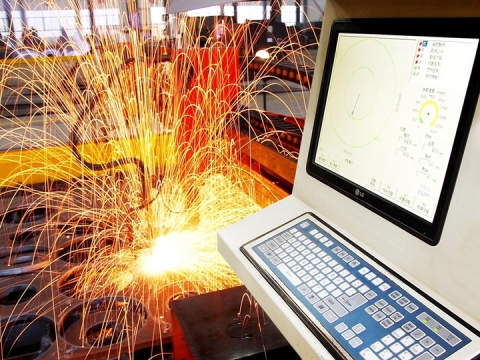

This plasma cutter is a standout cutting tool and exceeded my expectations. It works great for my metal cutting projects with stainless steel and aluminum. I praise its fast cutting speed and ease of use, thanks to its intuitive interface and advanced CNC controller, providing a smooth cutting experience. Note that it runs on a 380V power supply, which is something to consider for those that don't have this voltage.

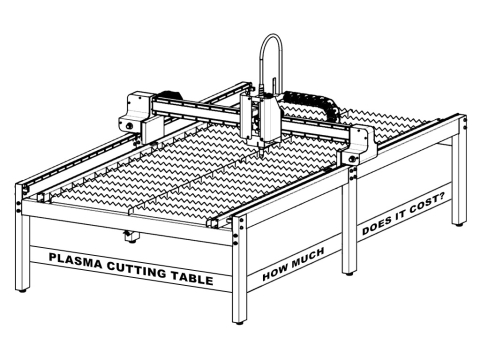

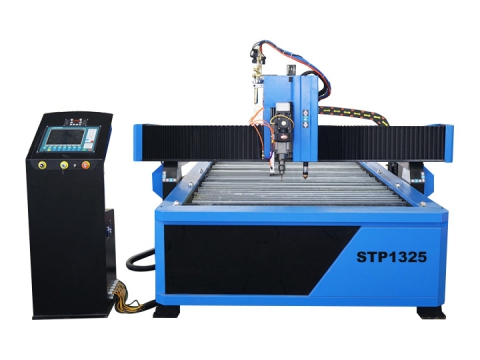

2026 Top Rated 4x8 CNC Plasma Cutting Table for Sale

Affordable 4x8 CNC plasma cutting table is an entry level CNC plasma table kit 48x96 inches working table to cut full sheet metals including iron, brass, steel, aluminum, copper, alloy for hobbyists or commercial use. Now the 2026 top rated CNC plasma cutter table for sale at affordable price with best budget.

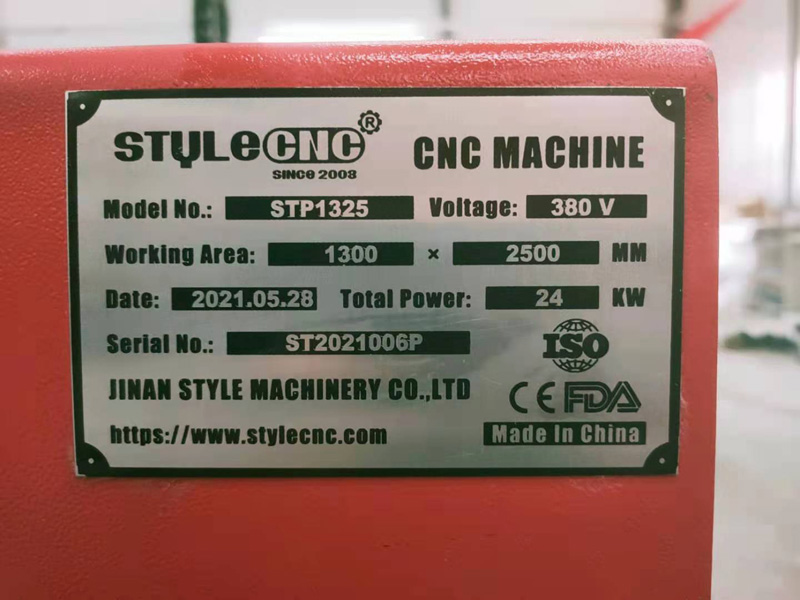

- Brand - STYLECNC

- Model - STP1325

- Maker - Jinan Style Machinery Co., Ltd.

