My old CO2 laser is limited to cut metal and so I purchased this hybrid laser cutter as an upgrade version. Instructions are easy to follow on how to put it together and set cutting parameters in the controller software. It has worked great for both sheet metal and wood, I have used it to cut a lot of stainless steel and plywood enough to pay for itself. A lot of bang for the money.

Fiber & CO2 Combo Laser Cutting System for Metal & Nonmetal

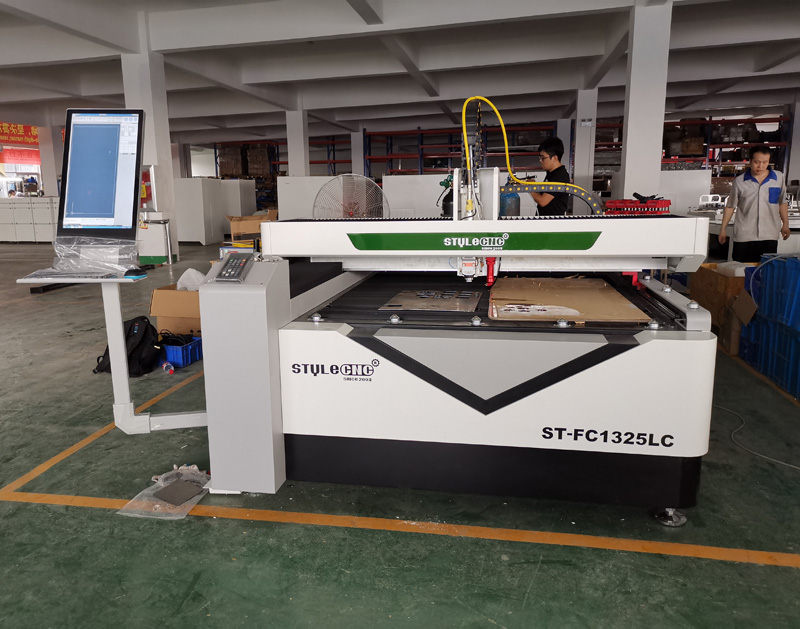

ST-FC1325LC 1500W fiber laser metal cutting machine combined with 150W CO2 laser cutting system is a professional full-size 4x8 hybrid laser cutter for metals (steel, aluminum, brass, copper, iron, alloy) and nonmetals (wood, plywood, MDF, plastic, acrylic, leather, fabric, paper). It is an affordable combination of features and performance in one machine, which saves space and allows for multitasking, making it a state-of-the-art option that offers the most flexible and accurate way to handle all materials.

- Brand - STYLECNC

- Model - ST-FC1325LC

- Maker - Jinan Style Machinery Co., Ltd.

- Sizing - 4' x 8' (48" x 96", 1300mm x 2500mm)

- Category - Fiber Laser Cutting Machine

- Laser Source - Raycus, IPG, MAX, RECI, YONGLI

- Power Option - 150W + 1500W, 2000W

- 180 Units in Stock Available for Sale Every Month

- Meeting CE Standards in Terms of Quality & Safety

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- 30-Day Money Back Guarantee for Your Purchase

- Free Lifetime Technical Support for End-Users & Dealers

- Online (PayPal, Alibaba) / Offline (T/T, Debit & Credit Cards)

- Global Logistics and International Shipping To Anywhere

The STYLECNC ST-FC1325LC Fiber & CO2 hybrid laser cutter machine represents a new generation in the line of laser cutting systems. Combining these powers of fiber and CO2 laser systems together, this is a state-of-the-art option that offers the most flexible and accurate way to work with both metal and non-metal material.

The ST-FC1325LC is a hybrid laser cutter equipped with a 1500W fiber laser cutting system for metal materials and a 150W CO2 laser system for non-metallic materials. This cutter uses the well-known brands Raycus, IPG, MAX and YONGLI for laser sources; it is well capable of the accurate cutting of various different materials.

