2024 Most Popular Laser Cleaners for Every Need

Need an eco-friendly cleaning tool to strip paint off wood or remove rust from metal for your repair shop or refurbishment business? Looking for a professional cleaner for cultural relic restoration? Searching for a commercial cleaning machine for industrial cleaning services? No need to waste time and effort to explore online or offline. A laser cleaner can meet these needs, which is user-friendly and easy to use for both beginners and professionals. Here is STYLECNC's picks of the most popular types and models of laser cleaning machines for every need in 2024, including automatic, portable and handheld series, as well as backpack and trolley types. All the laser cleaner machines are capable of removing rust, paint, coating, oxide, plating, oil, stains, dirt, residue and other contamination layers for metal, ceramic, stone, wood and rubber. STYLECNC's laser cleaning systems come with various power options including pulsed fiber laser powers of 50W, 100W, 200W and 300W, as well as CW fiber laser powers of 1000W, 1500W, 2000W and 3000W to match your surface treatment needs and budget. No matter what you're going to do? always one option fit for you.

2024 Best Handheld Fiber Laser Cleaning Machine for Sale

3-In-1 Handheld Laser Welding, Cleaning, Cutting Machine

2024 Best Handheld Laser Rust Removal Machine for Sale

Top Rated Portable Laser Paint Stripping Machine for Sale

Affordable 100W Backpack Laser Cleaner Machine for Sale

- Showing 5 Results On 1 Page

Free & Profitable Relevant Project Ideas

Most Popular Relevant Videos You Should Watch

Top Relevant Stories & Articles Worth Reading

Find & Buy Your First Laser Cleaner for Hobby & Industrial Use

Contaminants such as oils and adhesives, or even undesirable oxides, rust, phosphates or paint layers will appear on the surface of some workpieces, which must be removed before further processing. There are various industrial cleaning processes, and most users do not know how to choose the tools that suit them. Against this background, the efficient cleaning and stripping process using laser has become the focus of attention of production planners. The new laser cleaning machine designed by the experts at STYLECNC advances the development of cleaning and stripping processes, it enables low maintenance workpiece cleaning in a very small space, it can be used as a free-standing solution with manual loading, or as a Integrated into a fully automatic production line for repeatable and reliable results. In addition, this process can also be used when performing surface functionalization to improve surface wetting properties.

Definition

Laser cleaning is an effective method to remove dirt particles and films of different materials and sizes on solid surfaces. It is to form a laser beam with a specific spot shape and energy distribution after optical focusing and spot shaping of a continuous or pulsed laser with high brightness and good directionality. After the contaminant material absorbs the laser energy, it will produce a series of complex physical and chemical processes such as vibration, melting, burning, and even gasification, and finally make the contaminant detach from the surface of the material. Even if the laser acts on the cleaned surface, most All are reflected off, and will not cause damage to the substrate, so as to achieve the effect of cleaning.

A laser cleaning machine is an eco-friendly professional cleaning tool for surface treatment with handheld cleaning gun or CNC controller, which uses the instant high temperature ablation generated by laser beam to remove rust, coatings, paint, oil, oxides, grease, resin, glue, dust, stains, residues, or some other pollution & contamination layers. It is also known as laser cleaner, rust removal machine, paint stripping machine, coating removal tool, oxide remover, oil cleaner, dirt cleaning system, laser descaler machine.

A laser cleaning system uses the high heat energy of the laser beam to act on the surface of the object to instantly evaporate or peel off the dirt, rust or coating on the surface, so as to achieve a clean, environmentally friendly, energy-saving and efficient industrial tool, and gradually replace the traditional chemical cleaning method, mechanical cleaning method, and ultrasonic cleaning method. It can quickly remove paint, rust, oxides, coating, oil stains, product residues, restoration and preservation of historical cultural relics.

