2026 Best Metal & Nonmetal Laser Cutting Machine for Sale

2026 best mixed hybrid laser cutting machine STJ1610M works with a 130W, 150W, 280W, or 300W CO2 sealed laser tube, which can cut thicker nonmetals, and metal materials from 0.5mm up to 2mm, featuring autofocus cutting heads, improved motion systems with precision gears, and user-friendly control panel.

- Brand - STYLECNC

- Model - STJ1610M

- Sizing - 1600mm x 1000mm

- Laser Source - Yongli, RECI

- Power Option - 80W + 150W, 180W, 220W, 300W

- 360 Units in Stock Available for Sale Every Month

- Meeting CE Standards in Terms of Quality & Safety

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- 30-Day Money Back Guarantee for Your Purchase

- Free Lifetime Technical Support for End-Users & Dealers

- Online (PayPal, Alibaba) / Offline (T/T, Debit & Credit Cards)

- Global Logistics and International Shipping To Anywhere

In 2026, laser cutting machines for both metal and nonmetal materials are equipped with advanced features that provide enhanced precision and speed. These machines are designed to meet the needs of a variety of industries, including automotive, aerospace, advertising, and crafting. With better control systems, superior motion technology, and high-quality components, they ensure reliable and efficient performance, allowing manufacturers to achieve detailed, clean cuts with minimal effort.

Key advancements include autofocus cutting heads, improved motion systems with precision gears, and user-friendly interfaces. These improvements enable faster production times and more accurate results for both metal cutting and nonmetal engraving, such as acrylic, wood, and fabric. With energy efficiency and reduced operational costs, these machines provide significant value for businesses looking for quality and productivity.

