So far this automatic milling machine is as good as I expected and serves its purpose in my gunsmith shop to repair, design, modify, or build guns. Sturdy enough with its structure for metal fabrication. If you take the time to learn the CNC controller software, the mill table will be easy to use and provide excellent quality works. In addition, there are some upgrade kits to bring it to the next level. I recommend ST7090-2F for the price and quality.

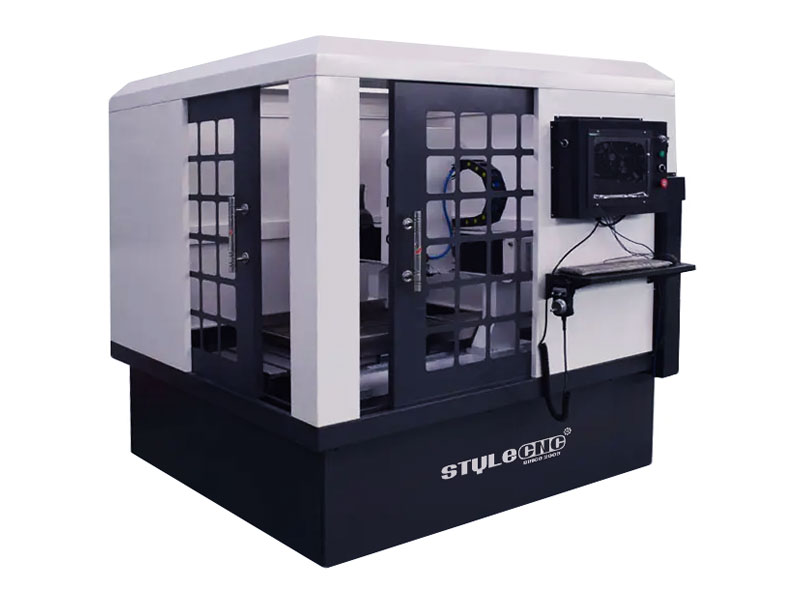

Automatic CNC Milling Machine for Mold Making

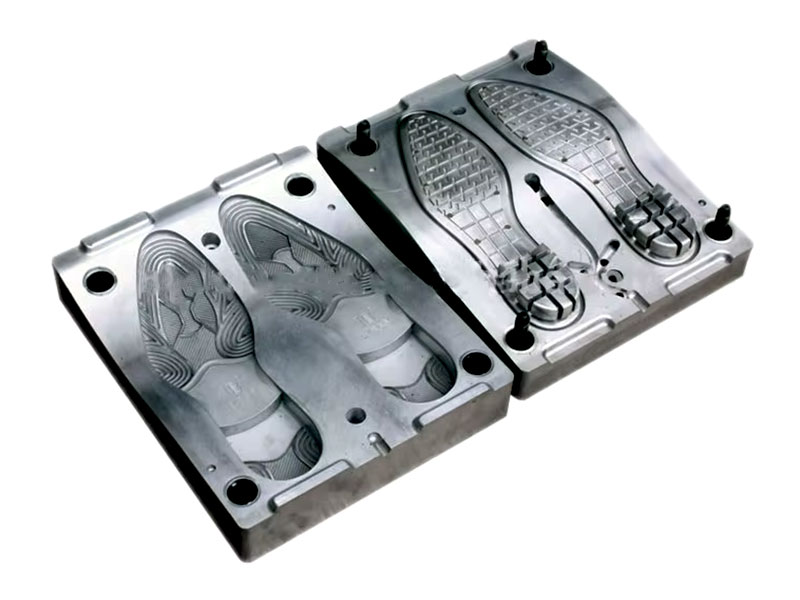

Automatic CNC milling machine is used for mold making and 3D milling works, including metal molds, clock parts, metal electrode, shoe molds, metal arts and crafts, jewelry and other molds making, the CNC mill can make 2D or 3D relief on various materials.

