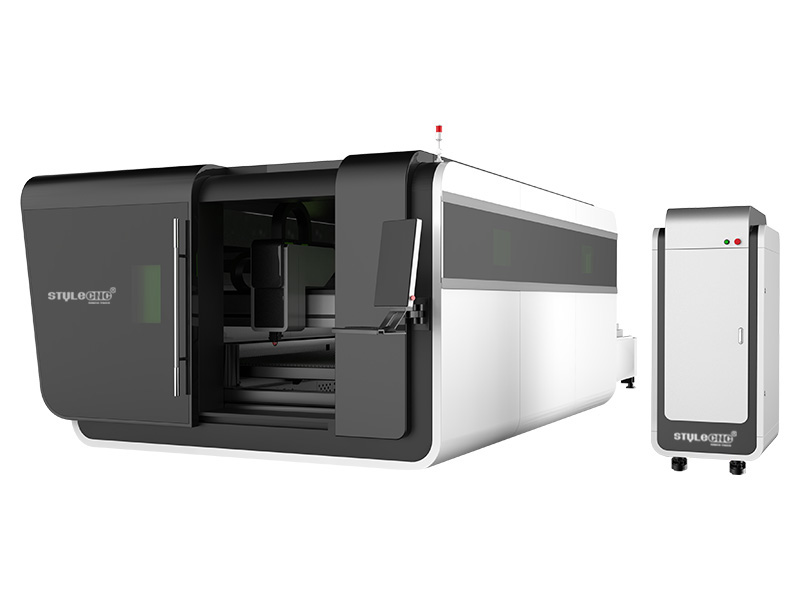

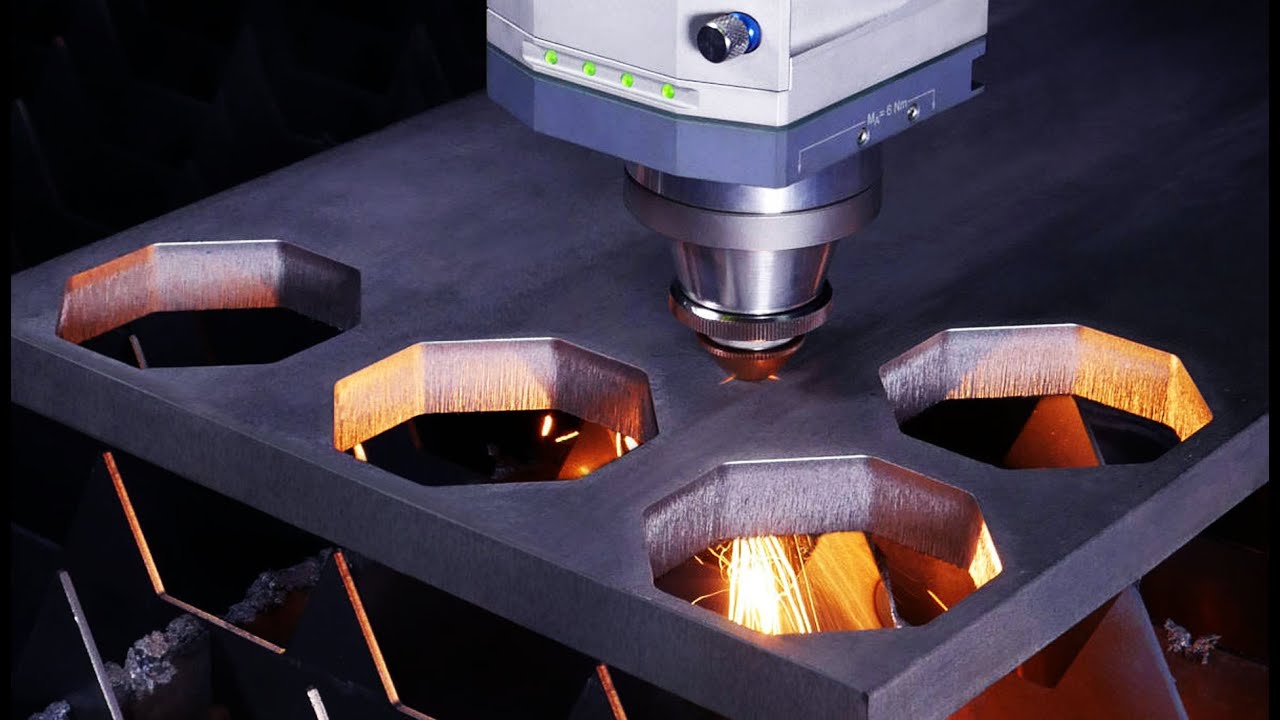

The whole production stay in safe with this enclosed cover of the fiber laser metal cutting machine, at least my boss thinks so. And the exchange table helped cutting 20mm MS a lot. An frame crane is all you need.

