Assembly takes about 30 minutes with all the parts put together, as most are built in, only connecting the wiring and controller is required. The small footprint is perfect for my jewelry store with a protective housing. The included english instructions is easy to follow for beginners, with a user-friendly control panel. I cut a Christmas ornament out of 22 gauge brass with great anticipation and it turned out perfectly with clean edges. I was impressed by its speed and precison. The fly in the ointment is that the ST-FC1390 cannot cut through thicker metals over 16mm due to the lower fiber laser power of 2000W - STYLECNC’s official explanation. I'll try try to test its limits with various thicknesses of metal. in the next week. All in all, the ST-FC1390 is a great laser metal cutter worthy of praise.

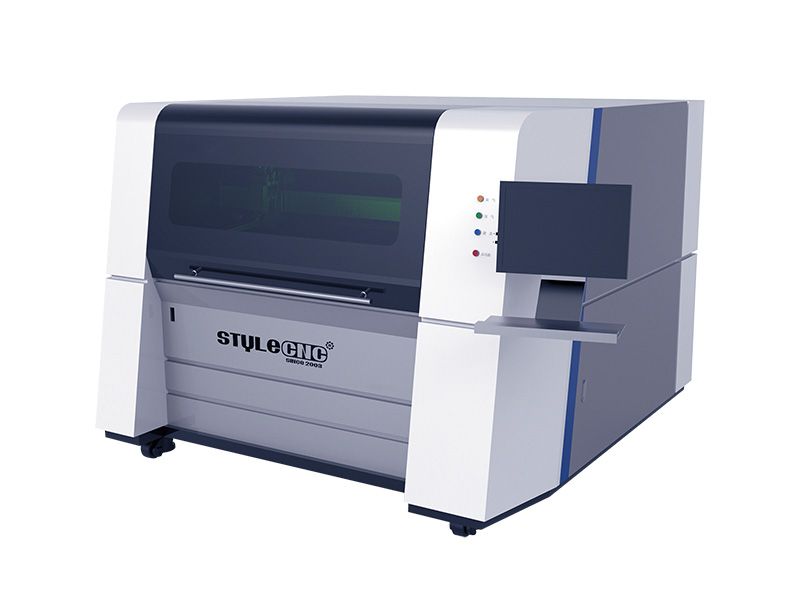

Entry Level Small Metal Laser Cutter for Beginners

ST-FC1390 small metal laser cutter is an entry-level fiber laser cutting system with compact structure for hobbyists and home use in small business to cut out personalized metal parts, signs, tags, logos, letters, jewelries, and cut through all types of sheet metals with fully enclosed design, environmental friendly operation, 1500W, 2000W, 3000W and 6000W laser powers for option. The ST-FC1390 is an ideal choice for individuals who are ready to start metal fabrication with professional precision and craftsmanship.

- Brand - STYLECNC

- Model - ST-FC1390

- Maker - Jinan Style Machinery Co., Ltd.

- Category - Fiber Laser Cutting Machine

- Laser Source - Raycus, IPG, MAX, RECI

- Power Option - 1500W, 2000W, 3000W, 6000W

- 180 Units in Stock Available for Sale Every Month

- Meeting CE Standards in Terms of Quality & Safety

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- 30-Day Money Back Guarantee for Your Purchase

- Free Lifetime Technical Support for End-Users & Dealers

- Online (PayPal, Alibaba) / Offline (T/T, Debit & Credit Cards)

- Global Logistics and International Shipping To Anywhere

For small enterprises as well as individuals who are planning to start a business, getting into metal fabrication can be intimidating. The ST-FC1390 entry-level small laser metal cutter by STYLECNC is here to fill that gap by providing a small but powerful option made just for newbies.

Put an end to worrying about risky working conditions and convoluted setups with this machine - it's safe and effective, allowing you to unleash your creativity without restrictions.

No need to worry about dangerous working conditions and complicated setups when you own the ST-FC1390, which is a safe and effective cutting tool, allowing your creativity to go wild.

The ST-FC1390 comes with an intuitive design and a straightforward CNC controller, making it ideal for beginners. Thanks to its flat learning curve, you can become a metalworking expert in a short time. You can get it for only $17,000.00, making it an affordable investment and perfect for startups and side projects.

