What is CO2 Laser Cutting Technology?

CO2 laser cutting technology is a gas-based laser system that uses a CO2 mixer as the active laser medium. Electrifying the gas mixture a high-energy beam of light is produced known as the laser. This concentrated laser beam is focused on the object and the laser heats, melts, and vaporizes the material to cut.

Laser-cutting technology offers more efficient machine production, better precision, and accuracy. CNC technology advanced them with a more accurate controlling system.

A laser cutting machine is a part and parcel of many industries now. This technology saves time and offers a higher production rate with minimal wastage, making it a popular choice day by day.

CO2 laser cutters have become the most affordable and best-value cutting tools in the recent years, and can be your good partner to bring your creations, ideas and designs to life with personalized gifts, crafts, arts, decors, signs and logos. With a carbon dioxide laser cutting system, you can easily engrave any graphics and cut any shapes & contours on wood, acrylic, plastic, foam, stone, fabric and leather.

Definition

CO2 laser is a pulsed wave beam in which carbon dioxide gas obtains continuous wave or high output area in the infrared of the medium. The wavelength is 10.6μm. It is a light source used for rapid prototyping. High-power lasers are used for cutting and drilling. The medium power output is used for engraving. Since the output wavelength is easily absorbed by water, it is also widely used in medical treatment.

A CO2 laser generator is a gas laser generator with CO2 gas as the working material. The discharge tube is usually made of glass or quartz material, filled with CO2 gas and other auxiliary gases (mainly helium and nitrogen, and usually a small amount of hydrogen or xenon). The electrode is generally a hollow nickel cylinder and a resonant cavity. One end is a gold-plated total reflection mirror, and the other end is a partial reflection mirror polished with germanium or gallium arsenide. When a high voltage (usually DC or low-frequency AC) is applied to the electrode, a glow discharge is generated in the discharge tube, and there is a laser output at one end of the germanium mirror, and its wavelength is in the mid-infrared band near 10.6 microns.

Carbon dioxide laser generators are usually made of hard glass, and generally adopt a layered sleeve structure. The innermost layer is the discharge tube, the second layer is the water-cooled casing, and the outermost layer is the gas storage tube. The diameter of the discharge tube of the carbon dioxide laser generator is larger than that of the He-Ne laser tube. Generally speaking, the thickness of the discharge tube has no effect on the output power, mainly considering the diffraction effect caused by the size of the light spot, which should be determined according to the tube length. The longer tube is thicker, and the shorter tube is thinner. The length of the discharge tube is proportional to the output power. Within a certain length range, the output power per meter of discharge tube length increases with the total length. The purpose of adding a water cooling jacket is to cool the working gas and stabilize the output power. The discharge tube is connected to the gas storage tube at both ends, that is, one end of the gas storage tube has a small hole communicating with the discharge tube, and the other end communicates with the discharge tube through the spiral return tube, so that the gas can circulate in the discharge tube and the gas storage tube flow, the gas in the discharge tube is exchanged at any time.

A CO2 laser tube is a sealed glass tube composed of hard glass, a resonant cavity and electrodes that produces a light beam for cutting and engraving materials.

The Hard Glass Part

This part is composed of GG17 material fired into discharge tube, water cooling jacket, air storage jacket and air return pipe. The sealed-off generator is usually a three-layer casing structure. The innermost is the discharge tube, the middle is the water purifier, the outermost layer is the gas storage sleeve, and the return gas pipe is used to connect the discharge tube and the gas storage tube.

The Cavity Part

This part consists of a total mirror and an output mirror. The total mirror of the resonant cavity is generally based on optical glass, the surface is gold-coated, and the reflectivity of the gold-film mirror is above 98% near 10.6um; the output mirror of the resonant cavity is generally made of infrared materials that can transmit 10.6um radiation Germanium (Ge) is the substrate, and a multilayer dielectric film is formed on it.

The Electrode Part

The laser generators generally use cold cathodes, which are cylindrical in shape. The choice of cathode material has a great impact on the life of the generator. The basic requirements for cathode materials are low sputtering rate and low gas absorption rate. As far as the machine is concerned, the quality and performance of the tube directly affect the working efficiency.

How Does It Work?

A CO2 laser cutting machine is a professional automatic engraving and cutting tool kit that uses a 1064μm laser beam to etch and cut nonmetals and metalloids. With a hybrid laser cutting system, it can even cut through thin metals.

The working method of CO2 laser-cut tech is shown step by step.

