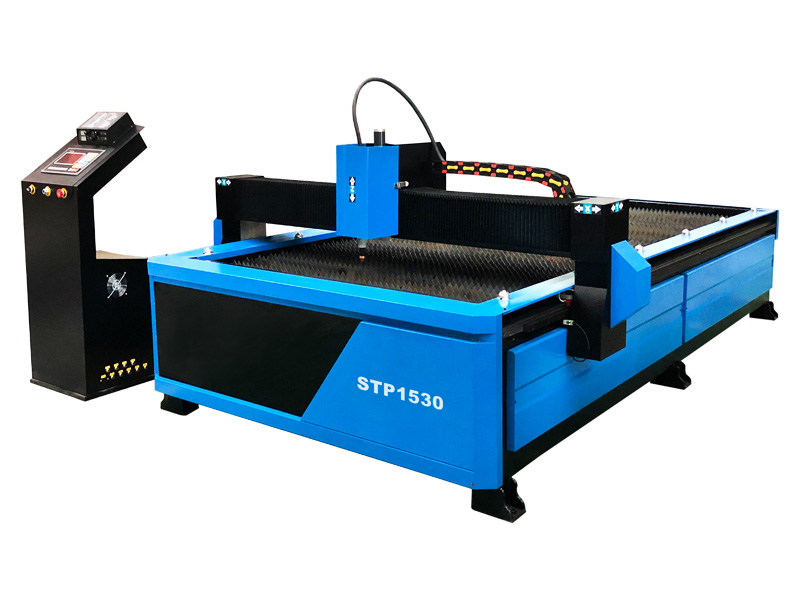

This CNC was purchased for my business expansion. Quality parts and easy to put together. I was curious how well it could cut. The torch automatically moved along the tool path to cut through sheet metal, resulted smooth contour cuts with a guide of CNC controller. Great cutting tool for commercial use.

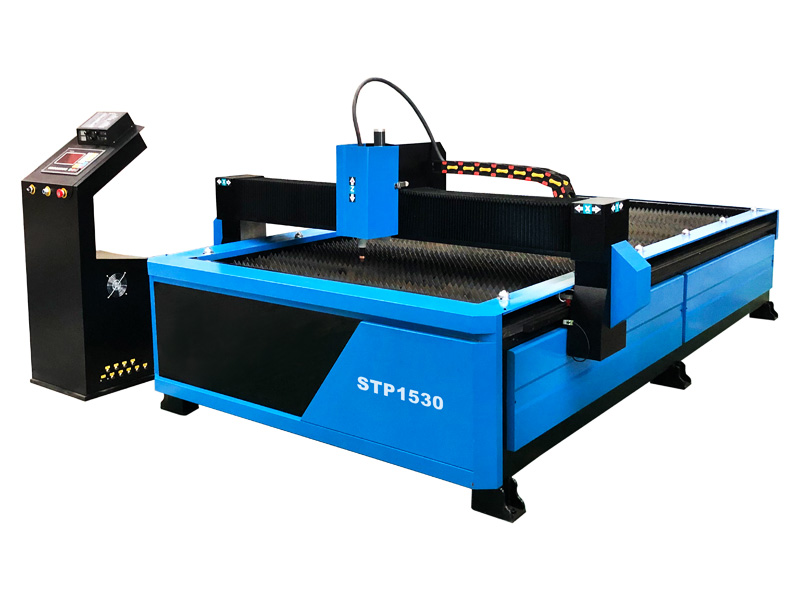

High Definition CNC Plasma Cutter for Metal Fabrication

High definition CNC plasma cutter is a type of 5x10 Hypertherm plasma table kit for custom sheet metal fabrication of aluminum, steel, copper, iron, alloy in machinery, automobile, metal parts, ship building, war industry, metallurgy and more. Now the best budget precision 5x10 CNC plasma table for sale at cheap price.