2026 Best Mixed Metal and Nonmetal Laser Cutting Machine Advantages

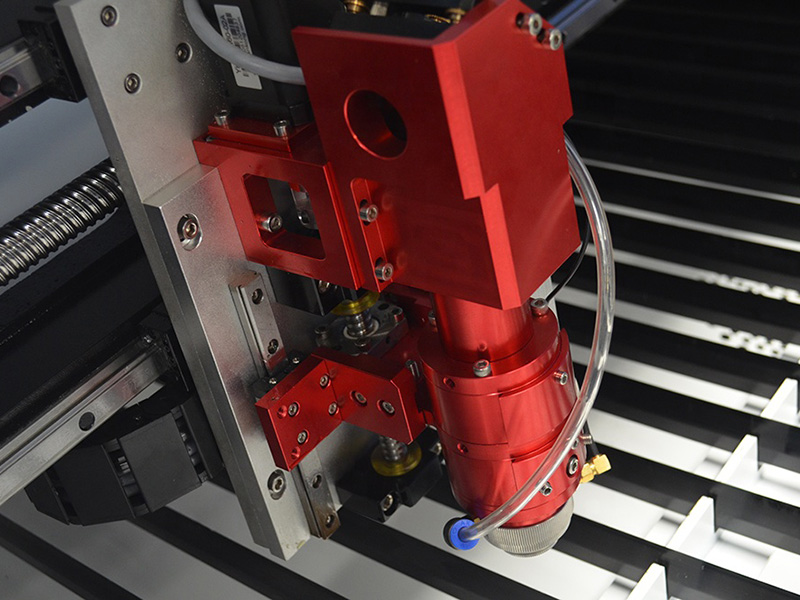

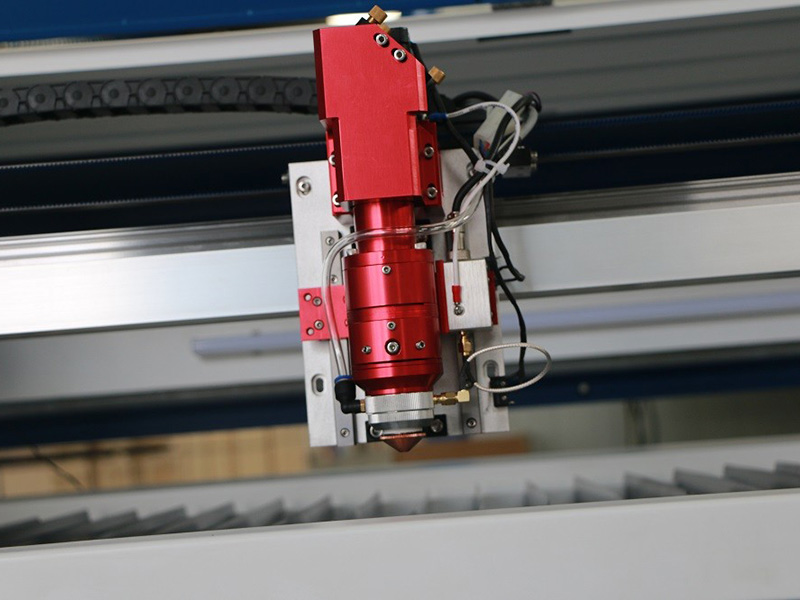

• United States imported sensor and precise autofocus laser cutting head, to improve precision and cutting effect for metal sheets based on perfect optical path.

• Italy imported steel-strip belts and precise gear wheels transmitting technology.

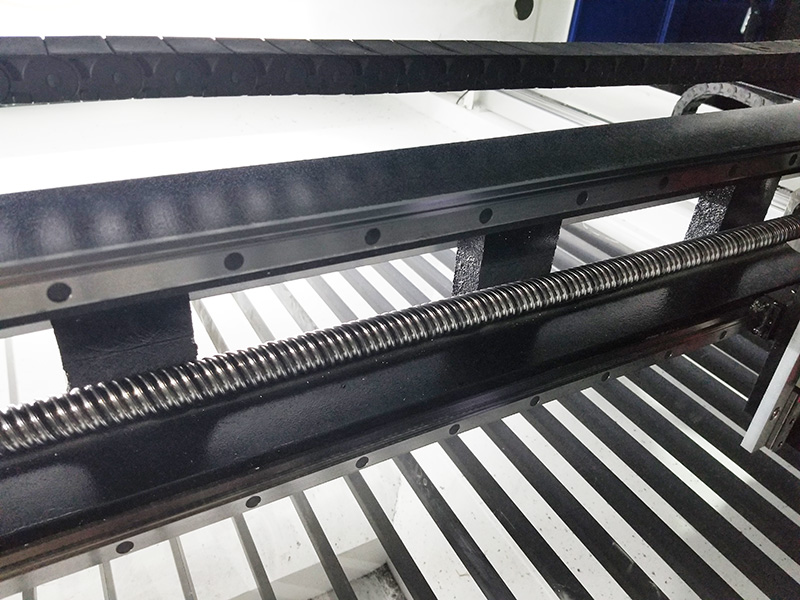

• The moving system adopts Taiwan HIWIN linear guide and precision gear, matched up with an advanced DSP-controlled 3-phase stepper motor to ensure working accuracy.