Step 1. A CO2 laser cutter relies on the controller (CNC or DSP) to drive the carbon dioxide gas laser tube to emit a beam.

Step 2. With reflectors, the light beam is transmitted to the cutting head.

Step 3. And then the focusing mirror converges the beam to a point, where can reach a very high temperature

Step 4. Thus the excess material is instantly sublimated into gas, which is sucked away by the exhaust fan, to create a cut.

A proper setting of the machine is the primary requirement to start the cutting project. A detailed knowledge of the machine and operating instructions is important as well.

Working Principle

A CO2 laser machine uses a glass laser tube to produce light beam, and works with a numerical control system to irradiate the beam to the surface of the object, and at the same time release high energy to melt and evaporate the surface of the object, thereby realizing the plan of cutting and engraving. The beam is a column of very high intensity light, of a single wavelength, or color. In the case of a typical carbon dioxide laser, that wavelength is in the Infra-Red part of the light spectrum, so it is invisible to the human eye. The beam is only about 3/4 of an inch in diameter as it travels from the resonator, which creates the beam, through the machine's beam path. It may be bounced in different directions by a number of mirrors, or "beam benders", before it is finally focused onto the plate. The focused beam goes through the bore of a nozzle right before it hits the plate. Also flowing through that nozzle bore is a compressed gas, such as Oxygen or Nitrogen. Generally speaking, higher power is used for cutting, lower power is used for engraving. The power is adjustable during operation. Turn it down for engraving and turn it up for cutting. The level of power will also affect the depth of engraving and the thickness of cutting.

Technical Parameters

| Brand | STYLECNC |

| Model | STJ9060, STJ1325, STJ1390, STJ1490, STJ1610, STJ1626 |

| Laser Power | 80W, 100W, 130W, 150W, 180W, 280W, 300W |

| Laser Type | CO2 Laser Tube |

| Laser Wavelength | 10.6 μm |

| Max Cutting Speed | 1400mm/s |

| Position System | Red Dot |

| Positioning Precision | ≤±0.01mm |

| Cooling System | Water Chiller |

| Drive System | Servo Motor & Driver |

| Graphic Format | BMP, AI, DST, CDR, PLT, DXF, JPG, PGN |

| Price Range | $3,000.00 - $20,000.00 |

Applications & Uses of CO2 Lasers

CO2 laser cutting technology is used in almost every industry. CNC laser cutting routers are very popular and efficient in cutting and shaping things. Several models are available on specific cutting projects. Mostly the machines are popular for their technological adaptability.

These cutting tools are used widely in industries. Let’s find out more about this.

⇲ CO2 lasers can handle various cuts from simple acrylic letters to complex 3D wood puzzles, from soft fabrics to hard plastics.

⇲ Useful for engravings on stone, glass, and crystal.

⇲ Creating designs and patterns on wood, acrylic, and other materials for artistic projects.

⇲ Producing detailed signs, logos, and lettering.

⇲ Creating accurate prototypes and models for engineering, architecture, and product design.

⇲ Cutting and engraving fabrics for clothing, accessories, decorative items, and so on.

The future of CO2 laser cutting technology is about to boost the cutting industry with many more features. Surely this is a blessing of modern science.

CO2 lasers can engrave and cut wood, plywood, MDF, chipboard, cardboard, fabric, leather, plastic, PMMA, acrylic, paper, bamboo, ivory, rubber, EPM, depron foam, gator foam, polyethylene (PE), polyester (PES), polyurethane (PUR), carbon fibers, neoprene, textile, jeans, polyvinyl butyrale (PVB), polyvinyl chloride (PVC), beryllium oxide, polytetrafluoroethylenes (PTFE /Teflon), and any materials containing halogens (chlorine, iodine, fluorine, astatine and bromine), phenolic or epoxy resins.

CO2 lasers are used to engrave text & patterns and cut shapes & contours in clothing, fashion, garment, shoes, bags, toys, embroidery, electronic appliances, molds, models, arts, crafts, advertising, decorations, packaging, and printing.

Advertising Industry.

• Double-colored board.

• Organic glass.

• Label.

• Crystal cup.

• Warranty signed.

Arts and Crafts Industry.

• Wood.

• MDF.

• Ivory.

• Bone.

• Leather.

• Plywood.

• Paper.

Packing and Printing Industry.

• Rubbery board.

• Plastic board.

• Double-layered board.

• MDF board.

• Plywood board.

Leather and Garment Industry.

