Affordable Wood CNC Machines for Beginners & Professionals

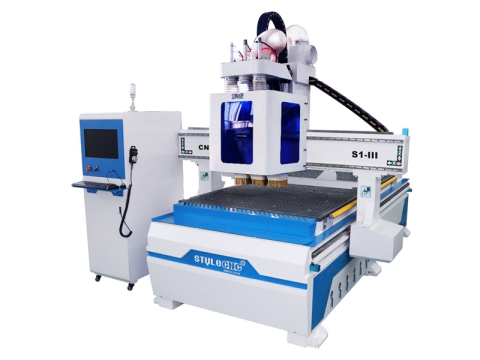

A CNC wood router is an automatic machine tool for wood cutting, relief carving, drilling & slotting, which works with 2D/3D designed files by CAD/CAM software. A CNC wood router machine is composed of bed frames, spindles, T-slot table or vacuum table, vacuum pump, CNC controller, motor driver, guide rail, rack and pinion, ball screw, power supply, limit switch, collets, tools & bits, and other parts & accessories. The most common types of wood routers include 3 axis, 4th axis, 4 axis, 5 axis CNC woodworking machines. The most used CNC wood router tables include 2ft by 3ft, 2ft by 4ft, 4ft by 4ft, 4ft by 6ft, 4ft by 8ft, 5ft by 10ft, and 6ft by 12ft. A wood router is applied in most popular woodworking plans and projects such as cabinet making, door making, sign making, arts & crafts, furniture making, and home decorations. Whether you are a craft carpenter or a professional woodworker, you can easily find your next CNC router at STYLECNC to automate your woodworking projects. Its user-friendliness, ease of use and multi-function make it easy for you to benefit and profit. Here is our collection of most popular CNC machines for woodworking, from single-spindle to multi-spindle kits, from small footprint to large format tables, from desktop to gantry styles, from hobby to industrial models, from primary 3 axis to professional 5 axis, from entry-level for beginners to high-end ATC series for experts, all types of CNC wood routers are available. In addition, a variety of customization options and add-ons are also available to personalize your machine tools. Just discover what you need, plan your budget, compare features and costs, find and buy the best one to start or upgrade your woodworking business.

Top Rated 4 Axis CNC Router 1325 with 4x8 Rotary Table

2024 Best 4x8 Wood CNC Router Machine for Sale

Entry Level Desktop CNC Router with 4th Axis Rotary Table

Cheap 4x8 CNC Wood Router Kit for Sale at Low Price

2024 Best CNC Router Lathe Machine with 4th Rotary Axis

Kitchen Cabinet Door Making CNC Router Machine for Sale

Profitable 4x8 CNC Router Table for Commercial Use on Sale

Pick Your Best 5x10 CNC Router with Tool Changer of 2024

Low Cost Industrial CNC Router Machine for Sale

Industrial 4x8 CNC Router Machine for Wood Door Making

4x8 Linear ATC CNC Wood Router 1325 for Woodworking on Sale

Automatic Tool Changer CNC Machining Center for Woodworking

Nesting CNC Wood Cutting Machine for Custom Furniture Maker

2023 Best ATC CNC Router with Oscillating Knife Cutter

Industrial 4 Axis CNC Wood Router with Drum ATC Spindle Kit

Multi Spindle CNC Woodworking Machine with Four Heads

Smart Nesting CNC Router Machine for Custom Cabinet Making

Multi-Head 3D 4 Axis Rotary CNC Wood Carving Machine

Most Popular CNC Machine for Woodworking with Tool Changer

ATC CNC Wood Router Table Kit with HSD C Axis and Aggregate

Dual Spindles Wood CNC Machine with 4x8 Table Size for Sale

Professional CNC Wood Carving Machine for Furniture Making

Three-Spindle CNC Wood Milling & Cutting Machine for Sale

Industrial 5x10 CNC Woodworking Machine with Dual ATC Kits

3D CNC Router for Woodworking with Rotary Table and 8 Heads

ATC 3D CNC Woodworking Router with 4th Axis Rotary Table

2024 Best 4 Axis CNC Router for 3D Curved Surface Carvings

Free & Profitable Relevant Project Ideas

Most Popular Relevant Videos You Should Watch

Top Relevant Stories & Articles Worth Reading

Maximize Your Woodworking Potential with A CNC Router Machine

A designer knows how much effort and dedication it requires to cut out the design for woodworking he wants to achieve. To make your effort more effective, a smart CNC wood router can bring greater support.

