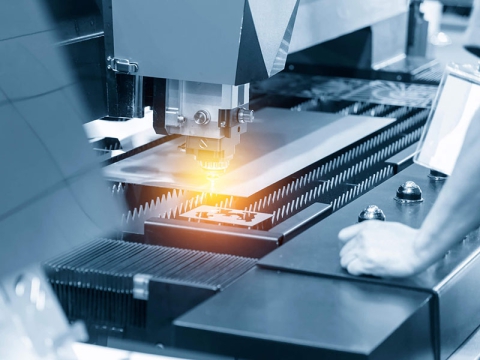

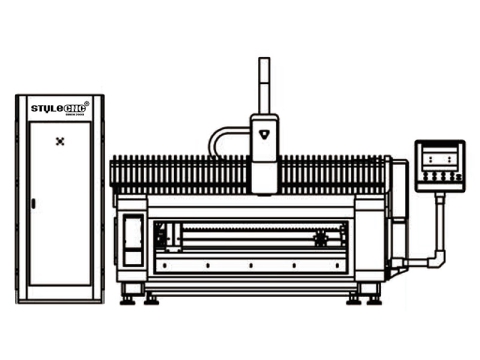

What Is A Fiber Laser Cutter?

A fiber laser cutter is an automatic laser metal cutting machine with CNC controller used to cut out precise metal shapes, contours, lines and prototypes on sheet metals, pipes and profiles at high speed to create metal parts, signs, arts, crafts, gifts, puzzles and decorations. It is designed for all types of metal fabrication, as well as your good metal working partner. It comes with various laser power options(1500 watts, 2000 watts, 3000 watts, 4000 watts, 6000 watts, 8000 watts, 10000 watts, 12000 watts, 15000 watts, 20000 watts, 30000 watts, 40000 watts, 60000 watts) for cutting through different thicknesses and types of metal including carbon steel, stainless steel, electrical steel, tool steel, galvanized steel, mild steel, aluminum zinc, aluminum alloy, aluminum, titanium alloy, iron, brass and copper.

How Fiber Laser Cutters Improve Manufacturing Efficiency?

With faster cutting speed, higher precision and less maintenance, these machines deliver better manufacturing support compared to other traditional cutting tools. That means within a short time, you will be able to increase your production capability. That means as a business owner, you are saving your costs when you have such a tool in your repertoire.

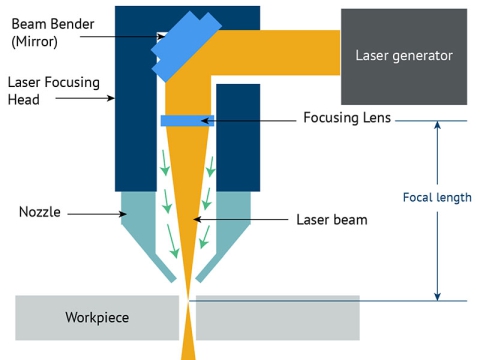

Fiber laser is a type of high-energy beam based on a fiber amplifier that uses glass fiber doped with rare earth ions as the gain medium. The pump light irradiates the rare-earth-doped glass fiber pump source, which induces the rare-earth ions to absorb photons, and the excited radiation has the same frequency as the incident photons. Under the action of pump light, it is easy to form high power density in the fiber, which results population inversion of the laser working substance. When a positive feedback loop (constituting a resonant cavity) is properly added, the laser oscillation output can be formed. These laser cutters have a wide range of applications, including material processing, communications, medical beauty, scientific research and military, instrumentation and sensors. It has been used for cutting, engraving, etching, marking, welding, surface treatment, cleaning, cladding, and some other applications.

The pump light entering the fiber has multiple modes, and different pump modes have different effects on different signal modes, making the analysis of laser generators and amplifiers more complicated. The doping profile in the fiber also has a great influence on the laser generator. In order to make the medium have gain features, the fiber is doped with working ions (i.e. impurities). The working ions are uniformly distributed, whereas the distribution of the pump light is non-uniform. Therefore, to improve the pumping efficiency, the ion distribution and the pumping energy distribution should be as close as possible.

