Here is a practical guide to helping you understand how laser marking works, as well as classification, pricing, pros and cons, configuration, technical parameters, purchase instructions, operation steps, care and maintenance. Whether you're a beginner or a pro, you'll easily learn and use a laser marking machine with this guide. Furthermore, as one of the most trusted manufacturers and brands, STYLECNC lists the most popular models with features and costs for both beginners and professionals. Are you ready? Let's get started.

Principle

Laser marking is a new type of non-contact, non-polluting and non-damaging engraving process, which integrates laser technology, computer technology and mechatronics technology. It is currently the mostly used advanced manufacturing technology. The principle is a marking method that uses high-energy-density laser to irradiate the workpiece locally to vaporize the surface material or undergo a chemical reaction of color change, thereby leaving a permanent mark. The process can be divided into the following steps:

Step 1: The laser acts on the surface of the material. The beam used in the field is usually a pulsed laser, and it outputs a pulse within a specific period of time. To control the beam acting on the material, it is necessary to control important parameters such as scanning speed and scanning distance.

Step 2: The material absorbs the laser energy. After the beam acts on the surface of the material, most of the energy is reflected, and only a small part of the energy is absorbed by the material and converted into heat. It needs to absorb enough energy to melt/vaporize the surface material.

Step 3: Local expansion occurs on the surface of the material, the roughness changes, and the mark is formed. When the material is melted and cooled in a short period of time, the roughness of the material surface will change, forming a permanent mark, which includes texts, patterns, signs and graphics.

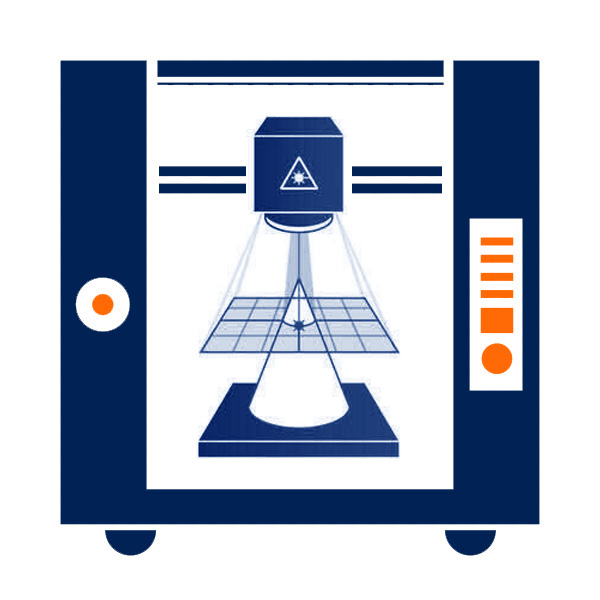

There are both 2D mark for flat surfaces, and 3D mark for curved surfaces.

2D Marking System

The mirror galvanometers are used to scan the beam and mark on 2D surface. The f˜ lens is used to concentrate the light on the 2D surface.

3D Marking System

The mirror galvanometers are used to scan the beam and mark on 3D surface. They will move the focus lens (instead of f˜ lens) back and start adjusting the beam not only on X axis and Y axis, but also on Z axis.

Marking Process

The system has six different marking processes include annealing engraving, marking, staining, foaming, removing and carbonizing, which is widely used in industrial manufacturing applications, school education, small businesses, home business, small shop and home shop.

Uses

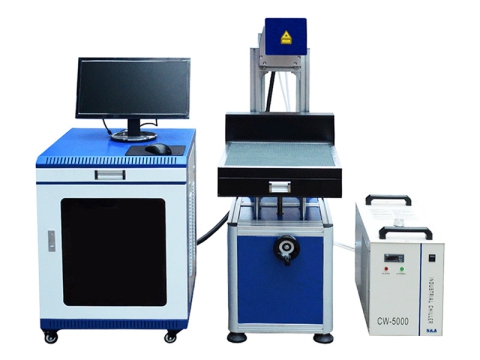

Fiber lasers with 1.06μm oscillators are used for generating power effciently, which are compact due to the oscillation principle, and they are more suitable for processing metals. UV lasers with 0.355μm oscillators are effected by the wavelength conversions, they can make detailed processing with a low thermal effect for the materials that have a high absorption rate for these wavelengths, however, the operating cost may be high. They are very good for plastic. CO2 lasers with 10.6μm oscillators are more easily absorbed by clear materials because they have a longer wavelength, this makes them good for marking glass or other clear materials. They are very good for PVC, paper, rubber, glass and wood.

