I went straight for a CNC lathe, despite having no previous manual turning experience. As a newbie, I was a little nervous at first, but the user-friendly controller made everything very easy to operate, without a hard learning curve, aside from the CAD software. However, this didn't bother me at all, as I already got all the vector files - my brother had created all the drawings for my business. All in all, it met my expectations and didn't let me down. I'm very satisfied with my choice.

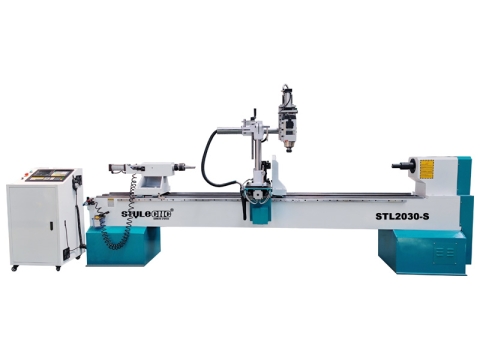

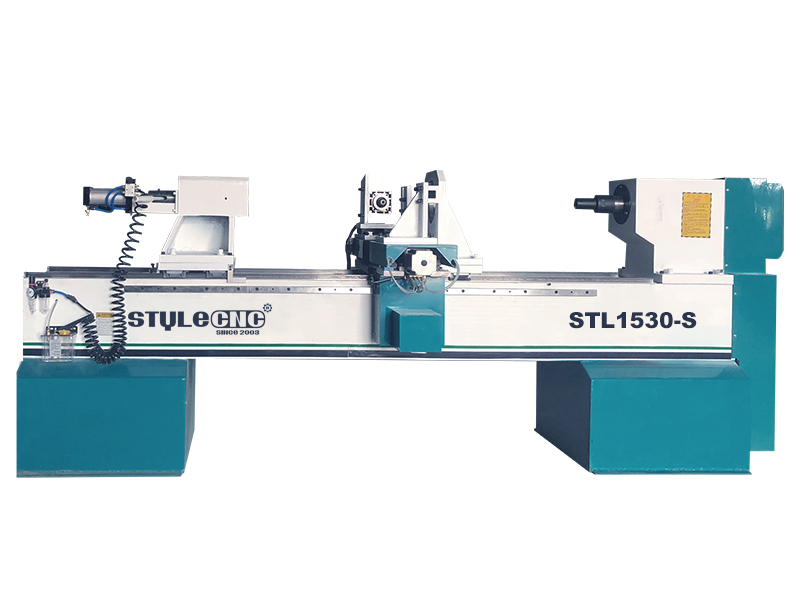

Professional CNC Woodturning Lathe Machine for Every Need

Find the most professional CNC woodworking lathe for every need at STYLECNC. Elevate your fine woodturning projects with STL1530 automatic wood lathe machine.

- Brand - STYLECNC

- Model - STL1530

- Maker - Jinan Style Machinery Co., Ltd.

- Category - CNC Wood Turning Lathe Machine

- 360 Units in Stock Available for Sale Every Month

- Meeting CE Standards in Terms of Quality & Safety

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- 30-Day Money Back Guarantee for Your Purchase

- Free Lifetime Technical Support for End-Users & Dealers

- Online (PayPal, Alibaba) / Offline (T/T, Debit & Credit Cards)

- Global Logistics and International Shipping To Anywhere

A professional CNC woodturning lathe machine is a highly advanced tool designed for shaping and cutting wood with precision. Unlike traditional manual lathes, this machine uses computer numerical control (CNC) technology, allowing for automated, repeatable, and highly accurate woodturning processes. It is widely used in industries that require fine detailing, such as furniture making, woodworking, and custom woodcrafts.

The CNC woodturning lathe operates by using pre-programmed commands to control the movement of the cutting tool along the wood. This makes it ideal for creating intricate shapes, patterns, and designs that would be difficult or impossible to achieve by hand. The machine can handle various types of wood, from softwoods to hardwoods, allowing for a range of applications including spindle turning, bowl turning, and complex carvings.

One of the key advantages of a professional CNC woodturning lathe is its efficiency. It allows for high-speed production while maintaining exceptional accuracy and consistency. No matter if you're working on a single prototype or a batch of products, this machine reduces the time spent on manual labor and ensures high-quality results every time.

Professional CNC Woodturning Lathe Machine Features

• The STL1530 series lathe uses dual blades to turn one piece at a time. Rough turning and finish turning tools work together to improve work efficiency and wood surface turning quality.