Working Principle

A laser cleaner generates various beams through different types of generators, and adjusts the energy density to expand the dirt by heat. When the expansion force of the dirt is greater than the adsorption force of the dirt to the substrate, the dirt will leave the surface of the object. The beam can generate thousands of degrees or even tens of thousands of degrees in the vicinity of the focal point, causing the dirt to evaporate, gasify or decompose instantly. The divergence angle of the beam is small and the directivity is good. The beam can be condensed into spots of different diameters through the condensing system.

It uses pulsed laser rays to hit the surface to be treated with high pulse peak power. The material dissipates quickly and only a very thin layer is heated in the process. In this way, one pulse after another, all types of impurities or coatings are gradually removed from the workpiece, including cooling lubricants, oils, oxide and graphite layers, rust, paint and phosphate layers. In addition, the user can also use this process to pre-treat the surface (eg "roughing") according to the requirements of the subsequent process. In short, the process is very flexible and energy-efficient. However, when it comes to mechanical manufacturing, professional knowledge and technical know-how play a decisive role. Core process parameters such as processing time must be adjusted according to the specific requirements of the task, and should be as simple as possible through the machine control system. Otherwise it will be difficult to implement in daily applications. Furthermore, the process technology must be flexible in all respects and can be used as a stand-alone solution or integrated into a production line. It has high reliability and high efficiency, and saves space.

Uses

It is used to clean organic pollutants and inorganic substances for paint removal, paint stripping, rust removal, coating removal, glue removal, cultural relics restoration, and oil dirt removal. And it is used in precision mold cleaning, selective paint removal for weld inspection, historic masonry conservation, removing oxides, oil, grease & production residues.

⇲ Removal of coating layer on metal or glass surface and quick paint removal.

⇲ Quickly remove rust and various oxides.

⇲ Remove grease, resin, glue, dust, stains and production residues.

⇲ The metal surface is roughened, and the metal surface in a narrow space is cleaned.

⇲ Paint removal, rust removal, oil removal before welding or before bonding, oxide and residue treatment after welding.

⇲ Mold cleaning, such as tire molds, electronic molds, and food molds.

⇲ Oil stains are removed after the production and processing of precision parts.

⇲ Quick cleaning of nuclear power components maintenance.

⇲ Oxide treatment, paint removal and rust removal during the production or maintenance of aerospace weapons and ships.

⇲ Cultural relics cleaning, rock cleaning, and building exterior surface cleaning.

Price & Cost

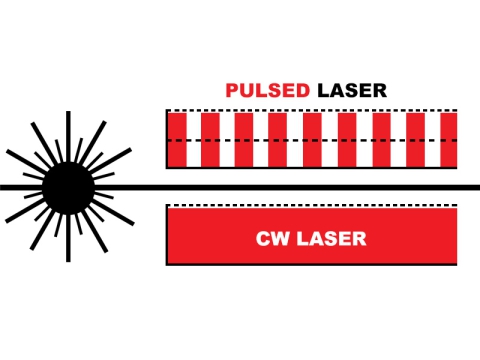

Its price is different from the pricing methods of traditional cleaning such as detergents. Compared with the attributes of cleaning agents as consumables, laser beam cleaners can be used repeatedly. As a cleaning tool kit, its price depends on different configurations. For example, if a laser generator with higher power is used, the price will definitely be higher, and pulsed laser price is higher than CW (continuous wave) laser.

In 2024, the average cost to buy a handheld pulsed laser cleaner is $8,000 on the world market.

The true cost of owning the 100W portable laser cleaner with handheld pulsed laser gun is $7,000. It typically costs $10,000 for the 200W pulsed laser beam cleaning machine. Beyond the sticker price, however, there are the costs of shipping, tax, custom clearance, and other expenses customers need to consider.

The price of 1000W portable CW laser cleaning machine starts from $5,200. The price range of 1500W handheld CW laser cleaner is from $5,600. The minimum cost of 2000W high power laser beam cleaning machine is $6,700. The 3000W CW laser cleaning gun is priced from $8,800. In addition, the price of an automatic laser cleaning system with CNC controller or robot can be as expensive as $18,000.