• Fabric.

• Textile.

• Synthetic leather.

• Man-Made leather.

• Jeans.

Architectural Model Industry.

• ABS board.

• Model.

Production Totem Industry.

• Appliance signs.

• Anti-fake commodities.

From the technical and economic point of view, carbon dioxide laser machine is not suitable to cut thicker sheet metals compared with fiber laser machine. The typical products that have been used are automatic elevator structural parts, elevator panel, machine tool and grain machinery enclosures, various electrical cabinets, switch cabinets, textile machinery parts, engineering machinery structural parts, large motor silicon steel sheets.

Patterns, signs, marks and fonts of stainless steel (generally 3 mm thick) or non-metallic materials (generally 20 mm thick) for decoration, advertising and service industries, such as the design of art photo albums, the marks of companies, units, hotels, shopping malls, Chinese and English fonts in stations, docks, and public places.

Special parts that require even slitting. The most widely used typical part is the die-cutting board used in the packaging and printing industry. It requires a slot with a width of 0.7 to 0.8 mm on a 20 mm thick wooden template, and then inserts a blade in the slot. Use fashion on the die-cutting machine to cut out various packaging boxes with printed graphics. A new field of application in recent years is the oil screen pipe. In order to block the sediment from entering the oil pump, a uniform slit with a width of 0.3 mm is cut on the alloy steel pipe with a wall thickness of 6 to 9 mm, and the diameter of the small hole at the starting and cutting hole cannot be greater than 0.3mm.

Key Components of A CO2 Laser Cutter

A detailed knowledge and idea of the key components of a CO2 laser cutter/router is going to help make the experience easier for beginner to expert operators. The first step in training the operation of a CNC router is to learn the parts and their functionalities. This article is for all types of users, beginners, intermediate, and experts. Therefore, we have tried to provide all the information required to run a CO2 laser CNC router properly.

The basic parts of a CO2 laser cutter at a glance,

☑ Laser tube, the core component that generates the laser beam

☑ Necessary power supply to excite the gas mixture

☑ The optical system consists of mirrors and lenses that guide and focus the laser

☑ CNC controller, the brain of the laser cutter

☑ Laser head that houses the focusing lens and nozzle

☑ Cooling system which is essential for maintaining the optimal operating temperature

☑ The exhaust system removes fumes and debris generated during the cutting

☑ The work surface is the area where the material is placed for cutting

☑ Finally, interfaces with the CNC controller to manage the cutting process

Top-Rated CO2 Laser Cutting Systems for Beginners

CO2 laser cutting system requires knowledge and expertise. Operating a CO2 laser cutter is not the easiest job for any individual. Yet entry-level machines can be a safe pick for beginners.

Entry-level CO2 laser cutters are mostly used for small businesses and projects. These machines require basic knowledge as instructed in the provided manual. They are easy to operate and do not require additional training. S steady hand can easily operate an entry-level CO2 laser cutter.

Here, we have listed our top-rated CO2 laser cutting systems for beginners for their firsthand projects. To learn more, simply click on the model in the list.

1. STJ9060

2. STJ1390

3. STJ1390-2

4. STJ1610

5. STJ1610A

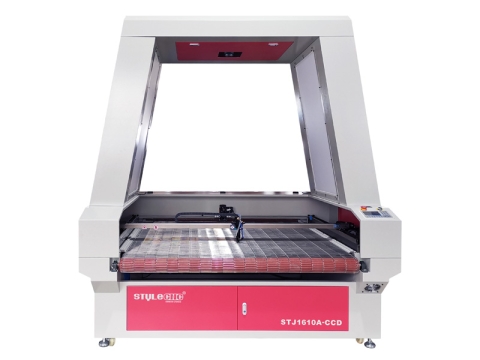

6. STJ1610-CCD

7. STJ1610A-4

8. STJ1630A

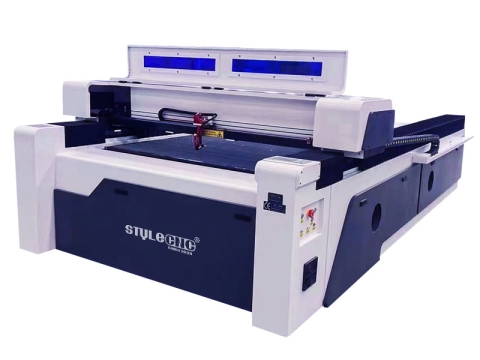

Best CO2 Laser Cutting Systems for Professionals

The best CO2 laser cutting systems for professionals are the most advanced CO2 laser machines on the market. These are full of features and require more space than entry-level, small business models. Additionally, a professional laser-cutting system requires expertise and the right instructions. Training enhances the performance of the operators and ensures higher efficiency.

