I am amazed at the quality of this laser metal cutting machine. When I powered it up and tested it out, I was impressed with its cutting capabilities and precision, performing well on thick metals (over 1 inch) with a fiber laser power of 6 kilowatts. The full-size 5x10 work table makes most sheet metal cuts feasible, and the fully enclosed protective cover allows safe metal cutting. All in all, great value for money.

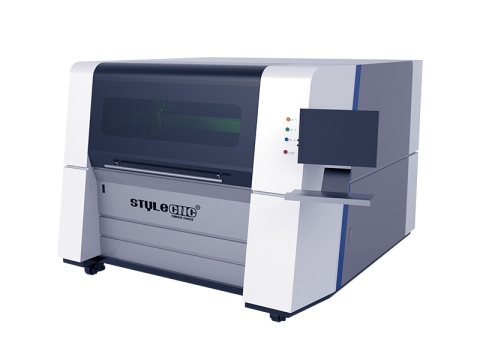

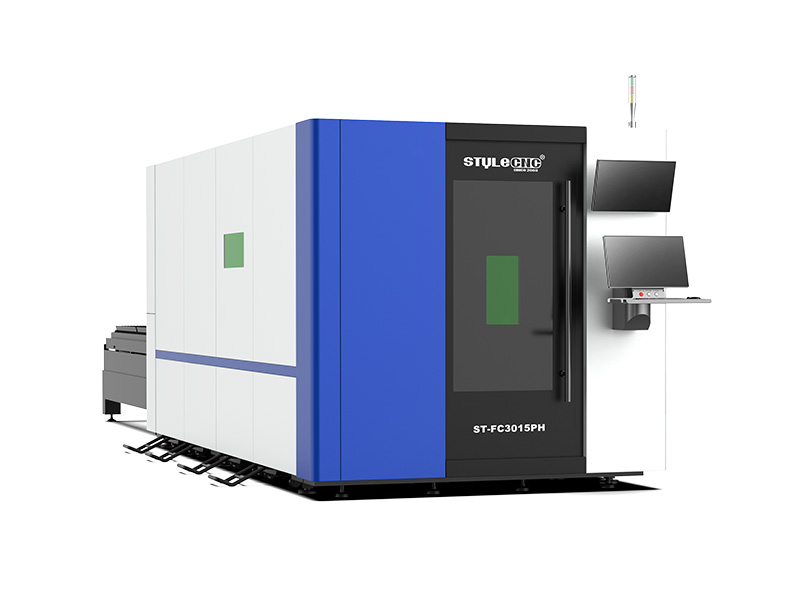

5x10 Fiber Laser Cutter with Fully Enclosed Cover for Metal

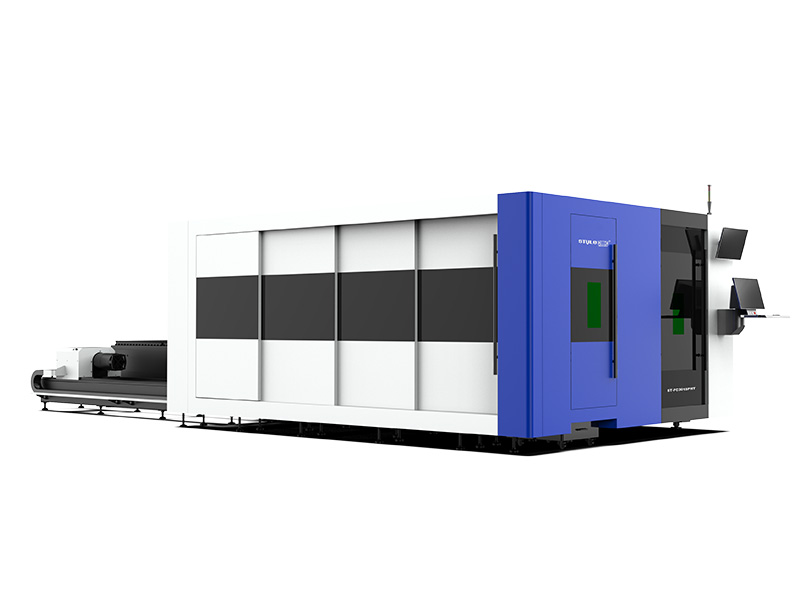

ST-FC3015PH fiber laser cutting machine comes with dual 5x10 automatic exchange working tables for full-size sheet metal cuts (a rotary attachment is optional for metal tubing), and a fully enclosed cover for safety metal fabrication, which makes it professional for both primary metal cuts and industrial metalworking. The 5-foot by 10-foot cutting table is large enough to handle metal of any size. The Cypcut software integrates CAD and CAM in one program to complete drawing, editing, nesting and cutting in easy steps.

