I am a newbie to laser engraving, bought this unit to upgrade classic stone hand engraving business. The STJ1325S engraver was easy to set up right out of the package by following the manual instructions. The RD controller was easy to configure and convenient to use. Some of the projects we have done so far are personalized memorial granite stones, garden memorial stones, memorial plaques for outdoors, cemetery headstones, and grave markers. We have experimented with different markers for stones and this laser engraver seems to etch automatically with most all of them.

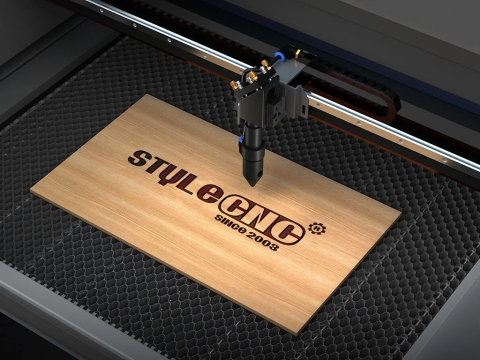

4x8 Marble, Granite, Stone Laser Engraving Machine for Sale

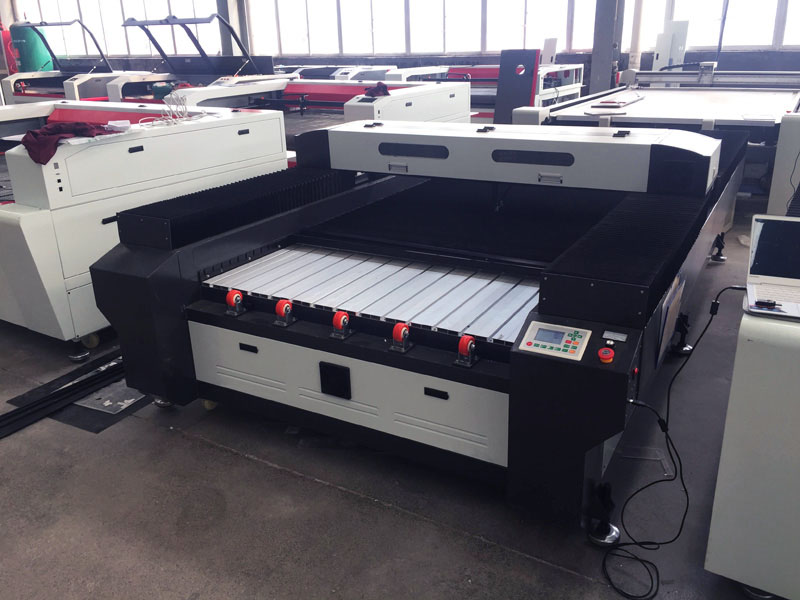

Industrial 4x8 laser stone engraving machine is a 48 x 96 inch laser engraving table to etch marble, granite, gravestone, headstone, tombstone, slate, jade, pebbles, rocks, bricks. Now the 4x8 industrial stone laser engraver for sale at affordable price.

- Brand - STYLECNC

- Model - STJ1325S

- Maker - Jinan Style Machinery Co., Ltd.

- Category - Laser Engraving Machine

- 360 Units in Stock Available for Sale Every Month

- Meeting CE Standards in Terms of Quality & Safety

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- 30-Day Money Back Guarantee for Your Purchase

- Free Lifetime Technical Support for End-Users & Dealers

- Online (PayPal, Alibaba) / Offline (T/T, Debit & Credit Cards)

- Global Logistics and International Shipping To Anywhere

What Is A Laser Stone Engraving Machine?

A laser stone engraving machine is a type of CO2 laser engraver used to engrave stone (including marble, granite, headstone, gravestone, tombstone, soapstone, ceramic tiles, and other types of stone). Stone laser engraving machine adopts a 4x8 full sheet worktable, which is convenient for engraving, and the engraving format is not limited. It can accurately splice and engrave graphics and can produce large-format graphics without considering the w8 of the object. The engraving frame can be adjusted up and down, which can meet the engraving of different thicknesses of stone.