High-Power 6000W Fiber Laser Metal Cutting Machine for Sale

6000W fiber laser metal cutting machine is a 6x12 CNC laser cutter table that comes with a high power laser generator for full-size metal cutting, and an exchange pallet for automated metalworking, featuring with faster speed, higher precision, and various power options of 2000W, 3000W, 4000W, 8000W, 12000W, 20000W, and up to 40000W for commercial use in industrial metal fabrication, performing thicker sheet metal cuts with clean edges, allowing for metal tubing using an optional rotary attachment.

- Brand - STYLECNC

- Model - ST-FC4020GA

- Maker - Jinan Style Machinery Co., Ltd.

- Sizing - 6' x 12' (72" x 144", 2000mm x 4000mm)

- Category - Fiber Laser Cutting Machine

- Laser Source - Raycus, IPG, MAX

- Power Option - 2000W - 6000W, 8000W - 40000W

- 180 Units in Stock Available for Sale Every Month

- Meeting CE Standards in Terms of Quality & Safety

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- 30-Day Money Back Guarantee for Your Purchase

- Free Lifetime Technical Support for End-Users & Dealers

- Online (PayPal, Alibaba) / Offline (T/T, Debit & Credit Cards)

- Global Logistics and International Shipping To Anywhere

Thick metal fabrication is an indispensable part of industrial manufacturing. In the era of pursuing high-speed and high-precision metal cutting, traditional mechanical cutting tools such as slower water jet cutters and rougher plasma cutters can no longer keep up with the pace of modern metal manufacturing. At this time, a more efficient thick metal cutting tool came into being - high power fiber laser cutting machine, which is an ideal choice for high-quality metalworking.

6000W fiber laser cutter is a metal cutting tool that use a high-power laser beam to cut out complex shapes and profiles from metals such as steel, aluminum, and brass with high precision and high speed, resulting in clean and smooth edges. A higher-powered 6KW laser cutter can cut through thicker metals and achieve high-quality finishes in a shorter amount of time compared to lower-powered laser metal cutting systems.

ST-FC4020GA fiber laser metal cutting machine features with larger full-size 6x12 working table, faster cutting speed, higher laser power - 6000W (2000W, 3000W, 4000W, 8000W, 12000W, 20000W, and 40000W for option), and higher cutting quality, compared with other metal cutting tools. The state-of-the-art IPG laser generator, combined with user-friendly and easy-to-use CNC cutting software, and high-strength welded body (made of standard heat treatment and large CNC milling machine), as well as a fully enclosed fireproof and dustproof safety protection housing, make it the ideal choice for most metal fabricators.

6000W fiber laser cutter is a professional high-power laser metal cutting machine that works with an automatic CNC controller to easily cut through carbon steel up to 25mm thick, stainless steel up to 18mm thick, aluminum up to 16mm thick, copper and brass up to 10mm thick, with a maximum speed of over 60 meters per minute. All in all, 6000 watts of laser power is more than enough to handle most metal cuts.

Why Choose 6x12 Fiber Laser Cutting Machine 6000W for Metal Fabrication?

• Heavy-duty machine bed structure design, stable, sturdy and durable.

• Stable and reliable optical path system allows continuous cutting.