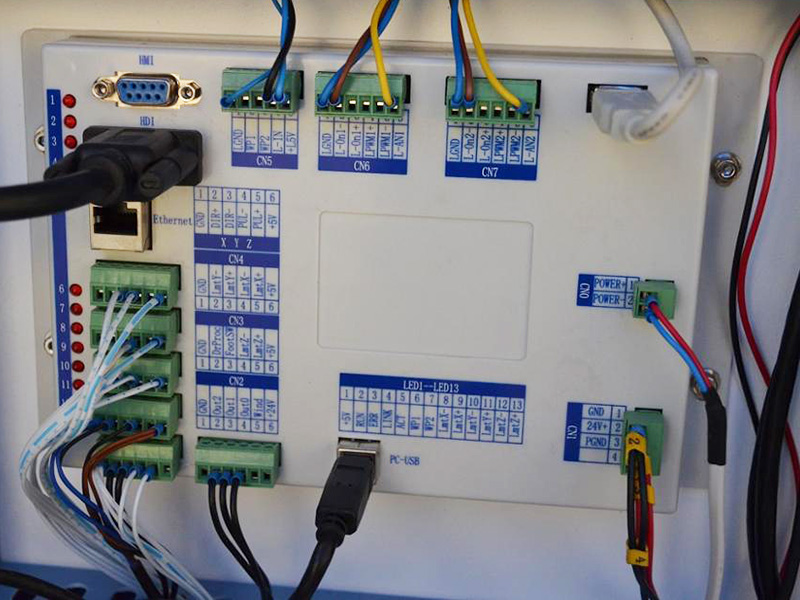

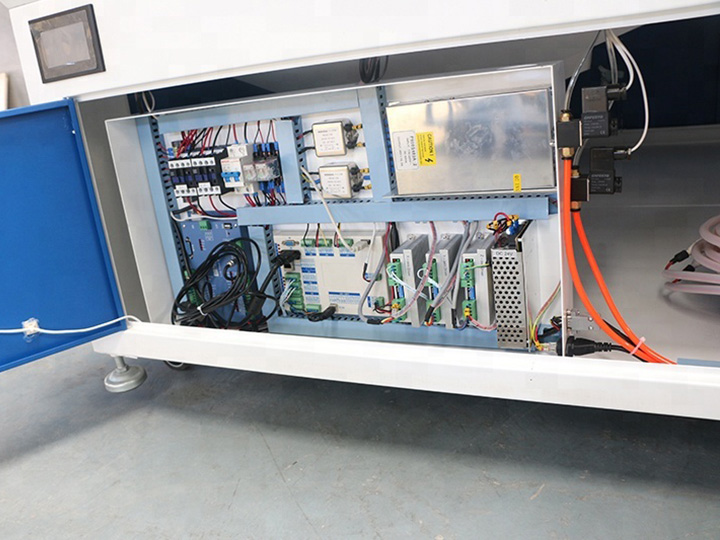

• RD6332M panel control system with 256MB memory storage, compatible with USB, wire net, and various memories, more functions than Leetro, and double memory storage.

2026 Best Mixed Metal and Nonmetal Laser Cutting Machine Advantages

Mixed metal and nonmetal laser cutting machines have become essential in modern industries, offering significant advantages for precise, efficient production. Below are key features that enhance their performance:

• Imported Sensor and Precise Autofocus Laser Cutting Head: Featuring sensors from the United States and a precise autofocus laser cutting head, these machines improve cutting accuracy for metal sheets. The optimized optical path enhances cutting effects, ensuring cleaner cuts with minimal distortion.

• Italy Imported Steel-Strip Belts and Gear Wheels: The use of high-quality Italian steel-strip belts and precision gear wheels ensures smooth and reliable transmission. This contributes to the durability and long-lasting performance of the machine while maintaining precise movements.

• Advanced Moving System: The moving system incorporates Taiwan HIWIN linear guides and precision gears, along with an advanced DSP-controlled 3-phase stepper motor. This combination ensures high accuracy and consistent performance during operation, minimizing errors and maximizing efficiency.

• RD6332M Control System: The RD6332M panel control system offers 256MB of memory storage, supports USB and network connectivity, and is more advanced than traditional systems like Leetro. It also provides double memory storage, increasing the machine's ability to handle complex designs and larger workloads.

• High-Speed Processing: These machines are capable of high-speed processing, cutting through a variety of materials with minimal downtime. The high-speed capability makes them ideal for both low- and high-volume production runs, reducing production time without compromising quality.

Energy Efficiency and Low Operational Costs: Designed with energy-efficient features, these laser cutting machines consume less power compared to traditional methods. This not only reduces operational costs but also makes them a more environmentally friendly option for businesses looking to reduce their carbon footprint.