Although stone engraving has a long history, the use of laser engraving stone is still an emerging industry, which is developing rapidly and in the ascendant. According to the analysis of professionals of laser engraving machines, this development trend is unstoppable. There are many industries suitable for laser engraving. Lasers can not only engrave relatively soft objects, such as wood, leather, fabric, and paper, but also hard objects, such as stone, glass, and acrylic.

Advantages of Industrial 4x8 Marble, Granite, Stone Laser Engraving Machine

With a unique design and excellent technique, the stone laser engraving machine is the most popular CNC laser equipment in stone engraving industries and many other hard materials engraving industries.

• Special design for stone, marble, granite, headstone, tombstone, gravestone, and other nonmetal materials.

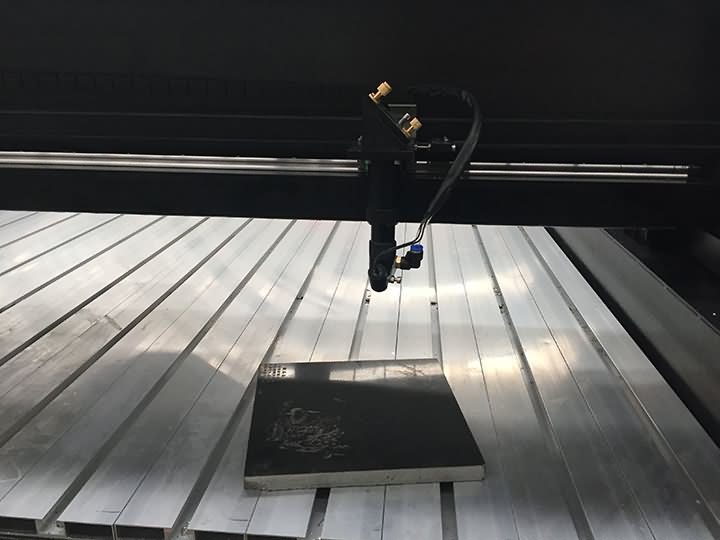

• Red light pointer to make the laser visible, which can make the engraving work more precise.

• The laser engraver includes all the parts that make it work perfectly: laser tube, water pump, air pump, exhaust fan, wide pipe, linear rail, Lasercut5.3 software, and focus lens reflecting mirrors.

• Channel feeding: the feeding can be unlimited.

Technical Parameters of Industrial 4x8 Marble, Granite, Stone Laser Engraving Machine

| Model | STJ1325S |

| Working Area | 1300mm*2500mm (4x8 feet) |

| Laser Power | 60W/80W |

| Laser Type | Sealed CO2 Glass Laser Tube |

| Cooling Mode | Water Cooling and Protection System |

| Compatible Software | CorelDraw, Photoshop, AutoCAD |

| Position System | Red Light Pointer |

| Graphic Format Supported | PLT, DXF, BMP, AI, DST, JPG |

| Driving System | Stepper Motor |

| Working voltage | 220V, 50Hz or 110V, 60Hz |

Features of Industrial 4x8 Marble, Granite, Stone Laser Engraving Machine

• The professional laser stone engraving machine is equipped with an aluminum table, which can hold heavy-duty stone material.

• The laser engraving head can be customized with different lengths, which will solve the thickness problems successfully.

• Laser stone engraving machine can be equipped with a dual table for stone and for other materials cutting.

• The machine's body front is equipped with wheels, which can load big stones easily.

Industrial 4x8 Marble, Granite, Stone Laser Engraving Machine Details

Laser Stone Etching Machine Auxiliary Wheel

RD Controller for Laser Stone Etching Machine

CO2 Laser Tube

Length Adjustable Laser Head

Applications of Industrial 4x8 Marble, Granite, Stone Laser Engraving Machine

Applicable Materials

Non-metal materials such as stone, marble, granite, gravestone, headstone, tombstone, acrylic, glass, ceramics wood, bamboo, double color boards, paper and leather.

Applicable Industries

• Monument (tombstone/gravestone) industry.

• Model industry (construction models, aviation and navigation models, and wooden toys).

• Advertisement.

• Decoration.

• Arts and Crafts.

• Electronics.

