CNC Laser Fabric Cutter for Home Use with Automatic Feeder

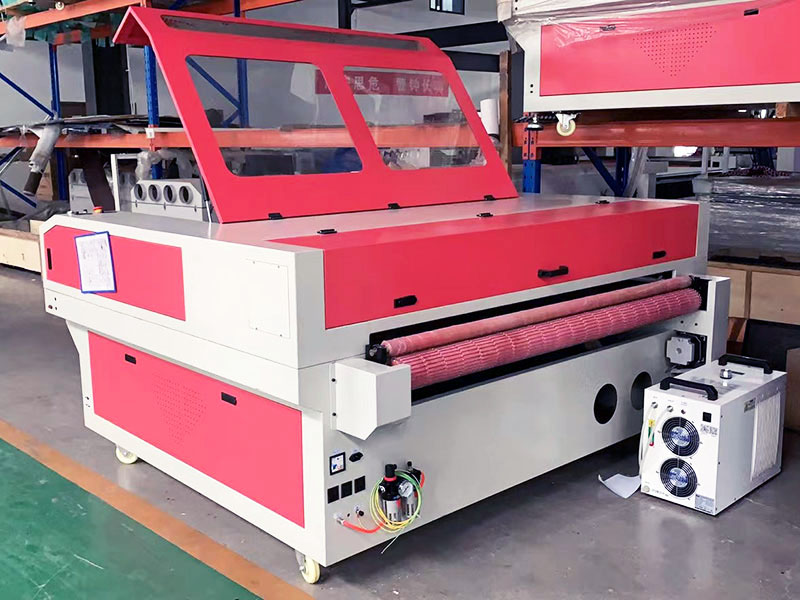

STJ1610A CNC laser fabric cutter for home use with an automatic feeding system is used for precisely cutting fabric, textile and leather to make personalized clothing, fashion, suits, sportswear and workwear in home shop and small business. Now the affordable fabric laser cutting machine for sale at cost price.

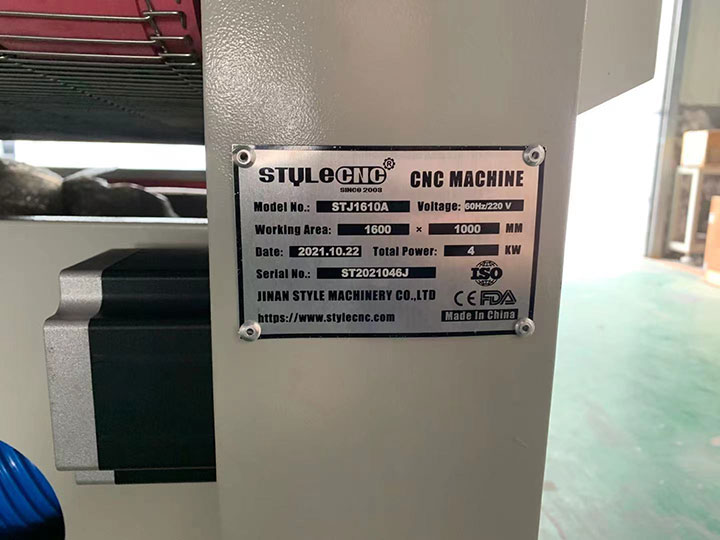

- Brand - STYLECNC

- Model - STJ1610A

- Maker - Jinan Style Machinery Co., Ltd.

- Sizing - 1600mm x 1000mm

- Category - CO2 Laser Cutting Machine

- Laser Source - Yongli, RECI

- Power Option - 100W, 150W

- 360 Units in Stock Available for Sale Every Month

- Meeting CE Standards in Terms of Quality & Safety

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- 30-Day Money Back Guarantee for Your Purchase

- Free Lifetime Technical Support for End-Users & Dealers

- Online (PayPal, Alibaba) / Offline (T/T, Debit & Credit Cards)

- Global Logistics and International Shipping To Anywhere

What is Laser Fabric Cutter?

A laser fabric cutter is a type of CO2 laser cutting system that uses high-energy-density laser beams to complete rapid cutting work on clothing fabrics. Fabric laser-cutting machines are widely used in the textile and garment industry. Laser fabric cutting machines are applied to cut fabrics, lint-free cloth, linen, cotton, chemical fiber, woven fabrics, lace, leather, mesh, trademarks, clothing accessories, and more flexible fabrics.