To showcase your creativity or to make your business boom, you can always count on STYLECNC to get your desired computer-controlled wood router. SYLECNC is trusted since 2003 with almost all kinds of precise cutting solution.

At the same time, this piece of writing includes advanced piece of instructions, guidelines, and recommendations that will come handy in times of choosing your desired automatic wood CNC machine.

If that is why you are here, let's get started.

What Is A CNC Wood Router?

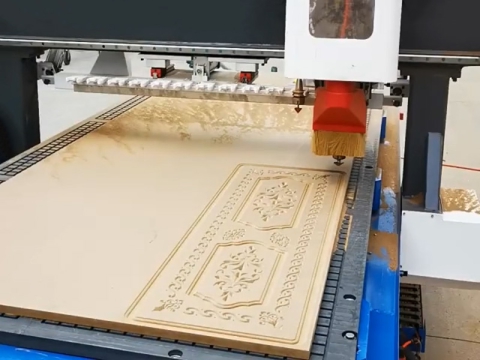

A CNC wood router is an automatic computer-controlled machine tool for smart 2D, 2.5D, and 3D cutting, milling, carving, drilling, and grooving on popular woodworking plans, including wood arts & crafts, signs making, cabinets making, door making, gifts, modeling, decorations, wardrobe, and more furniture making projects & ideas.

Such a CNC router consists of bed frame, spindles, vacuum table or T-slot table, controller, operating system, software, gantry, driver, motor, vacuum pump, guide rail, pinion, rack, ball screw, collet, limit switch, power supply, and some additional parts & accessories.

How Does A Wood CNC Machine Work?

A wood CNC machine uses computer signals as instructions to control the movement, timing, logic and other functions through the computer, so as to drive the spindle and bits to complete woodworking automation.

Unlike handheld, palm, plunge, plunge base, and fixed base routers, the functional software of a CNC wood router is CAD/CAM. CAD software allows users to create the designs they wish to work on a woodworking CNC machine. After completing this design, the CAM software will convert the design into a tool path code that the wood CNC machine can understand. Then, the computer converts this code into a signal that controls the movement of the drive system of the machine. The drive system includes a spindle, which is the part that saves the actual machine position. The spindle rotates 8,000 to 50,000 times per minute to cut the material. In short, the user creates a design and uses the software to make instructions for the machine.

3 axis table kit cuts along three axes at the same time: X-axis, Y-axis and Z-axis. X axis makes the router bit move from front to back, Y axis makes it move from left to right, and Z axis makes it move up and down. They are used to cut 2D flat woodworking projects.

Compared with 3 axis, 5 axis machine tools can cut along two additional axes. These automatic computer-controlled machine tools can cut five sides of a piece of material at the same time, thereby expanding the capabilities and flexibility of operators. Unlike their 3-axis counterparts, these computer-controlled 5 axis machine tools are usually used to cut large 3D woodworking projects. In addition, 5 axis table kits have a higher gantry and a longer X-axis, which allows them to cut larger woodworking projects. However, if the gantry is higher and the X-axis is longer, the accuracy and stability will be worse. For proper quality control, the height of the gantry and the length of the X-axis should be limited as much as possible. Although computer-controlled woodworking routers look like simple power tools, they are highly complex technologies and require a certain amount of expertise to operate. 5 axis CNC wood milling machines tend to be more expensive than traditional 3 axis CNC wood routers, but ultimately provide high quality, greater flexibility, allowing users to use their designs more creatively.

What Are The Types Of Wood CNC Machines?

To categorize the types of an automatic woodworking machine, three possible categories can be made:

Types based on table sizes (work area): 2x3 table tops, 2x4 table tops, 4x4 table tops, 4x6 table tops, 4x8 table tops, 5x10 table tops, 6x12 table tops.

Types based on applications: Home types, Desktop types, 3D types, Hobby types, Commercial types, Industrial types.

Types based on axis: 5 axis, 4 axis, 4th axis (rotary axis), and 3 axis CNC wood routers.

What Are CNC Wood Routers Used For?

These automatic machine tools are mostly used for woodworkers and carpenters to do woodworking in industrial manufacturing, small business, small shop, home business, home shop, school education. Besides, craftsman and hobbyists will also find a computer-controlled wood CNC machine useful.