Types

As you are looking for, we always call them as laser metal engraving machine, part marker, tool marker, wood engraver, jewelry marker, gold marker, stainless steel engraving machine, bearing marker, plastic engraving tool, glass etching machine.

Types Baser On Laser Sources: Fiber lasers, CO2 lasers, UV lasers.

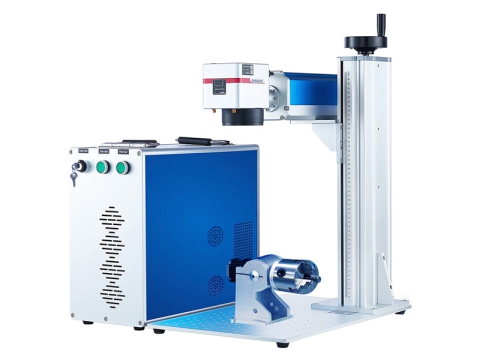

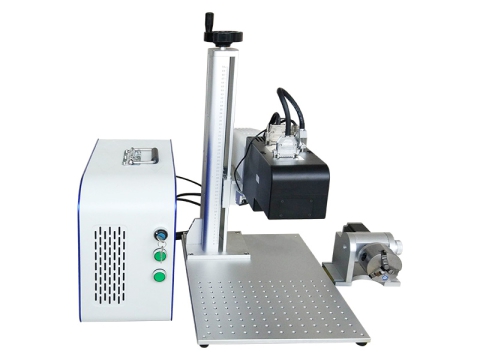

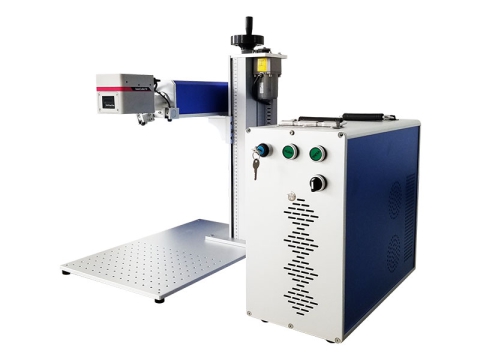

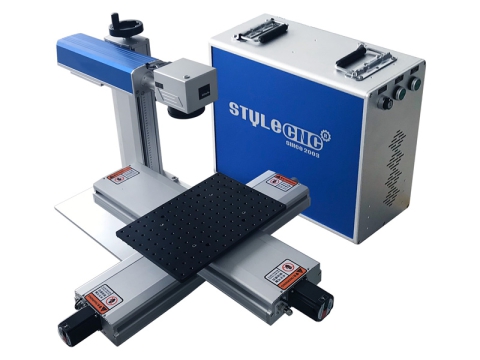

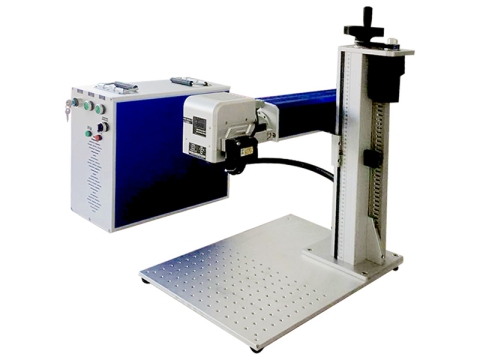

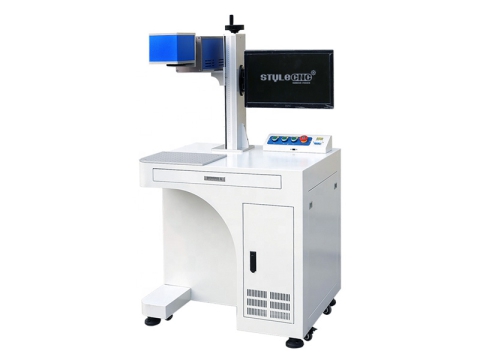

Types Baser On Table Sizes: Mini markers, portable markers, handheld markers, desktop markers.

Types Baser On Applications: Home engravers, hobby engravers, industrial engravers.