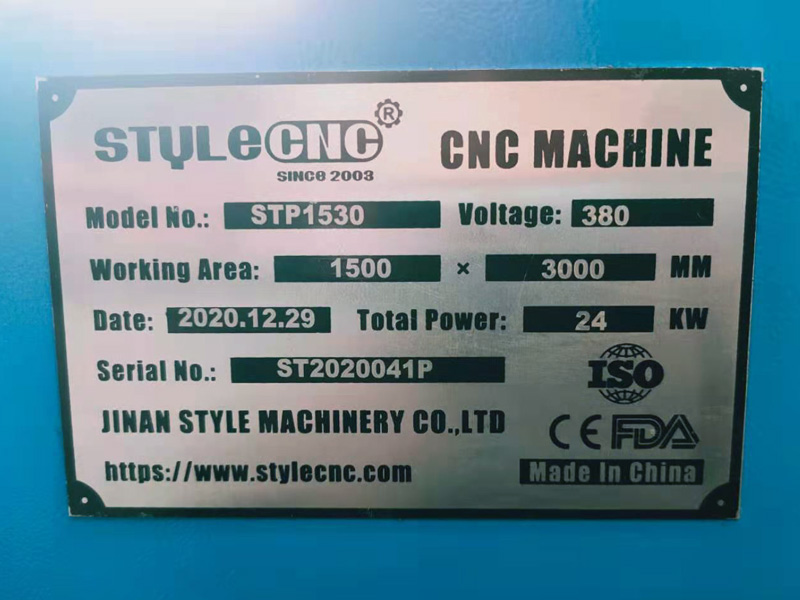

- Brand - STYLECNC

- Model - STP1530

- Maker - Jinan Style Machinery Co., Ltd.

- Category - CNC Plasma Cutter

- 360 Units in Stock Available for Sale Every Month

- Meeting CE Standards in Terms of Quality & Safety

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- 30-Day Money Back Guarantee for Your Purchase

- Free Lifetime Technical Support for End-Users & Dealers

- Online (PayPal, Alibaba) / Offline (T/T, Debit & Credit Cards)

- Global Logistics and International Shipping To Anywhere

High-definition CNC plasma cutters are cutting instruments that use plasma, a superheated ionized gas, to produce precise cuts in metals. These devices are widely used in industries that require high accuracy, such as metal fabrication, automotive, and manufacturing. High-definition plasma cutters make cleaner, smoother cuts with less waste than traditional plasma cutters.

Operators can program intricate designs into these machines thanks to CNC (Computer Numerical Control) technology. Once programmed, the machine can cut consistently without human intervention. This increases manufacturing efficiency and guarantees that every cut meets the needed criteria.

A variety of metals, such as copper, aluminum, and steel, can be cut with high-definition plasma cutters. They save time and money by reducing the need for additional finishing stages thanks to their accuracy and rapid cutting speed. These gadgets are essential equipment for metalworking businesses trying to boost productivity and enhance product quality.

Features of High-Definition CNC Plasma Cutter for Sheet Metal Manufacturing

1. Welded structure of thickening square tube, together with top brand guide rail to ensure high running speed and accuracy.

2. Hypertherm plasma power supply together with a highly sensitive arc pressure adjuster. Self-adjusting can choose the best distance between the plasma gun and the working piece automatically to ensure high-accuracy cutting.

3. High definition CNC pasma cutter for sheet metal uses STARFIRE control system with FastCAM software for auto material saving function, large capacity storing function, convenient to read and process.

4. The plasma cutting torch with a professional cooling system can quickly cool the surface of the material to avoid burr and residue.

5. The high-precision rack and pinion driven stepper motor allows the CNC plasma cutting machine to operate with low noise, smooth movement and precise coordinate positioning.

6. Perfect software compatibility, such as Ucancam, Type3, and ArtCAM.

Technical Parameters of High-Definition CNC Plasma Cutter for Sheet Metal Manufacturing

| Model | STP1530 |

| Table Size | 5x10 |

| Frame | Square tube Integral guide |

| X/Y/Z Rail | Taiwan HIWIN Linear guide |

| Transmission | X/Y rack and pinion,Z Taiwan TBI Ball Screw |

| Motor driver | Stepper Motor driver |

| Control System | STARFIRE |

| Cutting Thickness | 3mm-30mm stainless steel |

| Plasma Power Supply | PowerMax 45A/65A/85A/105A |

| Working Speed | 8000mm/min |

| Working Voltage | 220V,2PH or 380V,3 PH |

| Software | ArtCAM/Type 3/Ucancam |

Details of High-Definition 5x10 CNC Plasma Cutting Table with Hypertherm Plasma Cutter for Sheet Metal Manufacturing