What Makes The ST-FC1325LC So Special?

Versatility and Multi-Purpose

The ST-FC1325LC combines fiber and CO2 laser cutting systems into one machine, which saves space in your workshop and allows for multitasking.

Precision and Performance

This machine is capable of precise cuts with a repeat accuracy of up to 0.02mm due to its servo motor and ball-screw transmission. The ST-FC1325LC is another cutting-edge laser cutter with the newest technology that provides performance and versatility for your business.

Features & Advantages of Fiber & CO2 Hybrid Laser Cutting System for Metal & Nonmetal

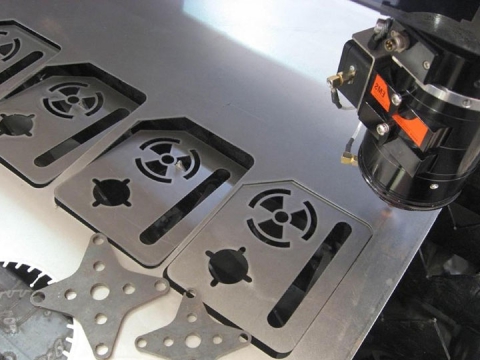

Cutting 4x8 full sheets of both metal and non-metal materials is possible with the ST-FC1325LC, a hybrid laser cutter that combines a fiber laser cutting system with a CO2 laser cutting system.

• Save the space in the workshop.

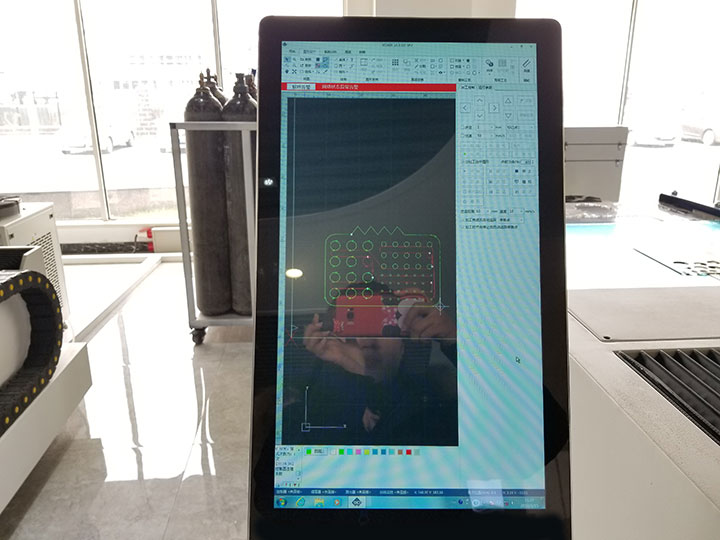

• Fiber and CO2 laser cutting software installed in one PC system, more convenient to operate.

• Servo motor and ball-screw transmission guarantee the precision of outcome quality (repeat accuracy + 0.02mm).

We have different choices of fiber laser powers for your working requirements (1500W/2000W/3000W), which are suitable for maximum thickness up to 10mm on carbon steel, 6mm on stainless steel, and 3mm on aluminum sheet.

Compared with the Hybrid CO2 Laser Cutter

• Larger range of metal materials.

• Larger range of thickness on metal cutting.

• Higher precision due to ball screw transmission.

• Smoother cutting edges.