STYLECNC's ST-FC1390 is an excellent pick for individuals who are prepared to get started with metal fabrication. Its compact size, powerful laser source, and user-friendliness make it an ideal tool for novices just starting out on the road to professional precision and workmanship. ST-FC1390 small metal laser cutter for beginners is one high precision fiber laser cutting system to cut thin metals which adopts Taiwan TBI grinding ball screw and Hiwin guide rail, the positioning accuracy of the small laser metal cutting machine tool can run up to 0.008mm and the cutting acceleration is 0.5G.

Technical Parameters of Entry-Level Small Metal Laser Cutter for Beginners

| Model | ST-FC1390 | ST-FC1313 |

|---|---|---|

| Laser Power | 3000W (1500W, 2000W, 6000W for Option) | |

| Working Area | 1300mm x 900mm | 1300mm x 1300mm |

| Repeat Positioning Accuracy | ±0.008mm | |

| Maximum Speed | 40m/min | |

| Maximum Acceleration | 0.5G | |

| Transmission Mode | Grinding Precision Screw Drive | |

| Specified Voltage and Frequency | 220V for 1500W and 2000W | 380V for 3000W and 6000W | |

| Packing Size | 2280x2240x1870mm | 2680x2240x1870mm |

Features of Entry-Level Small Metal Laser Cutter for Beginners

An entry-level small metal laser cutter offers essential features for precise cutting and easy operation. It is designed to be user-friendly, reliable, and cost-effective, making it a great choice for beginners and small business owners.

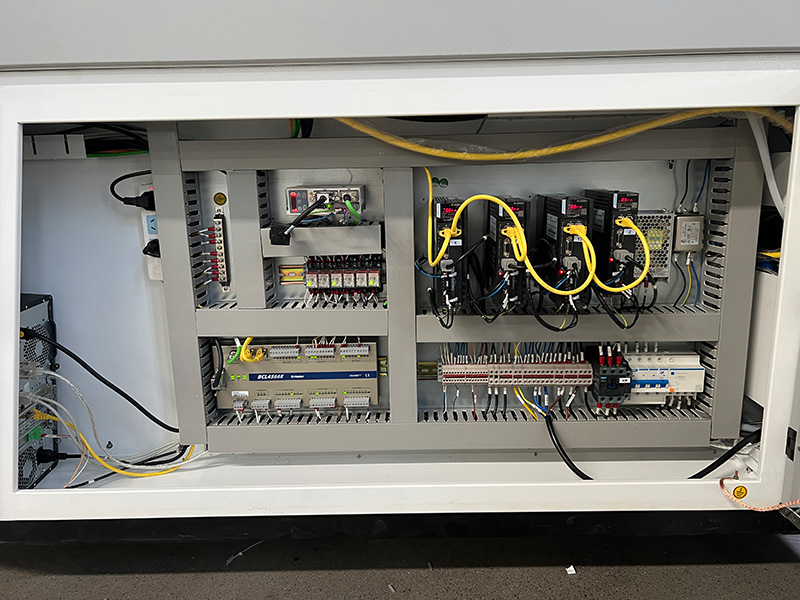

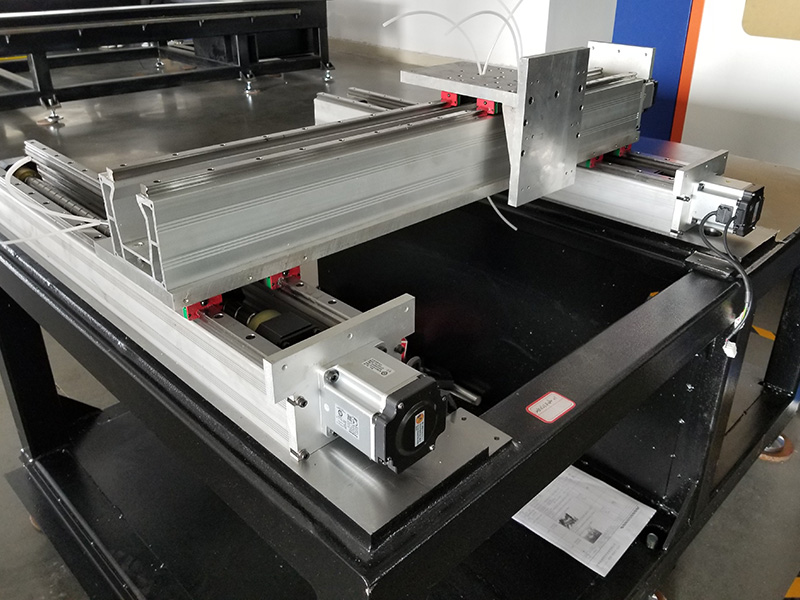

• Dual guide rails and grind ballscrew driving

In order to prevent the Y-axis lead screw from bending and causing deformation of the cutting line, dual guide rails and dual ball screws are used on both sides of the Y-axis to ensure straightness and circularity during high-speed cutting.