Here are some of the fields where a CNC wood router will have access:

• Furniture Making: home furniture, art furniture, antique furniture, office furniture, cabinet making, door making, cabinet doors, interior doors, home doors, cupboard doors, table legs, sofa legs, wood spindles, corners, screens, headboards, composite gates, MDF projects, wood crafts, wood arts.

• Advertising.

• Die Making.

• Hollowing.

• Relief Carvings.

• Wood Cylinders.

• 3D Woodworking Projects.

• Sign Making.

• Custom Woodworking Plans.

Technical Parameters

| Brand | STYLECNC |

| Models | STM6090, STM1212, STM1218, STM1224, STM1325, STM1530, STM2030, STM2040, STM25120 |

| Table Sizes | 2' x 3', 2' x 4', 4' x 4', 4' x 6', 4' x 8', 5' x 10', 6' x 12' |

| Materials | Hardwood (Solid Wood), MDF (Medium-Density Fiberboard), Plywood, Particleboard, Wood Veneer |

| Axis | 3 Axis, 4th Axis, 4 Axis, 5 Axis |

| Capability | 2D Machining, 2.5D Machining, 3D Machining |

| Control Software | Type3, Ucancam, Artcam, Alphacam, Cabinet Vision |

| Operating System | Mach3, Nc-studio, Syntec, DSP, Siemens, Nk200, Nk260, NK300 |

| Price Range | $2,580 - $38,000 |

How Much Does A CNC Wood Router Cost?

Table sizes, features, durability, performance, quality, precision, speed, brand, manufacturer, customer service and support are some of the crucial factors that will play a good role in determining the overall price of an automatic CNC machine for woodworking.

The average cost of owning a CNC woodworking router machine in 2024 is approximately $3,600 from budget-friendly home classes to costly commercial types. Most entry-level CNC wood routers with small sizes range in price from $2,580 to $5,280 for beginners in woodworking, while some large-format models will full-size working tables can be as expensive as $7,200 for experienced craftsmen and carpenters. The professional wood CNC routers come with a price tag from $3,680 to $16,000 for enthusiasts, depending on the machine's features and capabilities. The enterprise and industrial woodworking CNC machines can cost anywhere from $18,000 to $120,000 for commercial use, which are pricey to own and operate. In addition, the high-end smart CNC woodworking machines combine multiple kits in one (including cutter, miller, driller, slotter, sander, laminator), with relatively high prices ranging from $12,000 to $160,000, and are popular in custom furniture manufacturing, such as personalized door and cabinet making.

If you have an idea to buy a wood CNC machine overseas, the fee of customs clearance, tax, and shipping costs should be included in the final price.

Whether you are a small business owner or an industrial manufacturer, don't just focus on price, matching your woodworking plans is what you should consider.

Pick Up Your Budget

| Types | Minimum Price | Maximum Price | Average Price |

|---|---|---|---|

| Entry Level | $2,380 | $3,600 | $2,780 |

| Hobby | $2,580 | $5,200 | $3,800 |

| Enthusiast | $3,680 | $10,600 | $6,780 |

| Professional | $5,680 | $12,800 | $7,980 |

| Commercial | $12,000 | $80,000 | $22,000 |

| Industrial | $18,000 | $100,000 | $28,000 |

| Enterprise | $20,000 | $120,000 | $36,000 |

How To Choose The Best Controller For Woodworking?

Computerized Controller

That is, by installing a control card on the PCI slot of the computer motherboard, and installing the software driver on the computer to control the walking of the machine's X, Y, Z axis and the rotation of the spindle motor, the processing effect can be previewed, and you can see it at any time to the processing track, if the program loading error can be corrected in time.

The controller has a humanized interface, simple and convenient operation, complete functions, and high program compatibility. Various CAM software can be imported directly or indirectly.

Handle DSP Controller

That is, you can control the movement of the machine in your hand. It saves space and does not occupy a computer; the disadvantage is that the operation is relatively troublesome, after all, all functions are integrated on a control panel, and it is easy to press the wrong function keys if the operation is unskilled.

It is widely used with various computerized woodworking machines (including four-axis linkage) without occupying a separate computer, which greatly reduces the footprint of the equipment and is more convenient for tool setting.

The disadvantage is that there is no preview and other functions, and the interface is not as intuitive as a computer.

