Waht is CNC?

CNC is an automated program that uses computers to control mechanical movement and working processes. It is a smart manufacturing system that integrates traditional mechanical manufacturing technology, computer technology, modern control technology, sensor detection technology, network communication technology and opto-mechanical technology. It features with high precision, high efficiency, automation, and plays a pivotal role in the realization of flexible automation, integration and intelligence in the modern industrial manufacturing industry.

In strict adherence to the terminology, there is a difference in the meaning of the abbreviations NC and CNC. The NC stands for the order and original Numerical Control technology, whereby the abbreviation CNC stands for the newer Computerized Numerical Control technology, a modern spin-off of its older relative. However, in practice, CNC is the preferred abbreviation. To clarify the proper usage of each term, look at the major differences between the NC and the CNC systems.

The machining under numerical control does away with the majority of inconsistencies. It does not require the same physical involvement as machining. Numerically Controlled machining does not need any levers or dials or handles, at least not in the same sense as conventional ma-chining does. Once the part program has been proven, it can be used any number of times over, always returning consistent results. That does not mean there are no limiting factors. The cutting tools do wear out, the material blank in one batch is not identical to the material blank in another batch, and the setups may vary. These factors be considered and compensated for, whenever necessary.

The emergence of the numerical control technology does not mean an instant, or even a long term, demise of all manual machining tools. There are times when a traditional machining method is preferable to a computerized method. For example, a simple one time job may be done more efficiently on a manual machining tool than a CNC machine. Certain types of machining jobs will benefit from manual or semiautomatic machining, rather than numerically controlled machining. Automatic machine tools are not meant to replace every manual machine, only to supplement them. In many instances, the decision whether certain machining will be done on a computer-controlled machine or not is based on the number of required parts and nothing else. Although the volume of parts machined as batch is always in important criteria, it should never be the only factor.

Consideration should also be given to the part complexity, its tolerances, the required quality of surface finish. A single complex part will benefit from computer numerical controlled machining, while fifty relatively simple parts will not. Keep in mind that numerical control has never machined a single part by itself. Numerical control is only a process or a method that enables a machine tool to be used in a productive, accurate and consistent way.

Waht is CNC Machine?

A CNC machine is a mechatronics automated power tool that combines a computer numerical control system with a traditional machine. It performs part or all of the numerical control functions according to the control program stored in the computer memory, and is equipped with a special computer system with interface circuits and servo drives. CNC controller realizes machine action control by using digital instructions composed of numbers, characters and symbols. It usually controls mechanical quantities and switching quantities such as position, angle, and speed.

Different types of CNC machines cover an extremely large variety. Their numbers are rapidly increasing, as the technology development advances. It is impossible to identify all the applications, and they would make a long list. Here is a list of 16 most common types of 2024:

Type 1. Mills & Machining Centres

Type 2. Lathes & Turning Centres

Type 3. Drilling Machines

Type 4. Boring Machines & Boring Mills

Type 5. EDM Machines

Type 6. Punch Presses & Shears

Type 7. Flame Cutters

Type 8. CNC Routers

Type 9. Water Jet Cutters

Type 10. Laser Machines

Type 11. Grinders

Type 12. Welding Machines

Type 13. Benders

Type 14. Winding Machines

Type 15. Spinning Machines

Type 16. Plasma Cutters

CNC machining centres and lathes dominate the number of installations in industry. These two groups share the market just about equally. Some industries may give a higher need for one group, depending on their needs. One must remember that there are many different types of lathes and equally many different kinds of ma-chining centres. However, the programming process for a vertical machine is similar to the one for a horizontal ma-chine or a simple CNC mill. Even between different groups, there is a great amount of general applications and the programming process is generally the same. For example, a contour milled with an end mill has a lot in common with a contour cut with a wire.

CNC Mills & CNC Machining Centres

Standard number of axes on a milling machine is three-the X, Y and Z axes. The part set on a milling system is al-cutting tool rotates, it can move up and down (or in and out), but it does not physically follow the tool path.