Types Baser On Functions: Color engravers with MOPA laser source, 3D deep engraving system, online flying engraving machines.

Pricing

If you have an idea to buy a cheap laser marking machine, you may wonder how much does it cost? how to get a fair price or final price?

According to different powers, sources, software, control system, driving system, spare parts, kits, other hardwares and softwares, you will get a final price range from $3,500.00 to $70,000.00.

A fiber laser engraver has an affordable price range from $3,500.00 to $28,500.00. A CO2 laser marking system is priced from $4,500 to $70,000.00. An UV laser marking machine costs from $10,000 up to $30,000.00. If you want to buy overseas, the fee of tax, customs clearance and shipping costs should be included in the final price.

Pros & Cons

Pros

Laser marking is one of the fastest stipping solutions available in the market. This results in high productivity and cost benefits during manufacture. Depending on the material structure and size, different machines or generators can be used to further increase the speed. It's permanent and at the same time resistant to abrasion, heat and acids. Depending on the parameter settings, certain materials can also be marked without damaging the surface. Thanks to the high precision of marking, even very delicate graphics, 1-point fonts and very small geometries will turn out clearly legible. At the same time, stipping with the laser ensures constant high mark quality results.

As a modern precision engraving method, this type of technology has unparalleled advantages compared with traditional engraving methods such as corrosion, EDM, mechanical scribing, and printing:

• Laser is used as an engraving method, and there is no processing force between workpieces. You can get benefits of no cutting force, small thermal influence, and no contact to ensure the original accuracy of the object. At the same time, it has wide adaptability to materials, which can make fine marks on the surface of a variety of materials and has good durability;

• The space control and time control are very good, and the material, shape, size and processing environment of the processing object are very free. It is especially suitable for automatic engraving and special surface engraving. And the engraving method is flexible, which can not only meet the needs of laboratory-style single-item design, but also meet the requirements of industrialized mass production;

• Laser marked lines can reach the order of millimeters to micrometers. It's very difficult to imitate and change this type of mark, which is extremely important for product anti-counterfeiting;

• The combination of laser and CNC control technology can form efficient automatic engraving equipment, which can print various characters, symbols and patterns. It is easy to use software to design marking patterns, change marking content, and adapt to the high-efficiency and fast-paced requirements of modern production;

• It has no pollution source and is a clean and pollution-free high environmental protection laser technology;

Laser marker has been widely used in all walks of life, opening up broad prospects for high mark quality, high-efficiency, pollution-free and low-cost modern manufacturing and production. With the continuous expansion of modern marking applications, the requirements for miniaturization, high efficiency and integration of laser manufacturing systems are also higher.

Cons

Industrial lasers are invisible and cause certain damage to eyes and skin. Therefore, safety protection measures must be taken during use to avoid direct or scattered radiation from the optical output mirror. At the same time, appropriate precautions should be taken to prevent the output beam or reflected beam from directly hitting the human body. Both scattered and reflected light can cause skin and eye damage. Appropriate protective goggles should be worn at all times during the operation, and shielding tooling can also be installed within the processing range to isolate the radiated light and prevent the radiated light from scattering to cause damage to the eyes and skin.

• When the marker is working, do not install the sight;

• When operating the equipment, it is forbidden to look directly at the output head, and make sure to always wear goggles;

• Operations other than those mentioned for the controls, adjustments, or performance of the equipment may create a risk of radiation exposure.

Doing a good job of environmental protection measures for marking equipment can effectively avoid safety problems during use. The specific measures are as follows:

• The machine always works under the power supply with proper grounding and nominal voltage;

• When using the sight, you need to ensure that the smart generator is turned off;

• Do not expose the device to high humidity;

• Make sure that the ambient temperature and humidity are within the specified range before turning on the device;

• It is forbidden to look directly at the output head, and make sure to wear goggles when operating the product;

• In addition to the control, adjustment or performance mentioned in the equipment manual, other operations may cause the risk of radiation exposure;

• For collimated output, it is essential to keep the output lens clean. After use, replace the protective cover of the sight, do not touch the output lens, and do not use any solvent to clean it, you can use lens tissue for cleaning.