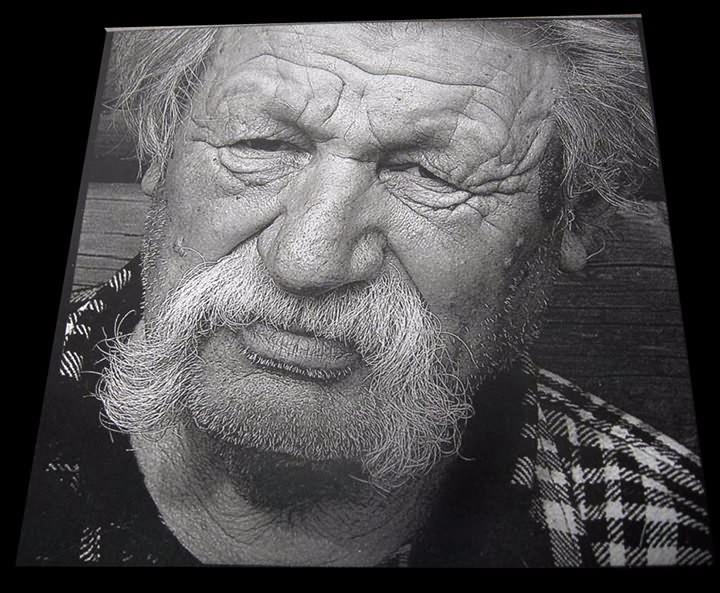

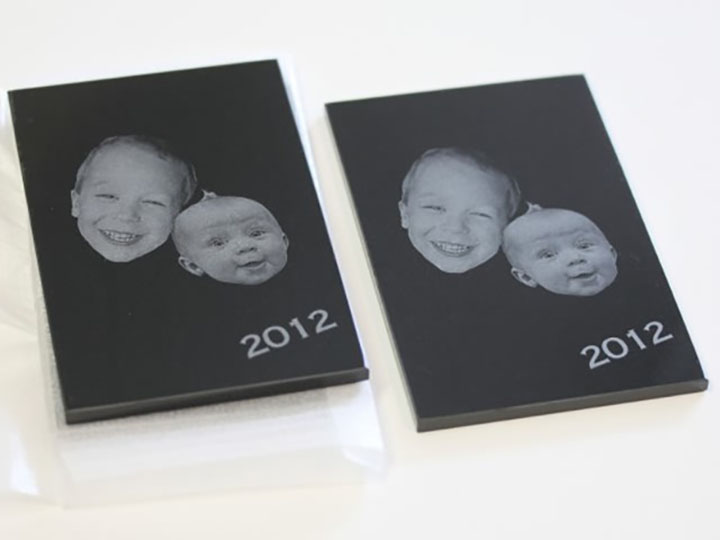

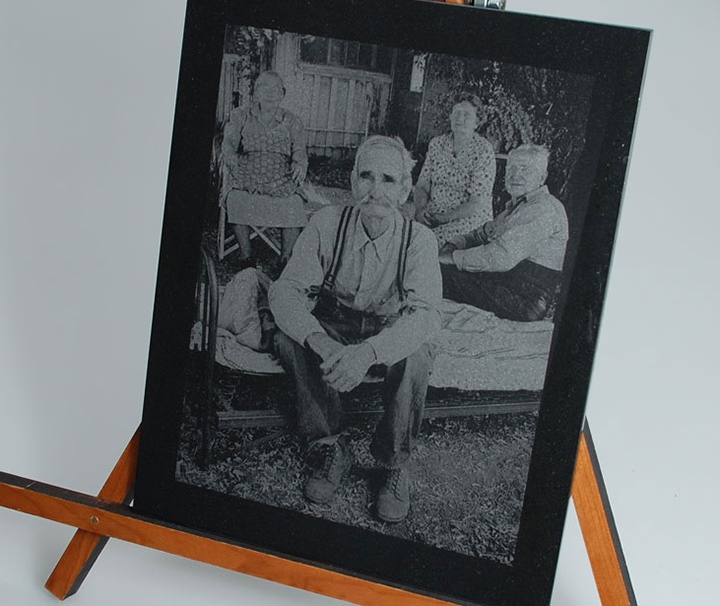

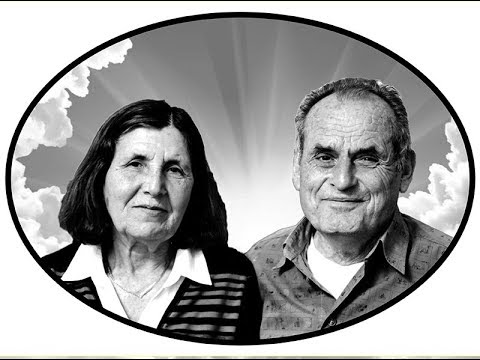

Industrial 4x8 Laser Engraved Marble, Granite, Stone Projects

The Best Stones for Laser Engraving Machine

Personalized laser stone engravings are becoming more and more popular in today's society. The thick, hard, wear-resistant, durable, elegant, and luxurious characteristics of stone carvings are unique in the fields of personalized prizes, gifts, decorations, and other fields. There are many kinds of raw materials and rich resources for stone carvings. The texture, color, and texture of many varieties of stone are suitable for laser engraving with good results. Among them, there are 6 most common types of stone:

Slate Stone

It is another natural stone suitable for laser engraving. Compared with marble, the texture of slate is slightly softer and the surface is slightly rougher. However, because slate is derived from sedimentary stone, with fine texture and uniform color, laser engraving products are widely used in wall decoration, floor, and so on.

Marble

In personalized sculptures, marble is the most ideal raw material of choice. The texture of marble is good and the color is solemn. Whether it is dark black, jet black, dark green, rose, or gray and white, it gives people a very elegant beauty. Therefore, based on many traditional products, it has recently developed to engrave photos, images, and texts with laser technology, which is very popular.

Granite

The texture is very hard, wear-resistant, and durable, and is widely used in prizes, souvenirs, and buildings. Granite belongs to the limestone system, its obvious feature is that it has spots, the color gives people the appearance of "salt and pepper", and some also have the texture of marble. Granite can accept a variety of polishing and finishing treatments. Because of the many colors of granite, especially black and white granite is often used for laser engraving on text, images, etc., which is very attractive.

Sandstone

As the name suggests, sand is formed by the natural condensation of fine sand. The color of the sand is produced by the process of washing and grinding the minerals with the hard rock. Since the sandstone is a mixture of various specifications, the texture is relatively soft, and the effect of laser engraving is very good.