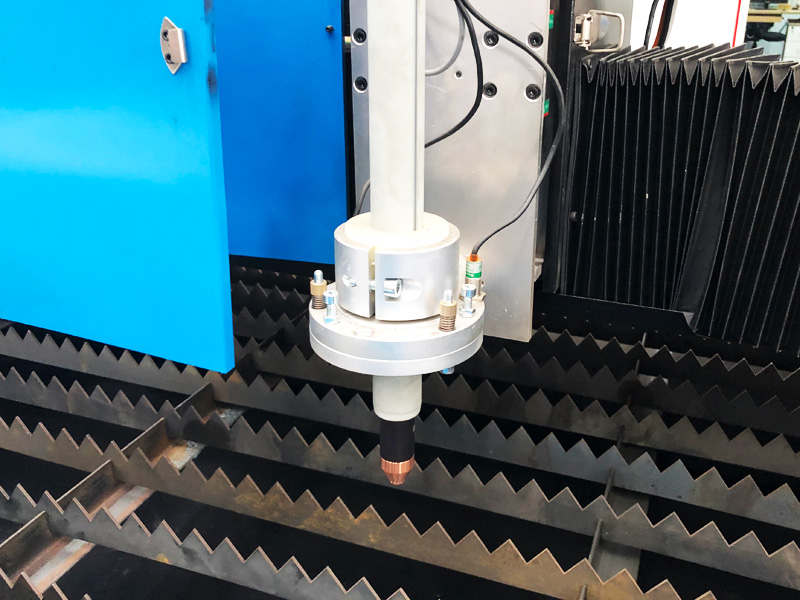

Hypertherm Plasma Cutting Gun.

Professional STARTFIRE Control System.

Hypertherm Plasma Cutting Nozzle.

Hypertherm Plasma Power Supply.

Identification Plate for STP1530.

Advantages of Using a High-Definition CNC Plasma Cutter

Metal cutting processes are made easier, faster, and more precise with high-definition CNC plasma cutters. They are crucial tools for companies seeking to boost production, cut expenses, and maintain high-quality standards. The following are the primary advantages that make these devices popular across sectors.

• Precision and Clean Cuts: These devices provide extremely precise cuts with clean edges. Their accuracy saves time during post-processing by removing the need for extra sanding or grinding. Excellent quality cutting is achieved even with thin materials and complex designs.

• Faster Production: High-definition plasma cutters operate at high speeds, completing tasks faster than other cutting methods. This speed allows businesses to meet tight deadlines and increase their overall productivity.

• Versatile Material Handling: These machines can cut a variety of metals, including stainless steel, carbon steel, and aluminum. Their versatility makes them valuable for industries such as automotive, construction, and manufacturing.

• Cost Savings: Long-term savings are advantageous for firms, despite the substantial initial investment. Automation minimizes labor expenses by reducing manual intervention, while an efficient cutting process minimizes material waste.

• User-Friendly Operation: These plasma cutters are simple to use because they have CNC control. Because of the machine's basic software, even a novice can figure out how to operate it with little to no training.

Applications of High-Definition CNC Plasma Cutting Machine for Sheet Metal Manufacturing

The high-definition 5x10 CNC plasma cutting table with Hypertherm plasma cutter is widely applied in industries of machinery, automobile, shipbuilding, petro-chemical, war industry, metallurgy, aerospace, boiler and pressure vessel, locomotive, etc.

All types of sheet metal materials, including copper, aluminum, stainless steel, and steel, can be processed using the 5x10 high-definition CNC plasma cutting table with Hypertherm plasma cutter. Similar to sheet metal, it is utilized for titanium plates, stainless steel, aluminum plates, galvanized sheets, and white steel plates.

