Are you struggling to find a more precise cutting tool for flexible materials? Is the laser cutting machine unable to meet your needs? You're in the right place. We are STYLECNC, and have launched a couple of automatic digital knife cutters suitable for precise cutting of flexible materials. As one of the top brands of CNC digital cutting machines, we're committed to providing our clients with top tier customer service and support. Offering a large scale inventory of digital cutters, cutting plotters, and CNC knife cutting machines at low prices is why our customers continue to stay loyal to us. Flexible materials that can be precisely cut include vinyl, cardboard, fabric, textile, paper, leather, die, stencil, dieboard, foam, plastic, rubber, cork, carpet, felt and flexible polymers to make gaskets, stickers, signs, tags, packaging boxes, display boards, clothing, fashion, sportswear, car interiors, shoes and hats.

You're already here, so we encourage you to review this guide and browse through all of our CNC digital knife cutting machines and quality blades and tools. You can feel free to tell us your requirements and budget. STYLECNC is here to help you find exactly what your business needs, and would send you a free quote with features and costs.

What are you waiting for, let's get started.

What Is Automatic Digital Cutting Machine (CNC Knife Cutter)?

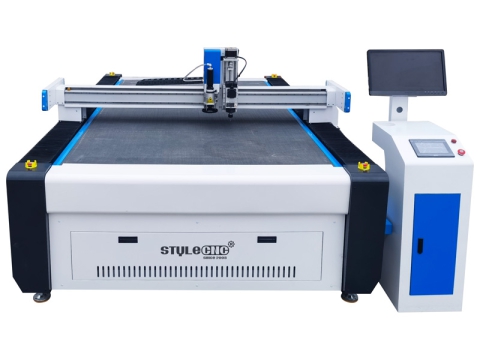

Automatic digital cutting machine (also known as CNC knife cutter) is a type of automated precision cutting system with CNC (Computer Number Controlled) controller which is used for high-precision cuts of heavier flexible and semi-rigid materials. It works with the multi-tool blades consisting of vibration knife, oblique knife, circular knife, punching knife, milling knife, punch roller, or marking pen. CCD camera and projector are optional for more precise cuts.

A automatic digital cutter is also known as digital cutting table, automatic flatbed cutter, cutting plotter, dieless cutter, flash cutter, CNC knife cutter, CNC drag knife, CNC tangential knife, CNC oscillating knife, automatic precision cutter, and CNC blade cutting table.

A drag knife can be assembled on your CNC router or spindle collet to cut fabric, leather and vinyl.

At home, outdoors, on vacation, in the streets, in a car or on an airplane – we are constantly surrounded by products likely to have come off a STYLECNC automatic digital cutter or cutting plotter. From street signs to storefronts, packaging to spacesuits, hot-air balloons to bullet-proof vests, airplane seats to windshields, STYLECNC's automatic digital cutters can cut all of the materials involved with the perfect tool for your project.

How Many Types of Automatic Digital Cutters?

Digital cutting machines are divided into digital gasket cutter, carpet cutter, fabric cutter, leather cutting tool, cardboard cutter, foam cutting system, paper cutter, film cutting tool, vinyl cutter and fiberglass cutting system.

What Are CNC Digital Knife Cutting Machines Used For?

CNC digital knife cutters are used for the cuts of special-shaped graphics made of non-metallic flexible materials. It can quickly complete various processes such as full-cut, half-cut, milling, perforate, crease and mark, solving the problems of special-shaped picture cuts, improving production efficiency, and reducing labor cost. It can reduce the defect rate caused by manual tool errors, help users complete high-quality cuts faster, more stable, and more accurately at low cost, improve user market competitiveness, and seize more market shares. Digital flatbed cutters are used in advertising packaging, clothing and footwear, automotive interiors, luggage, composite materials and other industries.

Graphics Industry

Applications: Outdoor advertising, displays, traffic signs, fleet graphics, exhibits, illuminated signage, store décor, decals, floor graphics, etc.

References: 3M, Airbus, Avery Dennison, Christinger, Fair-play, Fastsigns, Graphics Gallery, Imaba, Lufthansa, netService, PlotFactory, Quarmby Colour Studio, Sin Fung Advertisement, Stylographics, Supersine Duramark, Zebra Graphics, etc.

Packaging Industry

Applications: Printed or unprinted packaging, POP/POS displays, foam inserts, dies making.