All-In-One Controller

Independent integrated design, using industrial computer, PLC and other integrated control, rich interfaces, complete functions, can realize multi-axis control and automatic tool change.

It's mainly used for high-end computerized wood carving machines, computerized woodworking machining centers, and some computer-controlled milling machines, the anti-interference ability of the control system, as well as all aspects of performance, control accuracy and more, which are better than other types. The controller is integrated in the computerized operating system. It is not the mainstream, but it is the mainstream of the all-in-one type in the controller.

The disadvantage is that the price is high and the operability tends to be CNC wood cutting machine. For some customers, the operation is not as simple as the former.

How To Choose The Best Router Bits For Wood?

In woodworking, many details can affect the quality, accuracy and appearance of the final woodworking project, especially the selection of router bits for woodworking.

Choosing the right tool according to different processing materials and different machining processes is an important factor to ensure fast and efficient production.

What type of router bit is best for woodworking? What can each tool do in woodworking?

• Flat bottom or column router bits, mostly rely on the side edge for cutting, and the bottom edge is mainly used for flat polishing. The end face of the head of the column router bit is large, and the working efficiency is high. It is mainly used for contour cutting, milling plane, area and surface rough carving.

• Another relatively common type is straight, which is often used to carve large characters. The edge of the material cut by it is straight, which is generally used for PVC and acrylic cutting to make characters.

• Milling cutter is the most common tool in automatic woodworking. Milling cutters are divided into many types according to their shapes.

For example, double-edged spiral milling cutters used when cutting acrylic and MDF, single-edged spiral ball-end milling cutters for large deep relief processing of cork, MDF, solid wood, and acrylic. It is a prismatic milling cutter used when making high-density boards, solid wood doors, and furniture.

Of course, many tool manufacturers will also make special tools according to the special requirements of many customers, such as large chip-removing spiral milling cutters that are more suitable for cutting density boards and chip removal. The round bottom cutter is more suitable for precision small relief carving.

• The cutting edge of a ball end tool is arc-shaped, forming a hemisphere during the carving process of the wood cutting machine, the process is evenly stressed and the cutting is stable. Ball tools are not suitable for milling planes.

• Bullnose bit is a mixture of fluted column bit and ball end bit. In addition, it has the features of a ball end bit to carve curved surfaces, and on the other hand, it has the features of a fluted column bit and can be used for plane milling.

• Tapered flat bottom bits, abbreviated as tapered bits. They have the widest range of applications in the carpentry. The bottom edge of the cone bit, commonly known as the tip, is similar to a column bit, and can be used for the finishing of small planes. The side edge of the cone bit is inclined at a certain angle to form an inclined side surface during the working process.

The structural features of the cone bit can enable it to achieve the unique three-dimensional angle clearing effect of the carving industry. Cone bits are mainly used for single-line carving, area rough carving, area fine carving, 3D clear angle, projection carving, image gray scale carving.

• Tapered end mill, referred to as tapered ball nose bit. It's a mixture of cone milling cutter and ball milling cutter. Furthermore, it has the features of a cone cutter with a small tip, and on the other hand, it has the features of a ball bit, which can mill relatively fine curved surfaces.

• Tapered bullnose bit is a mixture of cone bit and bullnose bit. Moreover, it has the features of a cone shaped bit to cut relatively fine curved surfaces, and on the other hand, it has a bullnose shaper cutter. Because of its features, the tapered bullnose router bit is often used for relief carving.

• The V-Groove router bits are designed to cut deep or shallow V-shaped grooves.

• Drill bits are mainly used for drilling. When the hole is relatively shallow, clearing bottom router bits can be used to drill holes.

Buyer's Guide

Even if we provide you with the best support, you always have the autonomy to decide some of the factors that will work best only for you. Here are some of such recommendations from our side-

The first and the crucial factor you should keep in your mind is the total budget that you are willing to pay for the machine you want to purchase. If STYLECNC only claims that they provide the best product within your budget, you will always have reasons to validate our claiming. Therefore, do some research about the products that are available on the market within your budget. At the same time, we will encourage you to check the customer reviews (both the good and the bad) that users provide after using our products.

If everything seems satisfactory, go for the purchase. We are promising, we will always response in case you need us.

Here are 9 easy-to-follow steps to buy from STYLECNC:

Step 1. Consultation.