Technical Parameters

| Brand | STYLECNC |

| Laser Power | 20W, 30W, 50W, 60W, 70W, 80W, 100W, 130W, 150W, 180W, 200W, 300W |

| Laser Source | Fiber laser, CO2 laser, UV laser |

| Laser Generator | IPG, Raycus, JPT |

| Laser Wavelength | 10.6 μm, 1064 nm, 355 nm |

| Marking Depth | 0.01~0.5mm |

| Marking Speed | ≤15000mm/s |

| Marking Content | Letters, Numbers, Signs, Logos, Patterns, Pictures |

| Price Range | $3,000.00 - $70,000.00 |

| Cooling Way | Air cooling, Water cooling |

| Operation System | Microsoft Windows |

User's Guidance

A laser marking machine is beginner-friendly and easy to use, starting with some simple step-by-step prompts, including preparing designs, placing and fixing materials, setting and debugging marking parameters, calibrating the laser focus, previewing and running your engraving projects.

1. Check the waterway and circuit before turning on the power of marker. The boot sequence is:

• Turn on the incoming power and turn on the key switch. At this time, the machine exhaust and the cooling system are energized, and the ammeter shows a value of about 7A.

• Wait 5 to 10 seconds, press the trigger button on the external control panel, the ammeter shows the value is zero, after 3 to 5 seconds, the krypton lamp ignites, the ammeter shows the value 7A. (Refer to the operating instructions of the laser power supply).

• Power on the galvanometer.

• Turn on the computer and call up the required marking file.

• Adjust the power to the working current (10 ~ 18A), you can start marking.

2. After marking, turn off the power of each component in reverse according to the above sequence:

• Adjust the working current of the power supply to the minimum (about 7A).

• Shut down the computer.

• Turn off the power of the galvanometer.

• Press the stop button.

• Turn off the key switch.

• Disconnect incoming power.

Buyer's Guide

You can start shopping for a laser marking machine in a few easy-to-follow steps, from determining your specific needs to planning your budget, researching different brands and models, comparing features and costs, reading customer reviews online, and checking warranty, technical support, as well as any additional costs.

Step 1. Request A Consult.

You can consult with our sales manager online, and we will recommend the most suitable machine to you after being informed by your requirements.

Step 2. Get Free Quotation.

We will offer you with our detail quotation based on your consulted machine. You will get the best specifications and the affordable price within your budget.

Step 3. Sign A Contract.

Both sides carefully evaluate and discuss all the details (technical parameters, specifications and business terms) of the order to exclude any misunderstanding. If you have no doubt, we will send you the PI (Proforma Invoice), and then we will sign a contract with you.

Step 4. Build Your Machine.

We will arrange the machine making as soon as receiving your signed sales contract and deposit. The latest news about building will be updated and informed to the buyer during the manufacturing.

Step 5. Inspection.

The whole production procedure will be under regular inspection and strict quality control. The complete machine will be inspected to make sure they can work very well before out of factory.

Step 6. Shipping.

Shipping will start as the terms in the contract after your confirmation. You can ask for transport information at any time.

Step 7. Custom Clearance.

We will supply and deliver all the necessary shipping documents to the buyer and ensure a smooth customs clearance.

Step 8. Support & Service.

We will offer professional technical support and free customer service by Phone, Email, Skype, WhatsApp, Online Live Chat, Remote Service. We also offer door-to-door service in some areas.

Care & Maintenance

Laser marking machine is a professional engraver that integrates generator, CNC control system, machine and electricity. Nowadays, with more and more emphasis on copyright, it has become indispensable, whether it is used in manufacturing or DIY in terms of personalization, it is very popular in all walks of life. With the continuous expansion of market demand, the use of laser markers in all walks of life is becoming more and more widely, because its price is not cheap, and its maintenance is also valued by everyone.

After the machine is used for a period of time, if it does not pay attention to daily maintenance, its function is easily subject to certain wear and tear, which will directly affect the marking effect, marking speed and the life of the machine. Therefore, we must regularly perform maintenance.

Daily Maintenance

• Clean the dust, dirt and foreign matter inside the equipment, use a vacuum cleaner, alcohol and dust-free cloth to remove dust, dirt and foreign objects;

• Check whether the focal length is within the range of the standard focal length, and test that the laser reaches the strongest state;

• Check whether the lens of the field lens is dirty, wipe with lens cleaning paper;

• Check whether the parameter setting screen is normal and the parameters are within the setting range;

• Whether the machine is turned on normally, whether the machine main switch, control switch, and marking system switch are turned on normally;

• Confirm that the switch is normal and effective. After pressing the switch, check whether it is energized, whether the it is working normally.

