Affordable Laser Welder Machines for Beginners & Professionals

Are you considering whether there is an environmentally friendly welder that can join metal parts together without causing pollution? The answer is yes, it is a laser welding machine, which can meet spot welding, butt joint, lap joint, T butt, seam welding, narrow welds, deep welds and kissing welds in metal fabrication. Laser welder is on the way to replace traditional MIG and TIG welders with its professional and powerful capabilities in the applications of miniature, densely arranged, precise and heat-sensitive parts with jewelry, kitchenware, aerospace, automotive, electronic devices and components, commercial, shipbuilding, chemical and medical industries. Here is STYLECNC's selection of the most popular laser welders of 2024 for beginners and professionals, ranging from entry-level handheld laser welding guns to automatic laser welding systems with CNC controller, as well as professional 3D laser welding robot. All types of laser beam welders available in STYLECNC with powers of 1000W, 2000W and 3000W for machinists, operators, DIYers, makers, craftsmen, beginners, homeowners, shop owners, commercial users and industrial manufacturers. Look no further and start finding and purchasing your perfect laser welder for every need and budget.

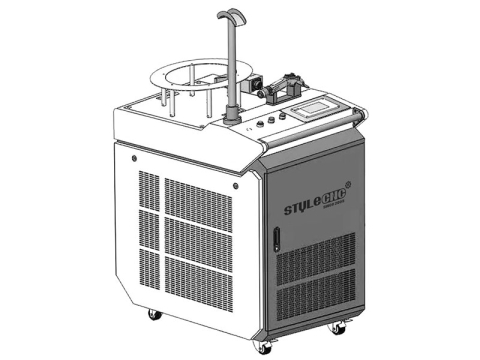

2024 Best Portable Handheld Laser Welding Machine for Sale

3-In-1 Handheld Laser Welding, Cleaning, Cutting Machine

Automatic Smart 3D Industrial Laser Welding Robot for Sale

Hi-Precision Automatic CNC Laser Welding Machine for Sale

- Showing 4 Results On 1 Page

Free & Profitable Relevant Project Ideas

Most Popular Relevant Videos You Should Watch

Top Relevant Stories & Articles Worth Reading

Pick Your Perfect Laser Beam Welding Machine for Home & Commercial Use

Laser welding machines are greatly used in automotive, aerospace, jewelry, and medical equipment manufacturing. They use laser technology to create precise and accurate welds between two materials, such as metals or plastics. With faster welding speeds, reduced heat input, and minimal distortion, they have become the most popular modern welding solutions. The power output of the laser, the size and type of the machine, the material compatibility, and the cost are some of the essential elements that play a good role when purchasing a new welding machine. A laser welder brings significant benefits to businesses looking to improve their production efficiency and quality of work. If the confusion is about where to choose, STYLECNC is always a reliable source to match your expectation. Anyway, this article is going to be a comprehensive guideline for those who are in search of a welder for hobby use and industrial commercial use.

Let's jump deeper into the discussion.

Definition

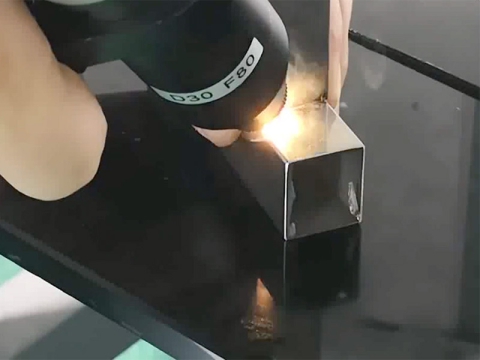

A laser welding machine is an eco-friendly welding tool kit that comes with a handheld laser gun, CNC controller, or single-arm robot to join pieces of metals or thermoplastics, which is frequently used in high volume applications with automation, which is based on keyhole or penetration mode welding.

A laser welder is a thermal welding machine that uses the high heat energy from the laser beam to connect parts together, including spot welding, seam welding, lap edge, T butt, butt joint, lap joint, narrow welds, deep welds and kissing welds. It is typically used by manufacturing businesses in the engineering, medical and electronics industries, through to welding thicker materials in the automotive and aerospace industries. It is also known as laser welding gun, welding tool, seam welding machine, bonding machine, brazing machine, joining machine, soldering machine.