CNC mills are usually small, simple power tools, without a tool changer or other automatic features. Their power rating is often quite low. In industry, they are used tool room work, maintenance purposes, or small part production. They are usually designed for contouring, unlike computer-controlled drills.

CNC machining centres are for more popular and efficient that drills and mills, mainly for their flexibility. The main benefit user gets out of a computer numerical controlled machining centre is the ability to group several diverse operations into a single setup. For example, drilling, boring, counter boring, tapping, spot facing and contour milling can be incorporated into a single CNC program. In addition, the flexibility is enhanced by automatic tool changing using pallets to minimize idle time, indexing to a different side of the part, using a rotary movement of additional axes, and a number of other features, CNC machining centres come with special software that controls the speeds and feeds, the life of the cutting tool, automatic in-process gauging and offset adjustment and other production enhancing and time saving devices.

There are two basic designs of a typical computer numerical controlled machining centre. There are the vertical and the horizontal machining centres. The major difference between the two types is the nature of work that can be done on them efficiently. For a vertical machining centre, the most suitable type of work are flat parts, either mounted to the fixture on the table, or help in a vise or a chuck. The work that requires machining on two or more faces in a single setup is more desirable to be done on a horizontal machining centre. A good example is pump housing and other cubic-like shapes. Some multi-face machining of small parts can also be done on a vertical machining center equipped with a rotary table.

The programming process is the same for both designs, but an additional axis (usually a B axis) is added to the horizontal design. This axis is either a simple positioning axis (indexing axis) for the table, or a fully rotary axis for simultaneous contouring.

This handbook concentrates on the vertical machining centres applications, with a special section dealing with the horizontal setup and machining. The programming methods are also applicable to the small CNC mills or drilling and/or tapping tools, but the programmer has to conceder their restrictions.

CNC Lathes & CNC Turning Centres

A CNC lathe is usually a machine tool with two axes, the vertical X axis and the horizontal Z axis. The main future of the lathe that distinguishes it from a mill is that the part is rotating about the machine center line. In addition, the cutting tool is normally stationary, mounted in a sliding turret. The cutting tool follows the contour of the programmed tool path. For the CNC lathe with a milling attachment, so called live tooling, the milling tool has its own motor and rotates while the spindle is stationary.

You will meet horizontal lathe and vertical lathe with modern designs. Horizontal lathe is the most popular type compared to the vertical lathe, but both types exist for either group. For example, a typical computer-controlled lathe of the horizontal group can be designed with a flat bed or a slant bed, as a bar type, chucker type or universal type. Added to these combinations or many accessories that make a computer numerical controlled lathe is an extremely flexible power tool. Typically, accessories such as a tailstock, steady rests or followup rests, part catchers, pullout-fingers and even a third axis milling attachment are popular components of the automatic lathe. A computer-controlled lathe can be very versatile so versatile in fact, that it is often called a CNC turning centre. All text and program examples in this handbook use the more traditional term CNC lathe, yet still recognizing all its modern functions.

CNC Drills & Drilling Machines

CNC drilling machine is a computer-controlled power tool for drilling, tapping, reaming on the substrate. There are 7 most common types of CNC drills listed below.

• Vertical Drill: The worktable and the headstock can move vertically on the column for processing small and medium-sized work pieces.

• Benchtop Drill: Referred to as Bench Drill. A small 3D drill with a maximum drilling diameter of 12-15 mm. It is installed on a fitter table and is mostly used for manual drilling. It is often used to process small holes of small work pieces.

• Rocker Arm Drill: The spindle box can move on the rocker arm, the rocker arm can rotate and lift, and the work piece is fixed. It is suitable for processing large, heavy and porous work pieces and is widely used in machinery manufacturing.

• Deep Hole Drill: A specialized power tool that uses deep hole drills to drill holes with a depth much larger than the diameter (such as deep holes in parts such as gun barrels, gun barrels, and spindles), in order to facilitate chip removal and avoid higher machine tools, generally a horizontal layout, often equipped with a coolant delivery device (input coolant from the inside of the tool to the cutting part) and a periodic tool retracting chip removal device.