References: Beiersdorf, Chesapeake, Edelmann, Hasbro Toys, Heidelberg, International Paper, Long Chen Paper, Mauro Benedetti, Mondi, Packaging Cooperation of America (PCA), Panther Packaging, Philip Morris, sanovi aventis, SCA,Seda, Smurfit Kappa, STI, TetraPack, Thimm Verpackung, Triwall, etc.

Leather Industry

Applications: Shoes, garments, upholstery, handbags, briefcases, car and airplane seats, etc.

References: Adidas, Akris, Bally, Cavallo, Clarks, Ecco, Gabor, Geox, Gucci, Louis Vuitton, Nike, Prada, Puma, Recaro, Rolf Benz, Samsonite, de Sede, Sergio Rossi, Timberland, etc.

Textile Industry

Applications: Garments, upholstery, airbags, flags, sun shades/umbrellas, car and airplane seats, etc.

References: BMW, Diesel, Ford, Hugo Boss, Interstuhl, Jil Sander, Joop, Levi Strauss, Mercedes, Triumph, Volkswagen, Zodiac, etc.

Composite Industry

Applications: Defense, functional textiles, rotor blades for wind wheels and helicopters, aircraft and automotive parts, etc.

References: 3C-Carbon Composite Company, ACE, Airbus, Audi, Bell Helicopter, BMW, Carbo Tech, DLR, Dyneema, Eurocopter, FACC, Ferrari, McLaren, Pilatus, Red Bull Racing, Scuderia Toro Rosso, SGL Group, ThyssenKrupp, etc.

Techtex Industry

Applications: Truck tarpaulin, carpets, awnings, hot-air balloons, sails, outdoor equipment, inflatable boats, etc.

References: Badertscher, Barrisol, Bieri, Daedler, de Sede, Eschenbach Zeltbau, Estrella Betten, Höcker HTS Structures, interstuhl, Kusch+Co, Quelli In Luce, Ruckstuhl, Sachsen Fahnen, W.Schillig, etc.

Specialty Applications

Applications: Adhesives, gaskets and filter materials, PVB film for auto glass, architectural models, foam, wood veneer, floor coverings, film for solar and photovoltaic systems, aluminium foil, watch faces, etc.

References: ABB, Daimler Chrysler, Dell, Ferrari, Herzog & De Meuron, LG Electronics, Pilkington, Porsche, Procter & Gamble, Red Bull F1-Team, Rolex, SaintGobain Sekurit, Samsung Electronics, Swatch, etc.

CNC Digital Knife Cutting Table Advantages

1. High speed with high quality, its cutting speed is 5-8 times faster than laser cutter.

2. Advanced computerized CNC control system, which is easy to operate with ethernet port.

3. Working without air pollution, no burnt edge, uniform in color.

4. It can cut soft materials with perfect edges and corner.

5. It adopts Japan YASKAWA servo motor and drive, fast speed with high precision.

6. It can be equipped with different knife tools & blades to meet a variety of needs.

7. Special safety sensing device meets the European standard.

8. Intelligent tabletop mapping.

9. Automatic tool calibration.

10. Multi-task repeat cutting, intelligent absorption.

Automatic Digital Cutter Features

1. Using vibratory knife cutting technology, save the cost and time of knife manufacturing, management, storage, etc. in the production and development process, bid farewell to the traditional manual knife cutting process, break the traditional mode of relying on workers for production, and take the lead in entering the era of digital mold making .

2. Multi-functional cutting head design, multiple sets of highly integrated processing tools, which can be used as a working unit for interactive cutting, punching and marking operations.

3. Difficulty, complicated patterns, template removal that cannot be achieved by tool molds, substantial expansion of the design space of shoe designers, creation of new models that cannot be copied manually, making templates attractive, making the design truly achievable, and not afraid of not being able to achieve it. field of.

4. For well-functioning emissions, the calculation system performs automatic emissions, accurately calculates, calculates costs, and accurately manages material distribution, and actually realizes a digital zero inventory strategy.

5. Through projector projection or camera shooting, grasp the leather outline and effectively identify leather defects. In addition, according to the natural pattern of the leather, the cutting direction can be adjusted randomly to increase output, reduce loss, and increase the effective utilization of materials.

6. Procedural computer simulation can eliminate the interference of workers' emotions, skills, fatigue and other personal factors on the existing supply, prevent hidden waste, and improve the use of materials.

How To Buy An Automatic Digital Cutter?

1. Consult:

We will recommend the most suitable CNC digital cutting table to you after being informed by your requirements.

2. Quotation:

We will offer you with our detail quotation according to the consulted digital cutting system. You will get the most suitable specifications, the best accessories and the affordable price.