Weekly Maintenance

• Keep the machine clean and clean the surface and interior of the machine;

• Check whether the red light preview can be turned on normally, the parameters are within the setting range, open the red light correction on the software to turn on the red light;

• To clean the field lens, first use special lens cleaning paper dipped in alcohol to wipe in one direction, and then wipe it with dry lens cleaning paper;

• Check whether the beam is normal, open the software and start manual marking for test.

Monthly Maintenance

• Check the lifting rail for looseness, abnormal noise, oil leakage, clean with a dust-free cloth and add lubricating oil;

• Clean the dust at the air outlet to ensure normal heat dissipation. Clean the dust, waste nodes and other foreign objects inside the equipment, use a vacuum cleaner, alcohol and dust-free cloth to remove dust, dirt and foreign objects;

• Check whether the beam becomes weak, use a power meter to test;

• Check whether there is any looseness in the power plug and each connection cable connector, check each connector part; whether there is poor contact;

• Check whether the red preview light path is shifted and perform red light correction.

Annual Maintenance

• Check the cooling fan, whether it rotates normally, and clean the power supply and control board dust;

• Check whether each motion axis is loose, abnormal noise, smooth operation, clean with a dust-free cloth and add lubricating oil.

Cautions

• Please wear protective glasses when working to avoid stimulating the bright light to damage the glasses;

• Special attention is forbidden to put your hand within the laser scanning range during use;

• When the machine is improperly operated, resulting in an emergency, immediately press the power off;

• To prevent electric shock, do not operate with wet hands;

• During the operation of the machine, do not put your head or hand into the machine to avoid personal injury;

• No specific system parameters may be changed at will without the permission of the equipment technician.

Trends

Automation & Intelligence

In the era of digital economy, the development of digital technology has greatly improved the efficiency of production and innovation. With the CNC control system, the marking tool will have the ability to analyze, judge, reason and make decisions on the process, so as to realize the various parts of manufacturing equipment. automation and intelligence. At the same time, the rising labor cost and the upgrading and iteration of industrial technology have also prompted the development of laser marker in the direction of higher automation and intelligence. It can be predicted that with the rapid advancement of the intelligent manufacturing strategy, digitalization and intelligence will become an inevitable trend of development, and highly intelligent multi-functional marking machine will continue to emerge, which will greatly improve industrial manufacturing efficiency to achieve efficient production management.

High Power, High Efficiency, High Precision

With the development of the laser industry and changes in the needs of downstream industries, medium and high-power marking machine has become a hot spot in the market. With the upgrading of the engraving tool, high-power and high-speed engravers will take advantage of its remarkable efficiency and accuracy. Further replace the traditional processing equipment, greatly improve the efficiency and quality of industrial manufacturing.

Flexibility & Integration

In the era of intelligent manufacturing, the processing scenarios of downstream users tend to be diversified and complicated, and the individualized demand for marking machine is increasing day by day, requiring makers to have more flexible product applications, suitable for different processing scenarios, and meet the diversified needs of customers. Therefore, adopting modular design, improving equipment integration, adaptability, and functionality, and realizing flexible production oriented to consumer needs will become an important development direction of the marking machine industry in the future.

Things To Consider

The laser-marked marks are difficult to wear and easy anti-counterfeiting, which makes a great role in promoting the improvements of product quality and grades. The existing laser marker in which the hardware must be installed on the computer’s motherboard and the whole marking process is inseparable from the computer and reduce the stability of marking machines, but also increase the cost and the size.

With the further integration of the laser manufacturing technology, it is becoming a trend that laser marker develops into the lighter and the smaller. The marking system can be divided into two parts: graphics editing and marking control. The work of graphics editing is achieved on the computer. The core of the control software runs on the control card. LDB file is used to store the data making by the graphics editing and through the USB device sends the data to the control card, which doesn’t need the involvement of the computer any longer when it’s marking. Research has focused on the improvement of oblique-line and correction algorithms, and a control algorithm to control the marking of the graphics, and analysis the FAT file system of the USB device.

So what are you waiting for? Contact us today and we'll help you find the perfect laser marking machine to meet your needs and budget. We can't wait to hear from you.