- Brand - STYLECNC

- Model - ST7090-2F

- Maker - Jinan Style Machinery Co., Ltd.

- Table Size - 700mm x 900mm

- 360 Units in Stock Available for Sale Every Month

- Meeting CE Standards in Terms of Quality & Safety

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- 30-Day Money Back Guarantee for Your Purchase

- Free Lifetime Technical Support for End-Users & Dealers

- Online (PayPal, Alibaba) / Offline (T/T, Debit & Credit Cards)

- Global Logistics and International Shipping To Anywhere

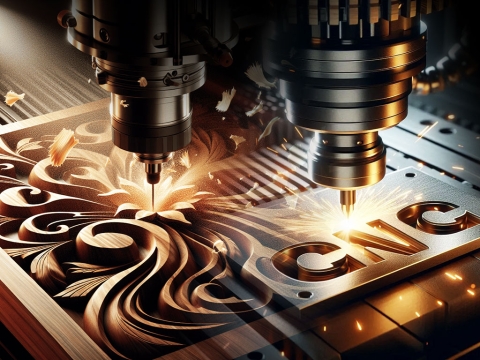

A CNC milling machine is an automatic computer-controlled manufacturing tool, working with programmed instructions, using a milling cutter to remove excess from a workpiece, resulting in precise shapes with high repeatability.

CNC milling machines are extremely popular for precision machining of most materials, including metals, wood, and composites, allowing complex designs and high-tolerance parts to be created with an automated process.

CNC mills are typically used in mold making, prototyping, making parts for aerospace, automotive industries, electronics, medical devices, and custom tooling along with fixtures. What gives them a critical standing within modern manufacturing workflows is that they can perform various functions, including cutting, engraving, tapping, grooving, milling, drilling, tapping, and surface finishing.

Features and Advantages of Automatic CNC Milling Machine for Mold Making

• Quality assurance: we will test the cue with laser interferometer before leaving the factory.

• Enclosed work space can ensure safe and contamination-free work.

• Gantry structure: Whole cast-iron structure, steady structure, high rigidity, precision 0.01mm. The double column is whole part, greatly increase machine rigidity.

• The CNC mill adopts high-speed water cooling variable frequency motor, big torque, strong cutting, high-frequency, long-lifetime, it can do a long time continuous working.

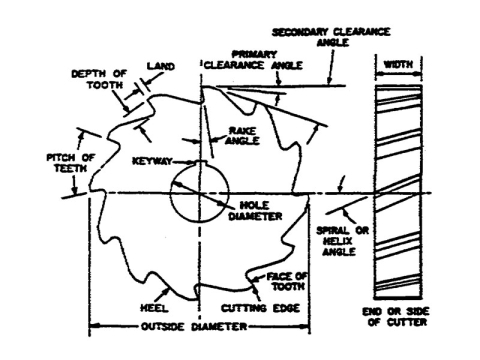

• HIWIN linear guide: it is made in Taiwan, it is used for linear reciprocating stadium.

• Servo motor and drives: it is from Japan with high precision and long life.

• Functional and easy-to-operate control system made by Taiwan SYNTEC with high performance and competitive price.

• All three axis adopt Germany ball screw and Taiwan linear orbits to make sure the accuracy and reposition precision.

• The computer-controlled milling machine adopts table movement to keep stable and high precision.

• Cooling system: Oil circulating oil cooler for spindle, cooling workpieces with water or oil in the tank or atomization liquid through or spray nozzle.

• Stable and rigid structure: With the gantry type bed and table are one, it is not only good rigidity, but also no installation error for both. Processing precision will not be affected even if being used for long time.

• This automaitc mill comes with a fully enclosed design, featuring external circulating cutting oil processing way. The milling table is fully casting with stable structure and great weight-bearing ability.

• The machine is equipped with accurate bidirectional ball screw of famous brand, Taiwan square rail and accurate bearing with strong rigidity and high dynamic accuracy. It also adopts Japan YASKAWA servo motor with high accuracy and high power make amplitude smaller and three-axis more stable.