• The standard working length is 1.5m, with options of 2m, 2.5m and 3m.

• The overall cast iron bed has undergone high-temperature annealing and vibration to eliminate stress, making it stable and permanent without deformation.

• The STL1530 series lathes come with a user-friendly operating system with a USB interface, which is easy to use and has good compatibility with Coredraw, Artcam, AutoCAD, and other software.

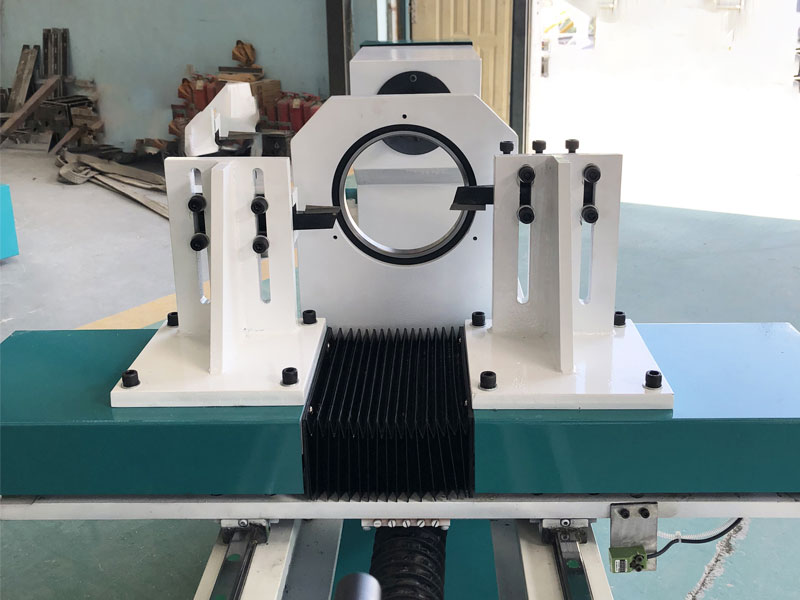

• The STL1530 series lathes are equipped with a Taiwan TBI ball screw and Taiwan Hiwin square guide drive, which has high precision and long life.

• Driven by a high-torque stepper motor, the Yako driver ensures fast work.

• Mature detail processing technology, every detail is strictly processed and inspected to create a perfect lathe machine.

• A perfect after-sales service team helps to handle any unexpected problems and issues in time.

Professional CNC Woodturning Lathe Machine Technical Parameters

| Model | STL1530 | STL1530-S | STL1530-S4 |

|---|---|---|---|

| Working Area | Max length 1500mm | Max diameter 300mm | Max length 1500mm | Max diameter 300mm | Max length 1500mm | Max diameter 300mm |

| Control system | 1000TC | 1000TC | 1000TC |

| Motor Power | 5.5KW asynchronous motor | 4KW Alpha servo motor(380V) | 5.5KW asynchronous motor(220V) | 4KW Alpha servo motor(380V) | 5.5KW asynchronous motor(220V) |

| Motor rotating speed | 0-3000rpm/min | 0-6000rpm/min (380V) | 0-3000rpm/min (220V) | 0-6000rpm/min (380V) | 0-3000rpm/min (220V) |

| Spindle power | NO | 3.5KW air-cooling with 18000rpm | 4 axis 3.5KW air-cooling spindle with 18000rpm |

| Transmission | Taiwan Hiwin square rails, Taiwan TBI ballscrews | Taiwan Hiwin square rails, Taiwan TBI ballscrews | Taiwan Hiwin square rails, Taiwan TBI ballscrews |

| Driver | Yako | Yako | Yako |

| Inverter | Best | Best | Best |

| Working accuracy | ±0.05mm | ±0.05mm | ±0.05mm |

| Working voltage | AC380V/3 phase or 220V/single phase/3 phase | AC380V/3 phase or 220V/single phase/3 phase | AC380V/3 phase or 220V/single phase/3 phase |

| Overall dimensions | 3100*1500*1500mm | 3100*1550*1500mm | 3100*1550*1700mm |

| Weight | 1600kgs | 1650kgs | 1700kgs |

| Main functions | Lathing | Lathing, grooving, drilling, milling, column carving | Lathing, grooving, drilling, milling, column carving, 3D carving |

| Optional | Sanding, Automatic tool changer, Chuck, DSP controller | Sanding, Automatic tool changer, Chuck, DSP controller | Sanding, Automatic tool changer, Chuck, DSP controller |

| Customized | Length: 2000mm, 2500mm, 3000mm | Diameter: 400mm, 500mm | Length: 2000mm, 2500mm, 3000mm | Diameter: 400mm, 500mm | Length: 2000mm, 2500mm, 3000mm | Diameter: 400mm, 500mm |

Professional CNC Wood Lathe Machine Features

Self-developed CNC controller for the automatic wood lathe.