• Center Hole Drill: Used for machining the center holes at both ends of spindle parts.

• Milling & Drilling Machine: The worktable can be moved vertically and horizontally, the drilling spindle is arranged vertically, and the drill can perform milling.

• Horizontal Drill: The spindle is arranged horizontally and the headstock can move vertically. Generally, it has higher processing efficiency than vertical drills, and can process multiple surfaces at the same time.

CNC Boring Machines & Boring Mills

A CNC boring machine is a automatic power tool that uses a boring tool to process prefabricated holes on a work piece. The rotation of the boring tool is the main movement, and the movement of the boring tool or the workpiece is the feed movement. It is mainly used to process high-precision holes or finish machining of multiple holes at one time, and it can also be engaged in the machining of other machining surfaces related to hole finishing. Using different tools and accessories can also be used for drilling, milling, and cutting. Its machining accuracy and surface quality are higher than those of a drill.

CNC boring machines come into horizontal types, floor types, diamond types and coordinate types.

• Horizontal boring machines: a boring tool with the most applications and the widest performance, suitable for single-piece small batch production and repair workshops.

• Floor boring machines and floor boring mills: The feature is that the work piece is fixed on the floor platform, which is suitable for processing work pieces with large size and weight, and is used in heavy machinery manufacturing plants.

• Diamond boring machines: Use diamond or carbide tools to bore holes with high precision and small surface roughness at a small feed rate and high cutting speed, mainly used in mass production.

• Coordinate boring machines: with precise coordinate positioning device, it is suitable for processing holes with high requirements on shape, size and hole spacing accuracy. You can also meet some other types, including vertical turret types, deep hole types and those for automobile and tractor repairs.

CNC EDM Machines

CNC EDM is a computer-controlled automatic power tool for machining molds and parts with complex shapes of holes and cavities. It is used for machining various hard and brittle materials, such as cemented carbide and hardened steel. It can process deep and fine holes, special-shaped holes, deep grooves, narrow slits and cut sheets. It can also process tools such as various forming tools, templates and thread ring gauges.

It has an intelligent and adaptive control pulse power supply, and makes a curve table with different materials, rough, medium and fine EDM parameters and standards, and writes it into the chip as a database. As long as the operator inputs the processing conditions such as electrode, workpiece material and surface roughness, the power tool can output the best processing standard parameters, and can continuously detect the electrical discharge machining status according to the given target (ensure a certain surface roughness to improve productivity). Compare and operate with the best model (digital model), control the relevant parameters according to the calculation results, and obtain the best processing effect. As the pollution degree of the working fluid and the field conditions such as chip removal conditions, processing depth and processing area change, the relevant pulse parameters can be adjusted automatically and continuously, and the productivity can be achieved on the premise that the surface roughness and other processing quality remain unchanged. The highest optimum stable discharge state.

Types of EDMs

• The mirror EDM machine is an EDM that can process a mirror effect. The EDM does not need to save molds. It can be directly used in production, saving labor and improving efficiency. With high precision, it has obvious advantages in the application of precision molds. The cost of mirror EDMs is expensive, which is priced from $12,000 to $80,000.

• The plastic mold EDM is used for the electric discharge machining of plastic molds. It is relatively common in our country, and the price is cheap and widely used.

• The fine hole EDM is used for drilling, which is to punch a hole in the mold.

• There are also some special EDMs, such as those for graphite and tungsten steel.

• ZNC EDM, Z-axis CNC, X-axis and Y-axis manual, is a more practical EDM.

• CNC EDM with XYZ three-axis numerical control has many functions, such as automatic mold matching, automatic center finding, automatic programming, G-code programming, and three-axis linkage discharge.

CNC Punching Machines

CNC punching machine is the abbreviation of digital control punch, which is an automatic machine tool equipped with a program control system. The control system can logically process the program specified by the control code or other symbolic instructions, and decode it, so as to make the puncher move and process the parts.