- Category - CNC Plasma Cutter

- 360 Units in Stock Available for Sale Every Month

- Meeting CE Standards in Terms of Quality & Safety

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- 30-Day Money Back Guarantee for Your Purchase

- Free Lifetime Technical Support for End-Users & Dealers

- Online (PayPal, Alibaba) / Offline (T/T, Debit & Credit Cards)

- Global Logistics and International Shipping To Anywhere

4x8 CNC plasma cutting table is an automatic power tool with CNC plasma cutting system, which is equipped with 48" x 96" table size. The best budget CNC plasma table is mainly used for full sheet metal cutting in home shop, small shop, school education, or industrial manufacturing.

What Is A CNC Plasma Cutting Table?

A CNC plasma cutting table is an important part of the cutting machines. It is a sophisticated piece of equipment consisting of a cutting bed, a plasma torch, a CNC controller, a power source, and specialized software.

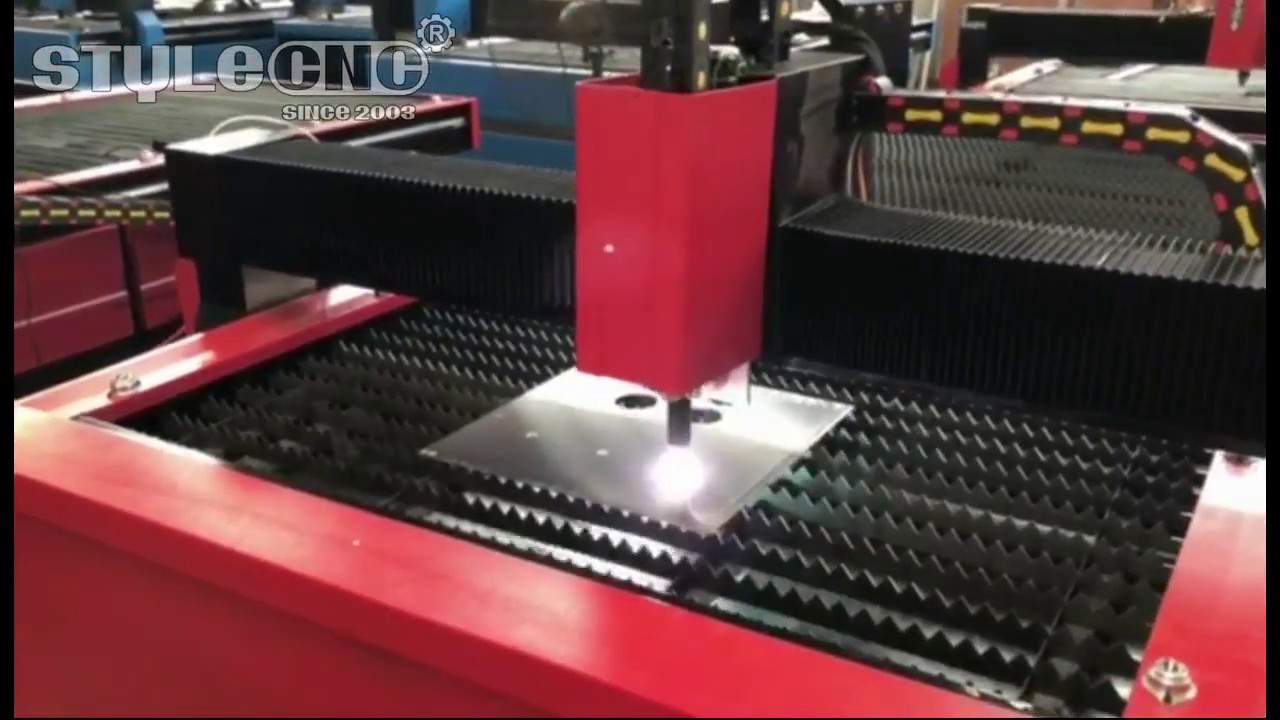

Various materials, most commonly metals are cut and shaped in the most precise way with minimal wastage. A high-temperature plasma ark generated by the torch melts through the material and is cut into shapes following the CNC-programmed pathways. The plasma cutting table can hold heavy-weight metals as well.

The 4x8 bed size is the most common configuration among others. This is popular due to its versatility and manageability.

Purpose of The Cutting Table

In manufacturing and fabrication, CNC plasma cutting tables offer more usability. Primarily a table enables efficient and precise cutting of various materials.

Parts and manufacturing items with complex shapes and intricate designs require high accuracy. A CNC plasma cutting table enables both accuracy and precision with less wastage. They feature versatility with a wide range of metals on work, such as steel, aluminum, stainless steel, copper, and more.