We will recommend the most suitable CNC wood cutter to you after being informed by your requirements: The materials you want to carve and cut. The max cutting areas of the materials (Length * Width * Thickness).

Step 2. Quotation.

We will offer you with our detail quotation according to the consulted digital woodworking machine: The best parts, accessories, bits, tools, and affordable price.

Step 3. Process Evaluation.

Both sides carefully evaluate the details (technical parameters, specifications and business terms) of the order to exclude any misunderstanding.

Step 4. Placing Order.

If you have no doubt, we will send you the PI (Proforma Invoice), then we will sign a contract with you.

Step 5. Production.

We will arrange the wood cutting machine production as soon as receiving your contract and deposit. The latest news about production will be updated and informed to the CNC wood carving machine buyer during the production.

Step 6. Inspection.

The whole wood carving machine production procedure will be under regular inspection and strict quality control. The complete digital wood carver will be tested to make sure they can work well before out of factory.

Step 7. Delivery.

We will arrange the delivery as the terms in contract after the confirmation by the digital wood cutter buyer.

Step 8. Custom Clearance.

We will supply and deliver all the necessary shipping documents to the CNC wood cutting machine buyer and ensure a smooth customs clearance.

Step 9. Support and Service.

We will offer professional technical support and 24/7 free customer service via Phone, Email, Skype, WhatsApp, Online Live Chat, Remote Service. We also have door-to-door service in some areas.

Why Should You Choose From STYLECNC?

STYLECNC has been one of the leading suppliers of your most creative cutting solutions for more than 21 years. At the same time, the brand has a reputation for delivering a helpful customer support in any case you need them.

No matter whether you are looking for an affordable computer controlled cutting tool or multiple items to run your business, STYLECNC is always here to give you the custom support and guidelines.

How To Use A CNC Wood Router?

Step 1. Turn On Machine.

Before starting up, ensure that all connections between the computer-controlled wood cutting machine and the computer are normal, and then turn on the power supply of the machine and the computer to enter the system.

Step 2. Mechanical Reset.

After starting the system (the system will judge whether the kit has "returned to the machine origin" before entering the active machining), the "return to machine origin" prompt dialog box will appear first, click the corresponding button, and the computer-controlled wood carving machine will automatically return to the wood carving machine origin. And proofread the coordinate system.

Step 3. Check I/O Status.

Check the input and output status of each signal, check whether there is a fault signal, to ensure that the machine can process safely.

Step 4. Load File.

Before machining, the user usually needs to load the required file, otherwise all the functions of the active machining are invalid.

Select [File (F)] -> [Open and Load (O)...] menu, a Windows standard file operation dialog box will pop up, and you can select the file to be cut. Perhaps click the right mouse button in the active machining window to pop up a shortcut menu, select [Open and Load (O)...], and select the desired processing file in the pop-up file operation dialog box. Then after clicking the "Open" button, the processing program is loaded into the system. At this moment, you can click on the "Active" window to check the current file.

Step 5. Manual Operation.

• Display manual operation interface.

Click the [Manual] window with the mouse, a manual operation interface will appear, on this interface, you can manually operate the CNC machine for woodworking.

• Manually move.

Manual movement can be completed by clicking the corresponding button on the manual operation interface with the mouse. You can also manually move the wood machine through the small number keys on the keyboard. Note that you must first switch the input focus to the manual window. The detailed method is to switch to the manual window first, then click any position of the manual window with the left mouse button, and press the corresponding number key on the keyboard to complete the manual movement.

Step 6. Set Origin of Project.

The origin of X, Y, Z, A coordinates in the programming is the project origin. Before machining, first manually move the wood machine's X, Y, Z, and A axis to the orientation of the project origin desired by the user, and clear the coordinate value of the current orientation in the coordinate window (or select [Operation (O )]->[Set the current point as the origin of the project]), so that the current orientation is used as the origin of the project for machining when the programming is executed.

Care & Maintenance

In order to keep all parts of the machine in good condition, it is important to insist on regular maintenance. This can eliminate many potential failures in the bud and prevent vicious accidents from happening. Operators should form a good habit of frequently maintaining the equipment used.

• Before turning on the machine every day, check whether the communication line, motor line, and optocoupler line are loose, and whether the voltage is stable. Then turn on the power of the machine, operate the machine to move back and forth twice, and start working.