CNC puncher is used for machining all kinds of metal sheet parts, and can automatically complete a variety of complex hole patterns and shallow drawing forming processing at one time (automatically process holes of different sizes and hole spacings according to requirements, or use a small die to nibble the round holes, square holes, waist-shaped holes and various shapes of curved contours can also be processed by special processes, such as shutters, shallow stretching, countersunk holes, flanging holes, reinforcing ribs, embossing). Through simple die combination, compared with traditional stamping, it saves a lot of die cost, can use low cost and short cycle to process small batch and diversified products, has a large processing range and processing capacity, so as to adapt to the market in time with product changes.

CNC Flame Cutting Machines

CNC flame cutting machine is an automatic cutting equipment that uses gas with oxygen or gasoline with oxygen to cut metal materials. The most common types include handheld cutters, profile cutters, portable cutters, cantilever cutters, gantry cutters, desktop cutters and intersecting line CNCs specially designed for intersecting wire cutting of steel pipes cutter.

CNC Routers

A CNC router is a type of computer-controlled machine tool used for carving, cutting or milling services. On the basis of the automatic router, the power of the spindle and the servo motor is increased, the body can withstand the force, while maintaining the high speed of the spindle, and more importantly, high precision. An automatic router machine has its own advantages, but it is very difficult to process products with relatively large material hardness, and it is obviously impossible to efficiently complete the processed products. The emergence of precision CNC router machines has greatly compensated for the shortcomings of traditional types. For example, the machining of metal, hardware and aluminum shells makes the machined products more refined and refined. The machine itself runs stably and reliably, with good processing quality, high efficiency, simple operation and convenient maintenance. It is widely used in molds, electronic products, hardware, plastics, jewelry, handicrafts, hairstyles, furniture, locks, shoemakers, glasses, automobiles, mobile phone cases, buttons, intermediate frames, lenses, glass covers and other industries. The most popular types of CNC routers include 3-axis, 4-axis, rotary 4th-axis, 5-axis, multi-axis to meet your different needs.

Water Jet Cutting Machines

Water jet cutting machine is an automatic power tool that uses high-pressure water jet cutting technology with the highest production capacity in the world. The project can be cut arbitrarily under the control of the computer, and it is less affected by the texture of the material. No deformation during cutting, clean and environmentally friendly. Because of its low cost, easy operation and high yield, water jet cutting is gradually becoming the mainstream cutting method in industrial manufacturing.

A water jet cutter is composed of a high pressure pump, a processing platform, a jet cutting head, a transmission system, and a switch water control system.

When the CNC waterjet cutter is working, the high-pressure water pump as the power source of the waterjet uses the hydraulic motor to forcibly compress the tap water or deionized water, so that the pressure of the water increases to tens to hundreds of MPa. When the water column is ejected through the beam nozzle, It has high pressure and kinetic energy to form a water jet. The machining platform is also controlled by a precise CNC program, and the X-axis and Y-axis are unidirectional or bidirectional linkage, and finally drive the water jet to achieve linear or curved cutting and descaling cleaning on the work piece.