We have enlisted our top-rated CO2 laser cutting machines for pros. Top-rated CO2 laser cutting systems are mentioned by their model names. To learn more, click on the name in the list.

1. STJ1325-4

2. STJ1610A-CCD

3. STJ1325

4. STJ1390M-2

5. STJ1610M

6. STJ1325M

7. STJ1630A-CCD

8. STJ1830A

Final Verdict

CO2 laser cutting systems are widely popular. They are considered the most efficient tools in the cutting industry. Laser cutting has revolutionized the traditional cutting methods. It is crucial to learn the difference between the systems for beginners and professionals. We hope this little effort from STYLECNC helps you find the proper guidelines in your CO2 laser cutter buying decision.

We are also providing a brief instruction regarding the key features of CO2 laser cutter systems for both beginners and pros.

| Beginner | Professional |

|---|---|

| Power Output: 40W to 80W | Power Output: 80W and above |

| Cutting and Engraving Capabilities: Basic materials | Cutting and Engraving Capabilities: Advanced materials |

| Work Area Size: Small to medium | Work Area Size: Large |

| User Interface and Software: Intuitive, easy-to-use | User Interface and Software: Advanced features |

| Safety Features: Essential components | Safety Features: Comprehensive safety systems |

How Much Does It Cost?

When you consider investing in a CO2 laser cutter, one of the frequently asked questions for everyone is does it make economic sense for your business? How much will you pay for it and how much time and cost can it actually save for your business?

CO2 laser cutter prices range from about $3,000 to $20,000+ depending on its features and laser powers, and the table size your projects required, as well as the considerations beyond cost. A small entry-level CO2 laser cutter starts from $3,600 used for home shop, while some hobby lasers can be as expensive as $7,800 with higher powers used for small business. The industrial carbon dioxide laser cutting machines cost anywhere from $6,000 to $19,800 used for commercial use.

How To Buy?

Step 1. Online Consulting.

We will recommend the most suitable laser cutter engraver to you after being informed by your requirements.

Step 2. Get Your Quote.

We will offer you with our detail quotation according to the consulted machine.

Step 3. Process Evaluation.

Both sides carefully evaluate and discuss all the details (technical parameters, specifications and business terms) of the order to exclude any misunderstanding.

Step 4. Placing Your Order.

If you have no doubt, we will send you the PI (Proforma Invoice), and then we will sign a contract with you.

Step 5. Machine Building.

We will arrange the laser cutter engraving machine production as soon as receiving your signed sales contract and deposit. The latest news about production will be updated and informed to the buyer during the production.

Step 6. Quality Control.

The whole laser engraver cutting machine production procedure will be under regular inspection and strict quality control. The complete machine will be tested to make sure they can work well before out of factory.

Step 7. Shipping and Delivery.

We will arrange the delivery as the terms in the contract after the confirmation by the buyer.

Step 8. Custom Clearance.

We will supply and deliver all the necessary shipping documents to the buyer and ensure a smooth customs clearance.

Step 9. Service and Support.

We will offer professional technical support and free service by Phone, Email, Skype, WhatsApp, Online Live Chat, Remote Service around the clock. We also have door-to-door service in some areas.

How To Use?

It is very dangerous for a CO2 laser cutter to break down during work. Novices must be trained by professionals before they can operate independently. STYLECNC experts have summarized 13 easy-to-follow steps for safe work based on experience as follows.

1. Prepare the materials to be cut and fix them on the workbench.

2. Call the corresponding parameters according to the material and thickness.

3. Select the corresponding lens and nozzle according to the cutting parameters, and check whether they are in good condition.

4. Adjust the cutting head to the appropriate focus.

5. Check and adjust the centering of the nozzle.

6. Calibration of cutting head sensor.

7. Check the cutting gas, enter the command to open the auxiliary gas, and observe whether it can be ejected from the nozzle well.

8. Trial cut the material, check the cross-section, and adjust the process parameters until the production requirements are met.

9. Prepare the cutting program according to the drawing required by the workpiece, and import it to the controller.

10. Move the cutting head to the starting point to be cut, and press "Start" to execute the cutting program.

11. The operator is not allowed to leave the machine tool during the cutting process. In case of emergency, quickly press the "Reset" or "Emergency Stop" button to terminate the operation.