• The water-cooled spindle machine tool should ensure the cleanness of the cooling water and the normal operation of the water pump. The water-cooled spindle motor must not be short of water. The cooling water should be replaced regularly to prevent the water temperature from being too high. The circulating water should be as much as possible, and a large capacity can be replaced water tank.

• Regularly clean the heat dissipation and ventilation system of the circuit box. Please regularly check whether the fans on the electric control box are working normally. Regularly clean the dust in the electric control box with a vacuum cleaner and check whether the terminal screws are loose to ensure the safety and reliability of the circuit. use.

• Clean the dust and debris on the exposed guide rail (polished rod), and clean it with No. 2 engine oil. After cleaning, add butter or No. 2 lithium-based grease.

• Clean the sensor (optocoupler, proximity switch) to prevent dust, powder and oil from sticking to the sensor, affecting its sensitivity or causing false touch.

• Move the machine head to the lower left or lower right position to stop to prevent collision, and then cut off the power supply; do not unplug the plug while it is live.

• Maintenance when it is not in use for a long time: When the machine tool is not in use for a long time, it should be powered on 1-2 times a week, especially in the rainy season when the ambient humidity is high, and the machine tool should be run empty for about an hour. Use the heat of electrical components to dissipate the moisture in the numerical control system to ensure stable and reliable performance of electronic devices.

• Maintenance of the inverter: The inverter has been debugged before leaving the factory. It is forbidden to debug and change the line without permission to prevent damage to the motor or the inverter due to data input errors.

• After one day's work is completed, take off the router bit first, and let the spindle chuck and lock nut be in a loose state. Doing so will help extend the life of the spindle chuck. Then we start to clean the work surface, which can be cleaned with a brush; note that it is best not to accumulate debris on the work surface to avoid deformation of the platform.

• The door of the electric control box should be opened as little as possible, and it is forbidden to open the door to work. Generally, there will be dust, wood chips or metal powder in the air during working. Once they fall on the circuit board or electronic devices in the electric control box, it is easy to cause damage. The insulation resistance between devices decreases, and even damages components and circuit boards.

• Regularly check whether the screws of each part of the machine are loose.

• Vacuum pump maintenance tips:

The wire mesh in the suction port of the water circulation air pump is used to prevent foreign dust particles from entering the pump body. The filter mesh should be kept clean at all times to avoid clogging and reduce the pumping speed of the pump. When the water pump is not in use, it should be powered on for a few minutes every few days to prevent the pump body from rusting and cannot operate normally. Loosen the butterfly nut of the vacuum pump, take out the paper filter element and clean the filter screen regularly with high-pressure air. If the filter element is found to be not ventilated smoothly or damaged, it should be replaced in time. According to the length of use, a high-pressure oil gun can be used to oil the bearings of each part.

• Operate in strict accordance with the instructions for use and abide by safe use regulations.

Troubleshooting

1. The motor makes abnormal noise.

Check the motor for overload; the motor may have an internal fault. At this time, it should be repaired or replaced in time.

2. The motor is in the opposite direction.

Directly check whether the motor line is out of phase or change the output UVW terminal (that is, the connection line between the inverter and the spindle motor).

3. The spindle motor heats up.

First check whether the water pump is working, and then check whether the circulating water is lower than the liquid level.

4. The motor is weak or unable to rotate.

Check the circuit, check whether the motor line is out of phase, and whether the cable is short-circuited.

5. The spindle is reversed.

During the working process of the machine, the main shaft reverses due to the connection between the frequency converter and the main shaft, and it only needs to replace the connecting line.

When the spindle is reversed, if the MDF is cut, the cutter will break, and the cutter may break when it is installed and used. Even if it doesn't break, it will be burned red. Therefore, when this abnormal phenomenon occurs, the operator should immediately stop the machine and check the main shaft.

6. During the working process, there is a phenomenon that the cutting is dislocated and the direction is opposite.

After starting up, if there are irregular movements when clicking continuously and quickly, it is a "phase loss" fault. Check the circuit between the output terminal of the driver and the stepper motor, find out the open circuit, and reconnect the fault to solve it.

7. When the machining axis is controlled manually or automatically, the machine tool does not respond:

• Check whether the data cable is connected firmly, if it is loose, connect it correctly.

• Check whether the drive circuit interface is loose or disconnected, and reconnect.

• Check whether the host power circuit is powered off.