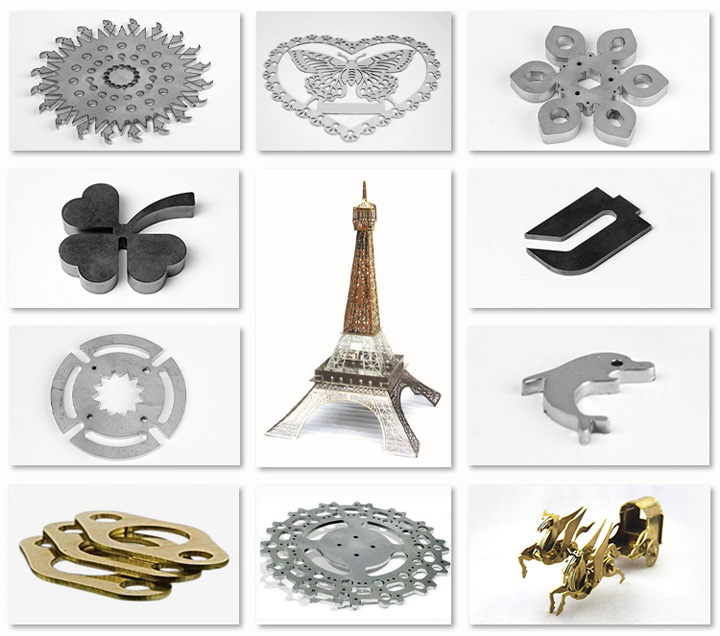

Easy to assemble, everything plugged in as it should. Control panel is user friendly. Software came with the all-in-one fiber laser metal cutter is easy to use, enabling automation and modular cut in metal fabrication. Had some parameter setting issues and they were prompt to respond online and sort it all out. Used it cut through 20mm mild steel plate to make metal parts, as well as custom handrails and guardrails from 6mm 304 stainless steel round tubing. 4000 watt high laser power kept cutting at a fast speed for smooth and clear cuts with fast speed. As others have reviewed and I can now also attest that STYLECNC is focused on product quality and customer support. This is why this brand has earned my five star rating. Would recommend them to all without reservation.