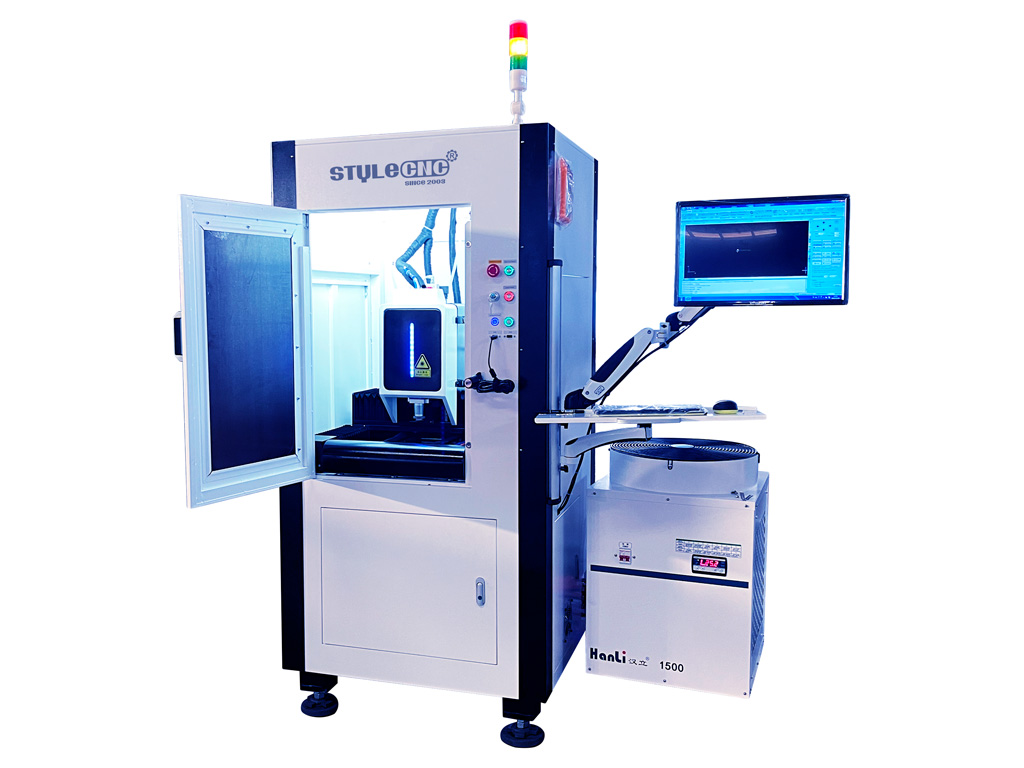

• Fully enclosed structure

The real-time working observation window adopts European CE standard laser protection glass, and the smoke from cutting can be filtered internally, which is pollution-free and environmentally friendly.

• Raytool laser cutting head with automatic sensor from Switzerland ensures a smooth and burr-free cutting surface.

• The English version of Cypcut software is installed, which is suitable for inserting files in DXF or AI format.

• Servo motor drive system makes the cutting effect the best.