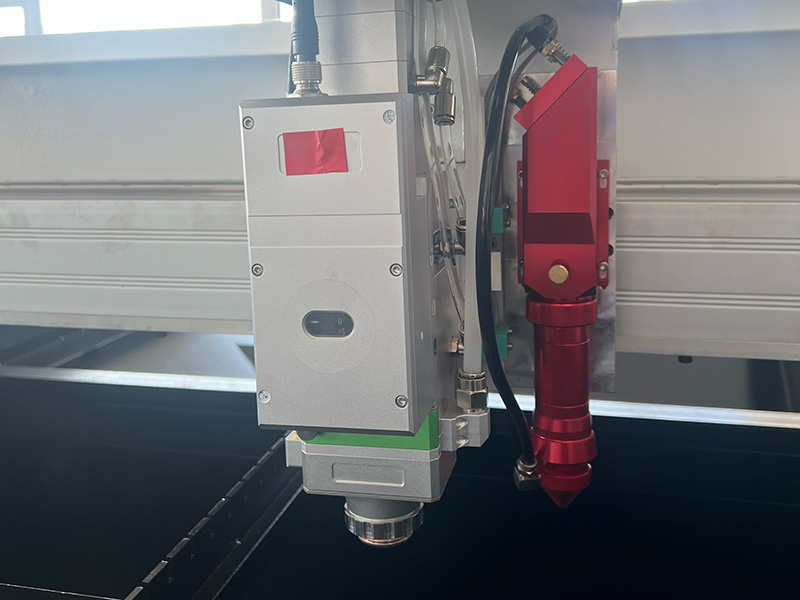

• The fiber laser and CO2 laser double heads cutter is an upgraded innovation edition of the standard mixed-head cutter.

• The feature of this combination leads the various of usage in all kinds of sheet metal industry.

Technical Parameters of Fiber & CO2 Combo Laser Cutting System for Metal & Nonmetal

| Model | ST-FC1325LC |

| Laser Power | 1500W Fiber Laser + 150W CO2 Laser |

| Laser Source | Raycus + Yongli |

| Laser Type | Fiber Laser and CO2 Laser |

| Working Area | 1300mm×2500×100mm |

| Transmission Method | Taiwan TBI ballscrew transmission |

| Driving System | Servo motor & driver |

| Max Moving Speed | 30m/min |

| Power Demand | 380V/50HZ or 220V/50HZ/60HZ |

| Machine Dimension | 3800*1850*1300mm |

| Control System | Au3tech control system |

| Cooling System | S&A water chiller |

Details of Fiber & CO2 Combo Laser Cutting System for Metal & Nonmetal

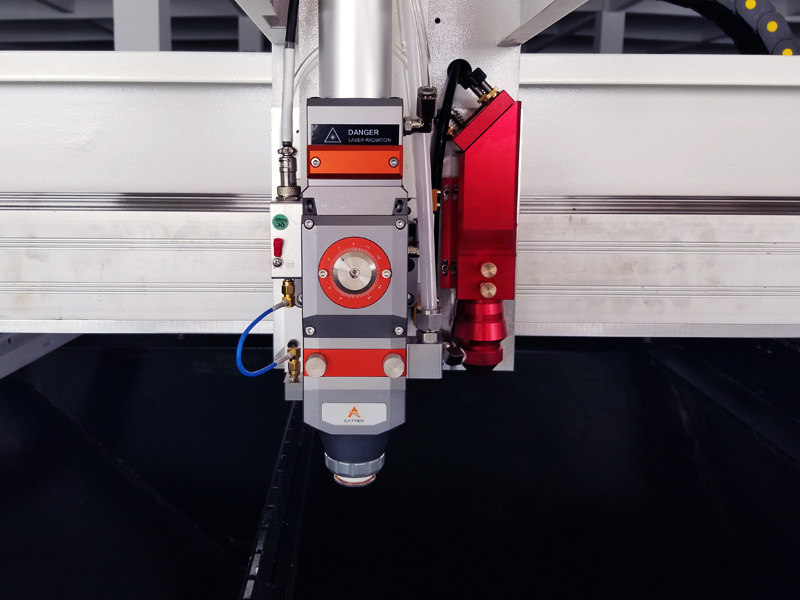

• ST-FC1325LC comes with a fiber laser cutting head for metal sheet cuts and a CO2 laser cutting head for non-metal cuts. It is one multipurpose laser cutter in the advertising industry.

