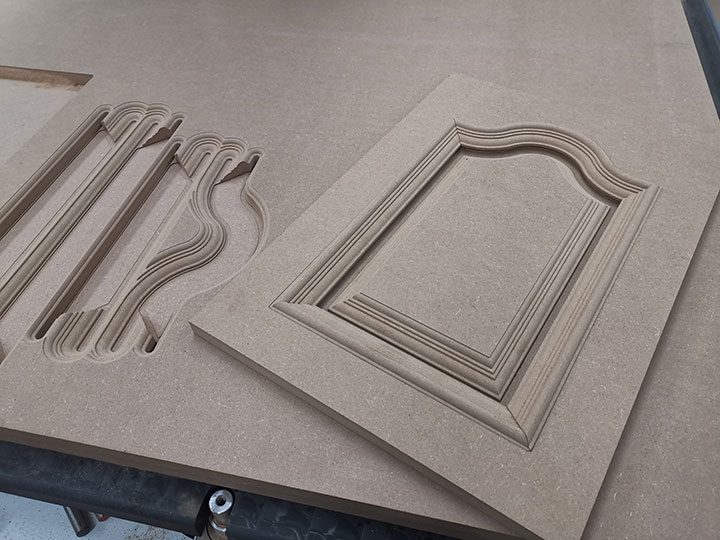

I have never used any power tool like this unit. I did a lot of research and like you have come to this CNC machining center. I had low expectations, but this kit was easy to use and has run a couple of months trouble-free. From the tool changer to the extra rotary axis, all works with automation. A great machine tool to make cabinet doors and home decorations. I would recommend this product to anyone looking to upgrade your woodshop.

Pros:

The software that comes with it is fine and free with a package that can give you good control over cutting parameters and strategies.

Cons:

Figure out how to handle dust because you will be making a lot of it. In addition, the large workbench will take up too much space.

5x10 CNC Wood Machining Center with 4th Rotary Axis on Sale

5x10 CNC wood machining center with 4th rotary axis is designed for 2D/3D popular woodworking, including wood furniture, wood cabinets, wood doors, wood decorations, stair spindles, wood balusters, roman columns, table legs, baseball bats. Now the best CNC wood machining center for sale at affordable price.

- Brand - STYLECNC

- Model - STM1530D-R1

- Maker - Jinan Style Machinery Co., Ltd.

- Table Size - 5' x 10' (60" x 120", 1500mm x 3000mm)

- 360 Units in Stock Available for Sale Every Month

- Meeting CE Standards in Terms of Quality & Safety

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- 30-Day Money Back Guarantee for Your Purchase

- Free Lifetime Technical Support for End-Users & Dealers

- Online (PayPal, Alibaba) / Offline (T/T, Debit & Credit Cards)

- Global Logistics and International Shipping To Anywhere

Advantages of 5x10 CNC Wood Machining Center

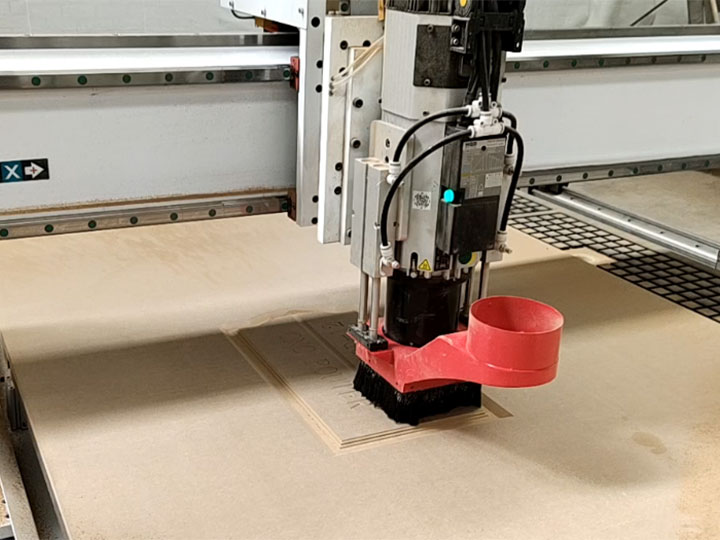

1. Italian HSD 9.0 kw Air cooling spindle: Well-known brands ,long working life, low noise, strong cutting ability to ensure the long time working,easier to change bearing.