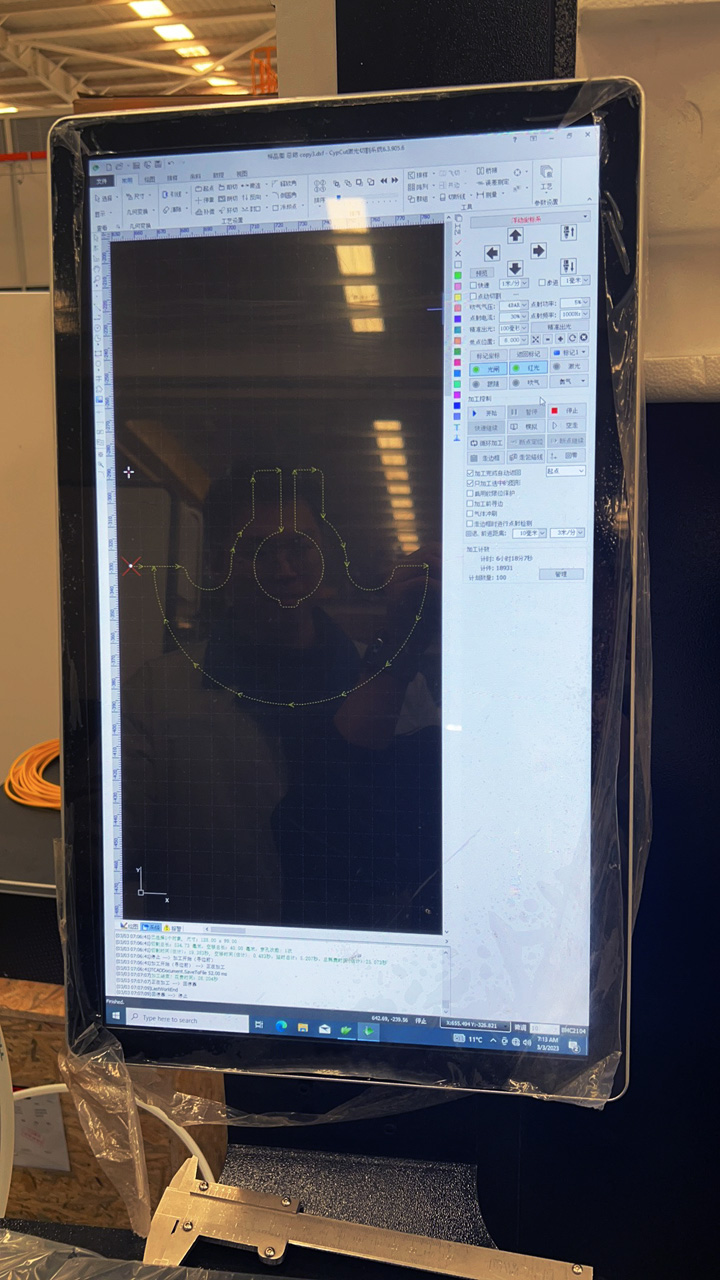

• An easy-to-use CNC controller - beginner-friendly and safe, allowing for automated metal fabrication.

• World-renowned IPG fiber laser with a service life of more than 100,000 hours allows high performance and low operating costs.

• Higher cutting quality, higher precision, higher efficiency, and faster cutting speed up to 60 meters per minute, resulting in smooth and clean edge cuts.

• Well-known high-precision servo motors, lead screws, and guide rails ensure efficiency and precision, and increase stability and reliability.

• 6x12 cutting table enables full-size cuts for both small business and industrial manufacturing.

• 6000W high laser power capable of cutting through most sheet metals.

6x12 High Power 6000W Fiber Laser Metal Cutting Machine Technical Parameters

| Model | ST-FC4020GA | ST-FC3015GA |

| Working Area | 2000x4000mm (6x12 feet) | 1500x3000mm (5x10 feet) |

| Laser Type | Fiber Laser Generator (Raycus, MAX, IPG for Option) | |

| Laser Power | 6000W (2000W, 3000W, 4000W, 8000W, 12000W, 20000W, 40000W for Option) | |

| Max Running Speed | 100mm/min | |

| Max Acceleration | 1.2G | |

| Repeated Positioning Accuracy | ±0.02mm | |

| Machine Weight | 8000KGS | 6000KGS |

| Machine Dimension | 10800X3350X2310mm | 8580X2880X2310mm |

| Remark | Automatic exchange worktable, enclosed cover | |

6x12 High Power Fiber Laser Metal Cutting Machine 6KW Features

• Heavy-duty machine bed structure design, stable, sturdy and durable.

• Stable and reliable optical path system allows continuous cutting.

• An easy-to-use CNC controller - beginner-friendly and safe, allowing for automated metal fabrication.

