2025 Best Budget 4x8 CNC Plasma Sheet Metal Cutting Machine

Are you looking forward to 4x8 plasma table plans? Review 2025 best budget CNC plasma sheet metal cutting machine with 48x96 inch table top, which can cut steel, copper, brass, aluminum, alloy, iron and custom sheet metal fabrication plans. Now the cheap 4x8 CNC plasma sheet metal cutting table for sale at low price.

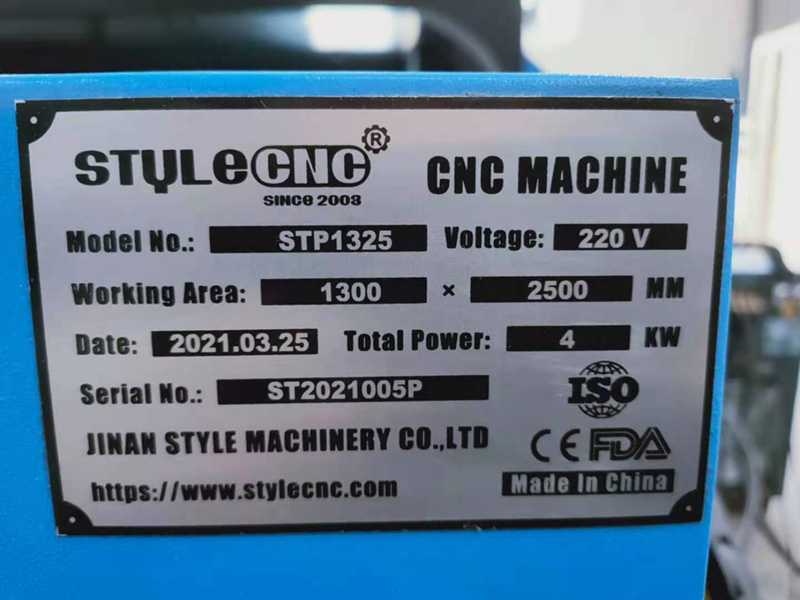

- Brand - STYLECNC

- Model - STP1325

- Maker - Jinan Style Machinery Co., Ltd.

- Category - CNC Plasma Cutter

- 360 Units in Stock Available for Sale Every Month

- Meeting CE Standards in Terms of Quality & Safety

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- 30-Day Money Back Guarantee for Your Purchase

- Free Lifetime Technical Support for End-Users & Dealers

- Online (PayPal, Alibaba) / Offline (T/T, Debit & Credit Cards)

- Global Logistics and International Shipping To Anywhere

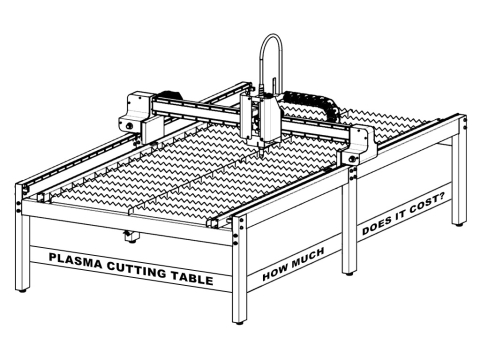

2025 best budget 4x8 CNC plasma cutting machine is a type of commonly used automatic plasma CNC cutter table for metal fabrication plans with a wide variety of purposes, the CNC plasma cutter machine carries a plasma torch over a 4x8 plasma table (48"x96" plasma table) based on programed X-Y axis coordinates.

What is a 4x8 CNC Plasma Sheet Metal Cutting Machine?

CNC (Computer Numerical Control) machines and routers are a common tool in modern-day industries. A 4x8 CNC plasma sheet metal cutting router is a computer-controlled machine used for cutting sheet metal with high precision. The "4x8" in its name refers to the machine's capacity. A 4x8 CNC machine can handle metal sheets up to 4 feet by 8 feet in size.

These types of machines are popular due to their affordability, ease of use, and reliability. This particular size of CNC metal sheet fabrication machine is mostly used for better production rate and precision.