12. When cutting the first workpiece, stop cutting to see if it meets the requirements.

13. Pay attention to check the auxiliary gas flow when cutting, and replace it in time when the gas is insufficient.

How To Maintain?

A CO2 laser cutter must be cared for and maintained regularly and regularly, so that it can engrave and cut more accurately and at a higher speed for you, which can also prolong the service life of the machine. STYLECNC summarizes 13 maintenance tips for everyone as follows.

1. When using the machine, the device should be turned on or off in strict accordance with the correct boot sequence.

2. The machine shell, laser power supply, and computer power supply must be well grounded. Regularly check whether the grounding screw is rusted or loose, and clean and fasten it in time.

3. Before starting work every day, observe whether the focusing lens is polluted, and clean it in time if any. Please be careful not to use too much force when cleaning the reflector, otherwise it will cause the optical path to shift! The maintenance of reflective lenses and focusing lenses at all levels should follow the principle of "cleaning in time if there is pollution". Special lens cleaner must be used for cleaning.

4. Before each machine works, please check whether each limit switch is working normally, so as to ensure that the equipment will not have collisions that affect the accuracy of the equipment during the working process. In addition, please pay attention to adjust the focal length and lock it tightly to ensure that the processing effect will not be affected by the decrease of the focal length, or even mechanical collision will occur.

5. If the moving parts such as trolley pulleys, slideways and linear guide rails are polluted or corroded, it will directly affect the processing effect. They should be cleaned regularly and lubricated on the guide rails to prevent rust.

6. After a long time of use (especially cutting), the honeycomb platform will stick to processing waste and even block the honeycomb holes. It may smoke or even burn when exposed to beam. It should be removed regularly.

7. The cooling water should be kept clean and replaced regularly. During processing, check whether the water level is sufficient and whether the water temperature is too high. It is strictly forbidden to use inferior circulating water. Poor-quality water can seriously affect the laser power and greatly shorten the service life of the laser tube. The damage to the tube caused by the use of poor-quality water by the user is not covered by the warranty. It is recommended to use pure water. The amount of cooling water should not be less than 30 liters, and the submersible pump must be submerged. During the working process of the machine, the water temperature must be checked at any time (the best working water temperature is 25~30°C, the maximum water temperature cannot exceed 35°C, and the minimum water temperature cannot be lower than 5°C). Once the water feels warm, it should be changed immediately. The water change method that does not affect the work is to discharge part of the hot water and then flush with cold water. Every three days, the water tank, water pump (especially the filter sponge of the water pump) and the water inlet and outlet hoses must be cleaned.

8. The laser tube is cooled by circulating water, so some white scale will appear in the tube after long-term use. We can add a small amount of vinegar to the circulating water, then take out the groove and rinse its interior with clean water to keep it in the best working condition and prolong its service life.

9. Pay attention that the smoke exhaust port and the exhaust duct cannot be blocked, and check and remove the obstruction at any time to keep it unblocked.

10. Adjust the light intensity not to exceed 20MA to prevent rapid aging of the laser tube.

11. Before starting work every day, the lens must be cleaned once.

12. Clean the reflector carefully on the machine, otherwise the optical path must be readjusted.

13. The third radiation mirror and focusing mirror must be removed and cleaned. After cleaning, the lens installation must be firm, but not too tight, so as not to break the lens.

14. Before each operation, please pay attention to the focal length. Inaccurate focal length will seriously affect the engraving effect.

15. After each operation, the work surface should be cleaned briefly. When cleaning, be careful not to fly dust.

16. Cleaning should be done after each operation. When doing cleaning work, when the power is cut off, you can gently push the beam and trolley, but it is strictly forbidden to push and pull violently.

17. Check the water protection switch regularly (once in half a month) to determine whether it is working normally.

18. Every other week, the guide rails must be cleaned, and lubricating oil should be added to the moving guide rails.

19. Every other week, clean up the peripherals of the machine (such as fans and air pumps).

20. After the machine works every day, it should be cleaned well. In the case of power failure, you can slowly push the focusing lens group and the X-axis guide rail seat, and it is strictly forbidden to push and pull violently. The bed body should be kept clean, especially the two linear guide rails. It is required to clean the oil stains on the guide rails and guide rail seats after work every day; transformer oil must be added to the linear guide rails and sliders before starting work the next day.