• Flatbed laser metal cutting machine with Raycus laser generator 1500W and 2000W with long laser cutting service life of up to 100,000 hours and 150W CO2 laser tube.

• The flatbed laser cutting machine combined with non-metal cutting adopts Taiwan Delta Servo Motor with a single ball screw driving system, which can ensure high-precision cutting.

• Lubrication system for mechanic system, which can lubricate the linear guide rail to make sure the high precision in laser metal cutting machine use.

• Flatbed laser metal cutting machine with Au3tech Control system and software in English language, applicable insert files with DXF or AI format. With nesting function, autonomic compose type for saving materials by saving spaces.

Fiber & CO2 Combo Laser Cutting System for Metal & Nonmetal Cutting Projects

How Does a Fiber & CO2 Laser Work Together?

The synergy between fiber and CO2 lasers in a single system is a technological marvel, offering unparalleled versatility for cutting diverse materials. This combination allows users to achieve precision, efficiency, and flexibility like never before. Here's how the magic happens:

Fiber Laser for Metals

Fiber lasers excel in cutting metals such as stainless steel, aluminum, and brass. Their high-intensity beam focuses on metals efficiently, delivering smooth edges and precision cuts even in reflective surfaces like copper. This makes fiber lasers a go-to choice for industrial metalworking tasks.

CO2 Laser for Nonmetals

CO2 lasers are optimized for nonmetal materials like woods, acrylic, plastics, and fabrics. Their longer wavelengths tend to interact more strongly with organic material, enabling clean cuts. It makes them perfect for uses in signage, art, and craft applications.

Dual-Laser Integration

The combo system intelligently switches between fiber and CO2 lasers based on the material. For instance, it can seamlessly cut a metal plate and then move on to cut a wooden panel. This flexibility eliminates the need for separate machines, saving time and resources.

Maintenance and Longevity of Fiber & CO2 Combo Laser Systems

To ensure your fiber and CO2 combo laser system operates smoothly and lasts for years, proper maintenance is crucial. Here are key aspects to focus on.

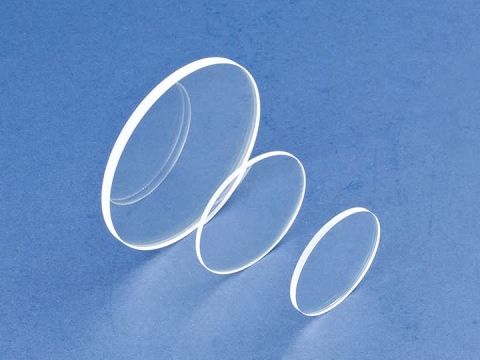

• Regular Cleaning: Keep the laser lenses and mirrors clean to maintain beam quality. Dust and debris can affect cutting accuracy, so clean these components with recommended solutions regularly.

• Scheduled Inspections: Conduct routine checks on vital parts such as cooling systems, alignment mechanisms, and power supplies. Identifying and fixing minor issues early prevents costly downtime.

• Proper Usage: Use the machine within its recommended parameters. Overloading the system or using incorrect materials can lead to wear and tear, reducing its lifespan.

• Software Updates: Update the system’s software periodically. Manufacturers often release updates to enhance performance and address potential bugs, ensuring smooth operation over time.

Maragall

Donovan

Have been needing a laser bought for ability to easily cut both metal and acrylic. The ST-FC1325LC is the right one for me. It came well packaged. The provided instructions, parts and accessories will have you up and running in 1hr. I have been using this automatic cutter for a month and I love it. It cuts through steel and acrylic sheet like butter. Its outstanding ability surprised me.

Danny

Farhang Hasan

Mükemmel, lazer kesiciden çok memnunum. Fiber lazer kafasını metal kesimler için test ettim - mükemmel çalıştı. CO2 lazer kafasını denedim - ahşabı iyi kesiyor. Çift amaçlı harika bir hepsi bir arada makine.