Tuff

This type of stone evolved from the slow precipitation of geothermal heat. The carbon dioxide bubbles "holes" produced by the thermal temperature of mineral-rich mineral water have a unique beauty, and the main color is dark brown. Or black. In addition, dark red and dark brown are also common, mostly used for floor and corner decoration.

Inland Pebbles (River Pebbles of River Rock)

River pebbles of river rock have been washed by water for many years at the bottom of the river bed, making them smooth, round, and bright. The ideal type of river rock is a flat, high-gloss black. The river stone laser engraving will gain a place in the fields of corporate gifts, park decoration, and so on.

STJ1325S is mainly used for heavy stone with large format engraving, if your stone is small, we also have STJ9060 and STJ1390 for option:

Things To Consider

If you are involved in this industry, it is necessary to learn and master some identification and processing knowledge and techniques to achieve professional-level results. The 1st thing to consider is the texture of the stone. Color and size should also be considered when using laser engraving techniques. Whether the engraving effect is good or not depends on the correct adjustment and control of the power and speed of the laser system. Among them, a common problem is that the motor power is too high during engraving, which is easy to cause a blurred appearance and can not achieve the ideal color. This method is called the direct engraving method, that is, the method of changing the color of the photos, patterns to be engraved are directly projected onto the stone.

Aside from direct engraving, added color may be placed on stone engravings. Penetration of the color is caused mostly by pore penetration by emission and polishing caused by lasers. The most common popular colors of added color for carved stone products are gold, silver, and copper. The product with nice effect, added color is as light as ink writes. After the color has been cast, it's then buffed and polished to create a real showpiece. With a laser engraver to permanently engrave scanned valuable photos and pictures onto the stone, a forever keepsake. It's the quickest-growing sector of the laser engraving market and is gaining ever more widespread acceptance.