The best budget 3-in-1 laser welding, cleaning, cutting machine costs from $4,700 to $9,800 with fiber laser power options of 1000W, 1500W, 2000W and 3000W.

Even if the configuration is similar, the costs from different manufacturers are not the same. Because the cost not only involves configuration, but also includes brand, after-sales service, and other factors.

Importance of Laser Cleaner

Laser cleaning is a cutting-edge advancement in surface cleaning technology. It is highly efficient and precise in removing contaminants, coating, and unwanted materials from the surface. Laser cleaners use high-energy laser beams to disintegrate surface contaminants. The technology has revolutionized the field of surface cleaning.

Advanced surface cleaning methods like laser cleaning play a crucial role in making the industrial manufacturing environment clean and safe. This offers several key advantages over traditional cleaning methods including unparalleled precision, non-contact operation, environmental sustainability, and versatility across a variety of materials and surfaces.

For a high standard of cleanliness and efficiency laser cleaners are crucial for any industry nowadays. It’s better, safer, more efficient, and advanced than most other techniques.

Better Than Traditional Cleaning Methods

We made a simple comparison to distinguish and pick the smart choice between the traditional cleaning techniques and the laser cleaning method.

| Aspect | Laser Cleaning | Traditional Cleaning |

| Environmental impact | Environmentally friendly, producing minimal waste and emissions. | May generate chemical waste, abrasive dust, or wastewater, contributing to environmental pollution. |

| Efficiency and Productivity | Faster and more efficient, reducing cleaning cycle times and increasing productivity. | May involve time-consuming manual labor or the setup and disposal of abrasive media or chemical solutions. |

| Regulatory Compliance | Helps industries meet regulatory requirements for cleanliness, quality control, and environmental protection. | May require additional measures to ensure compliance with environmental and safety regulations. |

| Cost Effectiveness | Higher initial investment but offers long-term cost savings with reduced consumables and maintenance costs. | Lower initial cost but may incur ongoing expenses for consumables, disposal, and maintenance. |

Applications & Benefits

Laser cleaners have a wide range of applications. These cleaners are used nearly in all industries. A good laser cleaner can efficiently increase the quality of cleaning within the budget. Unlike traditional cleaning techniques, laser cleaners come with several benefits. First, take a look at the industrial applications of these machines.

⇲ Automotive Industry.

⇲ Aerospace Industry.

⇲ Manufacturing Sector.

⇲ Electronics Manufacturing.

⇲ Medical Device Manufacturing.

⇲ Historical Preservation and Restoration.

⇲ Renewable Energy.

Laser cleaners bring benefits to industrial production and environment, such as:

☑ Environmental sustainability.

☑ Non-contact operation.

☑ Precision cleaning.

☑ Cost-effectiveness.

☑ Quality and consistency.

☑ Safety.

Technical Parameters

| Brand | STYLECNC |

| Laser Source | RECI / JPT / RAYCUS / IPG Fiber Laser Generator |

| Laser Type | Pulsed & CW Laser |

| Laser Power | 50W, 100W, 200W, 300W, 500W, 1000W, 1500W, 2000W, 3000W |

| Cleaning Type | Handheld Laser Beam Cleaning Gun |

| Scan Width | 5-100mm |

| Work Temperature | 0~40℃ |

| Cooling Method | Water Cooling |

Features

Today, as environmental protection laws and regulations become more and more stringent, and people's awareness of environmental protection and safety is increasing, laser cleaners can reduce the use of chemical agents and mechanical methods for cleaning. Its high efficiency, environmental protection, and clean features will make it widely used to all walks of life.