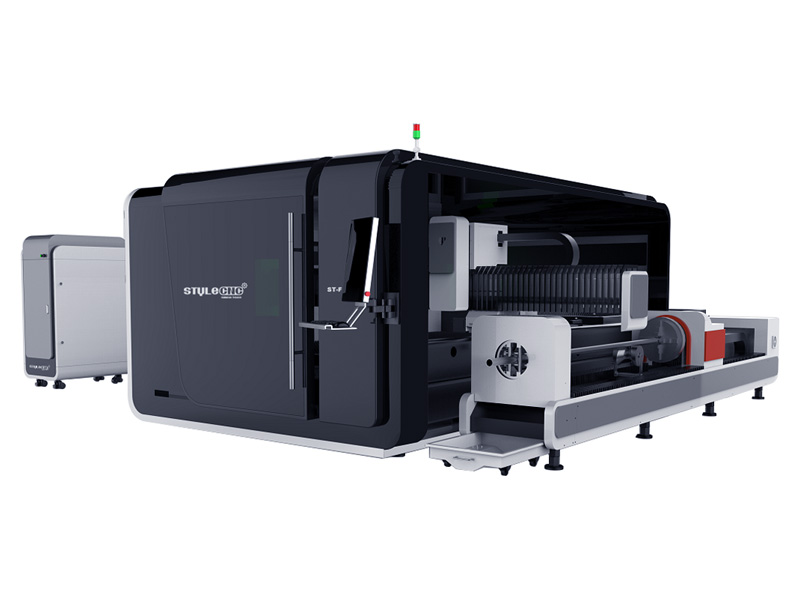

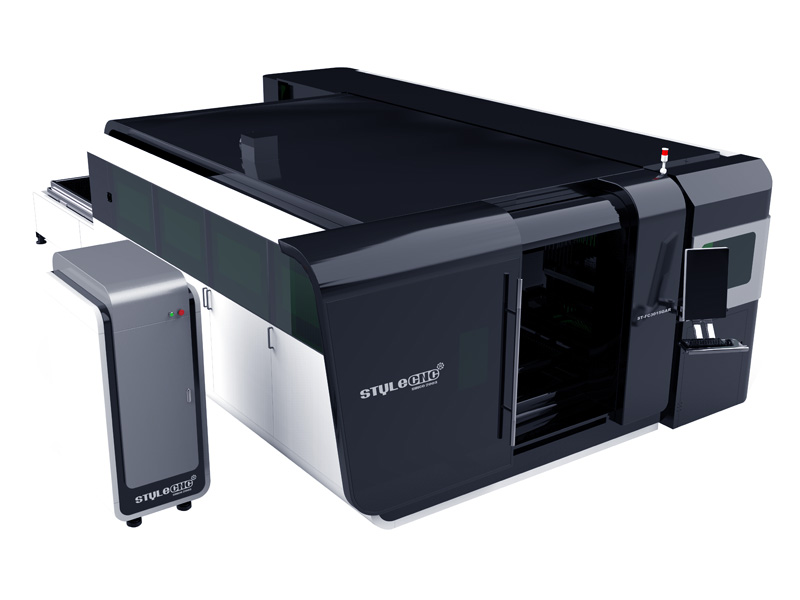

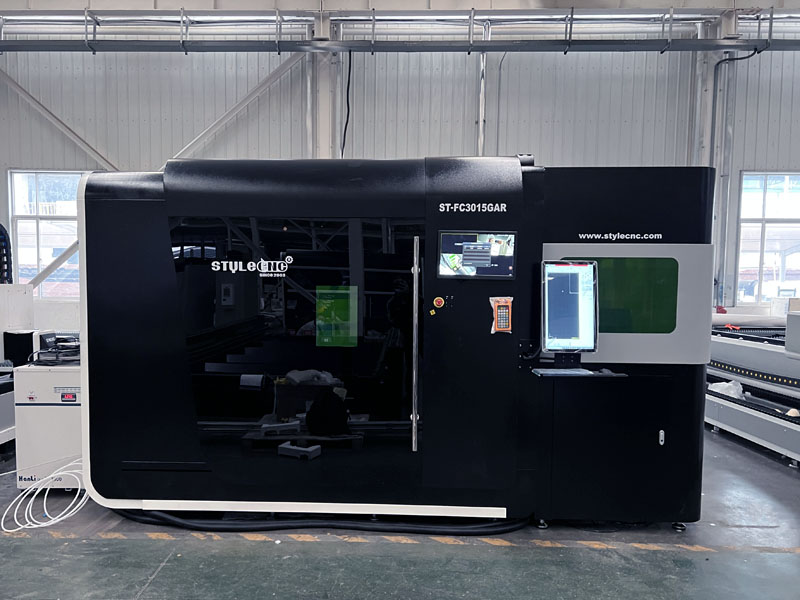

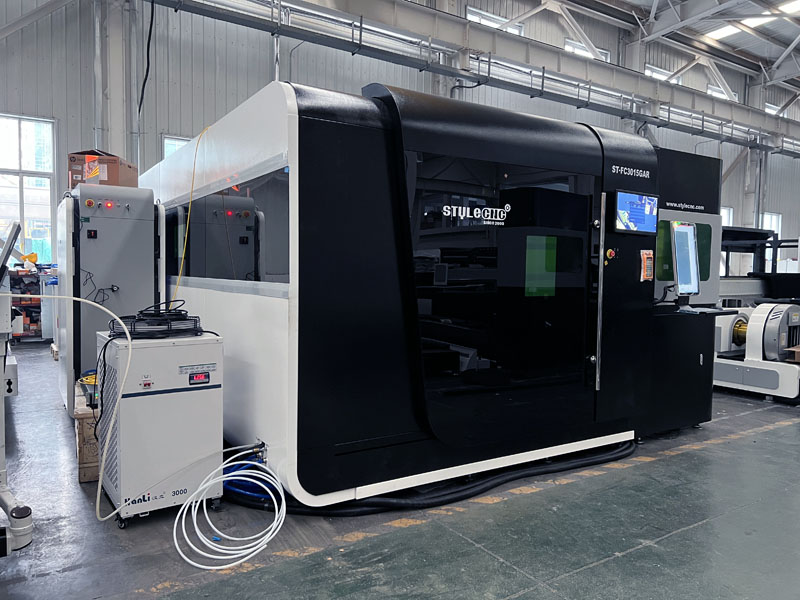

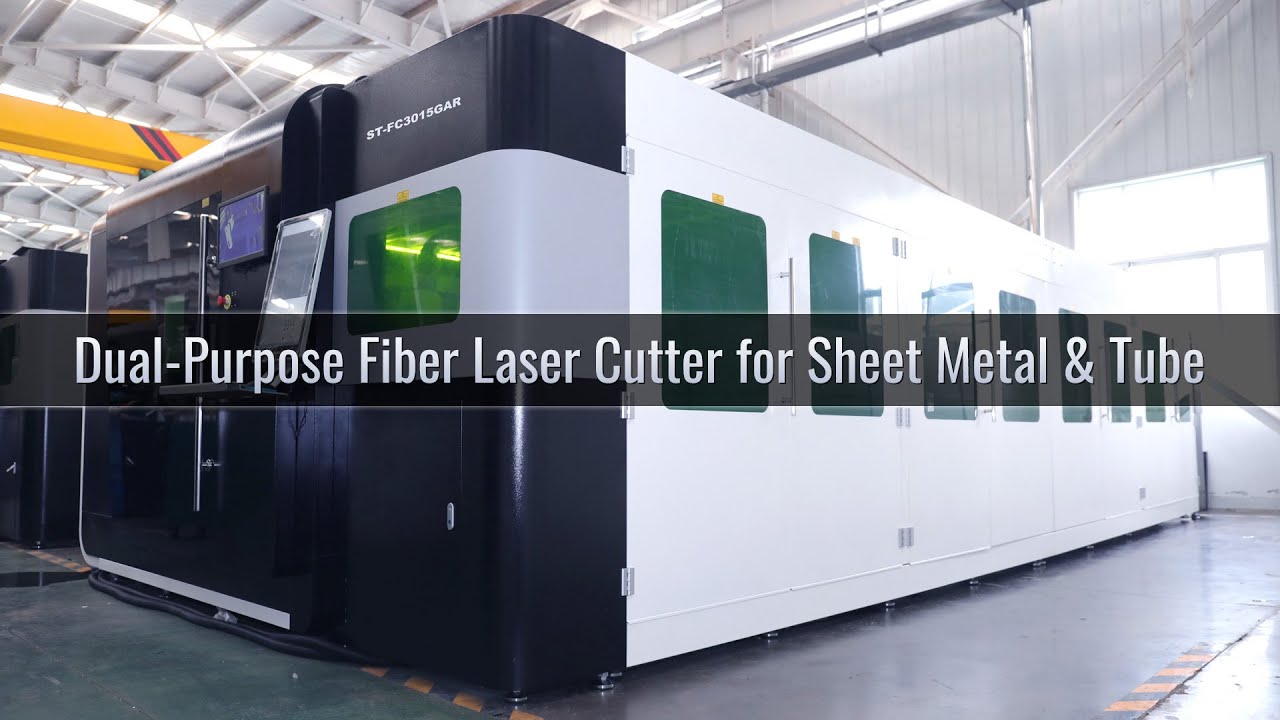

Dual-Purpose 6KW Fiber Laser Cutter for Metal Sheet & Tube

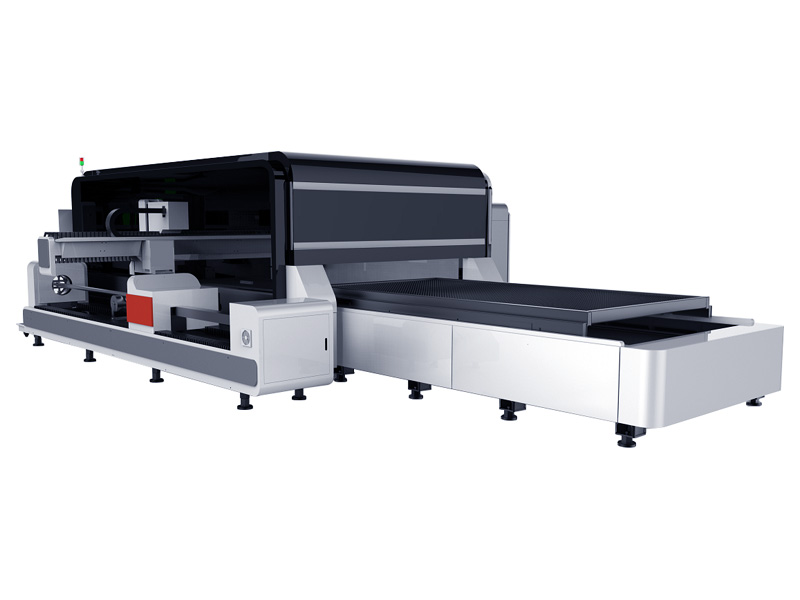