How to Choose the Best Laser Engraving Machine for Stone?

To choose the best laser engraving machine for stone, precision, power, and compatibility must be considered very carefully. There is a machine for every need, so it is important to evaluate the most important parameters in order to make the most efficient and durable decision. Read the following for the guide steps that are essential.

• Identify the Kind of Stone: The reaction of granite, marble, slate, and quartz to laser engraving differs. So, harder stones require a higher power laser while softer stones can be engraved with moderate power. Knowing your material will help in choosing the optimal machine.

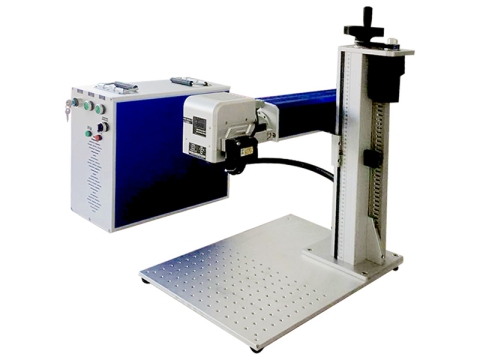

• Select the Appropriate Laser Type: CO2 lasers ranging from 40W-150W are good for engraving softer stones, but their capability to carve deep is limited. Fiber lasers have power ranging from 20W-100W and are optimal for metal but poor when it comes to deeply engraving stones. The application of stones using diode lasers is not imaginable due to their weakness. For fine detail, UV lasers are preferable but can be costly. Deep and lasting engravings are made with high-power CO2 lasers (100W and above) which remain unsurpassed.

• Think about the Laser Wattage and Power: The minimum requirement for stone engraving is an 80W CO2 laser, but for nuances, an even higher 100W is recommended. For mass production, 150W and above guarantees high speed of operation and depth of cuts with a stone laser machine.

• Verify Engraving Bed Size: The choice of engraving bed size should match the dimensions of large stone slabs by selecting machines with either 600x900mm or 1300x900mm beds. A laser system with a 400x600mm bed should be used to engrave detailed small workpieces.

• Assess Cooling & Ventilation Systems: The process of cutting stone releases heat and creates dust due to which proper ventilation and cooling systems need to be evaluated. Proper water cooling systems with chiller systems and ventilation through exhaust fans enhance laser machine performance while extending their lifespan.

• Evaluate Software Compatibility & Features: Review the software compatibility along with features especially LightBurn, RDWorks, and EZCAD which provide user-friendly design control. Select devices with adjustable power capabilities and automatic focus and rotary interface components for broad usage options.

• Balance Budget and After-Sales Support: Your budget should match the quality of your purchase along with your retention services. Customers should opt for brands that offer dependable products and warranties technical support and replacement parts to maximize equipment longevity.

Common Mistakes to Avoid When Engraving Stone with a Laser Machine

Users who operate laser machines toward stone engraving tasks demand high precision although mistakes during the process from experienced users can diminish the quality of end products. The following list shows the leading pitfalls which should be disregarded.

Incorrect Laser Power and Speed Settings

The stone surface can suffer from burning through excessive power usage and useless engravings occur when using insufficient power. To achieve clear and deep engravings test various rates of power with speed for finding the optimal setting. A proper calibration of settings to match the stone material hardness will produce reliable engraving outcomes.

Not Testing on a Sample Piece

Running tests beforehand prevents costly material mistakes because skipping these tests creates possible errors. The testing of a single piece using your equipment provides an opportunity to set the correct parameters which protects against mishaps in your final project. Testing allows professionals to identify unwanted surface cracks and imperfections which enable them to avoid starting a job until these issues are resolved.

Poor Focus Adjustment

Improper settings result in unclear as well as irregular engravings. The focus should be verified twice to achieve exact and detailed engraving results when working on complex designs. Correct adjustment of the focus lens improves engraving visibility by increasing the strength contrast and depth effect.