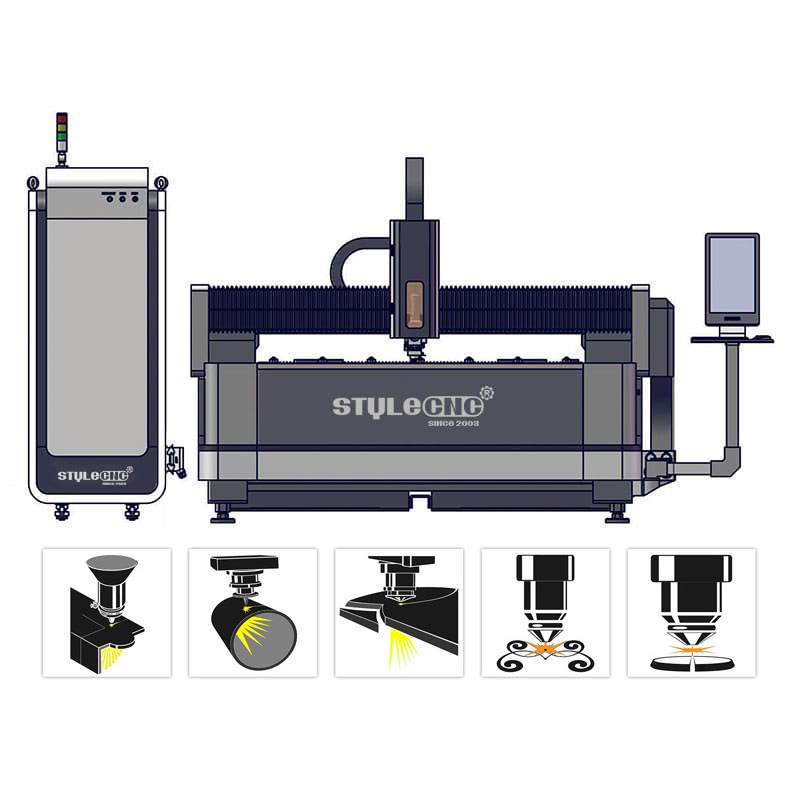

CNC Laser Machines

Laser machining is different from ordinary mechanical processing. It is a computer numerical controlled laser system that integrates optical, mechanical and electrical control, with a higher degree of intelligence. Numerical control and integration combine laser generators with computer-controlled programming, advanced optical systems, and high-precision and automated laser positioning to form automatic computer-controlled laser machines. In the process of laser machining, not only the focus position and moving speed of the laser must be precisely controlled and adjusted to meet the machining requirements of various complex parts. It is also required to control the size of the laser power, the rate of rise and fall of the laser power, the pulse frequency, pulse width and pulse intensity of the laser at the same time.

CNC laser machines can be used to engrave, cut, mark, etch, weld, clean metal, wood, plastic, acrylic, foam, rubber, paper, fabric, and leather.

CNC Grinding Machines

A CNC grinder is an automatic power tool that uses computer-controlled abrasive tools to grind the surface of substrates. A computer-controlled grinder uses a rotating wheel to wear the material into the desired shape through repeated grinding.

The operator enters the specifications into the computer, which sets the automatic grinder to work, creating the perfect, high-quality tool for the job. Manual machining by hand is a daunting task, and automatic machining can accomplish grinding with a high degree of computer control.

The most common types of automatic grinders include honing machines, superfinishing grinders, belt grinders, grinders, polishers, surface grinders, coordinate grinders, cylindrical grinders, vertical universal grinders, profile grinders, and centerless grinders.

CNC Welding Machines

Automatic CNC welding machine is a very complex optical, mechanical and electrical integration equipment that integrates computer control, motion control, image processing, network communication, and is composed of multiple difficult XYZ platforms. It requires high response and low vibration to the equipment. High-efficiency, stable ultrasonic output and ignition system, high-precision image capture, welding materials through automatic loading and unloading system to achieve automatic cycle welding. It is widely used in the production of light-emitting diodes (LED LAMP), SMD patches, high-power LEDs, triodes, digital tubes (DIGITAL DISPLAY), dot matrix boards (DOTMATRIX), backlight (LED BACKIGHT) and IC soft packaging (COB) CCD modules, and the inner lead of some featured semiconductors is soldered.

Automatic CNC welders have been widely used in the LED industry, and are indispensable equipment for packaging in the LED industry. Manual and semi-automatic welders have been gradually replaced by automatic wire bonders due to their inability to meet market demand in terms of production capacity.

