Whole house panel furniture customization has become the most profitable business for modern industrial kitchen manufacturer, wardrobe maker, cabinet maker, closet maker, door manufacturer, shopfitter and provider. New CNC woodworking machines these days have better functional features and more tech gizmos than machine tools from a decade ago. The furniture board can be automatically loaded and unloaded, and the cutting, carving, drilling and grooving job with your design will be done in minutes, and you just need to assemble it.

If you need to upgrade your panel furniture production line with a new woodworking CNC machine to make cabinets, closets, wardrobes, home doors, home decorations, and other personalized panel furniture, we suggest starting your buying process sooner rather than later, as it can fully automate your panel furniture manufacturing process, which not only saves labor and production costs, but also improves production efficiency. Buy early and benefit early.

Here's how to research, understand, locate, price and negotiate to buy your new CNC machine for cabinet and furniture making. Smartphones make these steps easier than ever. It is now entirely possible for a buyer to shop for a machine tool while waiting to pick up the kids or in line at the supermarket.

This guide explores the steps a buyer would take to purchase a new automatic CNC furniture making machine to make the shopping process quicker and stress-free.

Let's get started on whatever you need.

Panel funiture making requires multiple processes ranging from wood cutting and milling to drilling and grooving, as well as laminating and edging. Completing these tasks requires the cooperation of multiple CNC woodworking machines, which are collectively referred to as a panel furniture production line.

Panel Furniture Production Line

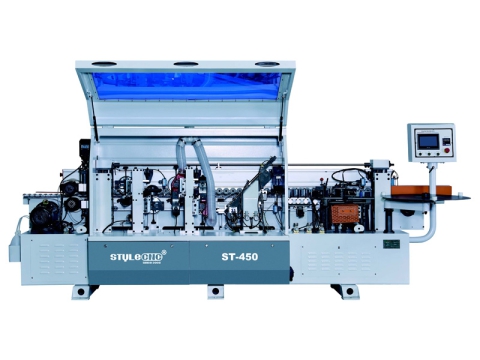

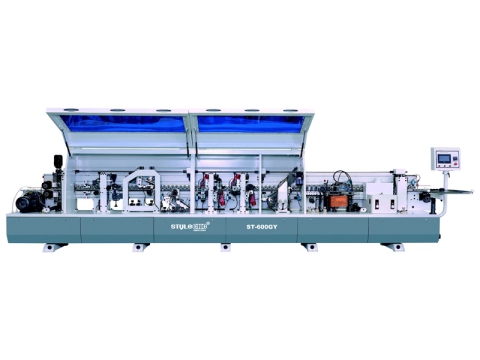

A panel furniture production line is a combination of multiple CNC woodworking machines for the entire panel furniture manufacturing process, working with automatic coder, feeder, holer, driller, sliding table saw, sander, slotter, cutter, miller, laminator, and edge bander.

What Is A Cabinet CNC Machine?

