Precision cutting tool for fabrics. Easy to use and essential in your clothing store. From feeding to cutting, everything is automatic. I tried cutting digital printed fabric and got precise cuts without the burnt edges that laser cutting tends to do. So far, this CNC cutter is perfect. Easy to get blades and tools for it too, which was a consideration. All in all, a game changer for my custom apparel business, and no more scissors.

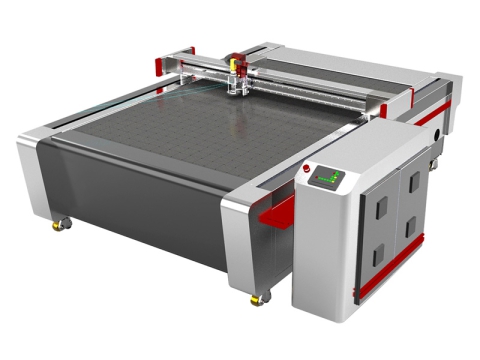

Industrial Automatic Digital Fabric Cutter Machine for Sale

Automatic digital fabric cutter is a type of industrial fabric cutting machine with CNC controller to cut textile and leather for commercial use in small business and industrial manufacturing.

- Brand - STYLECNC

- Model - STO1625A

- Maker - Jinan Style Machinery Co., Ltd.

- Category - CNC Digital Knife Cutting Machine

- 360 Units in Stock Available for Sale Every Month

- Meeting CE Standards in Terms of Quality & Safety

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- 30-Day Money Back Guarantee for Your Purchase

- Free Lifetime Technical Support for End-Users & Dealers

- Online (PayPal, Alibaba) / Offline (T/T, Debit & Credit Cards)

- Global Logistics and International Shipping To Anywhere

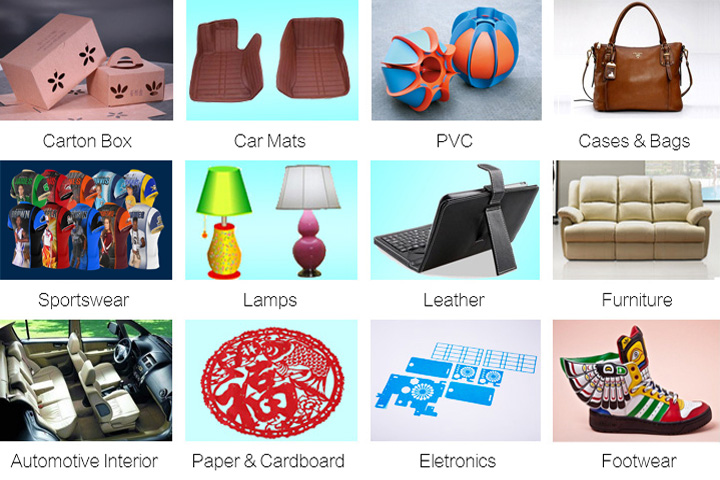

Digital fabric cutting machine is an automatic industrial CNC cutting system for fabric, textiles, leather, carpets, foot mats, leather seats, lining, tail box pads, car seat cushions, wire ring pads, and automotive interiors, it can also cut sponge, EVA, soft glass, silicone, rubber and more. Digital precision fabric-cutting machines are widely used in the industries such as costumes, shoes, furniture, sports goods, packages, home textiles, decorations, cars, and so on. This digital fabric cutting machine is also known as a CNC fabric cutting machine, industrial fabric cutting machine, digital fabric cutting system, digital fabric cutter, precision fabric cutter, digital leather cutting machine, digital textile cutting machine, industrial leather cutter, and industrial textile cutter.

Why Choose CNC Fabric Cutting for Textile and Leather?

Precision, efficiency, and versatility make CNC fabric cutting an excellent option for leather and textile applications. Detailed patterns and a reduction in material waste are made possible by the precise and reliable cuts that CNC cutters produce. By ensuring a precise fit between all the pieces, faults are minimized.

Productivity is increased by these devices since they automate the cutting process. Because it saves time and personnel costs, this is especially advantageous for large-scale manufacturing. Multiple types of fabrics, leather, and synthetic materials are among the materials that CNC fabric cutters can handle. Because of this, they can be used for a variety of things, such as upholstery and fashion.

The crisp, smooth edges produced by CNC cutting eliminate the need for additional polishing. Thanks to CNC technology, designs may be easily adjusted, making it easier to produce unique patterns or consistently repeat intricate cuts.