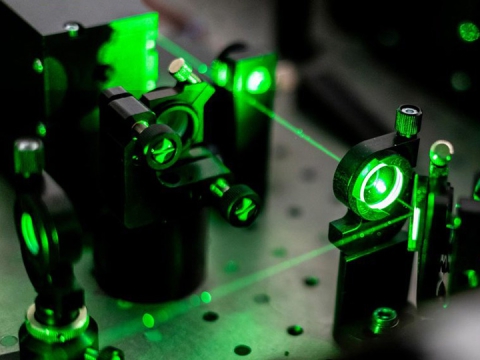

LBW - Laser Beam Welding

Laser Beam Welding (LBW) is a new type of fusion welding method that radiate a high-intensity beam to the surface of the material, and the material is melted to form welding through the interaction of the beam and the materials.

It uses the principle of atomic stimulated radiation to stimulate the working substance to produce a beam with good monochromaticity, strong directionality and high intensity.

The energy density of the focused beam can reach up to 1013W per square centimeter, which can convert laser energy into heat energy of more than 10,000 degrees Celsius in a few thousandths of a second or less.

The high heat energy released by the beam will increase the local temperature of the material. When the internal temperature reaches the melting point, the material will melt and form a molten pool, thereby enabling the welding of thin materials and precision parts.

Laser welding is a process that uses the radiant energy to achieve effective welds. Its working principle is to excite the active laser medium (fiber, CO2, YAG) in a specific way, causing it to oscillate back and forth in the resonant cavity to produce stimulated radiation. The heat energy from the beam is absorbed when it contacts the material, and welding can be performed when the temperature reaches the melting point of the material.

Cost & Pricing

If you've ever wondered how pieces of metal are joined together, then you've surely heard of a laser welder already, which welds metal with a laser gun and then uses a laser beam to heat and create precision metal joints the user desires.

Nevertheless, you might be wondering how much does a laser welder actually cost?

A good rule of thumb is that entry-level handheld laser welders start at around $4,700, while professional portable laser welding machines range from $6,500 to $9,800, with fiber laser power options of 1000W, 1500W, 2000W, and 3000W.

Automatic CNC laser welding systems can cost you anywhere from $12,500 up to $17,100, depending on how powerful and professional it is.

Industrial 5-axis laser welding robots range in price from $48,000 to $58,000, which is up to different power options and how smart it is.

3-in-1 fiber laser welder, cleaner, cutter all in one machine is priced from $4,700 to $6,800, which is affordable and budget-friendly for beginners.

The average cost for laser welders in 2024 is as low as $5,800 for handheld models, and as high as $52,800 for robotic types.

However, costs vary typically depending on the welder's configurations and features.

Furthermore, you can expect to pay a different price up to whether the welding machine is geared to starters or professionals.

Pick Up Your Budget

| Types | Minimum Price | Maximum Price | Average Price |

|---|---|---|---|

| Hanheld | $4,700 | $9,800 | $6,780 |

| Automatic | $12,500 | $17,100 | $15,600 |

| Robot | $48,000 | $58,000 | $51,200 |

| 1000W | $4,700 | $48,000 | $6,280 |

| 1500W | $5,200 | $50,000 | $6,590 |

| 2000W | $6,600 | $54,000 | $8,210 |

| 3000W | $9,800 | $58,000 | $12,300 |

Specifications

| Brand | STYLECNC |

| Laser Power | 1000W, 1500W, 2000W, 3000W |

| Laser Source | Fiber Laser |

| Laser Wavelength | 1070-1080nm |

| Melt Depth | 0.5-3.0mm |

| Welding Speed | 0-120mm/s |

| Cooling System | Industrial Water Chiller |

| Price Range | $4,700 - $58,000 |

Types

Laser welding is a versatile, low cost way of achieving high quality spot welds for different materials and thicknesses. It results across a wide range of materials. There are three common types, including CO2, YAG and fiber laser welders. There are high-power welders for large-format and thick sheets, and low-power welders for small-size parts. There are welders for metals and non-metallic materials such as plastics and ceramics.

Different types can be classified as follows:

• Wire and wire welds - cross welds, parallel lap welds, wire-to-wire butt welds and T-type welds.