2026 Best Mixed Metal and Nonmetal Laser Cutting Machine Applications

Laser cutting machines are increasingly versatile, offering a range of applications in various industries. By using different laser sources and settings, these machines can cut, engrave, and etch both metal and non-metal materials with precision and efficiency. Below are some key sectors benefiting from mixed metal and nonmetal laser cutting:

• Advertising Industry: Laser cutters are widely used for engraving and cutting acrylic, as well as for processing double-color plates and other materials used in sign-making. The precision of lasers allows for high-quality finishes on complex designs.

• Leather Processing Industry: Laser cutting machines can carve intricate patterns into leather and fabric, making them ideal for creating hollow designs and unique textures for fashion and upholstery.

• Arts and Crafts Industry: These machines are perfect for cutting and engraving various materials like paper, wood, bamboo, leather, shell, and ivory, which are commonly used in crafting decorative items.

• Model Industry: Laser cutters are essential for creating highly detailed models, whether for construction, aviation, maritime, or wooden toys. The ability to work with intricate patterns and small components makes lasers indispensable in model making.

• Packaging Industry: Laser cutters enable precise engraving and cutting of printed rubber plates, plywood, and templates used in packaging, improving both production efficiency and quality.

• Decoration Industry: Laser machines are used to engrave and cut materials for decorative items, as well as electrical and electronic components. They can handle both metals and nonmetals, providing versatility in design options.

2026 Best Mixed Metal and Nonmetal Laser Cutting Machine Features

• Use RD sensor and precise autofocus laser cutting head, to improve precision and cutting effect for metal sheets based on perfect optical path.

• Italy steel-strip belt and precise gear wheels transmitting technology.

• The moving system adopts Taiwan HIWIN linear guide and precision gear, matched up with an advanced DSP-controlled 3-phase stepper motor to ensure working accuracy.

• RD6332M panel control system with 256MB memory storage, compatible with USB, wire net, and various memories, more functions than Leetro, and double memory storage.

• Non-contact height-adjusting configuration enables cutting almost all materials with the lowest cost.

• Working table: Open the blade with specially treated material. Never fray and easy to operate, suitable for all kinds of hard materials.

• Steady chassis: Stability and precision during high-speed work.

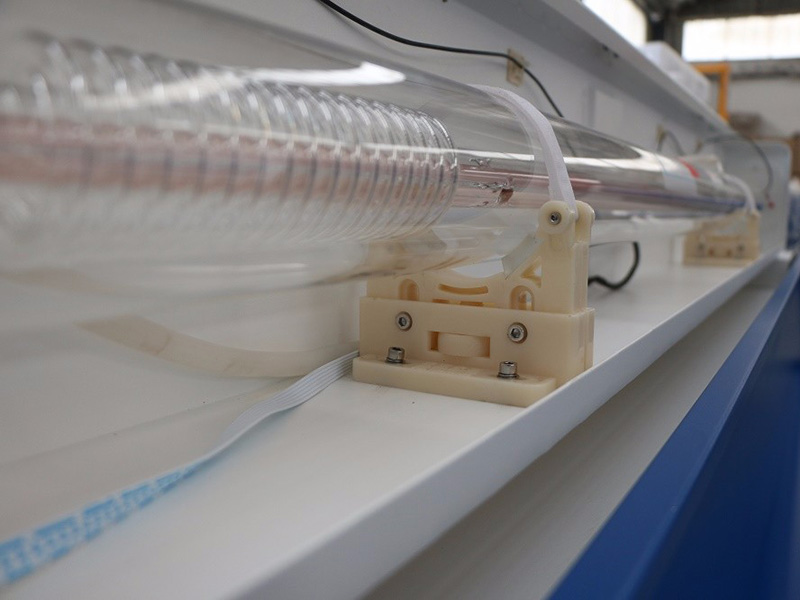

• High-efficiency tube with stable laser path, lifetime around 10000 hours.

