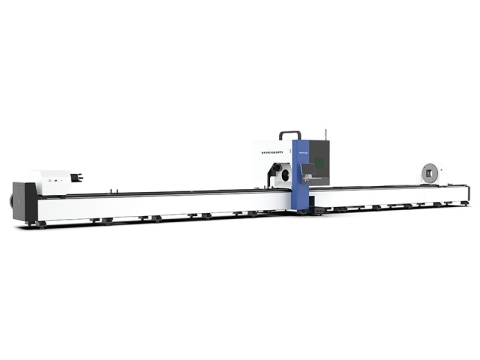

This is an amazing heavy-duty laser cutter, easy to use even with no experience, user-friendly for beginners, and can cut all types of metal tubing, whether it's steel or aluminum, the ST-FC12035K3 can handle it easily, making it a must-have cutting tool for every metal fabricator.

3D Tube Laser Bevel Cutting Machine with Automatic Feeder

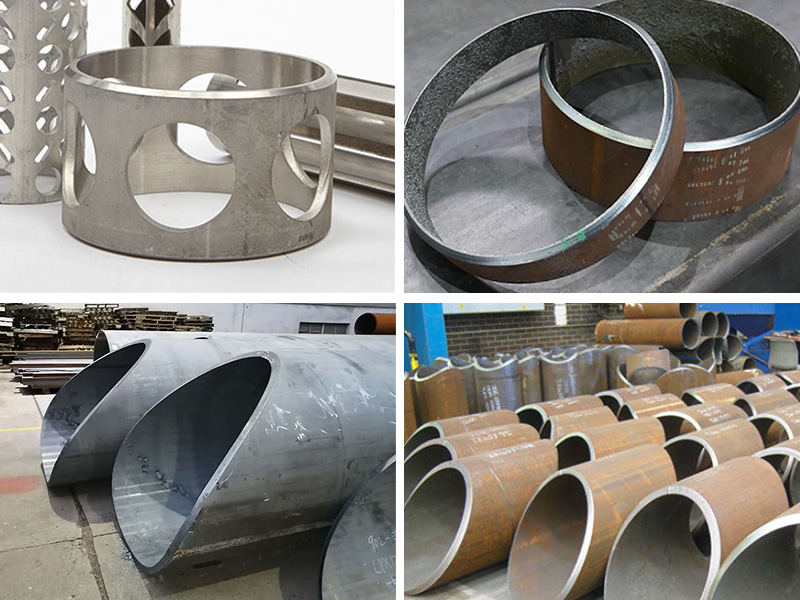

Looking for a professional metal cutting tool to create precise bevels of 15, 30 or 45 degrees on metal tubes or profiles for welding, assembly or fabrication? This 3D tube laser cutting machine with bevel cutter and automatic feeding system is the best option to help you get the job done with ease. The ST-FC12035K3 comes with three rotary chucks for rotating and moving metal pipes of heavy-duty and large-diameter, enabling the high-speed cuts of lines, holes, contours, bevels, and complex shapes in 2D/3D.

- Brand - STYLECNC

- Model - ST-FC12035K3

- Maker - Jinan Style Machinery Co., Ltd.

- Sizing - Φ20mm - Φ350mm

- Category - Fiber Laser Cutting Machine

- Laser Source - Raycus, IPG, MAX

- Power Option - 6000W, 12000W, 20000W

- 180 Units in Stock Available for Sale Every Month

- Meeting CE Standards in Terms of Quality & Safety

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- 30-Day Money Back Guarantee for Your Purchase

- Free Lifetime Technical Support for End-Users & Dealers

- Online (PayPal, Alibaba) / Offline (T/T, Debit & Credit Cards)

- Global Logistics and International Shipping To Anywhere

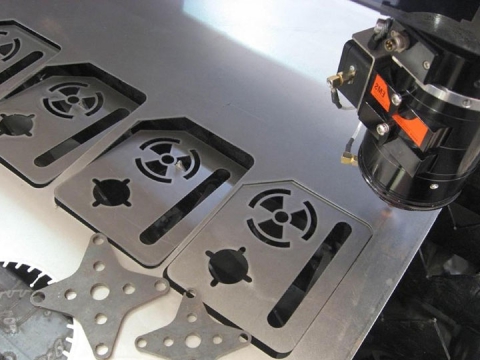

A laser tube cutter is an automated CNC machine that uses a high-power fiber laser beam to shape and cut tubular metal for the manufacture of structural components, functional parts, decorative elements, and metal tubing that require high precision.