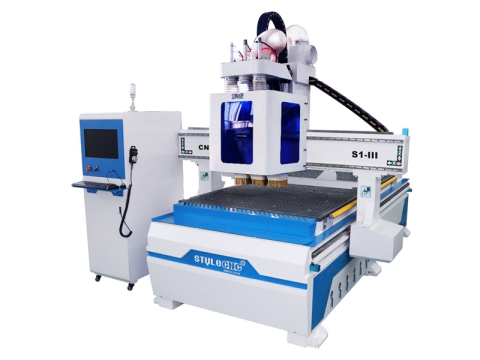

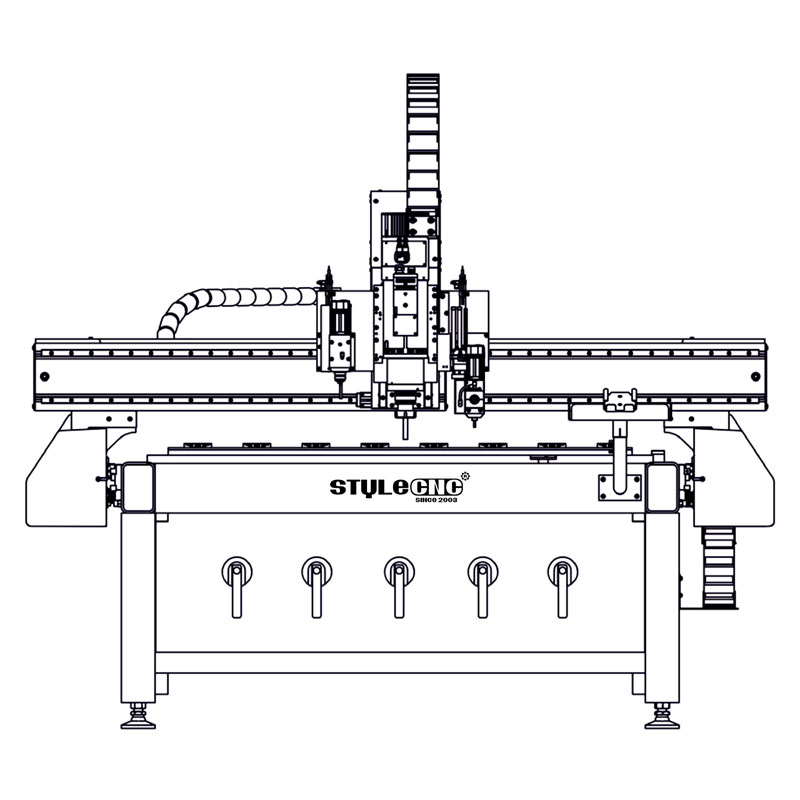

A cabinet CNC router is a computer-controlled automatic nesting machine tool for custom flat-panel furniture manufacturing including bedroom furniture, kitchen furniture, home decor, shop and office furniture, which is available from personalized wall decorations to space-saving built-in cabinets.

A cabinet CNC machine is a professional smart furniture making machine featuring with automatic labeling, coding, feeding, drilling, slotting, milling, cutting for whole house customization for cabinets, doors, closets, armoires, wardrobes, wall decorations, bookshelves, tables, screens, and built-in lockers.

How Do CNC Cabinet Making Machines Cost?

Cabinet CNC machines of various costs are available from the most-affordable to the most-expensive at STYLECNC. The least expensive CNC cabinet cutting machine on the market is the S1 with an effective price of $12,000. This model offers four spindles for multitasking. The S2 is right behind, at $18,000. S3 is an affordable automatic cabinetry shaper cutter starting at $20,000, appears to be a good buy. S4 is the most popular CNC cabinet making machine ranging from $22,000 to $41,000. S5 is a professional CNC furniture making machine over $26,000. S6 is an indstrial model as expensive as $5,5000.

In addition, a CNC cabinet drilling machine is priced from $5,500 to $48,000, a CNC wood sander cost anywhere from $2,000 to $8,000, an automatic edge banding machine ranges from $8,000 to 17,300.

Anyway, purchasing a complete set of fully automatic CNC cabinet furniture manufacturing machines requires an investment of at least $48,000.

How To Pick Your Best CNC Machine for Cabinet Making?

If you're choosing a brand new or used CNC cabinet making machine, you may ask which one is the best? But it's hard to find the right answer, depending on your specific needs.

If you're a small cabinet shop owner, an affordable 4x8 ATC CNC router with tool changer is an ideal choice.

If you're a professional cabinet maker, a smart CNC nesting machine is the best pick, featuring with nesting, routing, vertical drilling, cutting, side milling, and edge grinding all in one.

If you're an industrial furniture manufacturer, the best option is a complete panel furniture production line, including automatic coding machine, feeder, holer, drilling machine, sliding table saw, sanding machine, slotter, cutter, miller, laminating machine, and edge banding machine. However, you can also pick some of these machines as the best solution to match your cabinet furniture making projects.

In addition, you have plenty of other great options for every budget and need at STYLECNC.

Specifications

| Brand | STYLECNC |

| Model | S1, S2, S3, S4, S5, S6 |

| Features | Nesting, Feeding, Cutting, Milling, Routing, Sanding, Edging, Drilling, Grooving, Sealing, Lamination |

| Applications | Shop & Office Furniture, Kitchen Furniture, Bedroom Furniture, and Home Decor |

| Uses | Whole House Customization for Cabinets, Closets, Doors, Armoires, Wardrobes, Bookshelves, Wall Decorations, Screens, Tables, and Built-In Lockers |

| CAD/CAM Software | Mozaik, Cabinet Pro, SketchUp, Fusion 360, KCD |

| Price Range | $5,500.00 - $56,000.00 |

Features

A furniture CNC machine is an automatic woodworking tool kit with flexible functions, which is capable of cutting straight lines and any complex curve lines, and realize the integration of punching, slotting and cutting.