- Brand - STYLECNC

- Model - ST-FC3015PH

- Maker - Jinan Style Machinery Co., Ltd.

- Sizing - 5' x 10' (60" x 120", 1500mm x 3000mm)

- Category - Fiber Laser Cutting Machine

- Laser Source - Raycus, IPG, MAX

- Power Option - 1500W, 2000W, 3000W, 6000W, 12000W

- 180 Units in Stock Available for Sale Every Month

- Meeting CE Standards in Terms of Quality & Safety

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- 30-Day Money Back Guarantee for Your Purchase

- Free Lifetime Technical Support for End-Users & Dealers

- Online (PayPal, Alibaba) / Offline (T/T, Debit & Credit Cards)

- Global Logistics and International Shipping To Anywhere

5x10 fiber laser cutter is a large format automatic metal cutting machine working with a CNC controller, using a laser beam to cut through metals. The "5x10" designation refers to the cutting area dimensions, which is typically 5 feet by 10 feet, allowing for full-size sheets of metal to be cut.

Features and Advantages of 5x10 Fiber Laser Cutter with Fully Enclosed Cover for Metal

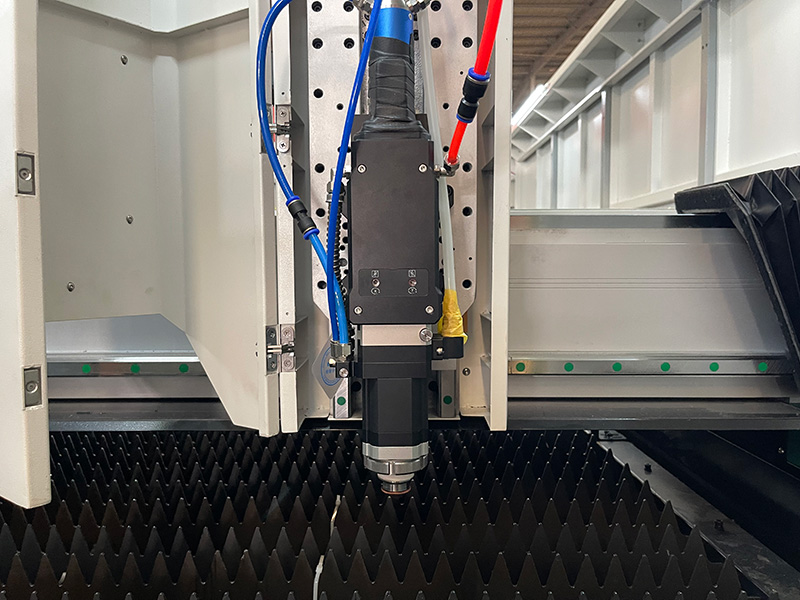

Swiss-engineered laser head

Swiss-designed laser head specifically engineered for a variety of power range applications. A drawer-type lens mount allows easy access for routine maintenance.