• Welds between slices - end welds, butt welds, center perforation fusion welds and center penetration fusion welds.

• Welds of metal wires and block components. It can successfully realize the connection between the metal wire and the block element, and the size of the block element can be arbitrary. Attention should be paid to the geometric dimensions of the wire-like components during welding.

• Welds of different metals. Welds different types of metals must solve the range of weldability parameters. The welding between different materials is only possible with certain material combinations.

Uses

Laser welders are widely used in manufacturing, shipbuilding industry, automotive industry, battery industry, aerospace industry, jewelry, biomedicine, powder metallurgy, electronics industry, IT industry, electronic devices, optical communication industry, sensor industry, hardware industry, automobile accessories industry, glasses industry, porcelain teeth, solar energy industry, electric heating industry and thin material, precision parts manufacturing.

It can realize spot, butt, stitch, and sealing welding, and consistent high quality results. It is especially suitable for miniature, densely arranged, precise, and heat-sensitive workpieces.

Taking automobile manufacturing as an example, this type of welding has achieved large-scale, and related automatic production lines and welding robots have appeared.

According to relevant statistics, in developed industrial countries in Europe and America, 50% to 70% of auto parts are processed by laser machining. Among them, laser beam welding and cutting are mostly used, and now LBW is a standard process in automotive manufacturing.

Automobile industry has also begun to attach importance to this advanced welding technology. In the automotive industry, laser manufacturing technology is mainly used for body tailor and parts welding.

The laser used in the welding of car body panels can weld metal plates with different thicknesses and different surface coatings together, and then press them, so that the panel structure made can achieve the most reasonable metal combination. Since there is little deformation, secondary processing is also omitted. LBW speeds up the process of replacing forged parts with body stamped parts.

The use of LBW can reduce the overlap width and some strengthening parts, and can also compress the volume of the body structure itself. This alone can reduce the weight of the body by about 50kg. Moreover, LBW technology can ensure that the solder joints are connected to the molecular level, which effectively improves the rigidity and collision safety of the car body, and at the same time effectively reduces the noise in the car.

Laser tailor welding is in the design and manufacture of the car body. According to the different design and performance requirements of the car body, different specifications of steel plates are selected, and the manufacture of a certain part of the car body, such as the front windshield frame and the door inner panel, is completed through laser cutting and assembly technology. It has the advantages of reducing the number of parts and molds, reducing the number of spot welding, optimizing the amount of materials, reducing the weight of parts, reducing costs, and improving dimensional accuracy.

However, LBW is mainly used for the frame structure of the car body, such as the top cover and the side car body. The traditional welding method of resistance spot welding has been gradually replaced by laser beam welder.

With laser technology, the width of the joint surface between the workpiece connections can be reduced, which not only reduces the amount of plates used but also improves the rigidity of the car body. It has been adopted by some of the world's major automakers and leading parts suppliers that produce high-end cars.

In aircraft manufacturing, it is mainly used in the splicing of large aircraft skins and long trusses to ensure the contour tolerance of the aerodynamic surface. In addition, it is also widely used in the assembly of fuselage accessories, such as the wing box of ventral fins and flaps. Later, the LBW technology is used to complete the welding and splicing in three-dimensional space. Not only the product quality is good, the production efficiency is high, but the process reproducibility is good, and the weight reduction effect is obvious.

In the jewelry industry, LBW can satisfy aesthetics and welding between different materials. It has been widely used in gold and silver jewelry repair holes, spot welding holes, and welding inlays.

LBW cladding has become the main technology for mold repair. The aerospace industry uses this technology to repair the heat-resistant and wear-resistant layers of nickel-based turbine blades in aerospace engines. Compared with traditional surface modification techniques, laser cladding features with low heat input, higher heating speed, minimal deformation, low dilution rate, high bonding strength, precise thickness control of the modified layer, good accessibility, good positioning, and high productivity.

Other industries such as mobile phone batteries, electronic components, sensors, clocks, precision machinery, and communications have introduced LBW technology.

Due to the high investment in equipment, laser beam welder is currently only used in high value-added fields. Even in these fields, LBW has not been fully utilized for a long time. However, with the development of new laser manufacturing technology and equipment, LBW is gradually squeezing into the "territory" occupied by traditional welder for a long time.

