.

Step 7. If the tube is found to be short of water, it should be shut down immediately to stop working, cut off the power of the pump, and at least shut down for more than half an hour, wait for the tube to cool naturally before the water can be started to work.

Step 8. Turn on the submersible pump, the cooling water should circulate normally, and the cooling water channel should be free from clogging and dripping.

Note: Do not connect the zero wire to the ground wire.

Operation

Here are eight operating steps on how to operate such a tool correctly for beginners and professionals, we hope that this manual can help you to understand.

Step 1. First turn on the main power switch, turn on the voltage regulator, and turn on the chiller (let the water in the tube fill up and cycle for 1-3 minutes). You should put antifreeze in the chiller in winter and snow days.

Step 2. Turn on the power of the machine and reset the machine.

Step 3. Turn on the fan power and air pump.

Step 4. Turn on the switch (turn on the machine to emit light), and then turn on the lighting switch.

Step 5. Press the burst button to detect whether the laser is emitted.

Step 6. Turn on the computer (the computer's USB cable is connected to the machine interface), open the control software, click the software up, down, left and right buttons to check whether the machine is moving. The machine movement indicates that the computer is connected to the machine.

Step 7. Put the workpiece and adjust the anxiety (in general, we only measure the distance from the cutting nozzle to the surface of the material), long focal length lenses for cutting thick materials, and short focal lengths for fine engraving machines.

Step 8. Operate the computer to transfer files, position the machine, walk the frame (test whether the area of the cut file is within the effective range of the workpiece), and start engraving.

Engraving VS Marking

Laser marking machine is an automatic printing system that uses a diode, solid-state, or metal CO2 laser tube to evaporate the surface material to expose the deep material, which leads to chemical changes in the surface material and physical changes to print marks, or to burn part of the material through beam energy to show the desired printing pattern and text.

Laser engraving machine is an automatic etching system that uses the beam from glass CO2 laser tube to cut and engrave variety of non-metallic materials. Unlike mechanical engraving machine, it uses the heat energy from the beam to etch substrates.

Application

The engraving systems use CO2 laser tube to engrave and cut glass, crystal, acrylic, wood, marble, cloth, leather, felt, paper, PVC, plastic, mosaic and other non-metallic materials. Laser marking systems use fiber, CO2, and UV laser to mark various metal and non-metal materials.

Depth

The engraved depth is from 0.1mm to 80mm with powers from 40W to 300W, all depending on the specific material. The marked depth is less than 5mm, and the power is between 20W and 200W.

Speed

The cutting speed of the engraver is maximum 200mm/s, and the engraving speed is maximum 500mm/s. The marking speed is three times faster than the engraving speed.

Precision

The precision of marked projects are much higher than that of engraved projects. The marker can work on the surface of the material with a thin beam, and the thin line width can reach 0.01mm. It has created a broad application space for precision machining and increasing anti-counterfeiting functions.

Work Area

The laser marking machine can generally mark the format of 200*200mm, and the engraving machine can engrave large format. The marking system uses galvanometer scanning, so the working area is relatively small. To put it bluntly, the laser etcher is to replace the spindle of the CNC machine with focusing lens, and use the beam instead of the tool for processing, so as long as the X/Y/Z axis is large enough, you can process as many large formats as you want, but the accuracy is not good.

Generator

The optical path system of the engraver kit is composed of three reflective lenses and a focusing mirror, and the generator is a glass CO2 laser tube. Its life is generally within 2,000-10,000 hours. CO2 glass laser tubes are all disposable. The generators of laser marking systems include metal tube, fiber and YAG lasers, the lifespan is more than five years, and the metal tube lasers can be inflated again for use.

Care & Maintenance

Whether it is used for hobby or commercial use, whether it is used for metal or wood, a laser engraver machine needs regular care and maintenance.

• There should be no other debris on the equipment, and the surface should be kept clean.

• Production personnel should strictly follow the operating standard operating procedures for production operations, and random operations are strictly prohibited.

• The circuit must be grounded reliably to protect personal safety.

• The cooling system should be regularly replaced with distilled or deionized water, and the water tank should be carefully cleaned when replacing the water.

• Keep the machine clean and tidy, don't wipe with a damp cloth, and clean with electricity.

• The machine should be turned on and off strictly in accordance with the on-and-off procedures, and random operation is strictly prohibited.

• Don't start the power supply and Q-switching power supply under the condition of no water or abnormal water circulation.

• The computer disk should be scanned and defragmented regularly, and junk files should be cleaned up frequently.

• The location of all PLT format files should be fixed and not moved randomly to prevent file damage.

• If the computer crashes or the software does not respond, turn off the galvanometer switch immediately.

• Regularly check the quality and quantity of cooling water, keep the internal circulating water clean, clean the water tank regularly and replace with clean deionized water or pure water.

• Keep mobile phones and strong magnetic objects away from the galvanometer of the engraving machine.

• Don't turn on the galvanometer when the computer etching software is not open.

• Do not disassemble the lens with your hands.

• Don't move the device without permission.

• Is there any abnormal noise when the equipment is working?

• Is the equipment damaged or missing parts?

• If there is a sudden power failure during operation, please press the red button immediately and pull it to the off or off position one by one, or adjust the power current adjustment knob to the lowest position.

• When the machine fails during operation, it should be stopped and reported promptly.

• The maintenance and inspection records should be established for the equipment, and all inspections and repairs should be recorded.