The CNC wood lathe with double blades for lathing one piece every time.

How a Professional CNC Woodturning Lathe Can Improve Your Woodworking

A professional CNC woodturning lathe can revolutionize your woodworking process by offering unmatched precision, efficiency, and versatility. Whether you're a hobbyist or a seasoned professional, incorporating CNC technology into your workshop can significantly enhance your results and streamline production. Here's how it can improve your woodworking.

Enhanced Precision and Accuracy

With CNC control, the woodturning lathe delivers precise cuts every time, reducing the risk of human error. The machine follows exact measurements and commands, ensuring perfect symmetry, tight tolerances, and flawless designs. This is particularly important when working with intricate patterns or delicate details, giving you a level of accuracy that manual methods can't match.

Increased Efficiency and Speed

A CNC woodturning lathe automates much of the woodworking process, enabling faster production times. While a manual lathe requires constant supervision, a CNC machine can run autonomously once programmed, allowing you to focus on other tasks or simply streamline workflows. This is ideal for businesses or workshops with high-volume production needs, saving time and boosting overall efficiency.

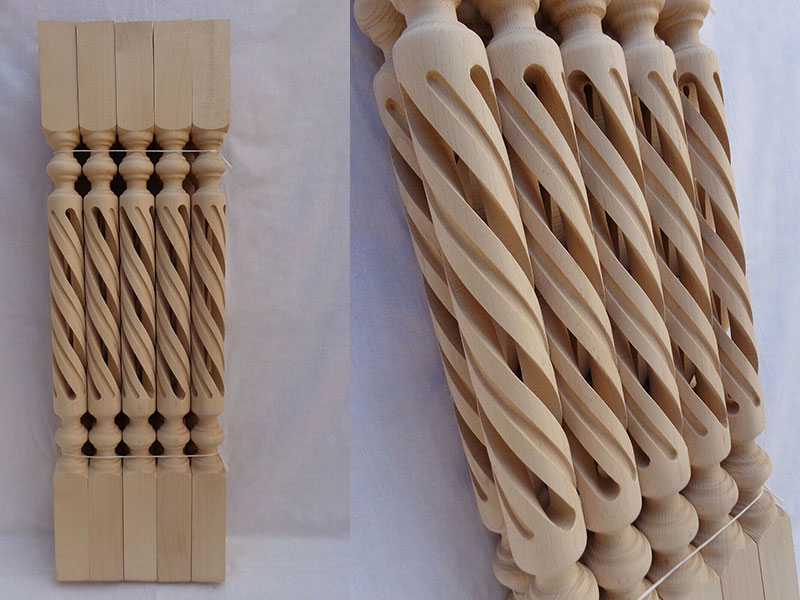

Versatility for Complex Designs

Unlike manual lathes, CNC woodturning machines are capable of executing complex and varied designs with ease. From curved spindles to intricate bowl shapes or 3D carvings, the CNC lathe offers the flexibility to work on a wide range of projects. It can handle more detailed and varied tasks than traditional methods, offering creative freedom for custom work.

Consistency Across Multiple Projects

Whether you're working on a single piece or a large batch, the CNC woodturning lathe ensures consistency. It can reproduce identical pieces with perfect accuracy, making it easy to produce duplicates of your designs. This consistency is crucial for businesses that need to deliver high-quality products at scale, maintaining the same level of craftsmanship throughout production.

Reduced Material Waste

CNC woodturning lathes use precise measurements to minimize material waste. Unlike manual turning, where slight errors can result in wasted wood, a CNC lathe maximizes material usage. The accuracy of each cut ensures that minimal waste is generated, which is both cost-effective and environmentally friendly.