Traditional cutting methods lag with precision and accuracy and this is the key reason that CNC laser fabric cutters are gaining popularity progressively. Traditional cutting methods like scissors, rotary cutters, and manual fabric cutting machines usually fail to cut intricate patterns.

On the other hand, a CNC laser fabric cutter with an automatic feeder offers versatility and flexibility with better efficiency.

Key Components

A detailed knowledge of the key components will help run the machine more easily even at home. Let’s take a look at the key components in brief.

✔ Laser Tube and Laser Head: This is the source of the laser beam with a CO2 gas mixture. The mixture is excited with electrical energy and the power is measured in watts (W). The laser head focuses and directs the beam onto fabrics.

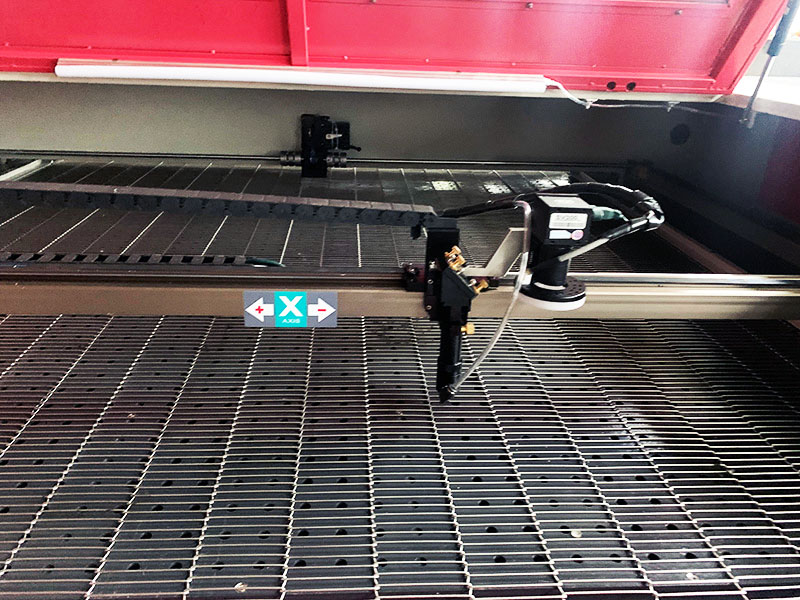

✔ Cutting Bed: The fabric is placed on the surface of the bed during the cutting process. Honeycomb and Knife Edge are two common types of bed for CNC laser fabric cutting.

✔ Control Panel and Software: The control panel is the interface of the operating system. Various compatible software does the designing and the cutting such as AutoCAD, CorelDRAW, Adobe Illustrator, etc.

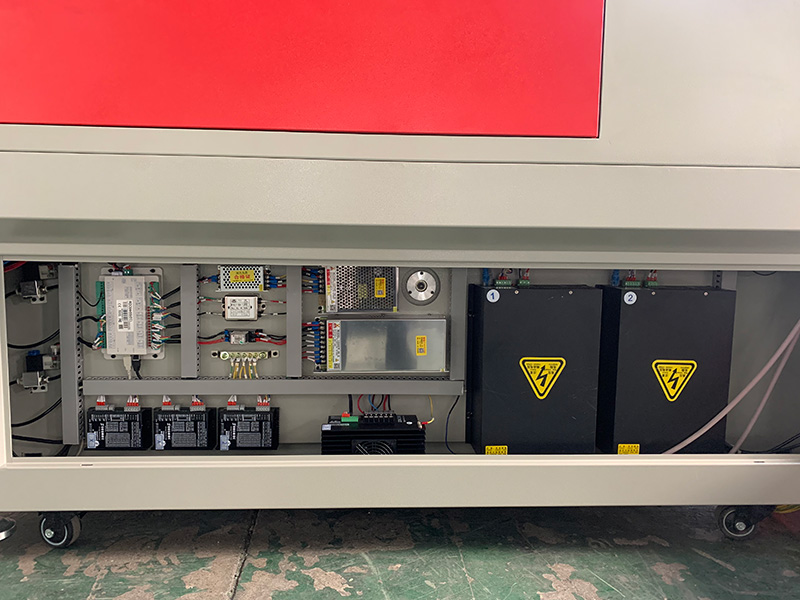

✔ Cooling and Ventilation: The cooling system saves the laser machine from overheating. The ventilation system combines an exhaust fan, air assist, and filter to remove smoke, fume, and intake air quality.