Fiber laser generators are similar to traditional gas and solid laser generators, which are composed of pump sources, resonators, gain media. The pump light is coupled into the gain fiber through the optical system, and the gain fiber generates spontaneous emission after absorbing the pump light, and outputs stable beam.

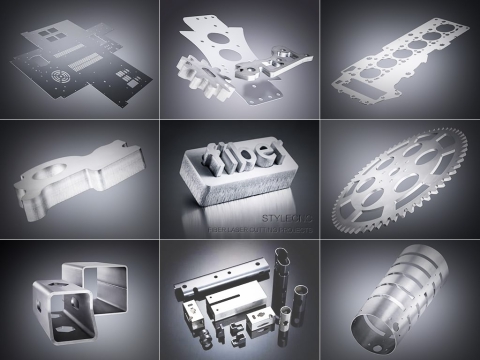

What Are Fiber Laser Cutting Machines Used For?

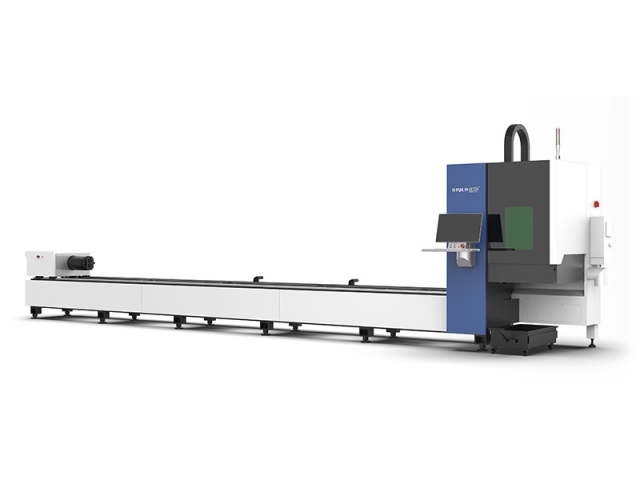

A fiber laser metal cutting machine is an automatic smart cutting tool kit with computer numerical controlled system to cut through metal sheets, tubes and profiles made of stainless steel, mild steel, carbon steel, galvanized steel, tool steel, brass, copper, iron, gold, silver, titanium and aluminum. It is professional to cut out any profile on high-precision auto parts, ship fittings, aircraft accessories, and ideal for cutting out any shape on kitchen utensils, lighting, jewelry, decorations, signs, as well as a good helper for personalized metal fabrication business.

Applied Industries

Fiber lasers are used in electronics, automobiles, aviation, aerospace, auto parts, subway parts, electrical appliances, textile machinery, precision accessories, engineering machinery, food machinery, ship building, household appliances, metallurgical equipment, tool machining, elevators, metal arts, metal crafts, metal gifts, metal decorations, advertising, kitchenware, metal external machining, and some other manufacturing industries.

Applicable Materials

Fiber lasers can cut through carbon steel, stainless steel, silicon steel, alloy steel, spring steel, mild steel, aluminum, galvanized steel, tool steel, aluminized zinc plate, copper, brass, pickling sheet, titanium, silver, gold, iron, alloy, and other metal sheets and tubes.

How Does A Fiber Laser Cut Through Metal?

A fiber laser cutter uses a generator with the CNC control system to dope the pump material into the optical fiber, and the laser of a specific wavelength emitted by the semiconductor laser is coupled to make the optical fiber generate beam. Then, the machine converges the beam into a small diameter spot to form a beam of high energy density and extremely bright light, which acts on the metal to be cut, which causes the temperature of the metal at the irradiation point to be sharp it rises and reaches the vaporization temperature instantaneously, causing evaporation and forming holes. And the machine uses this as the starting point, according to the shape requirements of the part to be cut, the beam and the part are moved relative to each other according to a certain trajectory to form a slit. At the same time, the auxiliary gas blowing device is used to remove the slag.