Features

Laser welding features concentrated and controllable heating range, small deformation and high speed.

In order to help you make up your mind, let's compare laser beam welder with arc welder.

The diameter of the laser spot can be precisely controlled. Usually, the diameter of the spot irradiated on the surface of the material is in the range of 0.2-0.6mm, and the closer to the center of the spot, the higher the energy (the energy decays exponentially from the center to the edge, that is, Gaussian distribution). The seam width can be controlled below 2mm.

However, the arc width of arc welder cannot be precisely controlled and is much larger than the diameter of the laser spot, and the width of the seam of arc welder is also much larger than that of laser, usually more than 6mm. Because the energy of laser is very concentrated, less material is melted, and the total heat required is small, so the welding deformation is small and the speed is fast.

Writing can be used as a metaphor for laser and arc. Laser beam welding is like writing with a 0.3mm signature pen. The words must be so thin and fast, and the paper is basically unchanged after writing. It can be said that it refers to where to hit.

Arc welding is like writing with a large brush Not only is it thick, but the thickness of the characters varies with the force used, and the writing is slow. After writing, the paper is inevitably deformed due to too much water soaking.

Laser Deposit Welds

Repair and modification with reconditioned quality.

Spot & Seam Welds

From smallest welding spots to continuous seams.

Scanner Welds

No time loss by movement of workpieces or processing heads.

Polymer Welds

Flexible method for high strength connections with perfect surfaces.

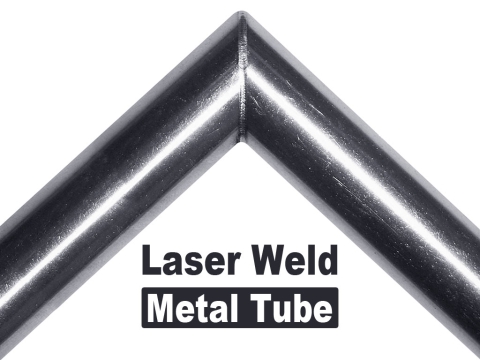

Tube & Profile Welds

Optimal laser beam welding of tubes and profiles.

Pros & Cons

Laser beam welding is a heat conduction process. The surface of the workpiece is heated by laser radiation, and the laser energy is controlled to be highly concentrated in a certain small range of spot.

The surface heat is diffused to the inside through heat conduction, and the width, energy, peak power and repetition frequency of the laser pulse are controlled by parameters to melt the workpiece and form a specific molten pool.

Compared with traditional argon arc welder, laser beam welder has a natural advantage and is widely used in the fields of industrial electronics, automobile manufacturing and aerospace and other precision mechanical parts.

• Since the focused beam has a much higher power density than the conventional method with times faster speed, and the heat-affected zone and deformation are smaller.

• Because the beam is easy to transmit and control, and there is no need to change the torch and nozzle frequently, it significantly reduces the auxiliary time of shutdown, so the load factor and production efficiency are high.

• Due to the purification effect and high cooling rate, the seam is strong and the overall performance is high.

• Due to the low balance heat input and high processing accuracy, reprocessing costs can be reduced. In addition, the moving cost of LBW is relatively low, which can reduce production costs.

• It is easy to realize automation, and can effectively control the beam intensity and fine positioning.

• Minimum heat input. The melting process is completed quickly at high temperatures, resulting in extremely low heat in the workpiece, and almost no thermal deformation and heat-affected areas.

• The energy density is large and the release is extremely rapid. It can avoid thermal damage and deformation during high-speed processing, and can process precision parts and heat-sensitive materials.

• The material to be welded is not easy to be oxidized and can be welded in the atmosphere without gas protection or vacuum environment.

• The laser can directly weld insulating materials, and it is easier to weld dissimilar metal materials, and can even weld metal and non-metal together.

• The welder does not need to be in contact with the workpiece to be welded. The beam can be bent or focused in any direction with a mirror or a deflection prism, and it can also be guided to hard-to-reach places for welding with optical fibers. The laser can also be focused through transparent materials, so it can weld joints that are difficult to access by normal methods or joints that cannot be placed, such as electrodes in vacuum tubes.

• The beam will not bring any wear and tear, and can work stably for a long time.

User's Guidance

Preparations Before Starting Up

• Check the power supply of the laser welder and whether the water circulation is normal.