CNC Laser Fabric Cutter Advantages

Fabric laser cutting machines have the advantages of convenient and fast, flexible conversion, accuracy and efficiency, energy saving, and environmental protection in the cutting of clothing fabrics, so it is favored by users in the textile and clothing industry.

No Burr/Fraying With Laser Fabric Cutting

Laser fabric cutting is done by a high-temperature process. It can make the cutting edge close up automatically. Hence, no need to recut the fabric patterns after one-time cutting.

No Distortion To Cut Fabric

In the process of cutting, the laser does not touch the processed fabric, but the laser beam works on the fabric.

High Precision

The diameter of the laser beam can be focalized into 0.1mm. Cutting is done exactly according to uploaded graphics through computer control.

High Efficiency & Easy Operation

Just upload the graphics into the cutting machine and the laser will cut the fabric into shapes as designed.

CNC Fabric Laser Cutter Technical Parameters

| Model | STJ1610A |

| Amount of Laser Head | Single head |

| Working Area | 1600*1000mm |

| Laser Power | 100w/150w |

| Laser Type | CO2 Sealed Laser Tube,10.6μm |

| Cooling Type | Water Cooling |

| Max.Moving Speed | 1600mm/s |

| Max.Working Speed | 1400mm/s |

| Laser Output Control | 0-100% Set by Software |

| Min.Character Engraved | Chinese:2.0mm×2.0mm,Englishletter:1.0mm×1.0mm |

| Highest Scanning Precision | 4000DPI |

| Locating Accuracy | ≤+0.02mm |

| Controlling Software | DSP Control System |

| Graphic Format Supported | DST, PLT, BMP, DXF, DWG, AI, LAS |

| Compatible Software | CORELDRAW,PHOTOSHOP,AUTOCAD,TAJIMA,etc. |

| Color Separation | Yes |

| Drive System | Stepper Motor |

| Auxiliary Equipments | Exhaust Fan and Smoke Pipe |

| Power Supply | AC110V/220V+10%,50HZ/60HZ |

| Working Environment | Temperature0-45℃,Humidity5-95%(No Condensate Water) |

CNC Fabric Laser Cutting Machine Features

Fabric laser cutting machine adopts an automatic feeding system for home use and small business, no manual feeding is required, which saves time and effort. Automatic typesetting is also applied to the machine, and typesetting is based on the most material-saving method, which saves time and effort, saves materials, and reduces waste.

✔ Auto feeding system can load materials automatically which can save you time. This laser-cutting system is especially suitable for the mass processing of textiles and garments.

The automatic skew detection system is optional. The fabric will be put on the rolling system, the table will move forward every time after cutting, and the rolling system can rotate the fabric when working.

In this way, the fabric can be processed effectively, also make sure the leather or fabric can be made straight, improving the production rate.

✔ Best quality laser head with red light positioning system. The four fixing screws on the laser head freely adjust the reflector angle for easy focusing, convenience to operate, and stability.

CCD camera is a great option to cut small outlines and shapes of special designs.

✔ Professional fabric laser cutting system, more precision, optional with CCD camera together, make sure the cutting faster and more precision, customized for fabric, cloth cutting.

✔ Scientific ventilation equipment, high power exhaust fan, and a strong honeycomb worktable play vacuum adsorption, which can make the soft material very flat.

✔ The machine can be 220V or 110V voltage, which makes the operation more convenient.

✔ Each machine is manufactured with a unique nameplate.

Set-up and Maintain

Setting up the machine properly is a skill that ensures the most efficient production. Maintaining is also necessary to reduce cost-effectiveness. Let’s take a look at the setup of your CNC laser fabric cutter and a few tips to maintain the machine well for a longer lifespan.