Ignoring Material Variations

Stones react differently to the processes of laser engraving. Investigation of physical characteristics in each stone material will enable you to optimize the laser settings for successful outcomes. The attempted depth of engraving determines the appropriate power setting for soft marble stones requires different settings compared to granite and quartz stones.

Inadequate Cooling and Ventilation

Stone engraving produces heat along with dust particles that create problems in quality outcomes and threaten the laser lens integrity. A suitable exhaust system removes stone dust particles which extends the operational life of your machine. The laser path will become inconsistent when dust builds up because there is no proper ventilation system.

Using Low-Resolution Designs

Even when using low-quality image files and vector designs with jagged edges the engravings will not obtain optimal quality. Images that get converted to high-definition black-and-white files deliver more precise engraving outcomes. The result of using vector graphics with defined outlines produces both clear borders and precise detailed engraved outputs.

Neglecting Regular Maintenance

Engravings lose effectiveness and quality due when lenses or mirrors become contaminated or ventilation systems get blocked. The machine performs decisively and creates dependable outcomes when operators maintain it by regular inspections and cleaning practices. Your laser engraver benefits from increased lifespan together with heat preservation through routine upkeep procedures.

Frequently Asked Questions

Can CO2 lasers really engrave marble and granite effectively?

Yes. CO2 lasers (60W-150W) excel at stone engraving with 1200 dpi resolution capability. They bleach marble surfaces to reveal underlying white stone and create high-contrast marks on dark granite. The 10,600nm wavelength is readily absorbed by stone, making CO2 laser engravers ideal for memorial work, decorative tiles, and custom signage.

How deep can laser engraving penetrate into stone?

CO2 lasers typically engrave 1-3mm depth per pass on granite and marble. Multiple passes achieve 5mm+ depths for dimensional reliefs and embossed effects. Depth depends on laser power, stone hardness, and pass quantity. Avoid excessive power to prevent faded or cracked appearance—proper calibration is essential.

Do I need different settings for marble versus granite?

Yes. Marble is softer and requires lower power to prevent over-burning, while darker granite needs higher power for visible contrast. Light-colored stones may need painting post-engraving for visibility. Test settings on sample pieces first, stone variations significantly affect results even within the same material type.

Can fiber lasers engrave stone like CO2 lasers do?

Fiber lasers work on dark stones like granite and basalt for fast, deep engravings, but struggle with light-colored marble and limestone due to IR beam reflection. CO2 lasers offer superior versatility across all stone types with better detail and finish for photorealistic images and intricate patterns.

What's better for tombstone and headstone engraving?

Stone laser engravers with 4x8 working areas handle full-size memorial stones efficiently. Use 80W+ CO2 lasers for weather-resistant engravings that withstand decades outdoors. The red light pointer ensures precise positioning for lettering, portraits, and decorative elements on gravestones.

Will laser engraving damage or crack the stone surface?

Proper laser settings prevent cracking. CO2 lasers work non-contact, eliminating breakage risk from traditional chiseling methods. However, excessive power creates micro-cracks and a sandblasted texture on softer stones. Avoid veined or highly porous stones; they produce uneven results regardless of settings.

Can I engrave photos on stone with laser machines?

Yes. Grayscale mode enables photorealistic engraving on polished marble and granite. Laser marking machines with proper resolution (1200 dpi) create different gray shades by varying power output. Black granite yields the best photo contrast; light marble requires post-engraving color fill for visibility.

Do laser-engraved stones need special maintenance?

Laser engravings resist chemical and atmospheric agents without special maintenance. For enhanced visibility, fill grooves with gold ink or specialized stone paints. Clean dust residue with soft cloth after engraving. CNC stone machines with proper ventilation systems minimize cleanup compared to traditional methods.

Raymond J Beers

Spencer Kloss

I have been interested in laser stone engraving for a long time. Looking forward to using it to make my own personalized decorations or create engravings on all conceivable stones. After a short research I came across the engraving machine from STYLECNC, the properties described here were very appealing, the 4x8 working area is very large in comparison and since the price was also right, I decided on this engraver. Other machines could either do less, did not seem as robust or simply cost a lot more. I have been using this unit for a month, and engraved some cool stone decorations with it. I am pleased with the results so far.