• The CNC mill is a type of multi-functional CNC machine, which is similar to the ordinary numerical control machine, the CNC milling machine realizes the engraving and milling process automatiically through that the numerical control system controls the milling machine movement according to processing procedure code.

Technical Parameters of Automatic CNC Milling Machine for Mold Making

| Model | ST7090-2F |

| Table Size | 700mm×900mm |

| Working Area | 700mm×900mm×300mm |

| X/Y/Z Axis Movement Accuracy | ±0.01/300mm |

| X/Y/Z Axis Repetition Accuracy | 0.005mm |

| Gantry Width | 820mm |

| Max Loading Weight | 350kg |

| Pressure Deformation of Working Table | <0.02mm (300kg) |

| Spindle Power | 2.2KW (Optional 5.5KW) |

| Tool holder | BT20 (Optional BT30) |

| Spindle rotate speed | 3000-18000rpm |

| Max movement speed | 12m/min |

| Total power | 13.5KW |

| Motor | Yaskawa Servo Motor |

| Power supply | 380V ± 10%50Hz |

CNC Milling Process

Automatic CNC Milling Machine for Mold Making Applications

CNC milling machine is ideal for milling most materials, including copper, aluminum, steel, iron, brass, wood, foam, and plastics. It's typically used for making injection mould, automotive, ironware mould, shoe mold, drop mold, metal molds, clock parts, copper electrodes, zinc electrodes, metal electrodes, metal crafts, metal arts, jewelry, jade, dental crown, and other molding industries. It's designed for batch machining molds, watch, eyeglasses, panel, brand, badge, outside surface's sleeking, three-dimensional graphics and words, It's easy for this milling machine to produce 2D or 3D reliefs on various materials.

Automatic CNC Milling Machine Projects

Maintenance Tips for CNC Milling Machines

CNC milling machine is a high-precision and high-efficiency machining equipment. Regular maintenance is important to keep its accuracy and extend its service life.

1. Dust Cleanup: Use soft cloth and detergent to clean the surface of the engraving and milling machine equipment, keep the appearance of the equipment neat, and prevent dust and debris from entering the equipment.

2. Parts Maintenance: Regularly check the various parts of the engraving and milling machine, including guide rails, transmission systems, spindles, fixtures, etc., to ensure that they operate normally, and find and solve problems in time.

3. Lubrication Maintenance: Lubricate the various parts of the engraving and milling machine according to the requirements of the equipment manual to ensure the friction coefficient and operation efficiency between the parts of the equipment.

4. Temperature Control: Regularly check the working temperature of the engraving and milling machine to avoid excessive temperature affecting the normal operation of the equipment, and deal with abnormal temperature problems in time.

5. Cooling System Maintenance: The cooling system must be used during the engraving and milling process to ensure the heat dissipation of the spindle and tool, reduce tool wear and extend the life of the equipment.

6. Regular Calibration: Calibrate the machine regularly to ensure the processing accuracy and stability of the equipment.

7. Safety Protection: Ensure that the safety protection facilities around the machine are intact to ensure the safety of the operator and avoid accidents.

8. Timely Maintenance: When equipment failure or problems are found, professional maintenance personnel should be contacted in time for repair to avoid the problem from expanding and affecting the normal use of the equipment.

In summary, CNC milling machines require regular maintenance and attention to detail to keep the equipment in good condition and improve its accuracy and efficiency.

Derek Christian

Terry Dunlap

Luca S Shepherd

Protap Kumar Roy

ভাল মেশিন এবং প্যাকিং. দ্রুত পরিবহন। বেশ কয়েক মাস ব্যবহারের পরে, আমি বলতে পারি এটির দামের জন্য এটি সত্যিই একটি ভাল সিএনসি ছাঁচনির্মাণ মেশিন।