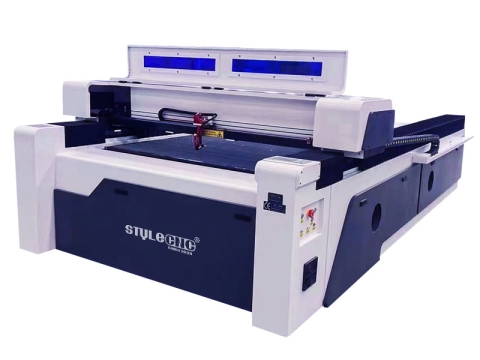

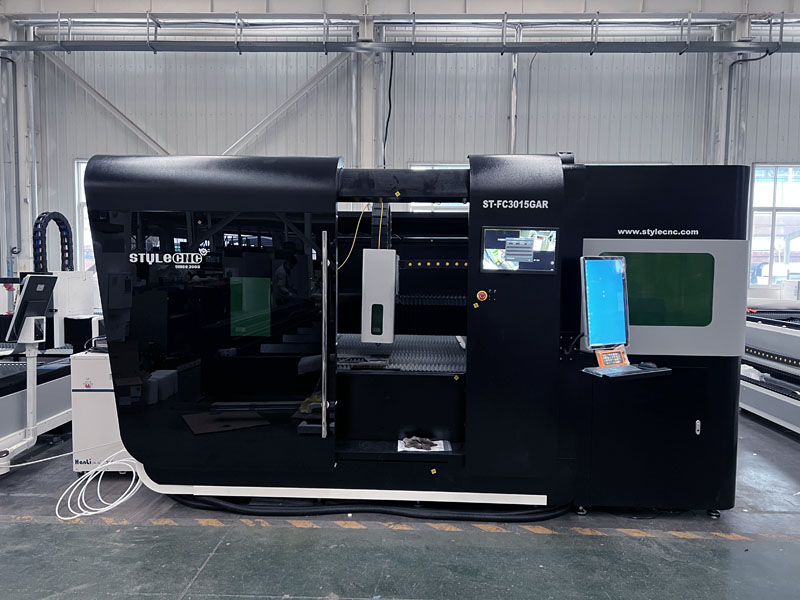

ST-FC3015GAR dual-purpose fiber laser cutting machine 6000W is a commercial laser metal cutter with fully enclosed housing and dual functions to handle metal plates and tubes made of steel, aluminum, titanium, copper, brass, iron, alloys in various thicknesses and sizes, and comes with different power options such as 1500W, 2000W, 3000W, 4000W, 8000W and 12000W to meet various budgets and needs. The switchable dual working platform makes sure that the workflow is seamless and as smooth as silk.