⇲ It is non-contact, can be transmitted through optical fiber, and combined with robots or manipulators, it is convenient to realize long-distance operation, and can clean parts that are difficult to reach by traditional methods. It is an excellent cleaning and maintenance tool for ships, aircraft, weapons and automobile.

⇲ In addition to rust removal, it can also clean different types of pollutants on the surface of various materials to achieve a high degree of cleanliness. It is a new application of surface engineering treatment. Pulse laser is more suitable for cleaning and descaling of titanium alloy surface, stainless steel weld bead cleaning, stainless steel welding spot cleaning, surface cleaning of precision parts before and after welding, and flange cleaning. UV lasers are suitable for cleaning large components.

⇲ Through the threshold calculation parameter setting, it can realize no contact, no grinding, no thermal effect, no harm to the human body of the substrate, easy to operate, especially suitable for cleaning molds and cultural relics.

⇲ Rust removal does not require chemical solutions, and there is no environmental pollution problem caused by chemical cleaning. It is a new technology, new process, and new method to replace pickling and phosphating.

⇲ After cleaning, the waste material forms solid powder, which is small in size and easy to handle, and does not cause re-pollution to the environment. It is green and environmentally friendly, and it is the reform and development trend of industrial cleaning.

⇲ Traditional cleaning processes such as pickling and sand blasting are not suitable for cleaning thin plate materials below 30mm because they inevitably cause visible damage to the surface of the substrate, and laser cleaners can show their talents.

⇲ It has strong flexibility and controllability. Through different parameter settings, the same laser beam cleaner can roughen the surface and improve the adhesion. Different powers, frequencies, apertures, and focal lengths can be set by preset effects, so as not to exceed the limits as little as possible, and only clean the required range and intensity to improve efficiency and reduce costs.

⇲ It can effectively clean micron-level pollution particles and realize controllable fine cleaning, which is suitable for cleaning precision instruments and precision parts.

⇲ It can be used stably for a long time, requires no consumables and materials, only needs a small amount of electricity, low maintenance and operating costs, can easily realize automatic operation, and can be used once put into infinite cycles.

⇲ It belongs to physical dry cleaning, which replaces the waste of water resources caused by traditional industrial cleaning, replaces the cleaning liquid and builder required by traditional surface treatment, eliminates ODS ozone-depleting substances, and is low-carbon, water-saving and energy-saving.

User's Guide

Precautions Before Use

⇲ Please ensure that the power socket is in good contact and the ground wire is reliably grounded.

⇲ Check to make sure that there is no dirt on the inside or outside of the cleaning head protection lens.

⇲ Check and make sure that the buttons and switches on the whole machine are in normal state.

Operation Steps

step 1. Take out the external power cord and power up the device.

step 2. Turn on the switch on the power socket (three-in-one socket with power filter, fuse and switch).

step 3. Turn on the green button switch on the machine, the green indicator light will be on after turning on, and the system will be powered on and initialized.

Step 4. After the system is started, adjust the parameters of the machine through the power knob and frequency knob on the machine (can be displayed on the display screen).

Step 5. After the parameter setting is completed, press the enable button on the machine, and the red indicator light of the button will light up after pressing (be sure to confirm that the button switch on the handle of the handheld head is released before pressing the button).

Step 6. Wear eye protection goggles, take out the hand-held cleaning gun inserted in the chassis by hand, aim the gun head at the workpiece to be cleaned, press the orange button on the handle of the hand-held head with your fingers, and the gun head will emit light for cleaning.

Step 7. Two black knobs on the cleaning gun can adjust the cleaning range.

Step 8. After use, turn off the red knob, green button and side power switch of the machine in turn, insert the cleaning gun back into the host storage box, and unplug the power plug.

Pros & Cons

Pros

☑ Integration: It can be used in the production line or independently.