Tube laser cutting machines come with one or more chucks that rotate and move metal pipes, enabling the high-speed cuts of lines, holes, contours, bevels, and complex shapes in 2D/3D.

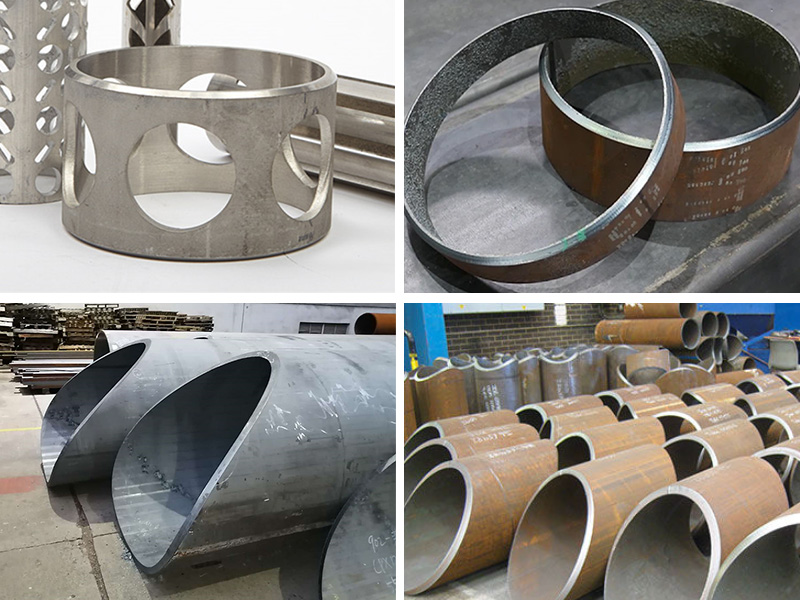

Laser tube cutting machines combine laser technology with CNC automation to manufacture high-quality metal tubing with minimal waste in modern metal fabrication such as construction, agriculture, auto parts, plumbing components, structural frames, electrical and medical devices. In addition, tube laser cutters can also cut high-strength and thick-walled metal pipes in aerospace, automotive, bridges, construction, energy sectors (oil and gas transportation), and mechanical equipment.