• Check whether the gas connection of the equipment inside the machine is normal.

• Check that the surface of the machine is free from dust, spots, oil.

Turn ON/OFF

Boot Steps:

• Turn on the power and turn on the main power switch.

• Turn on the water cooler, generator in sequence.

• Open the argon gas valve and adjust the gas flow.

• Enter the parameters of the work currently to be performed.

• Perform welder operations.

Shutdown Steps:

• Exit the program and turn off the generator.

• Shut down dust collectors, water coolers and other equipment in order.

• Close the valve of the argon cylinder.

• Turn off the main power switch.

Safety Operation Rules

• During operation, if there is an emergency (water leakage and abnormal sound from the laser), immediately press the emergency stop and quickly cut off the power supply.

• The welder external water circulation switch must be turned on before operation.

• Because the welding system adopts the water cooling method, and the power supply adopts the air cooling method, if the cooling system fails, it is strictly forbidden to start the machine.

• Do not disassemble any parts inside the machine at will, and do not weld when the safety door of the machine is open.

• When the welder is working, it is strictly forbidden to look directly at the laser or reflect it with your eyes, and to face the welding gun directly with your eyes to avoid eye injury.

• Do not place flammable and explosive materials on the light path or where the beam can be irradiated, so as not to cause fire and explosion.

• When the machine is working, the circuit is in a state of high voltage and strong current. It is strictly forbidden to touch the circuit components in the machine while working.

• Untrained personnel are prohibited from operating this machine.

Cautions & Warnings

The arrival of the laser welder has greatly improved your work efficiency, but in the process of use, in order to ensure the safety of the operator, we need to master the following safety operation specifications during the operation.

• The power density is high, and the beam is very thin, which can easily cause damage to human eyes and skin. Therefore, it is important to protect the eyes during welding operations. On-site operators must wear specific protective glasses.

• Direct irradiation on the skin will cause burns to the skin, and the long-term impact of diffuse reflection will also cause skin aging, inflammation and skin cancer lesions of the operator. On-site operators need to wear work clothes to reduce the impact of diffuse reflection.

• Carefully read the instruction manual and operate the welder strictly according to the operation rules to ensure equipment and personal safety.

• Check whether all parts of the welder are working normally. Before it works, check whether all parts are working normally. After the operation, check the machine and the workplace to eliminate hidden dangers and ensure safety without accidents.

• Avoid fire from laser exposure. Direct irradiation or strong reflection of the beam will cause combustibles to burn and cause a fire. In addition, there are thousands to tens of thousands of volts of high voltage in the laser, which will be damaged by electric shock. Therefore only trained personnel are allowed to operate the welder. The optical path system must be fully enclosed with metal to prevent direct exposure, and the welder workbench should also be shielded to prevent radiation exposure.

• The circulating water in the welding machine must be kept clean, otherwise, the output of the laser will be affected. The user can determine the cycle of changing the cooling water according to the start-up time and water quality. Generally speaking, the water change cycle is longer in summer than in winter. shorter.

• The casing must be connected with a safety ground to avoid injury.

• Pay attention to keep the environment clean, and check whether the optical components are polluted frequently.

• If an abnormality occurs during the operation of the welding machine, you must turn off the power before checking. If you need to perform maintenance on the welding machine, be sure to cut off the power supply and ensure that the charge on the energy storage capacitor has been discharged before proceeding to avoid electric shock.

Laser Hybrid Welding

Laser-TIG Hybrid Welding

• Using the arc to enhance the laser effect.

• High-speed is possible when welding thin parts.

• It can increase the penetration depth, improve the weld formation, and obtain high-quality welded joints.

• It can ease the precision requirements of the base metal end face interface.

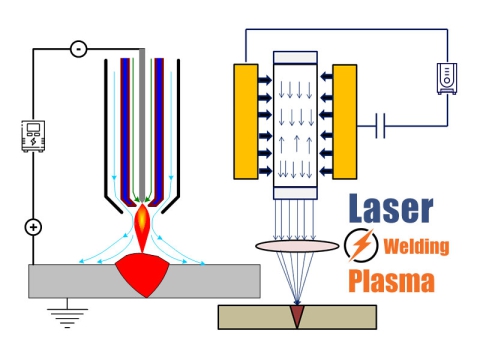

Laser-Plasma ARC Hybrid Welding

It adopts coaxial method. The plasma arc is generated by a ring-shaped electrode, and the beam passes through the middle of the plasma arc.