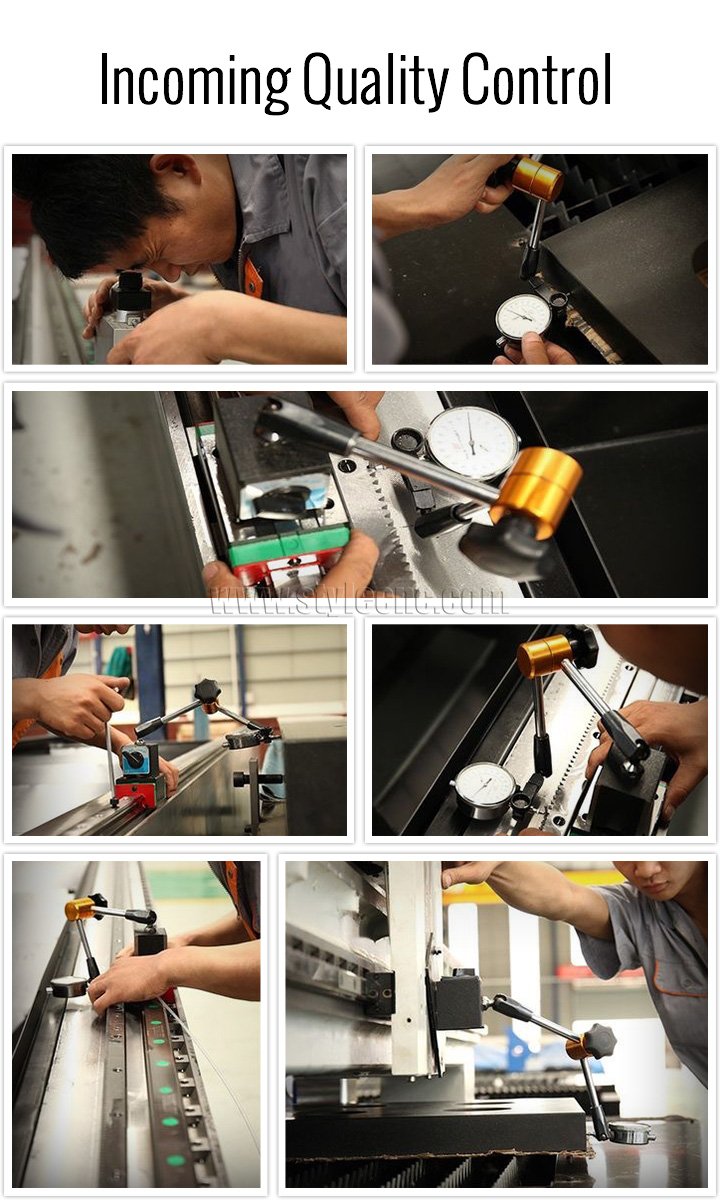

• The guide rail assembly and debugging are tested with a precision collimator with an accuracy of less than 0.01mm.

• The bed of this small laser metal cutting machine adopts high-temperature heat treatment, 24-hour furnace cooling, and precision machining with an 8-meter-long gantry CNC milling machine to ensure that it will not deform during 20 years of normal use.

• The sawtooth table can withstand heavy sheet metal without deforming.

Applications of Small Fiber Laser Metal Cutting Machine for Starters

Small fiber laser metal cutting machines are perfect for beginners who need precise, high-quality metal cutting. These machines are widely used across different industries and can handle a variety of metals, making them a versatile tool for small businesses and startups.

Application Industries

This machine is used in various industries like eyewear, electronics, home appliances, and metal signs. It’s ideal for cutting metal logos, letters, and jewelry names. Precision industries, hardware manufacturing, and microelectronics also benefit from its accuracy and efficiency.

Application Materials

The machine can cut through all types of metals, including stainless steel, carbon steel, and aluminum alloy. It is also effective with titanium alloy, galvanized steel, and copper. Additionally, it works well with coated metals like aluminum-plating zinc plates and pickle plates.

Projects of Entry Level Small Metal Laser Cutter for Beginners

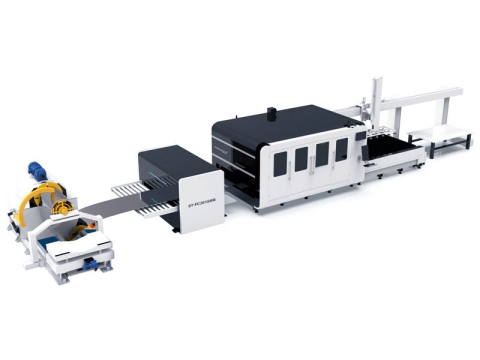

We also have a smaller size ST-FC3030 equipped with 300mm x 300mm laser cutting table available.