• World-renowned IPG fiber laser with a service life of more than 100,000 hours allows high performance and low operating costs.

• Higher cutting quality, higher precision, higher efficiency, and faster cutting speed up to 60 meters per minute, resulting in smooth and clean edge cuts.

• Well-known high-precision servo motors, lead screws, and guide rails ensure efficiency and precision, and increase stability and reliability.

• 6x12 cutting table enables full-size cuts for both small business and industrial manufacturing.

• 6000W high laser power capable of cutting through most sheet metals.

High power fiber metal laser cutting machine 6000W display displayed in factory.

High-precision 6000W IPG fiber laser generator.

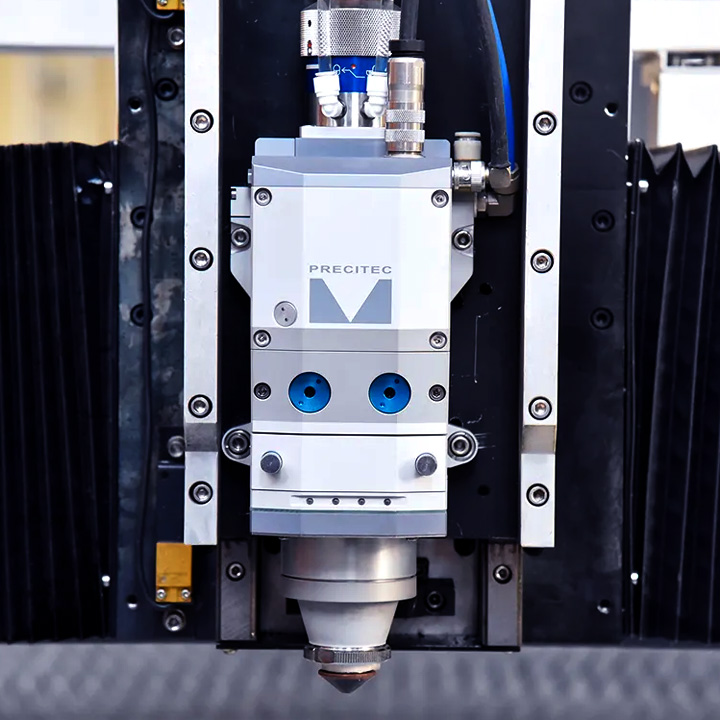

Germany Precitec ProCutter automatic focus laser cutting head.

User-friendly and easy-to-use CNC controller software.

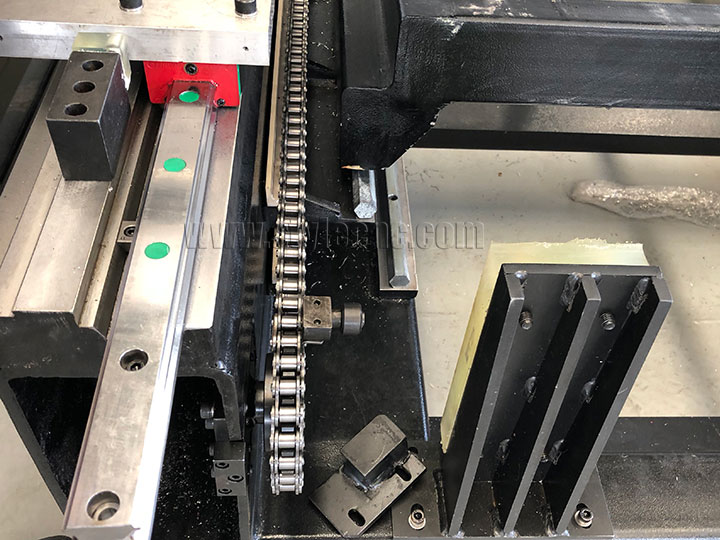

Automatic exchange pallet with chain transmission.

Dual cutting tables work at the same time, while one table is working, the operator can load the metal sheets to the other table, enabling cutting one by one to save time.

A rotary attachment is optional to cut metal pipe and metal tubes (Model: ST-FC4020GAR).

What Metal Materials can be Cut with a 6000W Fiber Laser Cutter?