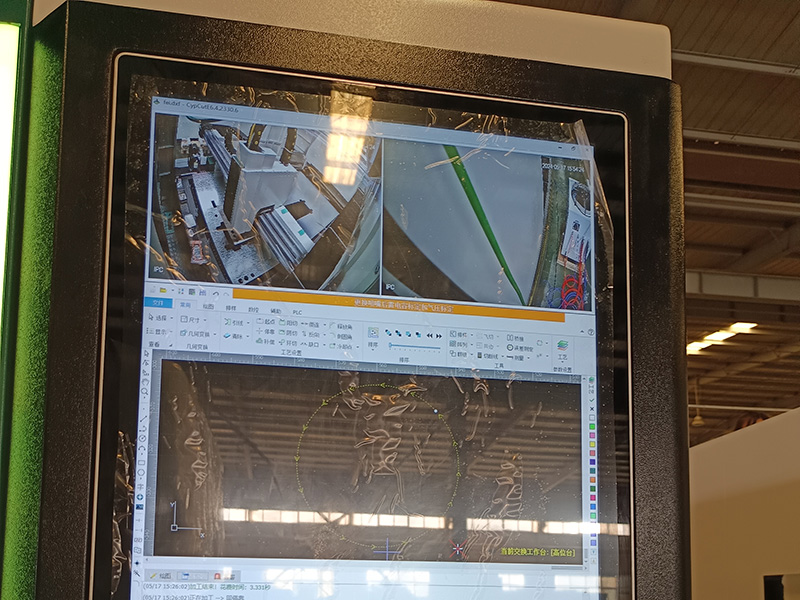

Cypcut Control system

The industry-standard fiber laser cutting software simplifies complex sheet cutting tasks with in-depth design tools, integrating CAD, nest, and CAM modules in one package. Complete drawing, editing, nesting, and workpiece framing in only a few clicks.

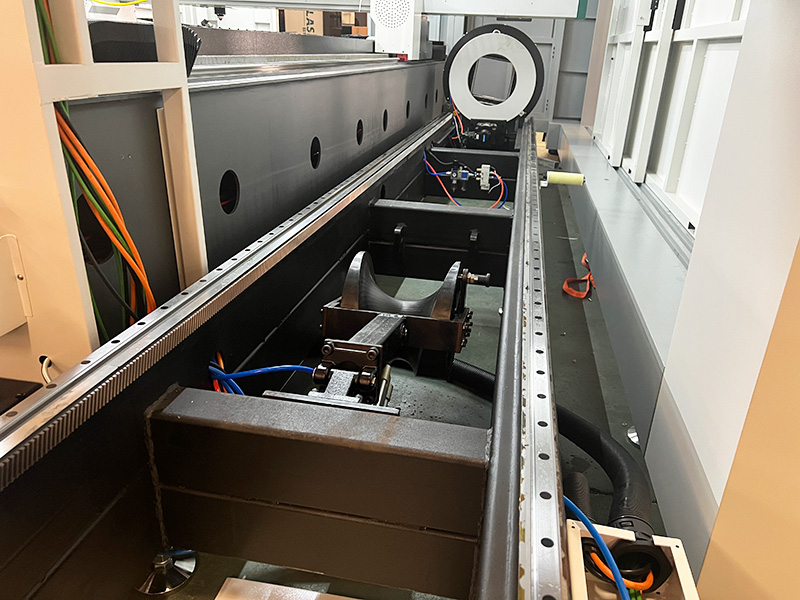

High rigidity machine frame

Thicker steel welding bed annealed at 600°C with good rigidity, excellent shock absorption, high precision, and keep working long years without deform.

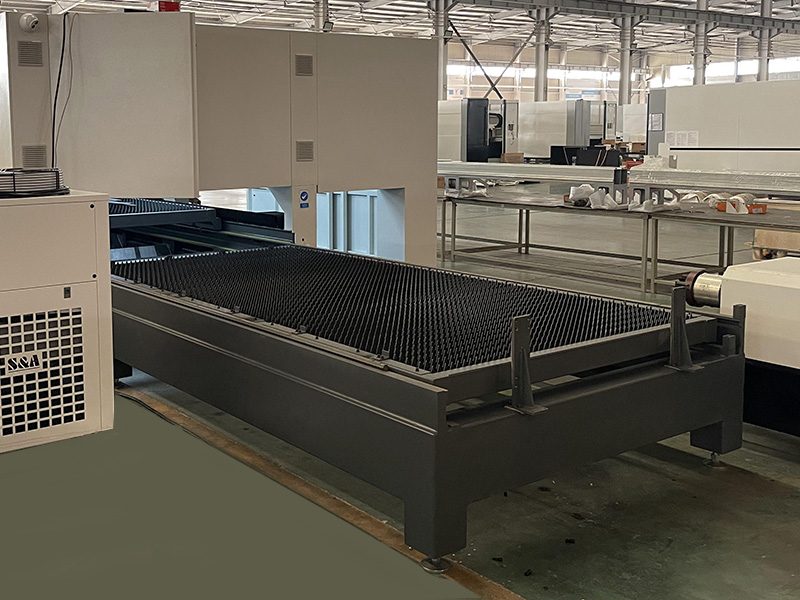

Sawtooth blade cutting platform

The cutting platform equipped with removable sawtooth blades to minimize laser beam reflections and disperse radiation, enhancing edge cut quality and facilitating kerf clearance.