How Thick And Fast Can A Fiber Laser Cut Metal?

Speed & Thickness

How thick of metal can a fiber laser cut through? What is the maximum speed? A fiber laser cutter comes with the ability to cut various thicknesses of different types of metals and alloys, working with gases such as oxygen, nitrogen or air to get clean and smooth cuts. Every brand of laser generator features with its own unique pros and cons to cut metals. In the case of the same generator, different powers will result in different maximum metal cutting thicknesses and speeds. Laser generators from different brands also vary in the accuracy and quality of their cuts. In comparison, the precision of IPG fiber laser is better than that of Raycus, MAX and RECI, and the speed is faster, but the price is also higher.

Find Your Cutting Parameters

• The entry-level 1500W low-power lasers are appropriate to cutting stainless steel up to 6mm, carbon steel up to 16mm thick, aluminum and copper up to 5mm thick, at maximum speeds in excess of 35m/min.

• The 2000W laser powers have the ability to cut carbon steel up to 16mm thick, maximum 8mm stainless steel and aluminum, and maximum 6mm brass and copper at speeds of up to 40m/min.

• The most popular 3000W lasers have great applicability for cutting carbon steel up to 20mm thick, stainless steel and aluminum up to 10mm, brass and copper up to 8mm at maximum speeds of over 45m/min.

• The professional 4000W mid-power lasers have the power to cut stainless steel up to 12mm, carbon steel up to 22mm thick, aluminum up to 14mm, copper and brass up to 10mm at speeds of up to 50m/min.

• The commercial 6000W medium-power lasers can release enough heat energy to cut carbon steel up to 25mm thick, stainless steel and aluminum up to 16mm, copper and brass up to 10mm at max speeds in excess of 60m/min.

• The industrial 8000W high-power lasers are capable of cutting stainless steel and aluminum up to 25mm, carbon steel up to 30mm thick, brass and copper up to 12mm at speeds of up to 70m/min.

• The 12000W hi-power laser cutters are ideal for cutting carbon steel, stainless steel and aluminum up to 50mm thick, copper and brass up to 20mm thick at maximum speeds of more than 80m/min.

• The 15000W power supplies are applicable for carbon steel and stainless steel up to 60mm thick, maximum 50mm aluminum, and maximum 30mm copper and brass at max speeds in excess of 90m/min.

• The 20000W high power lasers can easily cut carbon steel up to 70mm thick, maximum 80mm stainless steel, maximum 80mm aluminum, maximum 70mm brass and copper at maximum speeds in excess of 100m/min.

• The 30000W extra-high power lasers precise cutting stainless steel thickness ranges up to 100+ millimeters, and maximum 80mm thick carbon steel, aluminum, brass and copper at max speeds of over 110m/min.

• The 40000W ultra-high power lasers are usually used for precise cutting carbon steel, stainless steel, aluminum, brass and copper up to 120+ millimeters thick at speeds of up to 120m/min.

• The most powerful 60000W laser cutters are typically used to cut carbon steels and stainless steels with thicknesses ranging from 16mm to 200mm at speeds from 0.05m/min to 15m/min.

NOTE: The 1000W laser power option is discontinued and no longer available, replaced by free upgrade to 1500W.