Technical Parameters of Industrial Digital Fabric Cutting Machine

| Model | STO1625A |

| Working area | 1600×2500mm |

| Control system | Kinco touch screen control system |

| Precision | ±0.01mm |

| Cutting thickness | ≤50mm |

| Maximum cutting speed | 500-1000mm/s |

| Safety device | Infrared sensors |

| Drive system | Panasonic servo motor |

| Transmission system | Taiwan square linear guide and belt |

| Graphic format supported | DST,PLT, BMP, DXF, DWG, AI, LAS, etc. |

| Vacuum pump | Included |

| Working table | Flat table or Automatic feeding table |

| Voltage | 380V±10%, 50Hz or 220V±10%, 60Hz |

| Machine Size | 3570mmx2290mmx1165mm |

Advantages of Automatic Industrial Digital Fabric Cutting Machine

High Speed

Only need 80 seconds to finish one set of car foot mats, and only need 6 minutes to finish one set of car cushion mattresses.

High Efficiency

No need for any die mold, or die mold cutting machine, this digital cutting machine can press mark, cut, and mold on soft materials such as fabric, leather, textile, cartons, and more, saving much labor and cost.

Low Cost

The digital fabric cutting machine machine can do design, and cutting instead of manual design and cutting, saving labor, and material wastage costs.

Wide Applications

This digital leather cutting machine can cut textile, fabric, leather, paper, carton, PU, fiber, PVC foot mat, EVA, XPE, fiberglass, composite cladding, sponge cladding, sponge+drape+composite leather, plastic board, and other soft materials.

High Performance

The flatbed digital cutter adopts a Taiwan TBI ball screw or high-precision rack pinion with low noise, accurate transmission, long service life, and high precision.

Features of Automatic Digital Fabric Cutting Machine

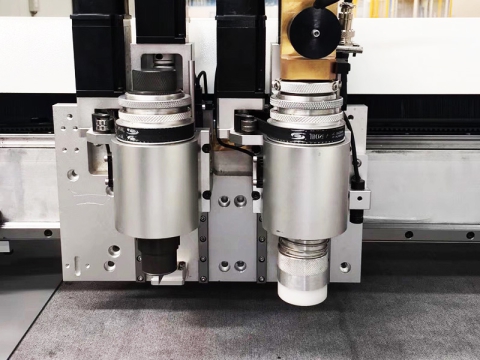

• Electric Oscillating Tool (EOT)

The Electric Oscillating Tool is ideally suitable for cutting soft, medium-density materials. The high oscillating frequency makes it possible to cut at high processing speeds for greater throughput.

EOT+POT+CCD+Marking pen.

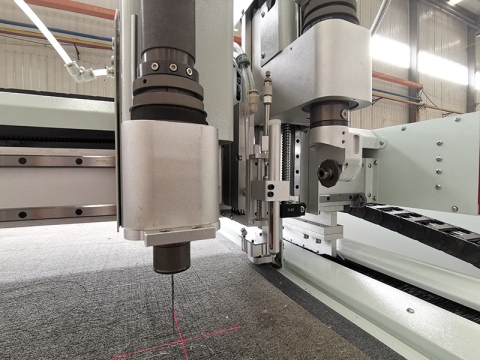

• Aluminum vacuum table with high density felt covered.

• Infrared sensors can effectively protect the safety of the operator.

• Taiwan Hiwin square rails to guarantte high speed cutting automotive interior designs.

• CNC controller - Automatic English operation system with touch screen, easier to operate.

• Stable structure - Thick wall square tube welding, side plate tempering treatment, the lathe bed is processed by five side milling machining center, aging treatment, solid without deformation.

• Kinco touch screen control system with high precision, high efficiency, high reliability, green and environmental protection automatic cutting.

• Modular structure design, simple and safe operation mode, to ensure the speed and accuracy of operation.

• Vacuum adsorption table, high-power vacuum pump, air volume up to 300m³/hour.

• Perfect lubrication system to extend the service life of the machine.

• The gantry-type movement is adopted, and the materials on the working table can be processed at will, so the operation is convenient.

• The X/Y axis is driven by a high-precision rack, with high-speed and precision.

• The Z axis is driven by a high-precision double nut automatic clearance ball screw with high precision.

• The digital leather cutting machine adopts a square linear guide rail to ensure the high precision and bear a large load.

• The wire adopts imported highly flexible shielded cable.