Professional CNC Wood Turning Lathe Machine Applications

The professional CNC woodturning lathe machine is a versatile and precise tool, designed for a wide range of woodworking projects. Its ability to automate the turning process allows for intricate and consistent results, making it perfect for both fine and high-volume production. Here are some key applications where this machine excels:

Cylindrical Workpieces

The CNC woodturning lathe excels in creating cylindrical shapes with high precision. Whether you're making wooden rods, poles, or any other cylindrical item, this machine ensures smooth and accurate cuts. It's perfect for large-scale production where uniformity and consistency are crucial.

Roman and Staircase Columns

One of the standout applications of a professional CNC woodturning lathe is its ability to craft intricate Roman columns and staircase posts. These designs often require a delicate touch and exact measurements, both of which are easily achieved with automated CNC technology. The machine can replicate complex patterns while maintaining precision, even for large volumes of production.

Furniture Components

CNC woodturning lathes are a game-changer in furniture manufacturing, particularly when it comes to components like table legs, chair legs, and washstands. The machine can handle detailed shaping, ensuring uniformity across multiple pieces, making it ideal for high-volume production or custom, one-off designs.

Children's Bed and Vehicle Wood Crafts

For projects like children's bed columns or wooden vehicle parts, CNC wood lathes provide the safety and precision required. These machines allow for creative and complex shapes while maintaining strength and durability, crucial for items like cribs, car interiors, and other wooden crafts that need to meet high safety standards.

Decorative Items

From vases to baseball bats, the CNC lathe is perfect for producing decorative wooden items. The automation ensures that even the most detailed designs can be replicated with ease, making it a versatile tool for both functional and artistic wood projects.

STL1530 only for lathing.

STL1530-S with 3.5KW spindle for lathing, carving, and grooving.

STL1530-S4 with 4-axis CNC router system for 3D carving.

Different Projects by Professional CNC Wood Turning Lathe Machine.

Professional CNC Woodworking Lathe Machine Package

Sturdy crate avoids the sea shipping damage.

How to Troubleshoot Common Issues with CNC Woodturning Lathes

CNC woodturning lathes are powerful tools, but like any machinery, they can encounter issues from time to time. Troubleshooting these problems quickly ensures your projects stay on track. Here's a guide to help you identify and fix some common problems with your CNC woodturning lathe.

• Inaccurate Cuts or Dimensional Errors: If your cuts are off or your pieces aren't the correct size, check the machine's calibration. Ensure the tool offsets and zero points are properly set. Sometimes, a slight misalignment or worn-out tools can cause inaccuracies. Recalibrate and check your tool's condition.

• Excessive Vibration or Noise: Vibration or strange noises during operation can be caused by loose parts or improperly balanced workpieces. Inspect the machine for any loose bolts, screws, or damaged components. Ensure the workpiece is securely clamped and that the spindle is properly aligned.

• Software or Program Errors: If your CNC lathe isn't following the programmed path, there may be an issue with the software. Double-check your code for errors, ensure it's compatible with the machine, and verify that your machine's firmware is up to date. Restart the machine and try running a test program.

• Tool Wear or Breakage: Dull or broken tools can cause poor surface finish or irregular cuts. Regularly inspect your tools for wear, and replace them as needed. Proper maintenance of your cutting tools will prevent damage to the workpiece and ensure smooth operation.

• Overheating: If the CNC lathe is overheating, it may be due to inadequate cooling or ventilation. Make sure the cooling system is working properly, and ensure there is sufficient airflow around the machine to keep it cool during operation.

Rymfred

Friedrich

I bought this lathe for my son as a Christmas gift with a great price. It performs good quality and easy to use. All the parts are tight and balanced. He is a beginner at this automatic lathe with CNC controller. With the instruction manual and YouTube video tutorials from STYLECNC, he is able to use it with no experience at all. It produces good smooth work in almost all types of woodturning cuts. He loves it and is having so much fun.

Juan Allman

I have owned this lathe machine for a few months, and it works really well. I upgraded from a smaller one. Turned some small woodworking projects of bowls and vases, and now working on table legs that will take advantage of the larger swing. This is a great automated lathe for woodworking and worth the money. It has a CNC controller for automatically turning without a manual. All in all an excellent CNC lathe for beginners.

Hilliard

The lathe works very smoothly and has way enough power. This lathe is outstanding for bowls, vases and baseball bats, etc. It is very accurate, smooth and quiet. I can hold a conversation while using this lathe. The warranty and the brand influenced my choice as well. All in all, I am very satisfied with this tool. I've been turning wood since middle school and this is the best lathe I've had the privilege to own and operate. Outstanding little lathe! You won't be sorry to buy this!