There are a few brands manufacturing these CNC metal sheet fabrication machines with 4x8 bed sizes. This site features the most regular fabrication projects for different industries. STYLECNC is offering a 4x8 CNC plasma sheet metal cutting machine in your budget. So, how good these affordable machines are from STYLECNC?

Components of the Machine

Knowing the machine components will surely advance your pace with the production rate of your business. Several primary issues and difficulties will only require your basic operating knowledge of the machine. To do that, knowing the components and their functionalities are a must.

Beginners should have a good command over the CNC router's operation system. The basic components of a 4x8 CNC plasma sheet metal cutting machine are,

• Plasma Torch: The device consists of a nozzle, electrode, and cooling system.

• CNC Control System: A computer-controlled system that controls the torch and the design.

• Cutting Table (4x8-size): The "4x8" refers to the table dimensions, accommodating sheets up to 4 feet by 8 feet.

• Power Supply: Provides electrical power to generate the plasma arc.

• Gas Supply: Supplies the plasma gas (commonly air, nitrogen, or oxygen).

• Cooling System: Keeps the plasma torch and other components cool and at optimal temperature.

How Does A Plasma Sheet Metal Cutting Machine Work?

Now that you know the components and their functionalities it will be easier to understand the working process of the machine. So, how does a plasma sheet metal cutting machine work?

Here is the step-by-step process of CNC plasma cutting.

Step 1. Design and Programming

The process begins with creating a digital design using CAD (Computer-Aided Design) software. The CAD design is then converted into a format that the CNC machine can understand, typically G-code.

Step 2. Setting Up the Machine

The sheet metal is placed on the cutting table. The operator sets up the CNC machine by loading the G-code. The table size (4x8) allows for handling large sheets.

Step 3. Initiating the Cut

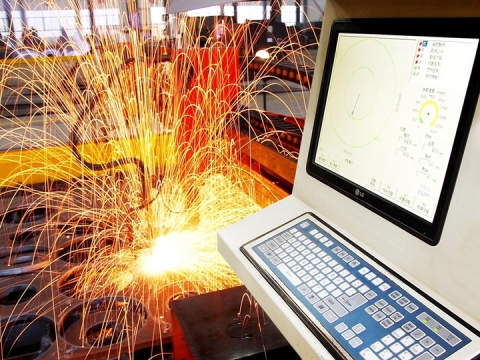

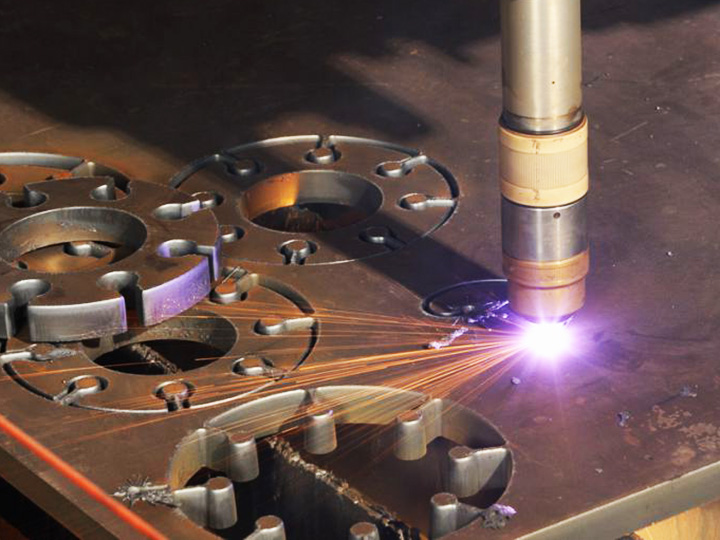

Start the plasma arc. The arc is established between the electrode and the metal workpiece. The plasma arc melts the material and pierces the metal at the starting point of the cut.

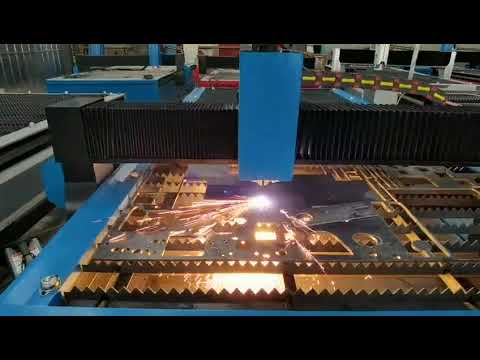

Step 4. Cutting the Metal

The CNC control system directs the movement of the plasma torch. As the torch moves, the plasma arc melts the metal along the cutting path.