Fiber Laser Cutter Machine Specifications

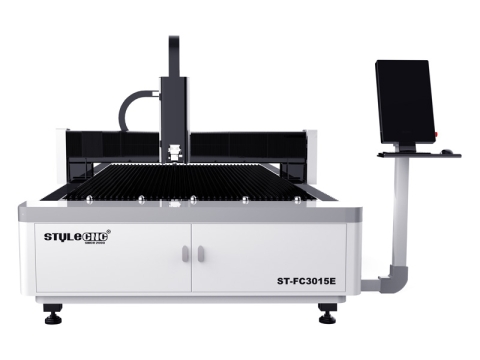

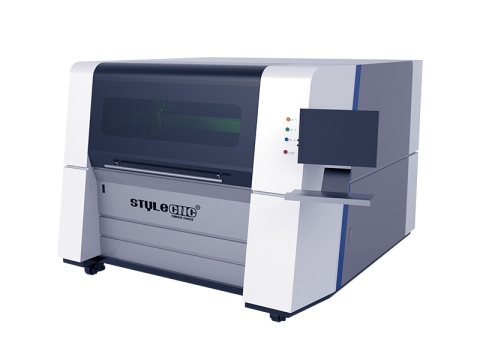

| Brand | STYLECNC |

| Laser Type | Fiber |

| Laser Source | Raycus, IPG, MAX, RECI |

| Laser Power | 1500W, 2000W, 3000W, 4000W, 6000W, 8000W, 10000W, 12000W, 15000W, 20000W, 30000W, 40000W, 60000W |

| Laser Wavelength | 1064 nm |

| Cooling System | Water Chiller |

| Max Cutting Thickness | 200mm |

| Max Cutting Speed | 120m/min |

| Price Range | $11,500 - $1000,000 |

| Applications | Sheet Metal & Tube Fabrication |

| Cutting Materials | Mild Steel, Carbon Steel, Tool Steel, Stainless Steel, Galvanized Steel, Silicon Steel, Spring Steel, Aluminum, Zinc, Copper, Brass, Magnesium, Titanium, Silver, Gold, Iron, Alloy |

How Much Does A Fiber Laser Cutter Cost?

When you wonder how much a fiber laser is worth, you'll need to factor in the costs of its power, table size, brand, and features. From low-end hobbyist models to high-end industrial models, you'll have to spend anywhere from $12,000 to $1,000,000. To make sure you can comfortably afford the cost, make sure you account for the following when budgeting for a fiber laser cutting machine you want:

• Hardware costs vary by brand and manufacturer, both in terms of raw materials and manufacturing processes, where hardware includes CNC spare parts and accessories such as machine bed frame, generator, cutting head, water chiller, gas cylinder, air storage tank, power supply, air compressor, cooling dryer, filter, exhaust fan and dust remover, and slag extractor.

• CNC control systems and laser cutting software vary in cost.

• After-sales service and support charges vary by dealer.

• Maintenance and care costs.

• Operational expenses.

• Additional costs.

If you're purchasing from outside your home country, you also need to consider the following factors:

• Shipping costs.

• Import taxes and duties.

Here's what you need to know about all the costs of owning a fiber laser cutting machine:

The average price of a brand-new fiber laser cutter in 2025 is around $32,600, 18% lower than the 2024 average of $39,800, according to data from Amazon, Google, and STYLECNC.