The plasma arc has two main functions:

On the one hand, it provides additional energy, which increases the speed, thereby improving the efficiency of the entire process.

On the other hand, the plasma arc surrounds the laser, which can produce the effect of heat treatment, prolong the cooling time, reduce the sensitivity of hardening and residual stress, and improve the microstructural properties of the weld.

Laser-MIG Hybrid Welding

In addition to the energy input of the arc to the weld zone, the laser also delivers heat to the weld metal. The hybrid welder is not two methods acting in sequence, but two methods acting on the area at the same time.

Laser and arc affect the performance of hybrid welder to varying degrees and forms. During working, volatilization occurs not only on the surface of the workpiece, but also on the filler wire, causing more metal to volatilize, thereby making the laser energy transfer easier.

MIG welder is characterized by low power cost, good weld bridging, good arc stability, and ease of weld structure improvement with filler metal. The features of beam welding are large penetration, high speed, low heat input, and narrow weld seam, but thicker materials requires a higher power laser.

At the same time, the molten pool is smaller than that of MIG welder, and the deformation of the workpiece is small, which greatly reduces the work of correcting deformation after welding.

Laser-MIG hybrid welder produces two independent molten pools, and the subsequent arc heat can be tempered after welding to reduce the weld hardness, saving time and costs.

Dual Laser Beam Welding

In the welding process, due to the high power density beam, the metal is rapidly heated, melted, and vaporized to generate high-temperature metal vapor, it is easy to generate a plasma cloud, which not only reduces the absorption by the workpiece, but also makes the process unstable.

If the power density that continues to be irradiated is reduced after the larger deep penetration holes are formed, and the larger deep penetration holes that have already formed absorb more beam, as a result, the effect on the metal vapor is reduced, and the plasma clouds can shrink or disappear.

Therefore, use a continuous or pulsed laser with a higher peak power, or two pulsed lasers with large differences in pulse width, repetition frequency and peak power to perform compound welding on the workpiece.

During the process, Co-irradiate the workpiece to periodically form large deep penetration holes, and then stop the irradiation in a timely manner, which can make the plasma cloud small or disappear, improve the absorption and utilization of laser energy by the workpiece, increase the penetration, and improve the ability.

It combines the two methods, and it uses the advantages of each to obtain the best effect, higher speed and good seam bridging ability. It is one of the most advanced welding methods at present, realizing the perfect combination of high speed and good quality.

It is a brand new welding technology in the automotive industry, especially for assembly gap requirements that cannot be achieved or economically feasible with beam welding. It has a wide range of applications and high-efficiency characteristics, while reducing investment costs, shortening production time, saving production costs and improving productivity, with stronger competitiveness.

Buyer's Guide

When purchasing a laser welding machine, there are several factors to consider. Firstly, the power and speed of the machine should be taken into account, as higher power output can result in faster and more efficient welding. Secondly, consider the size and type of materials you'll be welding, and ensure that the machine has a sufficient welding capacity to handle the thickness and material of the parts. Precision is also important, as a high level of accuracy is required for some welding tasks. Ease of use is another key factor to consider, as the machine should be simple to set up and operate. Maintenance requirements and costs should also be considered, as a machine with low maintenance requirements will be more cost-effective in the long term. Price is a significant factor in purchasing decisions, so it's important to establish a budget and choose a machine that fits within it. Finally, consider the warranty and customer support offered by the manufacturer to ensure that you can get assistance if you encounter any issues with the machine. By taking these factors into account, you can find a high-quality laser welder that meets your needs and budget.

Why STYLECNC is the best?

STYLECNC is a reputable brand that specializes in the manufacture and sale of high-quality laser welding machines. The brand has gained widespread recognition for its commitment to excellence, innovation, and superior customer service. Perhaps most importantly, STYLECNC is committed to providing exceptional customer service and support. The brand offers extensive training and technical support to help customers get the most out of their laser welders. Additionally, STYLECNC's machines are backed by strong warranties and guarantees, providing customers with peace of mind and ensuring their satisfaction.