Complex production processes such as "Laser Welding of Differentials" include several sub-steps from induction heating (if required) to welded joints to final workmanship checks. However, cleaning is always performed at the beginning of the process, as the phosphate layer and impurities must be removed from the ring gear and differential housing. The experts at STYLECNC developed this type of machine with similar applications in the field of automotive mass production in mind. Therefore, the machine tool developed can be integrated into the entire production line or used independently as a stand-alone machine. The machine tool is equipped with a rotary table which is independent of the working area for this purpose. It can also be loaded and unloaded during machining using an automatic workpiece conveyor system (or manually), if required, without interrupting machine operation. As an option, two other workpieces can be clamped simultaneously while cleaning two workpieces. The runtime can thus be shortened. There are no waiting times and no interruptions in the flow of workpieces.

☑ Process: ensure high reliability.

The fundamental advantage of this process technology is the use of intensely focused "light" for cleaning. The beam only needs to be switched on for a few seconds for each workpiece to be cleaned. In the production line, it is especially important to precisely position the beam to ensure high process reliability. Alternatively, the cleaning optics of the machine tool can be positioned manually.

☑ Flexible: suitable for a variety of tasks.

Laser machining technology is suitable for a wide variety of materials and for a variety of different tasks. Here, the very short pulse duration plays a very important role. It guarantees the same short interaction times, ensuring minimal surface damage. On the other hand, shorter pulse durations enable higher pulse peak powers. This property can in turn be used to achieve certain desired surface properties, for example higher surface adhesion can be achieved.

☑ Cost: small footprint, short processing time.

Compared with traditional industrial cleaning systems, the unit cost of cleaning with laser is lower. The small footprint of the machine tool is an element of cost reduction. On the other hand, It only requires a few seconds to start up and are virtually maintenance-free.

Cons

It is a new designed cleaning tool in recent years, and its process and ability are relatively insufficiently adapted. In addition, it can hurt your eyes, and the protective glasses must be worn during operation.

Cautions & Warnings

During operation, attention must be paid to maintenance, and the usual attention to maintenance and maintenance can increase the service life of the equipment, save costs and create greater benefits. The following introduces the precautions for the use of laser cleaners.

Today, when environmental protection is advocated, the laser beam cleaning system has the features of non-contact, no thermal effect, and no mechanical force on the surface of the cleaned object. It is widely used in industry, so what should be paid attention to when using?

⇲ Follow the switch sequence of the machine: turn on the water pump (water cooler) first, then turn on the power switch, and then turn on the laser switch. When shutting down, first turn off this switch, then turn off the power switch, and then turn off the water pump (water cooler).

⇲ Regularly clean the chiller once every two weeks, drain the dirty water in the machine, and refill it with new pure water (dirty water will affect the light output effect).

⇲ It is required to clean regularly and quantitatively every day, remove the sundries on the table, limiter and guide rail, and spray lubricating oil on the guide rail.

⇲ The mirror and focusing lens should be scrubbed with special cleaning solution every 6-8 hours. When scrubbing, use a cotton swab or cotton swab dipped in the cleaning solution to scrub from the center of the focusing mirror to the edge in a counterclockwise direction, and be careful to prevent scratches lens.

⇲ Cleaning method of exhaust fan and exhaust pipe: when there is a large amount of smoke during processing, it is necessary to clean the fan, remove the outer cover of the fan, scrape off the dust on the fan blades and the air passage with thin wood chips, and then blow it with a high-pressure gun. Net dust, the method of cleaning the smoke pipe is the same as the method of cleaning the water of the exhaust fan.

During the operation of the laser beam cleaning machine, a large amount of corrosive dust and smoke will be generated during the processing of the workpiece. These smoke and dust are deposited on the surface of the guide rail and the linear axis for a long time, which has a great impact on the processing accuracy of the equipment. , and will form corrosion pits on the surface of the linear shaft of the guide rail, shortening the service life of the equipment. In order to make the machine work normally and stably and ensure the processing quality of the product, it is necessary to do a good job in the daily maintenance of the guide rail and linear axis.