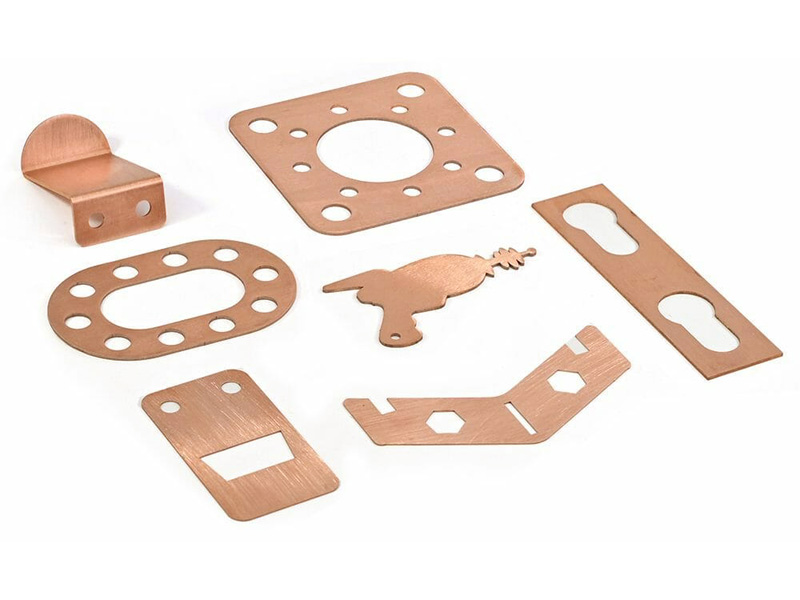

6000W fiber laser cutting machines can easily cut through stainless steel sheets, mild steel plates, carbon steel sheets, alloy steel plates, spring steel sheets, iron plates, galvanized iron sheets, galvanized plates, aluminum sheets, copper plates, brass sheets, bronze sheets, gold plates, silver sheets, titanium plates, as well as metal tubes and pipes with an attached rotary attachment.

What is a High-Power 6KW Fiber Laser Cutting Machine used for?

High-power fiber laser sheet metal cutting machines are popular in making signs, billboards, LED luminous letters, kitchenware, metal letters, sheet metal fabrication, metal parts, metal tags, hardware products, chassis, cabinet processing, metal artworks, metal crafts, elevator panels, auto parts, glasses frames, electronic parts, and nameplates.

A sheet-tube integrated fiber laser metal cutter features with a horizontal mechanical structure design, which can cut metal plates and tubes for multiple purposes. The worktable is easy to exchange. It can not only cut round tubes and square pipes, but also drill holes on the forming box.

• Cut wires and holes of different diameters from different directions.

• Cut the inclined part of the tube end.

• Cut the branch tube that intersects with the main round tube.

• Cut square holes, waist holes and round holes on the tube.

• Cut various shapes and profiles on the surface of the square tube.

• Cut sheet metals of different sizes.

• Drill holes on the forming box.