Package of Entry Level Small Metal Laser Cutter for Beginners

1. Strong water resit bottom in plywood.

2. Laser source (separated plywood case) and spare parts on the laser bed.

3. Corner protected by foam and fixed by a protective film.

4. All are covered by strong and hard protective film.

5. Vacuum packing.

6. Inside steel frame protector.

7. Plywood packing and steel strip outside fixed the box.

8. Finishing packing by normal container or frame container.

Maintenance and Safety Guidelines for First-Time Users

Starting with a small metal laser cutter can feel exciting yet daunting, especially if you’re new to this technology. Proper maintenance and adherence to safety protocols are essential to keep your machine running smoothly and ensure safe usage. By following these simple guidelines, you can maximize the lifespan of your laser cutter and minimize risks.

1. Regular Cleaning: Dust, debris, and metal residues can accumulate during cutting. Clean the lens, mirrors, and machine bed after each session to maintain optimal cutting precision and prevent damage to sensitive components.

2. Monitor Cooling Systems: Most metal laser cutters use a water or air cooling system to prevent overheating. Check the coolant levels regularly and replace the water or antifreeze as needed to avoid system failure.

3. Inspect Components: Perform routine inspections of belts, rails, and electrical connections. Tighten loose screws and replace worn-out parts promptly to avoid breakdowns during operation.

4. Wear Protective Gear: Always wear safety goggles designed for laser cutting to protect your eyes from harmful radiation. Avoid wearing loose clothing that could catch fire or interfere with the machine.

5. Follow Ventilation Guidelines: Ensure the laser cutter is placed in a well-ventilated area. Proper exhaust systems are crucial for removing fumes and metal particles generated during cutting.

6. Emergency Preparedness: Keep a fire extinguisher nearby and familiarize yourself with the machine's emergency stop button. Knowing how to react in unexpected situations can prevent serious accidents.

Pre-Sale Service of Small Fiber Laser Metal Cutting Machine for Starters

1. Free Sample Cutting Service

For free sample cutting/testing, please send us your CAD file (.plt or .ai), we will do the cutting in our factory and make a video to show you the cutting process and result or send samples to you to check the cutting quality.

2. Progressing Solution Design

According to the customer’s product processing requirement, we can design a unique solution that supports higher manufacturing efficiency and better processing quality for customers.

3. Customized Machine Design

According to the customer's application, we may revise our machine according to the customer's convenience and high production efficiency.

After-Sale Service of Entry-Level Small Metal Laser Cutter for Beginners

1. We will supply the laser machine with a training video and a user's manual in English for installation, operation, maintenance, and troubleshooting, and shall give technical guidance by remote, such as TeamViewer, E-mail, Telephone, Mobile, WhatsApp, Skype, 24/7 online chat, and so on when you meet some problem of installation, operation or adjusting. (Recommended)

2. You can come to our laser machine factory for training. We will offer professional guidance. Direct and effective face-to-face training. Here we have assembled equipment, all sorts of tools, and a testing facility. Training Time: 3~5 days (Recommended)

3. Our engineer will do a door-to-door instruction training service at your local site. We need your help to deal with the visa formality, prepaid traveling expenses, and accommodation for us during the business trip and service period before their dispatch. It's better to arrange a translator (if not English-speaking) for our engineers during the training period.

Warranty of Small Fiber Laser Metal Cutting Machine for Starters

1. The entire machine comes with 1-year limited warranty (excluding consumable parts).

2. Long lifetime maintenance, the after-sale department will offer 24/7 English online support.

3. Except for the damage artificially, we are responsible for offering the fittings free of charge during warranty.

4. After the warranty period expires, the buyer only needs to pay the actual maintenance cost.

5. Certificate support: CE, FDA, SGS.

If you have an idea to get a free quotation of metal laser cutters, please answer the questions as follows and tell us by email, so that we can recommend the most suitable laser machine and quota the affordable price to you directly.

1. Do you need to cut metal sheets/plates, metal pipes/tubes only, or both?

2. If need to cut tubes, What are your tube length, diameter, and max thickness?

3. For cutting metal sheets, what is the maximum working area required?

4. After processing, what the materials will be used for? (Applications)

5. Which seaport is the nearest to you?

6. Do you have any experience in the fiber laser metal cutting machine?

7. What is your online chat way? Such as Skype and WhatsApp.

8. Are you an end user or reseller?

Why a Small-Format Fiber Laser Cutter Works for Precision Metal Fabrication?