⇲ Unbox the machine and prepare necessary tools like screwdrivers, wrenches, and safety equipment. Carefully unpack the parts and inspect them.

⇲ Assemble the machine starting with the frame assembly.

⇲ Place and install the cutting bed with clams or a vacuum hold-down system.

⇲ Attach the laser tube to the designated holder and connect the power cables and water cooling system.

⇲ Attach the laser head to the gantry.

⇲ Set up the cooling and ventilation system as instructed.

⇲ Connect to the power supply and turn on the machine to check if all components are working properly.

⇲ Install and configure the dedicated and compatible software. Connect the machine to the computer and calibrate all the settings and parameters.

⇲ Import design files and test simulation files.

⇲ Last but not least, fine-tune your settings and make sure the safety check-up.

How to Choose the Right CNC Laser Fabric Cutter?

A CNC laser fabric cutter is an asset for industrial and home manufacturing. These machines are available in a variety featuring different specs and usage. Therefore, it is crucial to find the right machine for your job. How to do that?

⇲ Asses your project needs. Select the type of project and the material type. Also, make sure the machine can provide the product size and volume you intend to manufacture. Use an automatic feeder and faster cutting speeds to increase efficiency for larger volumes.

⇲ Budget plays a vital role in choosing a CNC laser for fabric cutting. Estimate the initial cost and consider the long-term cost together. Machine cost, maintenance, and energy consumption can significantly make a difference over time.

⇲ It is important to research if the machine is going to be a value-for-money option for you. So, choose a model that is full of features. A good brand will ensure all the technical and manufacturing support you will need.

Warranty coverage is also an important aspect. Consider extended warranty coverage. This may cost additionally but is useful.

CNC Laser Fabric Cutter Applications

CNC laser fabric cutting machine is designed for cutting textile fabrics such as cotton, plush collars, real silk, polyester, chemical fiber, denim, flannel, genuine leather, artificial leather, soft surface leather, decorative leather, and packaging leather in home shop and small business.

Industrial Textile: filter cloth, bolting cloth, filter fabric, nonwoven, glass fiber, felt, synthetic fiber, fabric ducting, polypropylene (PP), polyethylene (PE), polyester (PES), polyamide (PA), cement packing, geotextile, coated fabric, PVC fabric, sponge, insulating material and other industrial flexible materials.

Non-woven fabrics For Health & Medical: insulating material, glass fiber, polyester fiber, Microfiber, Cleanroom Wiper, Glass cloth, Micro-fiber Wiper, non-dust cloth, clean wiper, paper diaper, etc.

Home Furnishing Fabrics: upholstery, carpet, mat, floor rug, mattress, curtain, doormat, valance, wallpaper, tablecloth, bed sheet, bedspread, counterpane, dust cover, sofa fabric, etc.

Garment Fabrics: sportswear, swimwear, diving suit, exposure suit, liner, lining, adhesive interlining, wadding piece, case-hardened cotton, synthetic leather, genuine leather, etc.

Automotive Interiors: car seat cover, car cushion, car mat, car carpet, car rug, pillowcase, airbag, auto dustproof cover, seat belt (safety belt), etc.

CNC Laser Fabric Cutting Machine Projects

Fabric laser-cutting machines are suitable for plush toy cloth processing, the clothing processing industry, and the leather processing industry.

All Types of Laser Fabric Cutting Machines You May Like

Large Format Industrial Fabric Laser Cutting Machine

Hobby Laser Fabric Cutting Machine

Multi Head Laser Fabric Cutter

Laser Fabric Cutting Machine with CCD Camera for Sportswear with Sublimation Printing

CNC Digital Fabric Cutting Machine

Safety Considerations!

Laser production requires several safety checkups. Following the safety rules can save workers and the machine from severe damage. Workers and experts should follow these safety considerations_

⇲ Wear personal protective equipment (PPE). This includes laser safety glasses, protective clothing, and gloves.

⇲ Ensure proper ventilation using a proper exhaust system and air filtration.

⇲ Keep a fire extinguisher within easy reach and train the workers how to use it.

⇲ Inspect the machine and its parts and maintain them daily.

⇲ Follow electrical safety rules and make sure proper electrical connections every single time.

Above all, consider long-term environmental effects and take necessary steps to reduce contamination.