Step 5. Finishing the Cut

The plasma torch retracts, and the CNC machine stops after the cutting is complete. The parts are now ready for removal.

Is it Worth Buying a Budget-Friendly 4x8 Metal Sheet Cutting Machine?

A budget-friendly CNC machine will always lack some features comparing larger industrial machines. Yet a good brand compromises very little with the performance of their machine. STYLECNC has been consistent and popular among other brands for providing better quality and more features with their budget-oriented CNC routers. There are several reasons of these budget CNC sheet metal fabrication machines are worth buying.

• Affordability: Budget machines are cost-effective and they are accessible to small businesses, hobbyists, and startups.

• Entry-level use: Ideal for beginners who want to explore metal cutting.

• Community support: Some budget machines have open-source communities where users collaborate, share projects, and provide support.

• Basic cutting needs: For straightforward cutting needs budget machines are a suitable option.

2025 Best Budget 4x8 CNC Plasma Sheet Metal Cutting Machine Features & Advantages

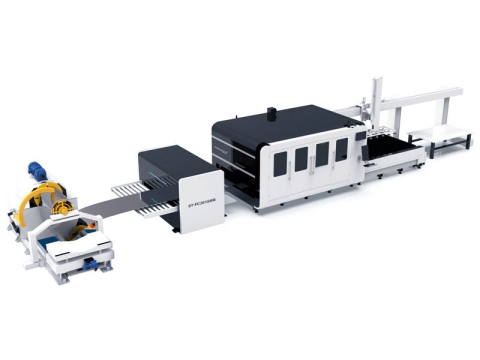

• The beam uses a light structural design, with good rigidity structure, light dead weight, and small movement inertia.

• The gantry structure, X, and Y axes all adopt straight rails that make the machine drive smoothly with high precision.

• Aiming at cutting three-dimensional LED characters, through metal panels and floor cutting, the accuracy can reach good.

• The CNC plasma cutting table is equipped with other advertising equipment, forming the advertising word processing pipeline. Completely solve the traditional manual processing methods. Improve the efficiency of several times.

• The cutting mouth is small and tidy, and avoid a second dressing processing.

• The CNC plasma cutting table is used to cut iron sheets, aluminum sheets, galvanized sheets, hundred steel plates, sheet metals, and so on.

• High cutting speed, high precision, low cost.

• The numerical control system disposes high, the automatic striking arc and the performance is stable.

• The plasma cutting machine supports Wentai, Astronautics Haire, and ARTCAM software.

• The control system uses the U-disk exchange processing document, easy to operate.

Technical Parameters of 2025 Best Budget 4x8 CNC Plasma Cutting Machine for Custom Sheet Metal Fabrication

| Model | STP1325 |

| Table Size | 4x8 |

| Working Area | 1300mm*2500mm |

| Power Supply | 65A - 200A |

| Cutting Thickness | 0.5-30mm or Customize |

| Driving System | 3 phases leadshine brand stepper motor |

| Input Voltage | 380V, 50HZ |

| Guide Way | Taiwan Hiwin square guide rails |

| Control System | Beijing START control system |

| Connect Way | USB |

| Working Model | Untouched ARC striking |

| Cutting Speed | 0-7500mm/min (According to the materials) |

| Graphic Format Supported | G code, *uoo, *mmg, *plt |

| Software Supported | CorelDraw, PhotoShop, AutoCAD, TAJIMA |

| Optional Parts | America Hypertherm power supply |

| Rotary device to cut pipes and tubes |

2025 Best Budget 4x8 CNC Plasma Sheet Metal Cutting Machine Details

4x8 CNC plasma cutting machine control system.

CNC plasma cutting head.

4x8 CNC plasma cutting machine sawtooth cutting table.

Identification Plate for STP1325.

Applications of 2025 Best Budget 4x8 CNC Plasma Cutting Table for Sheet Metal Fabrication

Applicable Industries: Sheet metal, kitchenware, components, decorations industry.