One person can operate multiple pieces of equipment at the same time, and an ordinary worker can complete the work of several senior skilled workers at the same time.

With the help of nesting software, it can surpass the original manual extensive production and realize intelligent operation.

Here are its 10 features.

Automatic Nesting

The nesting software can realize intelligent nesting, maximize the utilization rate of the board, and save the material cost of the panel furniture to the greatest extent. In the past, professional nesting workers took a day to complete the nesting task, but now ordinary workers can calculate it with nesting software in just a few seconds, and the calculation results are far better than manual nesting.

Automatic Output Tool Path

The nesting software can automatically output tool path G code files. In the past, professional layout workers were required to use software to generate tool path files semi-automatically, which was cumbersome.

One-Stroke Tool Path Optimization Technology

The tool path output by the nesting software is also optimized by mathematical methods. Ordinary rectangular material contour line cutting, the output tool path adopts one-stroke technology, which realizes the cutting of the entire board by one drop of the knife without lifting the knife, and the cutting efficiency is significantly improved.

Co-edge Cutting Tool Path Optimization Technology

Co-edge rectangular cutting adopts the shortest path optimization technology to achieve efficient cutting through the shortest tool path and the least number of knife lifts.

Unique Anti-drift Technology

It provides special-shaped path export, and also provides a unique anti-drift technology. The cutting sequence of the board and the position of the cutting point are all optimized and selected by special mathematical methods, so that the possibility of small board drifting will be minimized.

In order to further reduce the possibility of drifting, it also provides slope cutting technology and multi-layer cutting strategy to further reduce the possibility of drifting of small boards.

Punching & Slotting Functions

The typesetting software supports the functions of punching and slotting, so that only one process of material cutting is needed to realize the traditional three-process operation of material cutting, punching, and slotting, which improves work efficiency and reduces equipment investment.

Support Tool Change

The optimized typesetting software supports automatic tool change. During the cutting process, the tool can be changed automatically according to the preset tool number. In order to reduce the number of tool changes, it will automatically summarize and classify the cutting paths of various tools, and complete all paths step by step according to the tool numbers.

Support Row Drilling

Optimized typesetting software supports drilling operations. The software can print barcodes and QR code labels when cutting materials, and include the drilling operation instructions in the barcodes and QR codes. After the cutting is completed, the drilling equipment scans the corresponding barcode label and automatically drills holes.

Support Automatic Loading & Unloading

The optimized typesetting software supports fully automatic machines with loading and unloading devices. When exporting the path, the cutting instructions and loading and unloading instructions of all orders can be combined to generate a G-code file to realize fully automatic cutting operations.

Automatic Bill Splitting

The order dismantling module, which will realize the automatic dismantling of orders into work orders, and realize the intelligentization of the production process of furniture enterprises.

How It Works

The tool path is automatically produced by the CAD/CAM software. Through the intelligent design software to split single 3D modeling, it can realize the real effect of map rendering. Customized furniture shape and size at a glance. After the automatic assembly generated a single panel report and hardware statements, and outputs all sheet drawing format (DXF format drawings belonging to a common format, it can be open in all the software), each piece of plate holes, slots are automatically generated. Through the optimization by the automatic layout software to optimize the layout and generate the processing path (NC program), to maximize use of raw materials.

Pros & Cons

Pros

Are you still using traditional, inefficient sliding table saws? Are you still using its relatively backward craftsmanship to make furniture? The era of CNC furniture making machine has come into being, and its pros and cons are listed below.

• The design software automatically optimizes the typesetting, which greatly improves the utilization efficiency of the board. It uses a milling cutter to cut the material, can turn the direction arbitrarily, and can cut the opposite sex. The average utilization rate of each board is 2.7-2.8 square meters.

• Save labor, one person can operate several machines, reduce labor intensity, save the wages of master craftsmen who push table saws, and use 0.3 square meters more for each plate.

• The processing speed is fast, his work is continuous, and he can work continuously for eight hours without interruption, which greatly improves the work efficiency and reduces the labor intensity. One piece of equipment can produce 60-80 boards a day, and the production efficiency is greatly improved.

• The dust collection effect is good. It adopts a 3 kW full set of dust removal controlled by a solenoid valve, which realizes the dust-free factory, greatly improves the environmental quality of the factory, and enhances the dust collection effect of the machine. The suction is clean and its suction is strong Can reach more than 95 percent.

• Smart operation, zero error, zero failure rate. The operation is simple, and any small worker can go to work directly after 3-5 hours of training from the manufacturer.