• The contents of maintenance inspection include:

Daily Inspection

• The machine is clean and lubricated as a whole.

• Whether there are sundries on and around the machine.

• The current cannot easily exceed 20A.

• Whether mobile phones and strong magnetic objects are close to the galvanometer.

• Whether there is any abnormal noise during the operation of the equipment.

• Do not touch the lens with your hands or other objects.

• Strictly abide by the power-on and turn-off procedures for equipment switching and shutdown.

• If the computer crashes or the software does not respond, immediately turn off the galvanometer switch.

Regular Inspection

• The circuit is well grounded.

• Check the quality and quantity of cooling water.

• Use of electrical appliances and circuits.

• Parts and accessories cleanliness.

• Whether there is any abnormal noise in the movable property of the equipment.

• Whether there are damaged or missing parts.

• The operation of the refrigerator.

Cautions & Warnings

It is very dangerous for the laser engraving machine to fail when it is working. The beginners must be trained by professionals before they can operate independently. STYLECNC has summarized the following cautions and warnings based on experience, hoping to help users and operators.

• Follow general safety operating procedures. Start the laser strictly according to the start-up procedure.

• The operator must be trained to be familiar with the structure and performance of the equipment, and to master the relevant knowledge of the operating system.

• Wear labor protective equipment according to the regulations, and must wear protective glasses that meet the regulations near the beam.

• Do not process a material without knowing whether it can be irradiated or heated by a laser to avoid the potential hazard of fumes and vapors.

• When the laser engraving machine is running, the operator shall not leave the post without authorization or entrust others to use it. If it is necessary to leave, the operator should stop the machine and turn off the power switch.

• Keep fire extinguishers within easy reach, turn off lasers or shutters when not processing, and do not place paper, cloth, or other flammable materials near unprotected laser beams.

• When any abnormality is found during the processing, it should be shut down immediately, and the fault should be eliminated in time or reported to the supervisor.

• Keep the generator, bed and surrounding areas clean, orderly, and free from oil, and the workpieces, plates, and waste materials should be piled up according to regulations.

• The continuous working time cannot exceed 5 hours (more than half an hour of rest is required in the middle).

• Follow high voltage safety regulations during maintenance. Every 40 hours of operation or weekly maintenance, every 1000 hours of operation or every six months of maintenance must be carried out in accordance with regulations and procedures.

• After turning on the machine, it should be started manually at low speed in the X and Y directions, and checked to see if there is any abnormality.

• After inputting the new workpiece program, it should be trial run first and check its running condition.

• When it is working, pay attention to observe the operation to avoid accidents caused by the machine going out of the effective travel range or two collisions.

• During the etching process, operators are prohibited from leaving their posts without permission.

• In the etching process, the top cover must be closed to prevent the laser from deflecting and burning someone around.

• Because there are laser and high-voltage parts in the machine, it is strictly forbidden for non-professionals to disassemble the machine without authorization.

• The grounding of all parts must be completely reliable to prevent static electricity from hurting others.

• Don't place flammable and explosive items near the equipment to prevent fire caused by laser deviation.

• Don't place any irrelevant reflective objects inside the machine to prevent the laser from reflecting onto flammable and explosive materials or the human body, which may cause unpredictable losses and damage.

• During the working process, the operator must observe the working conditions at any time (such as: deformation of the hook edge, whether the laid paper is blown up by the air pump to block the laser, abnormal sound of the machine, water temperature of the circulating water).

• Place the machine in an environment free of pollution and electromagnetic interference.

• A voltage stabilizer should be used to start the machine when the voltage is unstable.

• The water cycle must be kept clean, and the water temperature should not exceed 20-30 degrees (purified water is recommended).

• Do not turn on the ammeter at the maximum value to avoid power breakdown and shortening the life of the tube.

• Basic restrictions on the use of power supplies (that is, the maximum current meter cannot exceed 20mA)

• If it fails or a fire occurs, please cut off the power immediately. The user must strictly abide by the above items, otherwise, the manufacturer will not be responsible for personal injury or damage to the machine.

Buyer's Guide

The first crucial aspect worth considering while purchasing a laser engraver is your specific needs and preference. That means if you are a hobbyist who loves to engrave occasionally, it would not be a better choice to go for a high-end expensive option. An affordable engraving tool with enough technical features will do the job for you. On the contrary, if you are looking for a machine for professional purposes, consider spending more on the tool.

Now comes checking the technical features once you have decided how much you are willing to pay for the tool. You'll have consider some things when you are planning to pick an engraver. Laser power and engraving speed are critical factors that can affect the depth and precision of your engravings. A larger engraving table can provide greater flexibility in the sizes of materials. In addition, the software compatibility is crucial to ensure that your laser works seamlessly with your preferred CAD/CAM software. Evaluating your options carefully and doing your research, you will find and buy an perfect engraver with high precision, efficiency, and versatility you need to create high-quality engravings.

Why STYLECNC?

STYLECNC is a well-known brand that is committed to providing high-quality engraving tools that are both precise and efficient. Their machines are designed with the latest technical features to ensure that users can achieve their desired engravings quickly and easily. STYLECNC also offers customization options, allowing users to tailor their lasers to their specific needs and preferences. They are mostly recognized for manufacturing and selling reliable and high-performance laser engravers that meet every need of hobbyists and professionals alike. STYLECNC has been focusing on product quality and customer satisfaction for many years, and growing step by step into a world-leading manufacturer that you can trust to provide an excellent laser engraving experience.