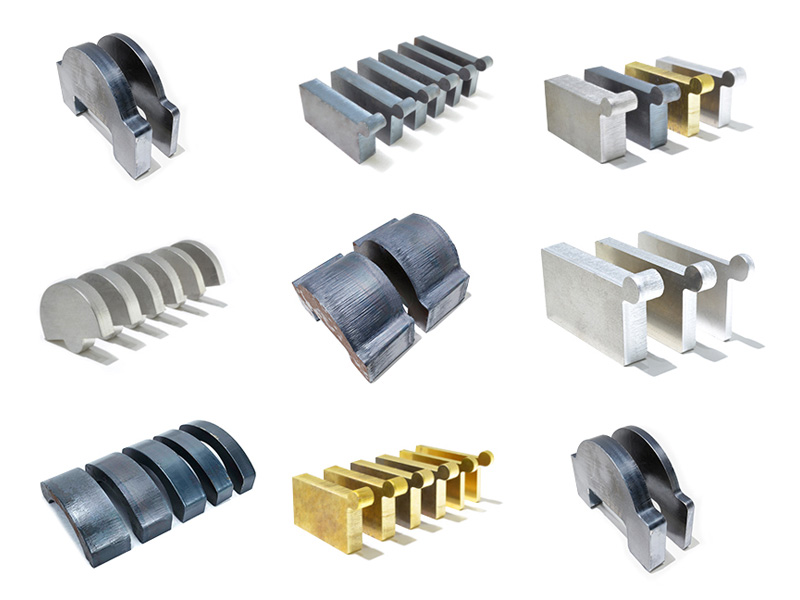

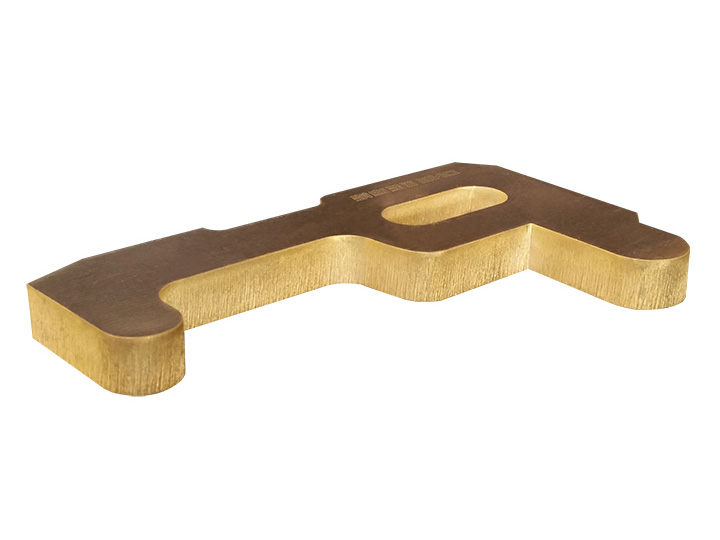

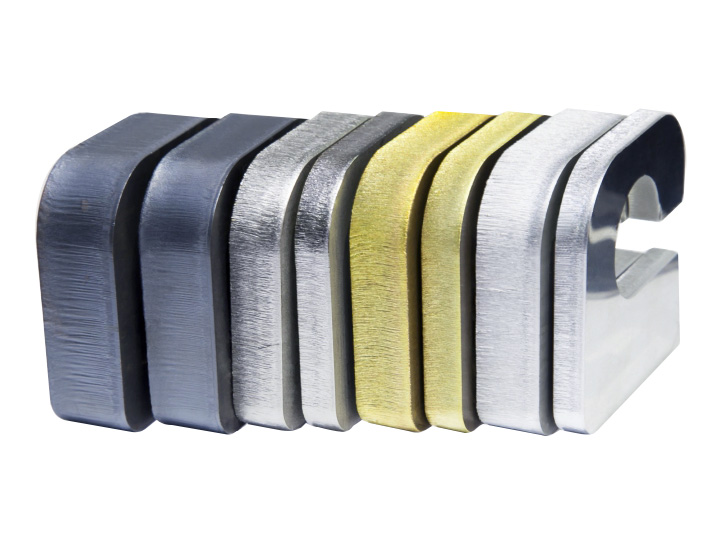

6000W Fiber Laser Cutting Metal Projects

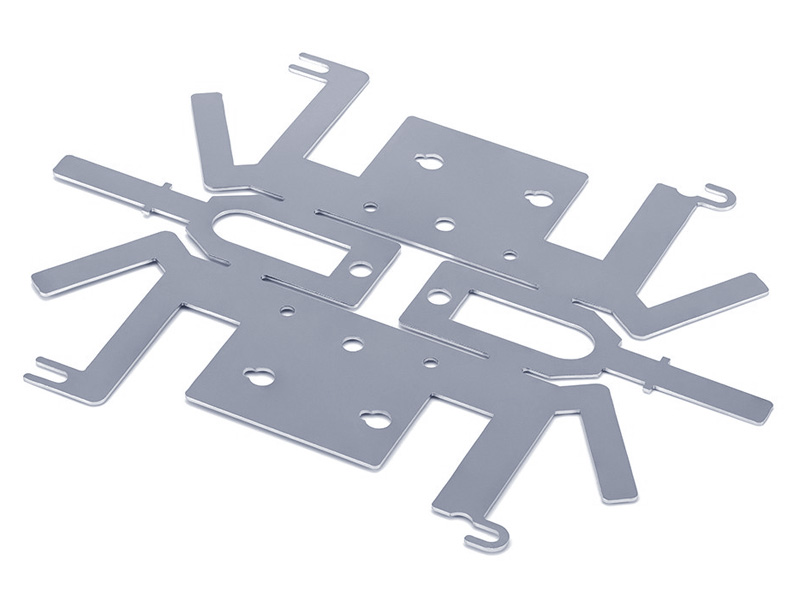

6KW laser cut thick metal projects

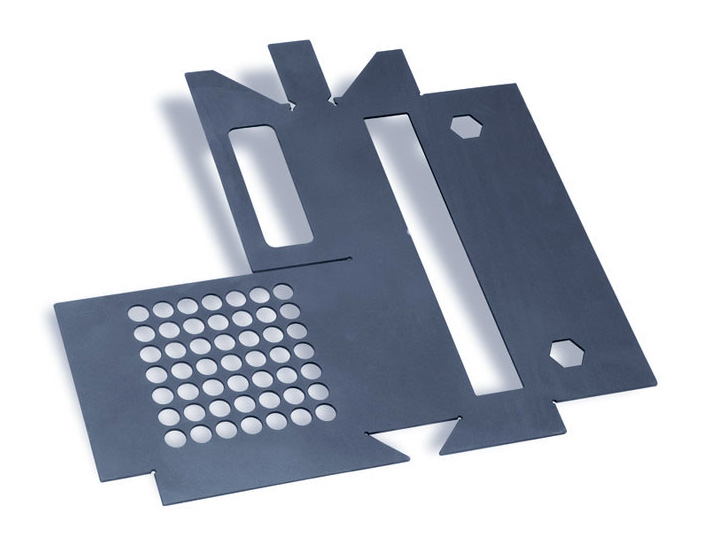

6KW laser cut thin metal projects

How Much does a 6000W Laser Cutting Machine Cost?

A 6000W fiber laser metal cutting machine with basic configuration starts at $50,000, while the top configuration is as high as $108,000. In short, the average cost of a high-power 6KW laser cutting machine is around $78,000 in 2025.

How to Buy a High-Powered 6000W Laser Cutting Machine for Metal Fabrication?

Purchasing a 6000W high-power laser metal cutter that fits your needs and budget is not accomplished in one fell swoop and requires a lot of consideration. Here are 6 easy-to-follow steps to help you buy an ideal cutter for your business.

• Step 1. Start by determining your specific cutting needs, such as the type of metal, width, length, thickness, and required speed.

• Step 2. Research reputable manufacturers and suppliers, comparing features, specifications, costs, and customer reviews.

• Step 3. Consider the cutter's warranty, service, and availability of replacement parts.

• Step 4. Request quotes from multiple vendors, making sure you understand the total cost, including shipping and installation.

• Step 5. Ask about training and technical support options.

• Step 6. Once you've gathered all the necessary information, make an informed decision based on your budget and requirements, and visit a showroom or facility to inspect a laser metal cutter working with 6KW fiber laser power option in action before finalizing your purchase.

Packing Service for 6x12 High Power Fiber Laser Metal Cutter Machine 6000W

• Plywood packaging with strong waterproof bottom and steel straps fixed outside the box.

• Separate plywood boxes to pack laser generator and spare parts.

• Corners protected with foam and fixed with protective film.

• Fully covered with strong protective film and vacuum packed.

• Internal steel frame protector to prevent collision.

• Complete packaging with normal container or frame container.

Pre-Sales Service for High Power 6x12 Fiber Laser Metal Cutter Machine 6KW

Free Sample Trial Cutting Service

For free sample cutting and testing, please send us your CAD file (.plt or .ai), we will cut it in the factory and make a video to show you the cutting process and results, or send the sample to you to check the cutting quality.

Progressive Solution Design

According to the customer's product processing requirements, we can design unique solutions for customers to support higher manufacturing efficiency and better processing quality.

Customized Machine Design

According to the customer's private needs, we can modify our machines according to the customer's convenience and high production efficiency.