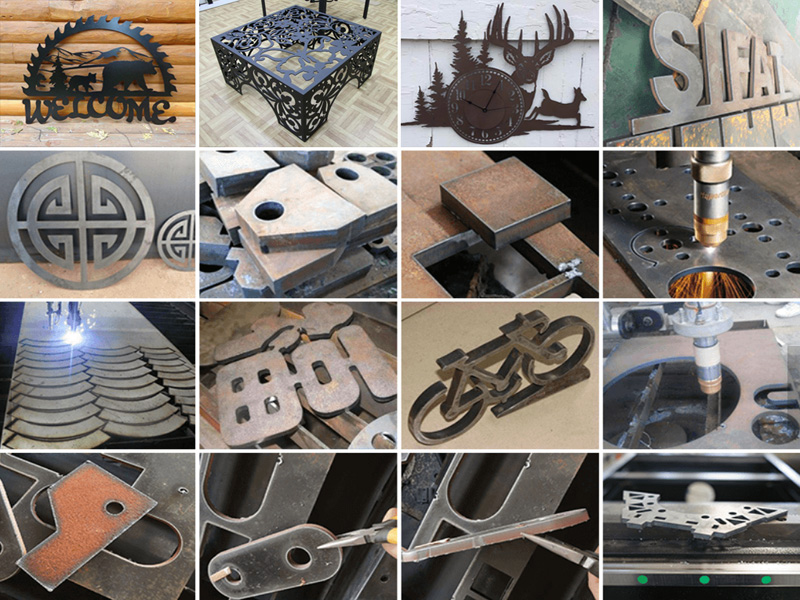

High-Definition CNC Plasma Cutter for Sheet Metal Manufacturing Projects

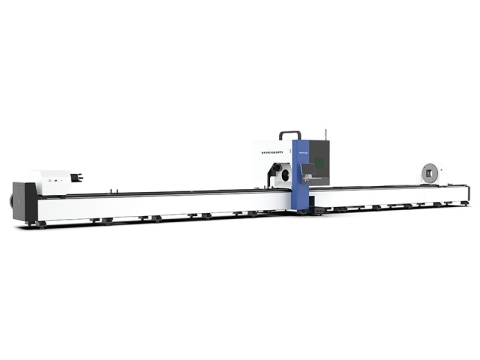

A rotary device is a good option attached to this high definition CNC sheet metal plasma cutting machine to cut metal tubes and pipes.

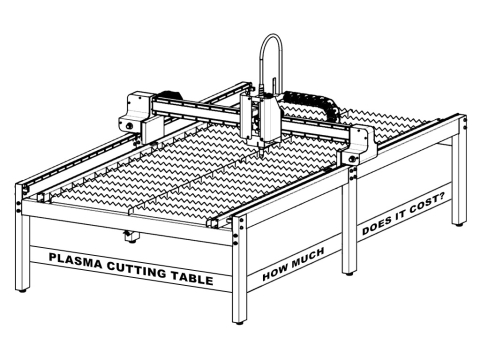

How to Choose the Right CNC Plasma Cutter for Your Business?

Choosing the correct CNC plasma cutter is crucial in ensuring smooth operations and maximum efficiency. A well-chosen tools can satisfy your company's needs, increase production, and reduce downtime. Here are the most essential factors to consider before making your decision.

Identify Your Needs

Understand the types of metals you’ll be working with and their thickness. If your projects involve a mix of thin and thick materials, opt for a machine that can handle a wide range of thicknesses effectively. The right cutter ensures smooth, precise cuts across all material types, avoiding quality issues.

Machine Size and Work Area

Match the machine’s cutting bed size with the size of your metal sheets. If you frequently work with larger sheets, a bigger machine will save time by reducing the need for repositioning materials. Make sure the machine fits your workspace without compromising safety or ease of access.

Software Compatibility

Ensure the machine’s software integrates seamlessly with your design tools like CAD or CAM. A user-friendly interface will minimize errors and help your team quickly adapt to the workflow. Software that supports automation features can further boost productivity.

Check Power Requirements

Verify that your facility’s electrical system can support the plasma cutter. Machines requiring higher voltage may need special wiring or upgrades to your power supply. Planning for these requirements helps avoid costly installation delays.

Customer Support and Maintenance

Choose a brand with reliable technical support and easy access to spare parts. This ensures any operational issues are resolved quickly, keeping your production schedule on track. Regular access to maintenance guides and troubleshooting assistance ensures smoother long-term operations.

Maintenance Tips for High-Definition CNC Plasma Cutters

Proper maintenance keeps your high-definition CNC plasma cutter running efficiently and prevents unexpected breakdowns. Routine care helps extend the machine’s lifespan, ensures consistent performance, and reduces the chance of costly repairs. Follow these essential tips to keep your plasma cutter in top shape.

Keep the Machine Clean

• After every use, clean the machine to remove dust, slag, and metal particles.

• A clean machine operates smoothly and maintains cutting precision over time.

• Regular cleaning prevents buildup that could interfere with the machine’s moving parts and cutting quality.

Inspect Consumable Parts

• Regularly inspect nozzles and electrodes for signs of wear or damage.

• Worn consumables can reduce cut accuracy and disrupt the production process.

• Prompt replacement ensures uninterrupted operation and high-quality results.

Lubricate Moving Parts

• Lubricate rails, bearings, and other moving components to reduce friction.

• Proper lubrication helps prevent wear and tear, extending the machine's lifespan.

• Smooth operation ensures precision cuts and reduces stress on the mechanical system.

Monitor Electrical Connections

• Periodically check that all electrical connections are tight and secure.

• Loose wires can lead to malfunctions or short circuits, damaging internal systems.

• A quick inspection prevents unexpected downtime and costly repairs.

Update Software and Firmware

• Install the latest software and firmware updates from the manufacturer.

• Updates often include performance improvements, bug fixes, and new features.

• Staying current ensures the machine runs efficiently and reliably over time.

Todd Palmertree

Mohammed

This CNC plasma cuts very easy on 220v, like cutting butter with a hot knife. Very good machine, but I also recommend purchasing the nozzles and the tips of the torch (consumables) they wear out quickly and for a good operation they must be in good condition.