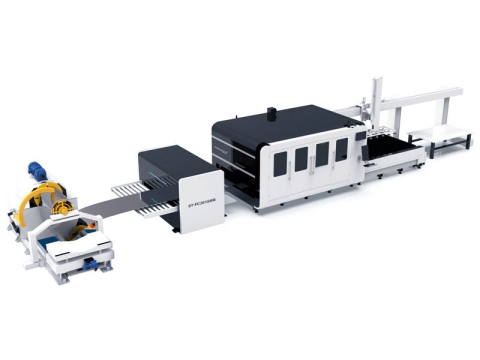

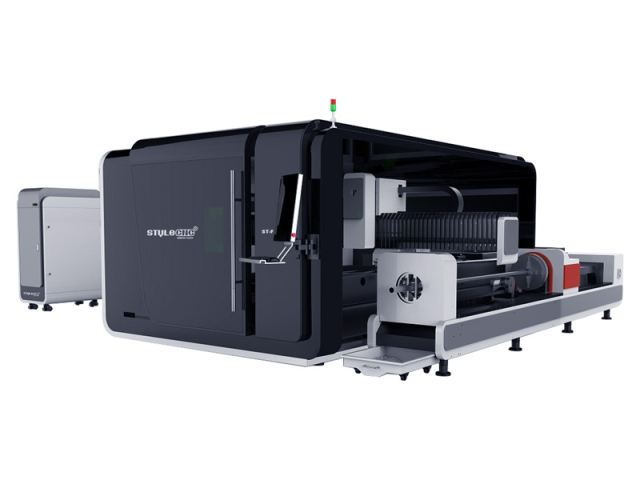

An affordable entry-level fiber laser cutter costs anywhere from $14,200 to $32,800 with lower powers of 1500W and 2000W for beginners with hobbyists, while a professional automatic fiber laser cutting system starts at around $29,800 with medium powers of 3000W, 4000W, and 6000W for precision cutting in in commercial use. An industrial CNC fiber laser cutting machine is priced from $88,000 to $500,000+ with higher powers of 8000W, 10000W, 12000W, 15000W, 20000W, 30000W, 40000W, 60000W for thicker metal fabrication in enterprise use. The best budget fiber & CO2 combo laser cutting tables range from $19,800 for multipurpose to cut metal, wood, MDF, plywood, acrylic, plastic, fabric, and leather.

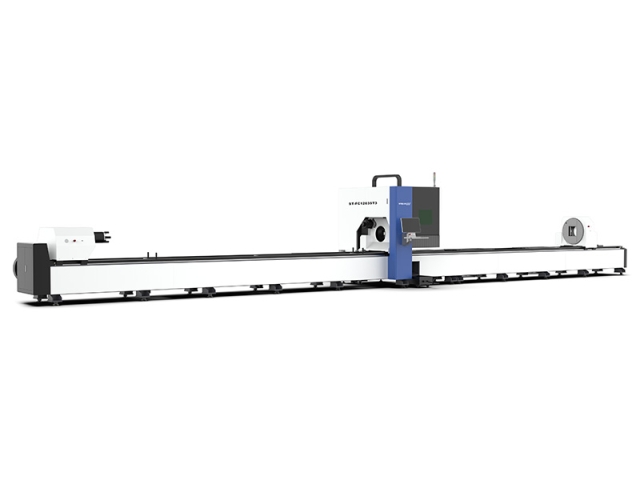

A low-cost fiber laser sheet metal cutter starts at $15,000, while some high-power IPG fiber laser sheet metal cutting machines can go up to $300,000+. A fiber laser tube cutter is priced from $45,500 to $117,500 for all types of pipe cuts. An all-in-one sheet metal and tube fiber laser cutting machine cost from $42,500 to $236,800. An automtic industrial 3D cutting robot ranges from $49,000 to $83,500 for multi-dimensional and multi-angle metal cuts.

Pick Up Your Budget

| Laser Powers | Minimum Price | Maximum Price | Average Price |

|---|---|---|---|

| 1500W | $13,000 | $34,000 | $17,210 |

| 2000W | $15,000 | $42,000 | $21,320 |

| 3000W | $20,000 | $60,000 | $26,010 |

| 4000W | $36,000 | $70,000 | $45,300 |

| 6000W | $37,000 | $80,000 | $50,100 |

| 12000W | $85,000 | $190,000 | $112,600 |

| 20000W | $120,000 | $300,000 | $165,100 |

| 30000W | $200,000 | $400,000 | $252,300 |

| 40000W | $320,000 | $600,000 | $391,800 |

| 60000W | $500,000 | $1000,000 | $721,900 |

Features

• Higher electro-optical conversion efficiency, which is more than 30%. The low-power laser machine has no need of a chiller. The air cooling will greatly save power consumption during operation, save labor costs, and achieve the highest manufacturing efficiency.

• Only requires electrical energy during operation without additional gas, which has the lowest operation and maintenance costs.

• Semiconductor modular and redundant design. There is no optical lens in the resonant cavity, no start-up time, and it has the advantages of no adjustment, maintenance, and high stability. It reduces the cost of accessories and maintenance time.

• The wavelength is 1.064 microns, which makes the beam with high quality and high power density. It is very conducive to the absorption of metal materials.