A high-precision small metal laser cutter in the 1390 format (1300mm x 900mm working area) delivers the tight tolerances needed for detailed metal work without the footprint and cost of a full-size industrial system. Fiber laser technology produces a focused beam with a spot size as small as 0.01mm, enabling intricate cuts on thin stainless steel, carbon steel, aluminum, brass, and copper sheets. This level of fiber laser cutting precision makes the 1390 format ideal for applications like custom metal signs, jewelry components, electronic enclosures, and architectural decorations. For businesses that don't need to process full 4x8 or 5x10 sheets, this compact format eliminates wasted material and reduces the initial investment compared to a heavy-duty fiber laser cutting machine.

Choosing the Right Laser Power for Your 1390 Metal Cutter?

Laser power determines both the maximum cutting thickness and the speed at which your machine processes materials. A 500W-1000W fiber laser source handles most thin-sheet applications, cutting up to 3-5mm carbon steel and 2-3mm stainless steel or aluminum at production speeds. Higher wattage options (1500W-3000W) expand your capabilities to thicker metals, but also increase the machine cost. The key fiber laser cutting machine advantages over CO2 systems include higher electrical efficiency, lower operating costs, virtually zero maintenance on the laser source, and superior edge quality on reflective metals. If your primary workload involves detailed cuts on metals under 6mm, the 1390 format with a mid-range fiber source strikes the best balance between capability and affordability.

Frequently Asked Questions

What metals can the 1390 fiber laser cutter process?

It cuts carbon steel, stainless steel, galvanized steel, aluminum, brass, copper, and titanium. Maximum cutting thickness depends on the laser power selected. A 1000W source typically handles up to 5mm carbon steel and 3mm stainless with clean edges and minimal burr.

Is this machine suitable for cutting metal tubes and pipes?

The standard 1390 is designed for flat sheet cutting. If your work involves round or square tubes, consider a dedicated metal pipe and tube laser cutting machine with a rotary chuck system for consistent circumferential cuts.

Can it cut detailed designs like 3D puzzles and models?

Yes, the high-precision beam is well-suited for intricate 3D metal puzzles and models with tight tolerances. The small kerf width allows for fine tab connections and complex interlocking geometries that assemble cleanly.

How much does a small fiber laser cutting machine cost?

Pricing depends on laser power, brand of fiber source, and automation features. For detailed pricing breakdowns across different configurations, review this guide on how much a laser cutting machine costs.

What maintenance does a fiber laser cutter require?

Fiber lasers are relatively low-maintenance compared to CO2 systems. Routine care includes cleaning the cutting nozzle and protective lens, checking assist gas pressure, and inspecting the chiller system. A detailed daily maintenance schedule for fiber laser cutting machines keeps performance consistent and extends component life.

What software does it use?

Most 1390 fiber laser cutters support industry-standard nesting software like CypCut or Au3Tech, which handles DXF and AI file imports, automatic nesting for material optimization, and real-time cutting parameter adjustments. The controller integrates directly with the software for seamless operation.

Does it require assist gas to cut?

Yes, assist gas (typically oxygen for carbon steel, nitrogen for stainless steel, and aluminum) blows molten material from the kerf and protects the lens. Oxygen produces faster cuts on carbon steel with an oxidized edge, while nitrogen delivers a clean, oxide-free finish on stainless and aluminum.

Jett Bramston

Mohammed Blake

First of all things, if you order this machine, fix the wiring so it the chassis is properly grounded. If the high voltage power supply wire got damaged causing a short, the chassis could become hot with high voltages.

Great value for the money, but not for the faint of heart due to lack of safeties, buy some eye protection.

Martindale

The laser machine was "functional" after the first start to use it for different metals and thickness you need to be willing to invest quite a bit time and mechanical changes to get this unit as you want it.

Dustin

Wesam Zahran

Jeff

Just got my new jewelry store up, and added this machine to cut metal jewelries of copper and silver. Tried it for 1 week, it has been cutting smoothly with precision. I'm pleased with this small laser cutter for the price I paid. Definitely worth the money.

Bennett Dobni

Camille Pissarro

Set up was easy right out of the box. Very satisfied with the performance of this laser metal cutter. So far it has done everything I have asked it to do. The cutting of 1/8, 3/16, 1/4 was so easy. As far as the laser software and the CAD software is concerned, it would be good if they were together in the same system and if possible that cutting shapes and contours could be generated from basic geometric figures.