2026 Best Mixed Metal and Nonmetal Laser Cutting Machine Technical Parameters

| Model | STJ1610M |

| Working Area | 1600*1000mm |

| Laser Power | 130W/150W/280W/300W mixed laser cutting tube |

| Laser Type | CO2 Sealed Laser Tube |

| Cooling Type | Water Cooling |

| Laser Output Control | (0-100% Set by Software ) |

| Min Engraving Speed | Chinese Word: 2.0mm*2.0mm, English Letter: 1.0mm*1.0mm |

| Highest Scanning Precision | 4000DPI |

| Positioning Accuracy | ±0.05mm/m |

| Positioning Speed | 20m/min |

| Max. Cutting Thickness | 40mm |

| Max. Cutting Speed | 20m/min |

| Controlling Software | RD Control System or optional |

| Graphic Format Supported | DST PLT BMP DXF DWG AI LAS, etc |

| Compatible Software | TAJIMA, CORELDRAW, PHOTOSHOP, AUTOCAD, All type of AUTOCAD software |

| Color Separation | Yes |

| Drive System | High-precision 3-phase Stepper Motor or servo motors as optional |

| Auxiliary Equipment | Exhaust Fan and Air Exhaust Pipe |

| Power Supply | AC110V/220V+10%,50HZ/60HZ |

Mixed Metal and Nonmetal Laser Cutting Projects

Package & Shipping for Mixed Metal and Nonmetal Laser Cutting Machine

Factors Affecting Laser Cutting Performance for Metal and Nonmetal

Laser cutting machines provide impressive precision and speed, but various factors can influence their performance. Understanding these factors ensures optimal cutting results and enhances the machine’s lifespan. Below are key aspects that affect laser cutting performance for both metal and nonmetal materials:

• Material Type and Thickness

The type and thickness of the material being cut significantly impact the laser’s ability to achieve clean cuts. Thicker materials, particularly metals, may require higher laser power or slower cutting speeds, while softer materials like plastics and wood can be cut more easily.

• Laser Power and Focus

Laser power and focus play a critical role in achieving precise cuts. Higher power allows for faster cutting of thicker materials, while proper focusing ensures that the laser beam stays sharp and accurate, preventing errors and inconsistencies.

• Cutting Speed

The speed at which the laser moves affects the cut quality. Faster speeds can lead to incomplete cuts or poor edge quality, while slower speeds may improve accuracy but increase production time. Finding the right balance is crucial for optimal results.

• Gas Assist and Pressure

The type of assist gas (such as oxygen, nitrogen, or air) and the pressure used during cutting help remove molten material and prevent oxidation. For metals, oxygen can improve cutting speed, but nitrogen can produce cleaner edges. Incorrect gas pressure can lead to rough edges or excessive heat.

• Material Surface Quality

The surface finish of the material can also impact cutting efficiency. Materials with rough surfaces or contaminants may cause the laser beam to scatter, resulting in inaccurate cuts. A clean, smooth surface allows for more precise and efficient cutting.

• Beam Quality

Beam quality, which refers to the laser's focus and consistency, is essential for achieving clean cuts. A high-quality beam results in better precision and smoother edges, while a poor beam may cause uneven cuts or excessive heat in the material.

• Environmental Conditions

External factors such as temperature, humidity, and air quality can affect the performance of a laser cutter. For example, excessive moisture in the air can lead to condensation inside the machine, potentially causing damage or inaccurate cuts.

Shipping Policy

After you confirm the order, we will figure out the delivery date according to the model and production schedule. For standard models, we will arrange production in 7 days and we will notify you of the exact phase of production process.

After-Sales Service and Support

We guarantee all of our metal and nonmetal laser cutting machines have a 1-year warranty (quick-wear parts not included).

Numerous feedbacks from our clients have proven that our metal and nonmetal laser cutting machines are stable in performance with rare malfunctions. However, we would like to handle it as follows once malfunction occurs:

• We guarantee we will give you a response within 24 hours.

• Our staff will assist and guide you to analyze the malfunction to locate the cause.

• If the malfunction is caused by improper operation of software and other soft faults, we will help you to solve the problem online.