CNC Bending Machines

A CNC bending machine is an automatic bender that uses the equipped mold (general or special mold) to bend the cold metal sheet into workpieces with various geometric cross-section shapes. A bender generally adopts the special CNC controller for automatic bending. The coordinate axis of the bending machine has been developed from a single axis to 12 axes, and the computer numerical controlled system can automatically realize the sliding depth control, the left and right tilt adjustment of the slider, the front and rear adjustment of the rear stopper, the left and right adjustment, the pressure tonnage adjustment and the slider. The bending machine can easily realize the actions of the slider downward, jog, continuous, pressure holding, return and stop in the middle, and complete the bending of multiple elbows at the same angle or different angles at one time.

CNC Winding Machines

A CNC winding machine is a winder that uses digital instructions composed of numbers, characters and symbols to realize the automatic winding, arranging, wrapping, cutting, wrapping tape, upper and lower skeleton, and positioning.

CNC winders are used to wind the stator and rotor of various motors, electric coils for automobiles and motorcycles, solenoid valve coils, fluorescent lamp ballasts, transformers, TV sets, mid-cycle and inductor coils for radios, line output transformers (high-voltage packages), speakers, earphones, voice coils for microphones, electric welders, winding yarns in the textile industry, sewing threads, embroidery threads, yarn colors cards, as well as fiberglass, fiber optics, wires, cables, and heat shrink tubing.

CNC Spinning Machines

The CNC spinning machine is a one-time spinner and former for metal, which is composed of six systems: mechanical, hydraulic, electric control, numerical control, heating and cooling. The mechanical structure includes four basic parts: bed, headstock, tailstock and rotary wheel frame. The hydraulic system includes hydraulic motor, hydraulic profiling, adjustment of feeding mechanism, pressure regulation and pressure relief insurance of tailstock. The numerical control system device for controlling the servo system and the programmable logic controller for controlling the hydraulic transmission system are connected with the industrial PC respectively. The new type of spinner realizes automatic processing and control. It is a multi-functional and general-purpose equipment with high precision and reliability.

CNC Plasma Cutters

A CNC plasma cutter is an automatic metal cutting machine that uses computer numerical control and the heat of high temperature plasma arc to cut sheet metal and tubes. In terms of appearance and size, it is similar to a computer-controlled router. CNC plasma cutting machine is a special equipment for plasma arc cutting under high temperature and strong electric field conditions. High-speed airflow, high-temperature, high-speed plasma arc flame flow melts the workpiece metal, and is blown away from the substrate to form a slit. Since the arc column temperature greatly exceeds the melting point of metals and their oxides, computer-controlled plasma cutters can also be used to cut stainless steel, aluminum, copper and other metals in addition to cutting carbon steel.

Trends

In future, high-speed, high-precision, composite, intelligent, open, parallel drive, networked, extreme, and environmentally friendly have become the development trends and directions of CNC machines.

High Speed

With the rapid development of automobile, national defense, aviation, aerospace and other industries as well as the application of new materials such as aluminum alloys, the requirements for high-speed machining are getting higher and higher.

• Spindle speed: Using an electric spindle (built-in spindle motor), with a maximum spindle speed of 200000r/min.

• Feed rate: When the resolution is 0.01μm, the maximum feed rate reaches 240m/min and precise processing of complex shapes can be obtained.

• Computing speed: The rapid development of microprocessors has provided guarantee for the development of CNC systems in the direction of high speed and high precision. Numerical control systems with CPUs that have been developed to 32-bit and 64-bit have been developed, and the frequency has been increased to hundreds of MHz and thousands of MHz. Due to the great improvement in computing speed, when the resolution is 0.1μm or 0.01μm, a feed speed of up to 24-240m/min can still be obtained.

• Tool changing speed: At present, the tool changing time of high-end machining centers is generally around 1s, and the highest is as high as 0.5s.

High Precision

The accuracy requirements are no longer limited to static geometric accuracy. The motion accuracy, thermal deformation, and vibration monitoring and compensation are gaining more and more attention.

• Improve the control accuracy of the CNC system: Use high-speed interpolation technology to achieve continuous feed with tiny program segments to refine the CNC control unit, and use a high-resolution position detection device to improve position detection accuracy (Japan has developed a 106-pulse /rev AC servo motor with built-in position detector, its position detection accuracy can reach 0.01μm/pulse), the position servo system adopts feedforward control and nonlinear control methods.