• The optical transmission of the whole machine is through optical fiber, no complicated light guide system such as reflecting mirror is needed, the optical path is simple, the structure is stable, and the external optical path is maintenance-free.

• The cutting head contains a protective lens, which makes the consumption of expensive consumables such as focusing lenses extremely small.

• They simplify the design of mechanical systems that can be easily integrated with multidimensional platforms or industrial robots.

• After the laser is added with the optical shutter, it can be multi-machine, split through the optical fiber, divided into multiple channels and work simultaneously, easy to expand the function, easy and simple to upgrade.

Pros & Cons

Pros

It is a new type of laser cutting technology in the world that outputs a high-energy density beam and gathers it on the surface of the part to instantly melt and vaporize the area on the part irradiated by the ultra-fine focus spot and move the spot through the CNC controller. Irradiate the position to realize automatic cutting. Compared with the bulky gas and solid laser, it has obvious advantages. It has gradually developed into an important candidate in the fields of high-precision cutting, lidar systems, space technology, medicine and other applications.

It can be used for flatbed cutting and bevel cutting, and the edges are neat and smooth. It is suitable for precision cutting of sheet metals. In addition, the robotic arm can do 3D cutting instead of the 5 axis laser cutter. Compared with CO2 laser cutters, these cutters will save space and gas consumption, and has a high photoelectric conversion rate. It is a new power tool of energy saving and environmental protection, and it is also one of the world's leading technological CNC machine tools.

• High accuracy: The positioning accuracy is 0.05mm, and the repeated positioning accuracy is 0.03mm.

• Narrow slit: The beam is focused into a small spot, so that the focus reaches a high power density, the material is rapidly heated to the point of vaporization, and the holes are vaporized. With the relative linear motion of the light beam and the material, the hole continuously forms a narrow slit, and the width of the slit is generally 0.10-0.20mm.

• Smooth cutting edge: There is no burr on the cutting edge, and the roughness of the cutting surface is generally controlled within Ra6.5.

• High speed: The cutting speed can reach 10m/min, and the maximum positioning speed can reach 30m/min, which is much faster than other metal cutting tools.

• High quality: It is a non-contact cutting, which endures little thermal influence, the part basically has no thermal deformation, and completely avoids the slump formed when the material is punched and sheared.

• Non-destructive cutting: The cutting head does not come into contact with the surface of the substrate, ensuring that the parts are not scratched.

• Good flexibility: It has good flexibility to cut any graphics, including metal pipes and other shaped metals.

• Dieless cutting: It does not require mold consumption, saves time and operating costs, reduces manufacturing costs, and is suitable for commercial use in large-scale industrial production.

• Material saving: With CNC programming, the parts of different shapes can be cut to maximize the utilization rate of materials.

• Easy to use: Using CAD software to design graphics, using CAM software to model and output files, using CNC controller to drive the machine to achieve automatic metal cutting..

• Safety and environmental protection: Less waste, low noise, clean, safe and pollution-free, greatly improving the working environment.

Advantages Compared with CO2 Laser Cutting Machine

• Higher beam quality: The focus spot is smaller, the cutting line is finer, the working efficiency is higher, and the cutting quality is better.

• Higher cutting speed: 2 times the same power CO2 laser cutter.

• Higher stability: Stable performance and the service life of key components can reach 100,000 hours.

• Higher electro-optical conversion efficiency: The photoelectric conversion efficiency of fiber laser cutter is about 30%, which is 3 times higher than that of CO2 laser, energy saving and environmental protection.

• Lower cost of use: The power consumption of the whole machine is only 20-30% of the similar CO2 laser.

• Lower maintenance cost: No working gas, no need for reflective lenses, save a lot of maintenance costs.

• Convenient product operation and maintenance: Optical fiber transmission, no need to adjust the optical path.

Of course, compared with carbon dioxide laser cutter, the cutting range of optical fiber is relatively narrow. Because of the wavelength, it can only cut metal materials, and it is not easy to be absorbed by non-metals, which affects its cutting range.