- Brand - STYLECNC

- Model - ST-FC3015GAR

- Maker - Jinan Style Machinery Co., Ltd.

- Sizing - 5' x 10' (60" x 120", 1500mm x 3000mm)

- Category - Fiber Laser Cutting Machine

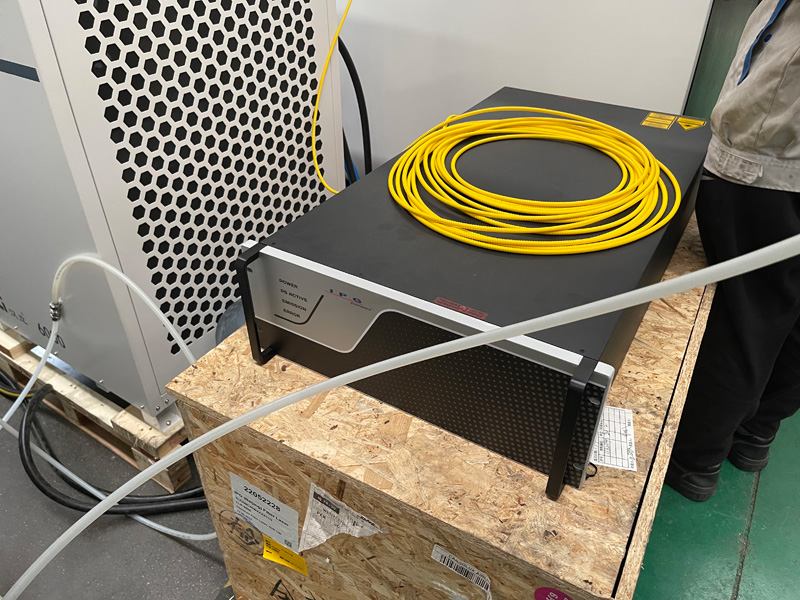

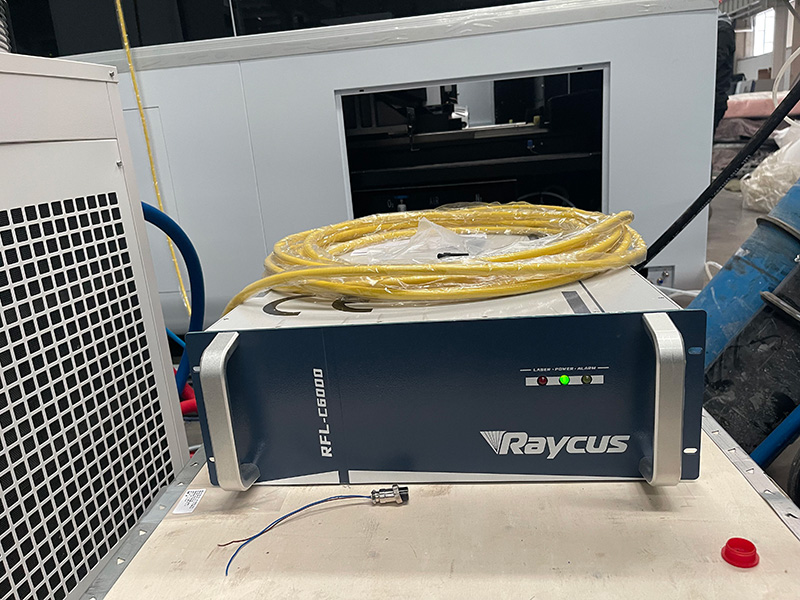

- Laser Source - Raycus, IPG, MAX

- Power Option - 1500W, 2000W, 3000W, 6000W, 12000W

- 180 Units in Stock Available for Sale Every Month

- Meeting CE Standards in Terms of Quality & Safety

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- 30-Day Money Back Guarantee for Your Purchase