3. Process Evaluation:

Both sides carefully evaluate and discuss all the details (technical parameters, specifications and business terms) of the order to exclude any misunderstanding.

4. Placing Order:

If you have no doubt, we will send you the PI (Proforma Invoice), and then we will sign a contract with you.

5. Production:

We will arrange the digital cutting plotter production as soon as receiving your signed sales contract and deposit. The latest news about production will be updated and informed to the CNC knife cutting machine buyer during the production.

6. Quality Control:

The whole production procedure will be under regular inspection and strict quality control. The complete digital cutter machine will be tested to make sure they can work well before out of factory.

7. Delivery:

We will arrange the delivery as the terms in the contract after the confirmation by the buyer.

8. Custom Clearance:

We will supply and deliver all the necessary shipping documents to the CNC knife cutter buyer and ensure a smooth customs clearance.

9. Support and Service:

We will offer professional technical support and free service by Phone, Email, Skype, WhatsApp, Online Live Chat, Remote Service. We also have door-to-door service in some areas.

How To Choose A CNC Knife Cutter?

High Performance Milling Knife

It adopts high-speed, high-performance, high-precision spindle motor. According to different materials and applications, its speed can reach up to 60,000 rpm, and the cut edge is smoother. It can cut 20mm thick non-metallic hard materials and flexible materials, and its performance is far better than traditional cutter meets the demand for uninterrupted work 24 hours/7 days to maximize material output. Equipped with professional and efficient dust suction device, the whole process has no peculiar smell, no dust, no health impact on employees, and meets environmental protection standards.

1. ABS plastic.

2. PVC foam board.

3. Acrylic board.

4. Aluminum-plastic board.

5. Insulation board.

6. MDF medium density fiberboard.

7. Density board.

High Frequency Vibration Knife

The high-frequency vibration knife cuts through the material through the principle of high-frequency vibration, and is equipped with a variety of amplitude tools for different materials to ensure high-speed, high-efficiency and high-quality production and processing of various non-metallic flexible materials. The blades can be cut at different angles, such as 45° , 26°, 16°, etc. to cut materials of different thicknesses.

1. Corrugated cardboard.

2. Honeycomb board.

3. KT board.

4. Gray cardboard.

5. PVC foam board.

6. Leather.

7. Carpet.

8. Corrugated plastic board.

Multi-Angle Bevel Knife

According to your own different needs, you can adjust the groove lines of different angles, and can cut 0°, 15°, 22.5°, 35°, 45° angles, and the material thickness is ≤16mm.

1. Honeycomb panel.

2. Moderately rigid PVC.

3. Corrugated paper.

4. Grey board paper.

5. Paper jam.

Creasing Knife

The creasing knife creases the material through the creasing wheel, and the perfect creasing effect can be obtained by replacing the creasing wheel with appropriate depth and width. Directional pressure can be used to adjust the indentation or wrinkling. With the software indentation tool, it can forward or reverse the direction of the material to obtain a higher quality indentation effect without damaging the surface paper of the material.

1. Corrugated paper.

2. Gray board paper.

3. PPC.

4. Coated paper.

Round Knife

The circular knife is driven by a DC motor to drive the blade to rotate at a high speed to cut the material. It is equipped with a round blade or a 10-angle blade to cut all kinds of woven materials, which can significantly reduce the drag force and help cut each fiber or thread.

1. Flag cloth.

2. Non-woven fabric.

3. Banner cloth.

4. Textile fabrics.

5. Woven materials.

6. Glass fiber.

7. Aramid fiber.

Drag Knife

Drag knife is suitable to cut various flexible materials ≤5mm.

1. Paper jam.

2. Self-adhesive stickers.

3. Thin plastic.

4. pp adhesive.

5. Chevron board.

6. Blanket.

7. Soft glass.

8. Imitation leather.

Safety Tips

1. When moving the CNC knife cutting table, the moving speed should be correctly selected according to the distance from the workpiece to prevent collisions when moving too fast.

2. When programming, determine the correct processing technology and route according to the actual situation, and prevent the workpiece from being scrapped or cut off in advance due to insufficient processing position or insufficient edge strength.

3. It is necessary to confirm whether the program and compensation amount are correct before thread cutting.

4. When starting the cut, pay attention to observe and judge the processing stability of the CNC knife cutter, and adjust it in time when it is found to be defective.

5. During the processing of the CNC knife cutting machine, the working conditions should be inspected and supervised frequently, and the problems should be dealt with immediately.