Advantages Compared with YAG Laser Cutting Machine

• Higher cutting speed: The speed is 4-5 times that of YAG, suitable for mass processing and production.

• Lower cost of use: The cost of use is less than that of YAG solid laser cutting.

• Photoelectric conversion efficiency: The photoelectric conversion efficiency is about 10 times that of YAG.

The price of the corresponding is relatively high, so the price is much higher than that of YAG laser, but much lower than that of carbon dioxide laser cutter. But its sexual parity is indeed the highest of the three.

Cons

If you stare at the cutting machine for a long time, it will cause very serious damage to the retina of the eye. All operators must wear goggles. Do not operate and observe with eyes exposed. In the cutting path of the machine, it is necessary to avoid the position of any part of the body, so as not to accidentally cause unnecessary injury.

The impact of dust during cutting on the human body. Using the machine in an unsuitable working environment will have the impact of dust. Working in a dusty environment for a long time will also cause great damage to the lungs and trachea. Improper protection will cause lung and respiratory diseases.

Oxygen is often used in the cutting process, and sparks flying during the cutting process can easily cause fire. Therefore, there should be no inflammable and explosive materials in the working area, and corresponding protective facilities should be provided at the same time.

As far as the material is concerned, the addition of the material itself or the coating on the material will produce components that are harmful to the human body at high temperatures, so it should be noted.

Safety depends on the safety guidance of the manufacturer and whether the protective equipment purchased by the enterprise meets the protective standards. Different types of machines have different degrees of damage to the human body, especially the eyes and skin. The exact grade depends on the operator's manual. First, each device comes with a protective goggle. During the cutting process, do not look at the laser for a long time, and do not look too close without a protective cover to avoid the cutting slag splashing on your body. Now almost all equipment is equipped with a dust removal system, which is basically not affected by smoke and dust. The metamorphic laser gas contains a small amount of carbon monoxide, and the carbon monoxide content is very small and will not cause harm to the human body.

Care & Maintenance

When using these machines to cut projects, it is necessary to learn the use and maintenance skills, in order to better exert the effectiveness of the equipment and maximize the efficiency of the equipment.

• The conveyor belt needs to be checked frequently to ensure the tension. The conveyor belt may seem like an inconsequential component, but the danger posed by it cannot be ignored. Mistakes during operation may result in personal injury or even death.

• Check the straightness of the track and the verticality of the machine every six months, and find that it is abnormal and timely maintenance and debugging. Without this, the effect of cutting may not be very good, the error will increase, affecting the cutting quality. This is the top priority and must be done.

• Use a vacuum cleaner to suck off the dust and dirt in the machine once a week. All electrical cabinets should be closed and dustproof.

• The guide rails should be cleaned frequently to remove dust and other debris, to ensure that the equipment racks are cleaned frequently, and lubricating oil is added to ensure lubrication without debris. The guide rail should be cleaned and lubricated frequently, and the motor should also be cleaned and lubricated frequently, the machine can move better during cutting, cut more accurately, and the quality of the cut product will improve.

• If any damage is found in the process of using the machine, it must be replaced in time, which is not only a type of protection for the machine itself, but also ensures that the machine always maintains an ideal cutting effect.

A fiber laser cutter needs regular inspection and maintenance. If there is deformation or other forms, you should know that the cutting head has been damaged a little at this time, and you need to replace it. Failure to replace will affect the cutting quality and increase the cost, and some products may need to be reprocessed to reduce production efficiency.

Caution

• Make the power socket in good contact and the ground wire well grounded.

• Make the voltage of the water chiller stable.

Since the refrigeration compressor is sensitive to the power supply voltage, the standard working voltage is 200 ~ 250V (100 ~ 130V for 110V models). If you really need a wider operating voltage range, you can customize it separately.

• The mismatch of power frequency will cause damage to the machine.

Please use 50Hz or 60Hz models according to the actual situation.

• To protect the circulating water pump, running without water is strictly prohibited.