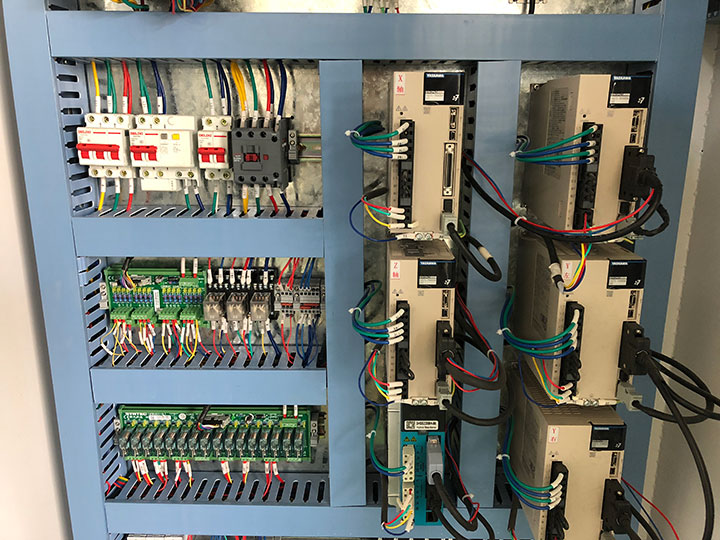

2. Japan YASKAWA servo motor and driver: High-performance drive motor to ensure that the machines high speed and accuracy.

3. Taiwan Syntec control system: Specified for carousel ATC CNC Router, linear ATC CNC router and other high configuration CNC machine.

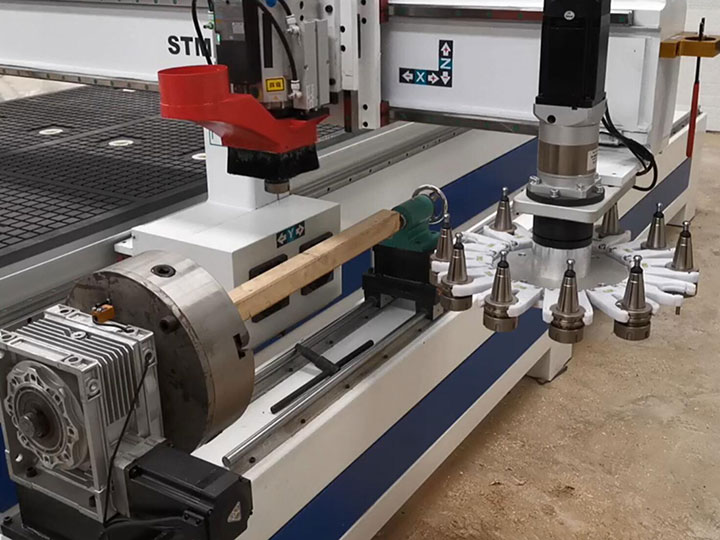

4. New type 8pcs carousel tool changer, can hold more tools, save more time.

5. Double layer compact table:strong,durable and easy meets different uses.

6. New technology Delta inverter, guarantees the high working speed and accuracy, and can realize milling with high speed,high rotating precision,good rotating with low noise. It engraves without any ripple but with smooth bottom level and clear outline.

7. 4th axis rotary can process cylinder materials.

Applications of 5x10 CNC Wood Machining Center

1. Woodworking industry: Three dimensional wave plate processing,cupboard doors, wooden doors, window processing, video game cabinets and panels, computer table and furniture auxiliary processing.

2. Advertising industry: Advertising signs, logo production, acrylic cutting, plastic molding, a variety of materials advertising decorative products production.

3. Die Industry: You can engrave copper, aluminum, iron and other metal molds, and artificial marble, sand, plastic plates, PVC pipe, wood and other non-metallic mold.

4. Other industries: You can carve all kinds of large relief, shadow carving, widely used in craft gift industry.

Technical Parameters of 5x10 CNC Wood Machining Center

| Model | STM1530D-R1 |

| Working Area | 1500x3000x200mm |

| Traveling Positioning Accuracy | ±0.03/300mm |

| Reposition Accuracy | ±0.03mm |

| Table Surface | Vacuum table with vacuum pump |

| Frame | Welded Structure |

| X, Y Structure | Rack and Pinion Drive, Hiwin Rail Linear Bearings |

| Z Structure | Hiwin Rail Linear Bearings and Ball Screw |

| Max Power Consumption | 3.0KW (Without Spindle) |

| Max Rapid Travel Rate | 33000mm/min |

| Max Working Speed | 25000mm/min |

| Spindle Power | Italian HSD 9.0KW Spindle |

| Spindle Speed | 0-24000RPM |

| Drive Motors | Yaskawa servo System |

| Working Voltage | AC380V/50/60Hz, 3PH (Option: 220V)) |

| Command Language | G Code |

| Operating System | Taiwan Syntec control system |

| Computer Interface | USB |

| Flash Memory | 128M(U Disk) |

| Collet | ER25 |

| X,Y Resolution | <0.03mm |

| Software Compatibility | Type3/UcancameV9 Software, (Option: Artcam Software) |

| Running Environment Temperature | 0 - 45 Centigrade |

| Relative Humidity | 30% - 75% |

| Rotary device | 300mm diameter, 3000 length |

Details of 5x10 CNC Wood Machining Center

CNC wood machining center with 4 axis rotary in factory

Italian 9KW HSD spindle

Delta inverter

Japan YASKAWA servo driver

Taiwan Syntec control system

4th rotary axis

Projects of 5x10 CNC Wood Machining Center