- Free Lifetime Technical Support for End-Users & Dealers

- Online (PayPal, Alibaba) / Offline (T/T, Debit & Credit Cards)

- Global Logistics and International Shipping To Anywhere

With the ST-FC3015GAR, you can stop being limited and start being creative in any way you want. The ST-FC3015GAR has two working stages, so you can keep working on your projects without stopping. One platform cuts at full speed while the other gets ready for the next job. This makes sure that the workflow is seamless and as smooth as silk. Forget about having free time and welcome nonstop work.

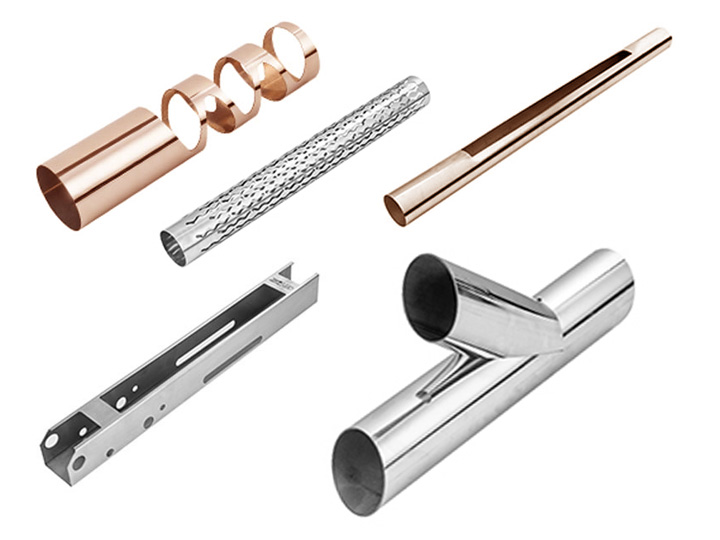

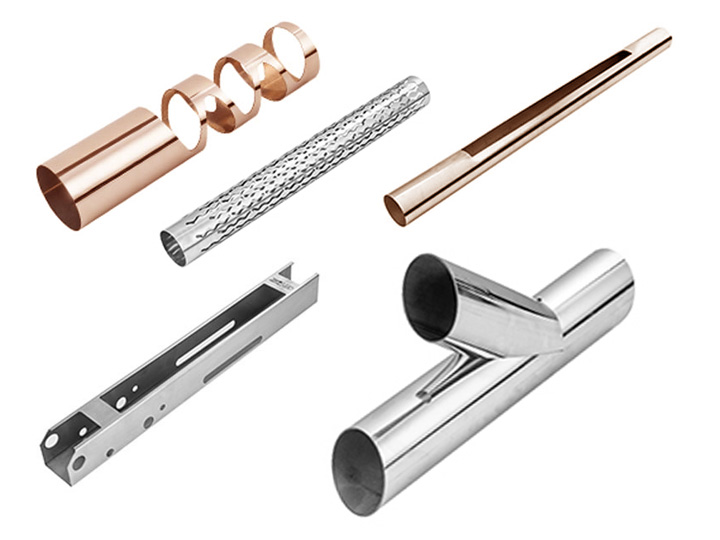

Tube Cutting Brilliance: Making Smooth Curves and Shapes

You can easily make curves and outlines with the ST-FC3015GAR because it has special features for cutting tubes. This machine cuts tubes like a pro, no matter what shape they are - round, square, or anything in between. This lets you use your creativity to make designs that amaze and please.

Safety First, Fun Always: A Clean and Safe Workshop Space

When you work with metal, safety is very important, and the ST-FC3015GAR knows that. This machine's fully covered cover not only protects you from flying sparks and debris, but it also keeps the work area clean and safe. So turn up the creativity and let the sparks fly - in a safe and secure way.