• Adopt error compensation technology: Use technologies such as backlash compensation, screw pitch error compensation and tool error compensation to comprehensively compensate for the thermal deformation error and spatial error of the equipment. Research results show that the application of comprehensive error compensation technology can reduce machining errors by 60% to 80%.

• Use grids to check and improve the motion trajectory accuracy of the machining center, and predict the processing accuracy through simulation to ensure the positioning accuracy and repeat positioning accuracy, making its performance stable in the long term and able to complete a variety of processing under different operating conditions. tasks and ensure the processing quality of parts.

Functional Compounding

The meaning of compound machine tools is to realize or complete as much as possible the processing of multiple elements from blank to finished product on one machine tool. According to its structural characteristics, it can be divided into two types: process composite type and process composite type. Process-complex machine tools such as boring-milling-drilling composite machining center, turning-milling composite turning center, milling-boring-drilling-turning composite-composite machining center. Process-complex machine tools include multi-faceted multi-axis linkage machining composite machine tools and dual spindles turning centers. The use of composite machine tools for processing reduces the auxiliary time for workpiece loading and unloading, replacement and tool adjustment, as well as errors generated in the intermediate process, improves part processing accuracy, shortens the product manufacturing cycle, improves production efficiency and the manufacturer's market response ability. It has obvious advantages over traditional production methods with decentralized processes.

Intelligent Control

With the development of artificial intelligence technology, in order to meet the development needs of manufacturing production flexibility and manufacturing automation, the degree of intelligence of CNC machine tools is constantly improving. Specifically reflected in the following aspects:

• Machining process adaptive control technology: By monitoring the cutting force, spindle and feed motor power, current, voltage and other information during the machining process, traditional or modern algorithms are used to identify the force, Wear, damage status and the stability status of machine tool processing, and adjust processing parameters (spindle speed, feed speed) and processing instructions in real time based on these statuses to keep the equipment in optimal operating status to improve processing accuracy and reduce processing surface roughness And improve the safety of equipment operation.

• Intelligent optimization and selection of processing parameters: Using the experience of process experts or technicians and the general and special rules of parts processing, we use modern intelligent methods to construct an "intelligent optimization and selector of processing parameters" based on expert systems or models, using It obtains optimized processing parameters, thereby achieving the purpose of improving programming efficiency and processing technology level, and shortening production preparation time.

• Intelligent fault self-diagnosis and self-repair technology: Based on existing fault information, modern intelligent methods are applied to achieve rapid and accurate fault location.

• Intelligent fault playback and fault simulation technology: It can completely record various information of the system, play back and simulate various errors and accidents that occur in CNC machine tools, to determine the causes of errors, find solutions to problems, and accumulate production experience.

• Intelligent AC servo drive device: An intelligent servo system that can automatically identify the load and automatically adjust parameters, including an intelligent spindle AC drive device and an intelligent feed servo device. This kind of drive device can automatically identify the moment of inertia of the motor and load, and automatically optimize and adjust the control system parameters to achieve optimal operation of the drive system.

• Intelligent 4M CNC system: In the manufacturing process, the integration of processing and inspection is an effective way to achieve rapid manufacturing, rapid inspection and rapid response, integrating Measurement, Modelling, Manufacturing and Manipulator (i.e. 4M) into one system. Realize information sharing and promote the integration of measurement, modeling, processing, clamping and operation.

We believe that the manufacturer's services should start from studying the user’s processing products, processes, production types, and quality requirements, help users select equipment, recommend advanced processes and tool auxiliary tools, and provide professional training personnel and a good training environment to help users Users can maximize the benefits of machine tools and process high-quality final products, so that they can gradually gain recognition from users.

Things To Consider

So far, we have covered 16 different common types of CNC machines in detail, and you should have the ability to differentiate. In terms of DIY and buying, be sure to choose the type depending on your business needs and budgets.