CNC plasma tables can rapidly cut through materials that offer maximum productivity. These tables offer the production of specific and custom parts and components. Therefore, featuring more customization and better efficiency CNC plasma cutting tables are gaining popularity day by day.

2026 Best 4x8 CNC Plasma Cutting Table Features

✔ STP1325 plasma CNC cutting machine comes with a thick square tube welded structure and square rails from Taiwan to ensure running speed and accuracy.

✔ Plasma torch with water cooling system is able to cool the material surface quickly to avoid burr and residue.

✔ The arc automatic adjusting system can choose the best distance between the plasma torch and working piece to ensure high-accuracy cutting.

✔ Plasma power supply adjusts current according to different thicknesses of the metal materials to ensure materials cutting without burr.

✔ Starfire CNC control system, large capacity storing function, convenient to read and process.

✔ FastCAM software with automatic nesting function to save materials.

✔ A rotary device for metal tube cutting is optional.

4x8 CNC Plasma Cutting Table Technical Parameters

| Brand | STYLECNC |

| Model | STP1325 |

| Table Size | 48" x 96" |

| Plasma Power | USA Hypertherm Power: 45A, 65A, 85A, 105A, 125A, 200A Chinese Huayuan Power: 63A, 100A, 120A, 160A, 200A |

| Cutting Thickness | 0.3-30mm (According to different plasma power) |

| Minimum Cutting Diameter | Depend on cutting thickness |

| Max Cutting Speed | 12m/min |

| Transmission | Taiwan Hiwin Square rail and Rack transmission |

| Drive Motor | Leadshine stepper motor and driver |

| Control System | Starfire control system with THC |

| Table | Blade table or Sawtooth table |

| Machine Frame | General machine frame or Heavy duty frame |

| Working voltage | 220V for machine, 380V for power supply (63A with 220V is available) |

| Optional Parts | Rotary device, Flame head, Drilling head, Marking head, Air compressor |

| Consumble Parts | Cutting nozzle and electrode |

2026 Top Rated 4x8 CNC Plasma Table Applications

The 4x8 plasma table is suitable for sheet metal cutting, kitchenware, components, decorations industry, ship building, construction equipment, transport equipment, transport equipment, bridge building, wind power, structural steel, agriculture machinery, and environmental protection equipment.

The 4x8 plasma table is suitable for various applications. We already know the purpose of the table. CNC plasma tables are already being used in almost every industry. This configuration is highly demandable with high versatility and efficiency. Here we will point out the usability and applications of CNC plasma cutting tables one by one.

⇲ Metal Fabrications

⇲ Signage and Artwork

⇲ Architectural Metalwork

⇲ Decoration Industry

⇲ Automotive Aftermarket

⇲ Metal Art and Sculpture

⇲ Kitchenware

⇲ Agricultural Machinery

⇲ Marine Industry

⇲ Prototyping and Small Batch Production and so on.

2026 Best 4x8 CNC Plasma Table Projects

Plasma Cutting Capacity of 4x8 CNC Plasma Table

| China Huayuan Power | USA Hypertherm Power | ||

|---|---|---|---|

| Power supply | Cutting thickness | Power supply | Cutting thickness |

| 63A | 8mm | 45A | 8mm |

| 100A | 15mm | 65A | 10mm |

| 120A | 20mm | 85A | 12mm |

| 160A | 30mm | 105A | 18mm |

| 200A | 40mm | 125A | 25mm |

| 200A | 30mm | ||

2026 Top Rated 4x8 CNC Plasma Cutting Machine Details

High Definition Plasma Cutter

Chinese Huayuan Plasma Power Supply

America Hypertherm Plasma Power Supply

Starfire Control System

Sawtooth Plasma Table

Identification Plate for STP1325

Tool Box with Machine Delivery

Package and Delivery for 4x8 CNC Plasma Table

We have been cooperating with several big transport agents and shipping companies for a long term, and the goods are packed with standard plywood cases for export, they can be transported to you safely as soon as possible.

Custom Colors for STP1325

We also have 4x8 CNC plasma cutter table with rotary device to cut metal tubes for option.

Significance and Advantages of 4x8 Size Table in Metal Fabrication

This is perhaps the most popular configuration of a CNC plasma cutting table for any industry. It is significant in metal fabrication and cutting. Several key reasons for being a proper choice are given here.