Features and advantages of Dual-Purpose Fiber Laser Cutting Machine for Metal Sheet, Tube and Pipe

• The machine comes with an exchanged double working platform. While working on one table, the other platform can load and unload the sheet workpiece;

• Auto feeding model is driven by frequency conversation drive-down motor, high transmitting power and safety factor, enabling stepless speed adjustment for different operating frequencies;

• Pipe cutting machine is specially designed for metal pipes, metal tubes;

• Fully enclosed cover will keep you safe and healthy at work;

• High precision transmission device which is perfectly work with servo system, thus it can make sure cutting precision and efficiency;

• Higher cutting quality and efficiency, cutting speed is up to 120m/min with appearance and beautiful cutting edge.

Technical Parameters of Dual-Purpose Fiber Laser Cutting Machine for Metal Sheet, Tube and Pipe

| Model | ST-FC3015GAR |

| Laser Cutting Area | 1500*3000mm |

| Laser Power | 6000W (1500W, 2000W, 3000W, 4000W, 8000W, 12000W for Option) |

| Max Cutting Speed | 120m/min |

| Repeated Positioning Accuracy | 0.02mm |

| Power Requirements | 380V/50Hz/60Hz |

| Machine Weight | 8600KG |

| Machine dimension | 9500*4100*2300mm |

Details of Dual-Purpose Fiber Laser Cutting Machine for Metal Sheet, Tube and Pipe