• The machine can pause at any time, increase or decrease the speed, adjust the depth at any time, and can preview the plane and three-dimensional diagram of the cutting path. The stepless speed regulation is convenient for cutting different materials and is suitable for different industries.

• With strong special-shaped processing ability, it is very suitable for customized production.

Cons

• Tool loss: It is generally suitable for plates with less impurities, otherwise the tool loss will be large. Ordinary cutting knives can open 20-35 particle boards.

• Batch processing is not supported: It is processed one by one, unlike electronic saws that can process many sheets at a time.

• Risk of use: Small and medium-sized panel furniture factories are highly dependent on equipment. Once the equipment fails, if the manufacturer does not sell it in time, the production will be paralyzed. This is a problem that most custom furniture factories worry about.

• Higher requirements for software: The software is the brain of the machine, and whether the machine works well depends to a large extent on the selected software. Therefore, the equipment needs to be equipped with mature software for furniture design and disassembly.

Buyer's Guide

If you're planning to buy a CNC machine for cabinet furniture making in today's marketplace, you'll find that features and prices have changed quite a bit. Here're 9 easy-to-follow steps a buyer would take to purchase a new CNC cabinet furniture making machine, whether you are a beginner or a professional. These nine steps make the buying process at STYLECNC quicker and stress-free. Let's begin.

Step 1. Pre-Sales Advice

We will recommend the most suitable CNC cabinet making machine to you after being informed by your requirements.

Step 2. Get A Quote

We will offer you with our detail quotation according to the consulted furniture CNC router machine. You will get the most suitable specifications, the best accessories and the affordable price.

Step 3. Pre-Purchase Evaluation

Both sides carefully evaluate and discuss all the details (technical parameters, specifications and business terms) of the order to exclude any misunderstanding.

Step 4. Placing An Order

If you have no doubt, we will send you the PI (Proforma Invoice), and then we will sign a contract with you.

Step 5. Machine Building

We will arrange the building as soon as receiving your signed sales contract and deposit. The latest progress will be updated and informed to the buyer during the machine production.

Step 6. Quality Control

The whole production procedure will be under regular inspection and strict quality control. The complete machine will be tested to make sure they can work well before out of factory.

Step 7. Shipping & Delivery

We will arrange the delivery as the terms in the contract after the confirmation by the cabinet CNC machine buyer.

Step 8. Custom Clearance

We will supply and deliver all the necessary shipping documents to the buyer and ensure a smooth customs clearance.

Step 9. Support & Service

We will offer professional technical support and free service by Phone, Email, Skype, WhatsApp, Online Live Chat, Remote Service. We also have door-to-door service in some areas.

How To Use?

Before starting processing, it is best to run the furniture CNC machine dry, because only dry running can ensure that all parts of the machine are very normal and ensure safety.

Step 1. Turn on the power and make sure that the emergency stop button is not touched.

Step 2. Turn on the computer connected to the machine, enter the predetermined operating system, find the software that controls the device, and double-click to open the software on the computer.

Step 3. Check whether the machine operating system is normal. If there is any error message about the machine in the system, it can no longer be used for work, and the cause of the error should be found out and repaired.

Step 4. Measure whether the size of the workpiece exceeds the range of the pneumatic clamp of the machine, and make adjustments. Once the workpiece is too large, it will affect the normal operation of the machine or cause damage to the machine.

Step 5. Start the pressure device of the machine, and the normal processing can only be carried out after the inspection is correct.

Things To Consider

The operator must be very familiar with the furniture CNC machine, whether it is the structure, the scope of application, the technical specifications and the safety rules that must be followed during use, they must be familiar with it to avoid accidents during use. In addition, before the formal operation, the operator is generally required to take an exam, and only those who pass the exam can operate.

Before officially starting work, it is necessary to conduct a comprehensive inspection of the machine. Check whether the bolts in each part of the machine are loose, check whether the transmission of the machine is running smoothly, check whether the buttons of the machine are normal, and check whether the machine’s Whether the lubrication system, pneumatic system and various safety systems are in good condition. When all these have been checked and there is no problem, it can be turned on normally.

When the machine is running, the operator must pay attention to his own health and safety. Whether it is loading or unloading, he must strictly abide by the safety requirements to avoid accidents.

Once the illegal operation is carried out, it is very easy to cause accidents, which will cause very serious damage to the cabinet CNC machine operators, so it is necessary to arouse the great attention of all users.