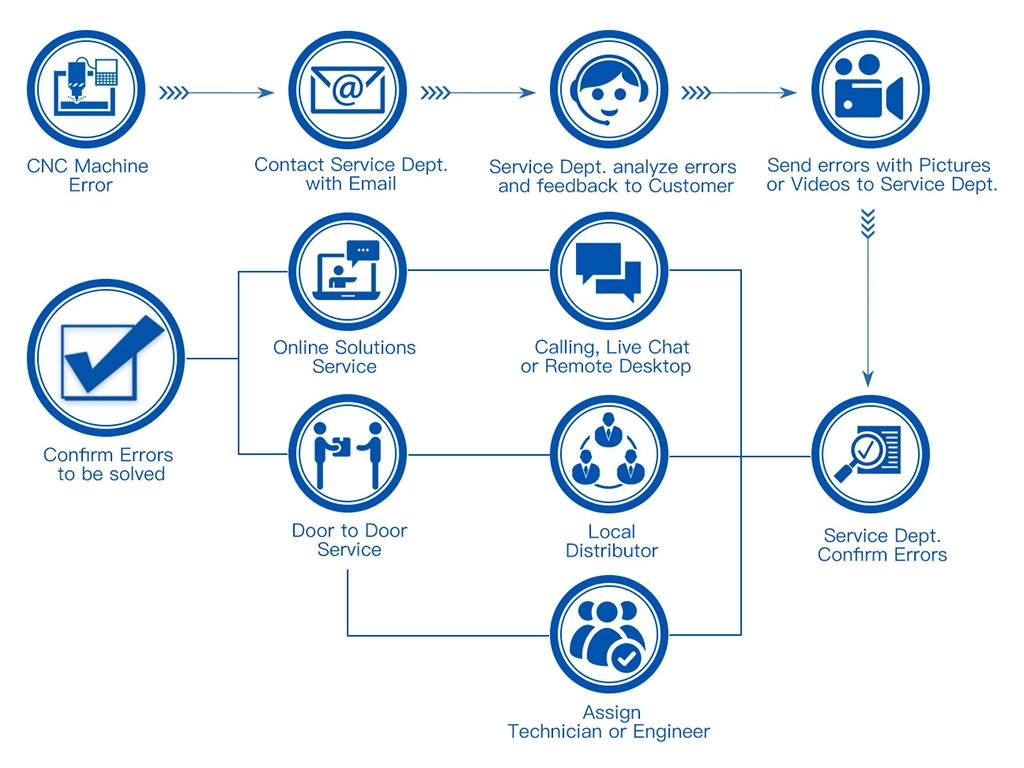

After-Sales Service for 6x12 High Power Fiber Laser Metal Cutting Table 6000W

1. We will provide English instructional videos and user manuals for setup, operation, maintenance and troubleshooting for the high-power fiber laser cutting machine, and provide technical guidance remotely when you encounter problems via email, call, Whatsapp, Skype, and 24/7 online live chat.

2. You can come to our laser machine factory for training. We will provide professional guidance. Direct and effective face-to-face training. We have assembled machines, various tools and testing facilities here. Training time: 3~5 days.

3. Our engineers will provide on-site guidance and training services at your local site. We need you to assist with visa procedures and prepay our travel expenses and accommodation during business trips and services before dispatching. It is best to arrange a translator for our engineers during the training period (if they do not speak English).

Warranty for High Power 6x12 Fiber Laser Metal Cutting Table 6KW

• The entire machine comes with 1-year limited warranty (excluding consumable parts).

• Lifetime maintenance, the after-sales department will provide 24/7 English online support.

• We are responsible for providing accessories free of charge during the warranty period except for man-made damage.

• After the warranty period, the buyer only needs to pay the actual repair cost.

• Certificate support: CE, FDA, SGS.

If you would like to get a free quote for a 6000W high power fiber laser metal cutter machine, please answer the following questions and let us know via email so we can send you its configuration details and quote you a budget-friendly price.

1. Do you need to cut metal sheets, metal pipes or both?

2. What is your tube length, diameter and maximum thickness if you plan to cut tubes?

3. What is the maximum working area required for sheet metal cutting?

4. What do you cut metal for? (Application)

5. Which seaport is closest to you?

6. Do you have experience with high-power fiber laser metal cutters?

7. What is your online chat method? For example, Skype and WhatsApp.

8. Are you an end user or a dealer?

Maxim Braghis

Ivonne Olguin

Easy to assemble and use. High performance and low operating cost. This laser metal cutter can cut carbon steel with fast speed and high precision, it adopts high quality fiber laser generator with up to more than 100,000 hours life-cycle.