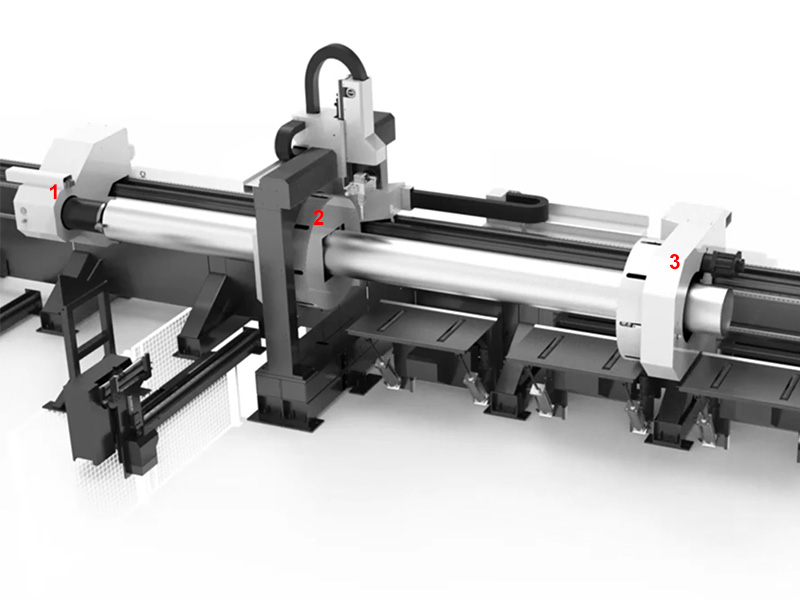

3D tube laser bevel cutting machine is a CNC metal pipe cutter with an automatic feeder and three rotary chucks for laser-cut tubes of heavy-duty and large-diameter. This tube cutter features strong load-bearing capacity and high cost-effectiveness, making it popular in industries such as construction machinery, oil pipelines, steel structures, building materials, decoration, elevator manufacturing, fitness equipment, furniture, advertising, and more metal fabrication industries.

Features of 3D Tube Laser Bevel Cutting Machine with Automatic Feeder

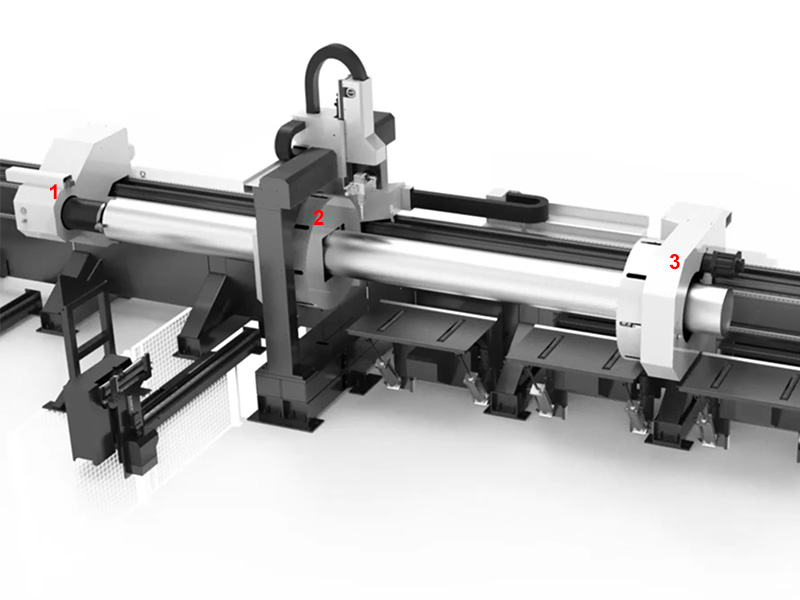

Laser bevel cutting machine with side-mounted design

Low center of gravity, strong stability, and the space under the tube clamp chucks is completely reserved to facilitate automatic loading and unloading.

Multiple pipes automatic loading unit

Automatic loading of heavy pipes is efficient and time-saving, shortens production preparation time, greatly improves operational safety, saves labor and reduces production costs.

Heavy Tube Cutting Controller FSCUT5000A

Three chucks full stroke tube cutting support, zero tail cutting and bevel cutting of H-shaped steel, U-shaped steel and L-shaped steel are feasible, stable performance, making it popular in steel structures, towers and bridges.

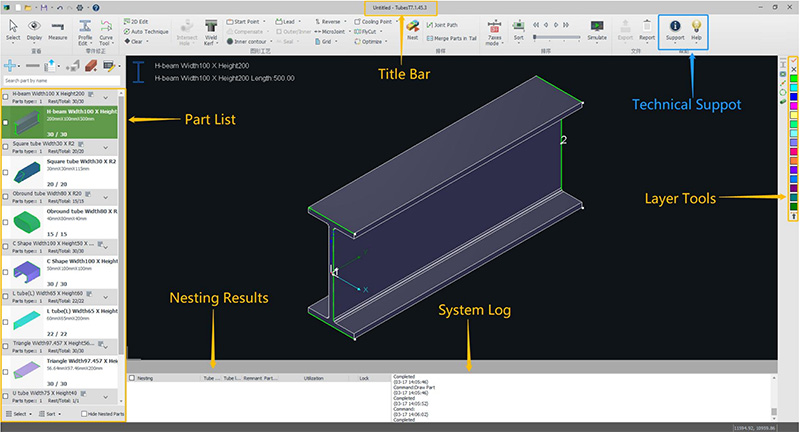

Smart tube nesting software

TubesT is a 3D tube nesting software designed specifically for the TubePro laser cutting system. From part drawing and modification, full type compensation, strategic nesting to report generation, TubesT will meet and exceed your production needs.