Before packing a new machine, the water tank must be emptied. Please make sure that the water tank is full of water before starting the machine, otherwise the water pump will be easily damaged. When the water level of the water tank is lower than the minimum requirement of the water level gauge, the cooling capacity of the chiller will drop, and the water level must be within the required range. The use of circulating pump drainage is strictly prohibited.

• Make sure that the air inlet and outlet channels of the chiller are smooth.

The air outlet above the chiller must be at least 1250px away from the obstacle, and the side air inlet must be at least 500px away from the obstacle.

• The air inlet filter must be cleaned regularly.

The air filter must be removed and cleaned regularly. Serious blockage of the air filter will cause the chiller to malfunction.

• Please pay attention to the effect of condensate.

When the water temperature is lower than the ambient temperature and the ambient humidity is high, condensation water will be generated on the surface of the circulating water pipe and the device to be cooled. When the above situation occurs, it is recommended to increase the water temperature or insulate the water pipe and the cooled device.

• This type of laser machine is an industrial equipment, please do not allow non-professionals to operate.

Trends

Laser cutting is one of the most important application technologies in the manufacturing industry. Technological workers continue to explore the technology and promote the continuous development of laser cutting technology. At the same time, companies need to step out of price competition and practice internal skills. Because of their many advantages, they have been widely used in automobile, rolling stock manufacturing, aviation, chemical industry, light industry, electrical appliances and electronics, petroleum and metallurgy.

With the increase of power, laser cutting is developing from light industrial thin metal fabrication to heavy industrial thick metal, and due to the improvement of high-power laser beam mode and the application of 32-bit microcomputer, favorable conditions have been created for high speed and high precision.

In order to meet the needs of 3D metal cutting in the automotive and aerospace industries, a variety of 5-axis and 6-axis 3D laser cutters have been developed. Currently, marine steel plate cutting generally uses flame cutting and plasma cutting. Deck and hull materials of special materials cannot be accurately cut. Laser cutter manufacturers may wish to try high-tech operations, vigorously develop computer network engineering, and improve business efficiency through the improvement of office tools.

At the same time, the high-precision 3D robot laser cutter has important strategic significance for improving the level of aerospace technology equipment. As the volume becomes smaller, the power increases and the auxiliary devices continue to improve for thick plate cutting and large format metal fabrication. The generator, power supply, host, control system and cooling circulation device are closely combined to form a complete set of compact laser cutter with small footprint and perfect function.

Strengthen the close connection with upstream and downstream enterprises in the supply chain to form a highly competitive and concentrated CNC laser cutter business circle. For some manufacturers, it is of great significance to enhance their competitiveness and expand market share. Focus on product structure optimization, product quality improvement, core technology mastery and innovation, and the expansion of corporate brand influence.

Buyer's Guide

A higher laser power of the machine will deliver better cutting capability. Therefore, we always recommend to our customers to choose these kind of machines with higher laser capability. The higher the power of the laser, the better the machine will be able to cut metals. At the same time, the software that would maneuver the machine is also worth checking. A user-friendly software interface will make that look easy for a person who will maneuver the machine. You may also look at the cooling system of the tool kit. it will save the machine from excess heat.

It is always necessary that you always look at the costs that you will have to spend for maintenance. It may look like a better purchase when the total cost of the machine seems lower. But in the long-term scenario, this can force you to spend higher on the maintenance.

Last but not the least. Consider from where you are making the purchase. I mean the reputation of the company or manufacturer matters in the long run. That is from where you will get the customer support in case you face any difficulties while using the tool.

Why Choose STYLECNC?

What do you think makes a good manufacturer? When you love the quality of their delivered products or the technical support that you get after the purchase, you name the brand as trustworthy. STYLECNC is renowned for delivering extra ordinary technical assistance and support when you need them the most. At the same time, STYLECNC always ensures that you get best rated machine that you need to get wholesome output. Grab your desired machine from the brand, and you certainly will love the decision that you did so.