• If a certain part is damaged, we will deliver a replacement part to you as soon as possible, so you can replace it by yourself, reducing unnecessary time costs.

How a Mixed Laser Cutting Machine Handles Both Metal and Non-metal?

A mixed laser cutting machine like the STJ1610M combines CO2 and fiber laser technologies into a single unit, allowing operators to switch between metal and non-metal materials without changing equipment. The CO2 laser source handles nonmetals such as wood, acrylic, MDF, leather, and fabric with clean edges and minimal charring, while the metal cutter with mixed laser cutting head processes thin stainless steel, carbon steel, and galvanized sheet with precision. This dual-purpose capability makes it an ideal solution for sign shops, small fabrication businesses, and workshops that handle diverse material orders without the floor space for two separate machines. If your workload involves primarily thin metal and thick nonmetal materials, the STJ1610M offers a cost-effective alternative to running dedicated systems.

Choosing the Right Wattage for Your Mixed Laser Cutter

Wattage directly determines the thickness and types of materials your machine can cut. The STJ1610M typically comes in 280W to 300W CO2 laser configurations, which can cut up to 2-3mm mild steel and up to 20-25mm nonmetals like wood and acrylic. For operators who primarily work with nonmetals but occasionally need thin metal cutting, a 280W CO2 laser cutter provides a balanced starting point. However, if your production demands heavier metal fabrication beyond 3mm, you may want to consider upgrading to a dedicated sheet metal laser cutter for that specific workload. Understanding your material mix and daily volume is the key to selecting the right power configuration.

Frequently Asked Questions

What materials can the STJ1610M mixed laser cutting machine cut?

The STJ1610M cuts both metals (thin stainless steel, carbon steel, galvanized sheet up to 2-3mm) and nonmetals (wood, acrylic, MDF, leather, fabric, rubber up to 20-25mm) using its dual CO2 and metal laser cutting heads. Material compatibility depends on the wattage and laser source configuration selected.

Is a mixed laser cutter better than buying two separate machines?

For small to mid-sized shops processing both material types at moderate volumes, a mixed laser cutter saves significant floor space, upfront investment, and maintenance costs. However, high-volume metal fabrication shops may still benefit from a dedicated fiber laser system alongside a CO2 laser wood cutting machine for non-metal work.

How much does a mixed metal and non-metal laser cutting machine cost?

Pricing varies based on wattage, working area, and features. A mixed laser cutter generally falls between the cost of a standalone CO2 machine and a fiber laser system. For accurate pricing details on specific configurations, check this guide on how much a laser cutting machine costs.

What is the working area of the STJ1610M?

The STJ1610M features a 1600mm x 1000mm (approximately 63" x 39") working area, which accommodates standard sheet sizes for both metal and non-metal projects. This 4x8 laser cutter and engraver size range is one of the most popular for versatile production shops.

Can it engrave as well as cut?

Yes, the CO2 laser head supports both cutting and engraving on non-metal surfaces. You can engrave detailed designs on wood, acrylic, glass, and leather, then switch to cutting mode for through-cuts on the same or different materials within a single job setup.

What maintenance does a mixed laser cutter require?

Routine maintenance includes cleaning the laser lens and mirrors, checking gas pressure and alignment, maintaining the water cooling system, and lubricating guide rails. The metal cutting head also requires periodic nozzle inspection. Most daily maintenance tasks take 15-20 minutes and significantly extend the machine's lifespan and cut quality.

Does STYLECNC provide training and technical support?

STYLECNC offers pre-sales consulting, machine installation guidance, operator training, and ongoing technical support via WhatsApp, email, phone, and online chat. Remote troubleshooting and software assistance are available to customers in 180+ countries.

Jean Lafortune

Sri Yuli

Assembly was easy to do with the instructions. Software was easy to use and got the first cut done without any snags. In my opinion this laser cutter is well worth the extra investment. All will be recommended to you familiar.