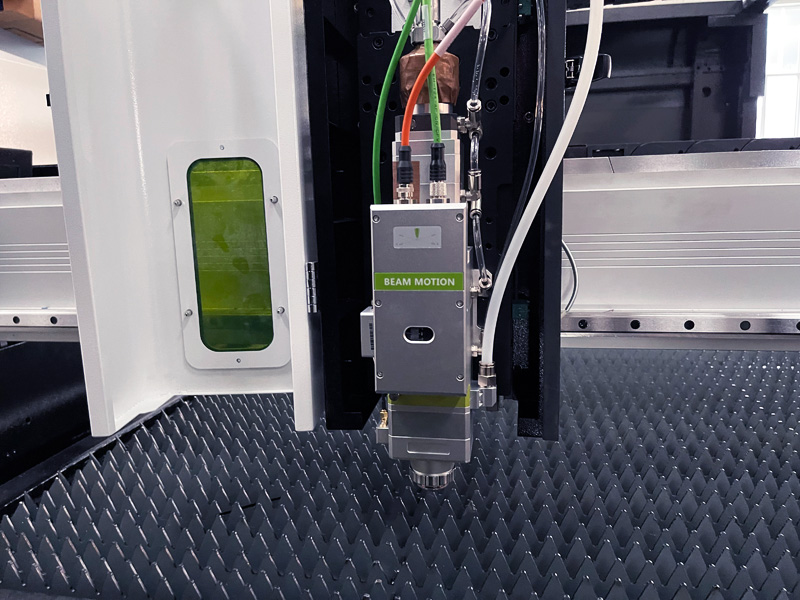

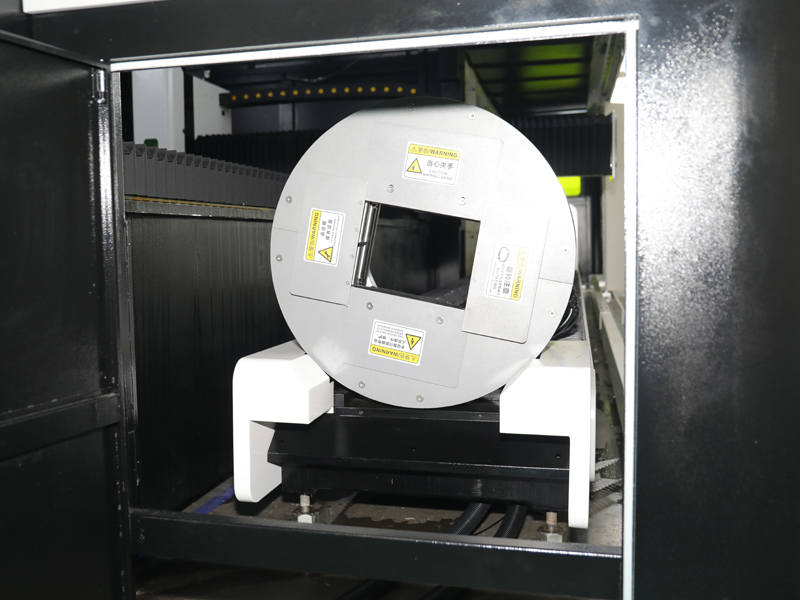

Swiss Raytool laser cutting head, Germany Precitec laser cutting head for choose.

Fiber laser visual cutting system.

2KW IPG laser cuting source.

6KW Raycus laser source.

Automatic exchange pallet with chain transmission.

Dual table automatic exchanging, cutting one by one to save time.

Automatic chuck for metal tube cutting.

Applications of Dual-Purpose Fiber Laser Cutting Machine for Metal Sheet, Tube and Pipe

Applicable materials: stainless steel, carbon steel, electrical steel, galvanized steel, aluminum zinc plate, aluminum, aluminum alloy, titanium alloy, copper, brass, iron and other metal materials.

Applicable industries: Kitchen appliance, electric control box, high-resolute device, mechanical equipment, electrical equipment, lighting, posters, auto parts, display equipment, hardware and other metal processing.

Dual-Purpose Fiber Laser Cutting Machine for Metal Sheet, Tube and Pipe Projects

Package

• Strong water resit bottom in plywood.

• Laser source (separated plywood case) and spare parts on the laser bed.

• Corner protect by foam and fixed by protective film.

• All covered by strong and hard protective film.

• Vacuum packing.

• Inside steel frame protector.

• Plywood packing and steel strip outside fixed the box.

• Finishing packing by normal container or frame container.

Service

Pre-Sale Service

Free Sample Cutting Service

For free sample cutting/testing, please send us your CAD file (.plt or .ai), we will do cutting in our factory and make video to show you the cutting process and result, or send samples to you to check the cutting quality.

Progressing Solution Design

According to customer’s product processing requirement, we can design the unique solution that supports higher manufacturing efficiency and better processing quality for customer.

Customized Machine Design

According to customer's application, we may revise our machine according to customer's convenience and high production efficiency.

After-Sale Service

• We will supply the laser machine with training video and user's manual in English for installing, operation, maintenance and trouble-shooting, and shall give technical guide by remote,such as TeamViewer, E-mail, Telephone, Mobile, Whatsapp, Skype, 24/7 online chat, and so on, when you meet some problem of installation, operation or adjusting. (Recommended)

• You can come to our laser machine factory for training.We will offer professional guidance. Direct and effective face-to-face training. Here we have assembled equipment, all sorts of tools and testing facility. Training Time: 3 to 5 days (Recommended)

• Our engineer will do a door-to-door instruction training service at your local site. We need your help to deal with the visa formality, prepaid traveling expenses and accommodation to us during the business trip and service period before their dispatch. It's better to arrange a translator (if no English-speaking) for our engineers during the training period.

Warranty

• The entire machine comes with 1-year limited warranty (excluding consumable parts).

• Long life-time maintenance, after-sale department will offer 24/7 English online support.

• Except the damage artificially, we are responsible for offering the fittings free of charge during warranty.

• After the warranty period expired, the buyer only need to pay the actual maintenance cost.

• Certificate support: CE, FDA, SGS.

Stephen Becerra

Philipp Bohm

Well packaged with perfect condition. Easy to make it work. I cut a variety of thickness stainless steel sheet and pipe with no problems so far. Resulted in clean and smooth cut outs. Worked great as expected. I am very impressed with the performance for the money you can't beat it. I hope this all-in-one laser metal cutter holds up well.