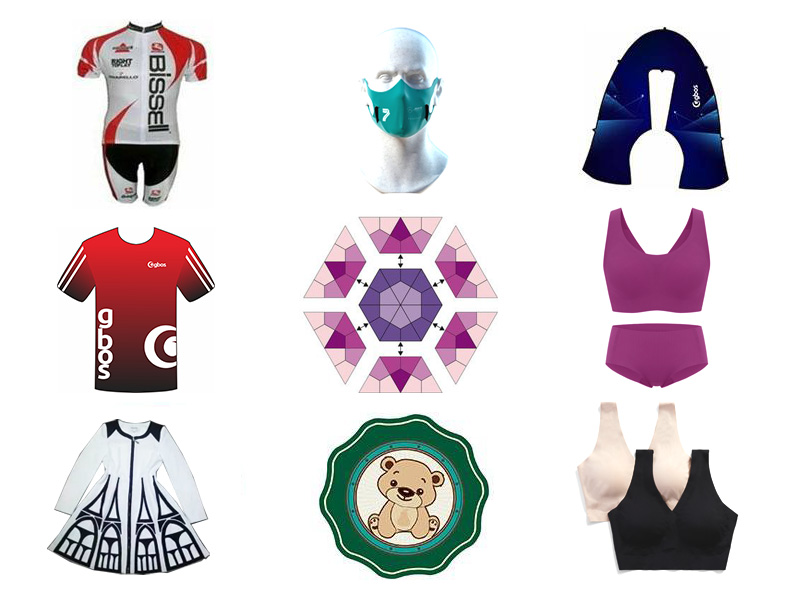

Automatic Digital Fabric Cutter Applications

Automatic digital fabric cutter is applied in industrial manufacturing for sofas, seats, car seat covers, car floor mats, car carpets, handbags, shoe industry, clothing industry, composite material industry, luggage industry, automobile industry, advertising and printing industry, electronic industry, decoration industry, furniture industry, packaging industry and more.

Industrial Digital Fabric Cutting Machine Projects

Automotive Interior Cutting Designs

Automatic digital fabric cutter can be configured with different cutting tools for different work, such as a V-cut tool for producing complex structural designs from foam or corrugated paper materials, a pneumatic oscillating tool for cutting tough and dense materials, a wheel knife tool for cutting glass and carbon fiber as well as textiles, and kiss cut tool for cutting vinyl and so on.

If you are not sure what type of tools you need, please send us an inquiry with your details of materials, we have a professional service team to recommend the best suitable industrial digital cutting machines and tools.

Maintenance Tips for CNC Fabric Cutting Machines

To ensure long-term performance and maintain your CNC fabric-cutting machine operating smoothly, maintenance is necessary. In addition to preventing malfunctions, routine maintenance increases the machine's lifespan. The following are essential guidelines for maintaining the best possible condition for your CNC fabric cutter. You can minimize the likelihood of unplanned downtime and maintain optimal performance from your CNC fabric-cutting machine by adhering to these maintenance suggestions.

• Debris, fabric fibers, and dust can gather on the parts and surface of the machine. To avoid accumulation that could compromise the quality of the cut, clean the cutting table, the blades, and the surrounding areas after every usage.

• Often examine the blades for damage. Ineffective cutting and increased machine load might result from dull or broken blades. To preserve accuracy, replace blades as necessary.

• Proper lubrication of moving parts, such as bearings and rails, helps to guarantee smooth functioning by lowering friction. As directed by the manufacturer, use the lubricants that are recommended.

• To keep your computer operating at peak performance, keep the software updated. Bugs can be fixed and cutting precision increased with updates.

• It is important to calibrate the machine regularly to guarantee that the depth and alignment are right. Sustaining consistent outcomes requires doing this.

• Check air filters and vacuum systems frequently to maintain ideal suction and hold-down strength if your machine has a vacuum table.

Following these maintenance tips will keep your CNC fabric-cutting machine performing at its best and reduce the chances of unexpected downtime.

Lara Porter

Lodano

This automatic digital cutter has completely changed my way of thinking in cutting fabric. I have always used different sizes of scissors for this job in the past, However, I used this automated fabric cutting machine on cotton fleece fabric in my clothing customization workshop, and it was like a hot knife through butter. It was precision with the clean edges. In addition, it is stable and easy to use and it has an impressive automatic controller. I think for the price you do get a quality machine which will save you cost and time.

Olivia

I use this digital cutting machine to cut fashion and textiles. Cuts perfectly well with smooth edge. I like how easy it is to use this fabric cutter. Great value for the price.