Automatic toolpath sequencing for tubes and profiles is a single click away. For square and round tubes, TubesT allows toolpath generation by tube face sequence or tube length intervals.

Intelligent three chucks zero tailing cutting

The three-chuck clamping range is from 20mm to 350mm, suitable for cutting various heavy pipes and saving material costs.

The reversing movement of multiple chucks achieves zero tailings, allowing for unrestricted cutting of long tubes and whole tubes.

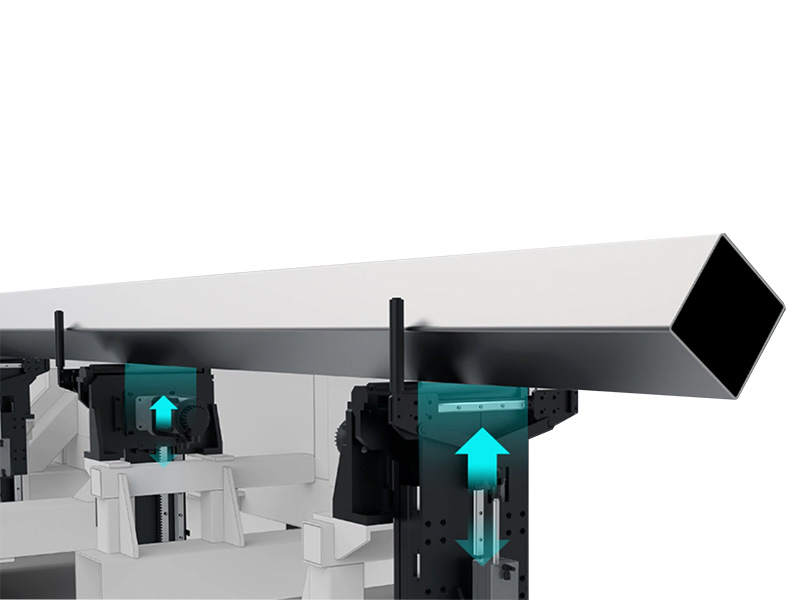

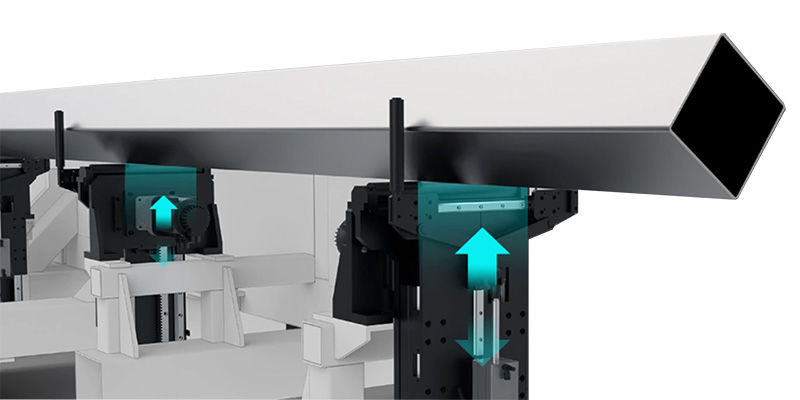

Full travel servo tube follow-up support system

The metal pipe follow-up support system adjusts the lifting height in real time, providing all-round effective support during the pipe processing, preventing the pipe from swinging and sagging, and improving the processing accuracy of heavy pipes.

Automatic flip blanking units

Drop pipe support with high pipe compatibility makes it ideal for metal pipes of various sizes, specifications and types.