1. Versatility: Metal sheets of 4 feet by 8 feet are considered standard for industrial manufacturing. The 4x8 bed size provides a versatile platform and allows fabricators to work with a variety of sheet sizes.

2. Optimal Material Usage: The 4x8 size allows fabricators to nest multiple parts on a single sheet. This minimizes costly material waste.

3. Cost-effectiveness: 4x8 CNC plasma cutting tables offer a balance between size and affordability. Despite having a 4 feet by 8 feet bed they require less space to set up. This offers accessibility to small to medium-sized fabrication shops and businesses while still being manageable in less space.

4. Ease of Integration: These tables are workflow-friendly with a standard setup that requires no extra modification to the workspace and are easy to integrate.

5. Adaptability to Various Projects: A diverse range of fabrication and manufacturing features makes them adaptable to small to large metal fabrication. Whether fabricating small components or cutting larger panels and sheets, the 4x8 size provides enough space to handle a diverse range of fabrication tasks.

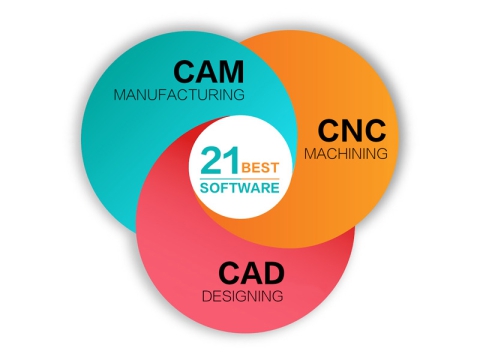

Components of a CNC Plasma Cutting Table

Knowing the components and parts of a CNC plasma cutting table is always a firsthand lesson for any beginner. The primary components are,

1. Plasma Torch

2. CNC Controller

3. Cutting Bed

4. Power Source

5. Software

6. Motion Control System

7. Torch Height Control (THC) and

8. Fume Extraction System

Tips for Maximizing Efficiency and Performance

It is important to measure and ensure the maximum efficiency of your cutting table to achieve ultimate profit out of your production. A few tips can boost your table’s performance in the long run. Additionally, you will find your CNC plasma cutting table a more cost-effective tool in the long run.

⇲ Regular maintenance is a must to ensure all components are in optimal condition.

⇲ Regular calibration is similarly important to maintain accuracy and consistency in cutting.

⇲ Use high-quality consumables such as electrodes, nozzles, and cutting tips.

⇲ Optimize cutting parameters by experimenting with different settings.

⇲ Make sure the material is properly secured before starting the machining.

⇲ Train the operator on nesting software and advanced software features.

⇲ Monitor performance metrics and quality of production routinely.

Themba Ncgobo

Mondriaan

Purchased on January 5th. Received yesterday. Packaged well without any damage. Hooked it up with a 220v adapter. Today was the first time I actually used this kit for cutting 1/8 steel diamond plate, and it cut out as well as I expected but way faster. I'll try this CNC plasma table with thicker and thinner metals soon and see how it goes. Overall, it's a quality metal cutter.

Cary Shelby

Terry J Scott

It worked pretty good, cuts 3/8 steel without a problem. Only time will tell if it will stand the test of time. I have had this for a while now granted I don't use it every day, but machine is still working great. I don't regret buying it.

Seong Ho Park

Veronica Salter

Keagan

The machine was well packed and well designed. The CNC plasma table was quick to set up and easy to use. It works as advertised. I have cut some 1/2 and 3/8 mild steel, all runs well. An amazing cutter. I also used this unit for cutting straight cuts and circles in tight spots on sheet metals. I will happy to use this machine tool to make the tricky metal cuts easier.

Mathew Bellamy

Александр Сергеевич Иванов

James Schmelke

Got this plasma a few days before. I'm impressed at how great this cutting tool works for the price. Assembly was easy and cut without issues. I tried cutting through some hot rolled steel plate (1/2 x 4 x 8). It cut well automatically and without touching. Overall, I'm very satisfied with the performance of this CNC plasma table and hope it lasts.

FLORENTINOFELIX

I have had this CNC plasma for 6 months and all functions work great like it should. This thing rocks. No complaints here. Thanks.

Michael

Hooked up the CNC system in 30 minutes and it cut well. Very impressed with the performance of this plasma table. Tried cutting steel ranging from 18 gauge to 3/16 and everything has been running smoothly. So much better than using a cut off wheel and ginder.