Computer-controlled plasma-cutting machines are widely used in industries. Due to the preferable size, these machines are considered versatile tool in the metal sheet fabrication. The 4x8 bed size allows regular manufacturing for metal sheet fabrication industries.

The industrial applications of the budget 4x8 CNC plasma cutting table for sheet metal fabrications are,

• Manufacturing metal parts and components

• Fabricating parts and body panels in automotive industries

• Custom metal projects, art, and decorative items and

• Construction industries for cutting beams, plates, and other materials

These machines are also used in kitchenware, components, decoration industry, and so on.

Applied Materials: Stainless steel, mild steel, brass, copper, aluminum alloy, sheet metal, spring steel, gold, silver, etc.

4x8 CNC Plasma Cutting Table for Custom Sheet Metal Fabrication Projects

2025 Best Budget 4x8 CNC Plasma Cutting Machine with Flame for Custom Sheet Metal Fabrication Projects

Maintenance and Troubleshooting Tips

STYLECNC experts provided some effective troubleshooting and maintenance tips. They are important to achieve longevity and peak performance of your machine.

Maintenance Tips

• Regularly clean the plasma torch, cutting table, and air filters.

• Check the condition of electrodes and nozzles frequently.

• Regularly check and adjust the alignment of the plasma torch.

• Periodically calibrate the X, Y, and Z axes.

• Check the coolant levels and clean the fans and vents.

• Lubricate the linear guides and ball screws.

• Apply lubrication to the gantry and carriage.

Troubleshooting Tips

• For poor cut quality check consumables, adjust cutting parameters, and ensure the torch height is correctly set.

• The machine is not starting? Check the power supply first. Make sure the emergency stop button is not engaged. Make sure that the CNC control software is functioning correctly.

• For inconsistent cutting experience check the air supply, inspect the torch, and the calibration.

• If the torch is not firing check all the electrical connections and verify gas flow.

• Ensuring a proper cooling system and inspection of the duty cycle of the machine will reduce any heating issues.

Potential Drawback

The budget 4x8 CNC plasma sheet metal cutting machine may not work the best with certain projects. The budget machines tend to lack a few features and the fixed bed size will only allow 4 feet by 8 feet metal sheet at most. For larger metal sheet fabrication manufacturing one might need to go for a larger industrial model.

Here we have mentioned a few concerns of budget 4x8 CNC plasma sheet metal cutting machines. Potential buyers should carefully consider them.

• The primary drawback is the budget and investment. Though, it is marketed as budget-friendly but still can cost up to several thousand dollars and additional expenses.

• Unlike manual cutting tools, CNC routers require certain expertise in the operating field of the machines. Lack of knowledge of machine handling and software proficiency will cause loss.

• Maintenance and operational costs can increase the ultimate cost of the machine nearly as a larger model.

Choosing the right machine

Our tips are proven useful when choosing a CNC router for your business. It is important to choose the right model whether it is a budget-friendly model or a high-end model. A proper selection can increase your profitability by a greater margin.

Take a look at the tips and factors provided by our experts,

• At the very first consider the cutting capacity that includes material type, thickness, and cutting area size. Remember, a 4x8 machine can handle sheets up to 4 feet by 8 feet which is the standard size in industries.

• Check the precision and accuracy of the machine. Ensure the consistency of production with minimal variation.

• A robust structured machine is more durable. A good brand makes sure the machine is made of quality materials.

• Take a dry test to find out the cutting speed and efficiency.

• Software compatibility and an easy control system are two key factors for a good CNC metal sheet fabrication machine.

A budget CNC plasma sheet metal cutting machine is a good investment if purchased considering the key factors. Even the resale value of your machine may add to your final profit. In purchasing a 4x8 CNC Plasma Sheet Metal Cutting Machine, we ensure ours are affordable and reliable on the market.

Nicholas

Megan

I have never owned an automatic plasma cutter with CNC controller. Bought the STP1325 to upgrade my car repair shop. Came in well packed, and everything is tight and fit well as you would expect. I used it for cutting some mild steel plates, worked well and got the job done accurately with faster speed than a manual plasma cutting tool.