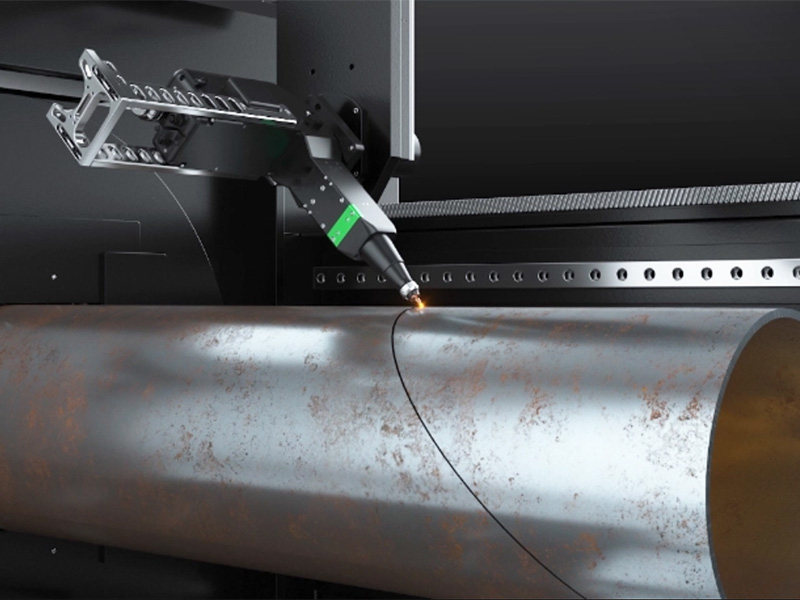

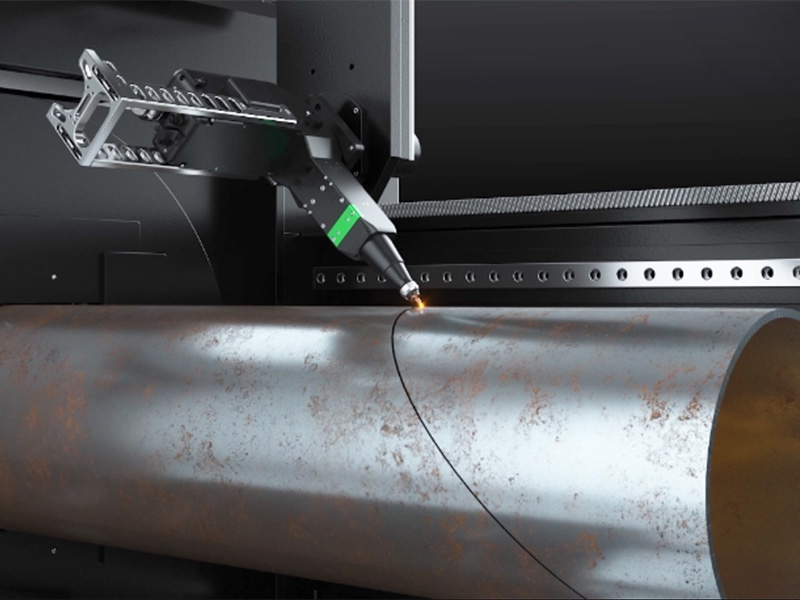

Beveling tube laser cutting head

The high-power laser cutting head comes with a professional bevel control system, which breaks through the conventional straight section and achieves a maximum 45-degree bevel cutting on metal tubes, reducing the number of steps and greatly improving the processing efficiency of metal pipes.

Technical parameters of 3D Tube Laser Bevel Cutting Machine with Automatic Feeder

| Model | ST-FC12035K3 |

| Laser power | 6KW / 12KW |

| Tube cutting length | 12500mm |

| Tube cutting diameter | Φ20-φ350mm □20-350mm |

| Maximum tube weight | 1200KGS |

| Max. chuck rotating speed | 60r/min |

| Y axis maximum speed | 60m/min |

| X maximum acceleration | 0.6G |

| Control system | EtherCAT bus control |

| Positioning accuracy | ±0.05mm/m |

| Repeated positioning accuracy | ±0.03mm/m |

| Power Supply | 380V/50HZ/3P (Options: 220V with transformer) |

| Dimensions | 29780*4000*3200mm |

| Overall weight | 17000kg |

3D tube laser bevel cutting machine projects