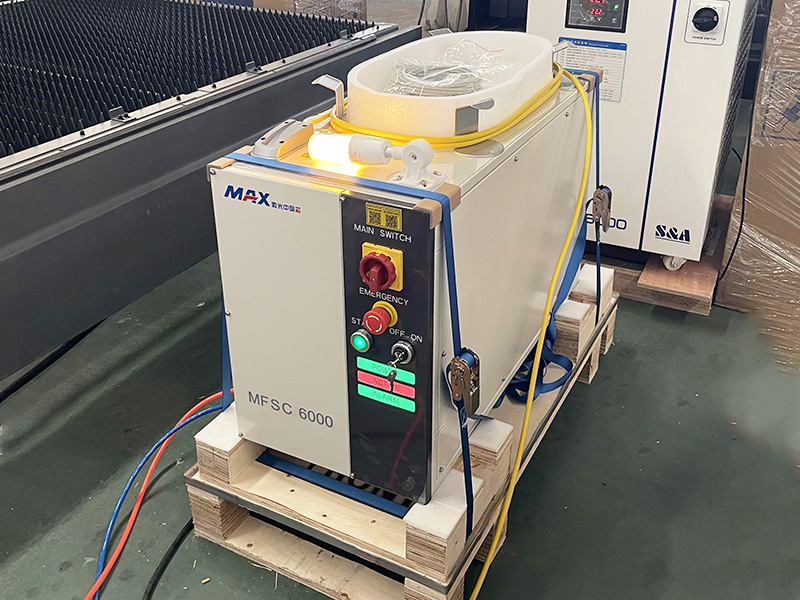

Max brand laser source

With long lifespan up to 150000 hours and high cutting speed. Raycus, IPG for choose.

Debris collection system

Multiple debris zones funnel below the platform to collect scrap and dust, channeling metal waste into a rolling cleanup tray.

Dual 5x10 automatic exchange working tables for full-size sheet metal cuts

Fiber laser cutting machine with automatic exchange working tables, fast and precise cutting various metals, dual tables for reduced downtime and continuous production.

A rotary attachment is optional for metal tube cutting

Technical Parameters of 5x10 Fiber Laser Cutter with Fully Enclosed Cover for Metal

| Model | ST-FC3015FM | ST-FC3015FMT |

| Working Area | 5x10 | 5x10 |

| Metal tube Cutting Dimension | No | D220mm, L6000mm |

| Laser Power | 6000W (1500W, 2000W, 3000W, 12000W for Option) | |

| Cutting Speed | 120m/min | |

| Max Acceleration | 1.5G | |

| Repeated Positioning Accuracy | ±0.02mm | |

| Power Supply Rated Voltage | 380V/50HZ/60HZ/3P | |

| Control System | Cypcut CNC control system | |

| Overall Size | 8270*2280*2150mm | 8270*3500*2150mm |

Applications of 5x10 Fiber Laser Cutter with Fully Enclosed Cover for Metal

Applicable Materials: stainless steel, carbon steel, electrical steel, galvanized steel, aluminum zinc plate, aluminum, aluminum alloy, titanium alloy, copper, brass, iron and other metal materials.

Application Industries: sheet metal processing, aviation, spaceflight, electronics, electrical appliances, subway parts, automobile, machinery, precision components, ships, metallurgical equipment, elevator, household appliances, gifts and crafts, tool processing, adornment, advertising, metal foreign processing, other manufacturing processing industries.

5x10 Fiber Laser Cutter with Fully Enclosed Cover for Metal Projects

Package of 5x10 Fiber Laser Cutter with Fully Enclosed Cover

1. Strong water resit bottom in plywood.

2. Laser source (separated plywood case) and spare parts on the laser bed.

3. Corner protect by foam and fixed by protective film.

4. All covered by strong and hard protective film.

5. Vacuum packing.

6. Inside steel frame protector.

7. Plywood packing and steel strip outside fixed the box.

8. Finishing packing by normal container or frame container.

Pre-Sale Service of 5x10 Fiber Laser Cutter with Fully Enclosed Cover

1. Free sample cutting service:

For free sample cutting/testing, please send us your CAD file (.plt or .ai), we will do cutting in our factory and make video to show you the cutting process and result, or send samples to you to check the cutting quality.

2. Progressing Solution Design:

According to customer’s product processing requirement, we can design the unique solution that supports higher manufacturing efficiency and better processing quality for customer.

3. Customized machine design:

According to customer's application, we may revise our machine according to customer's convenience and high production efficiency.

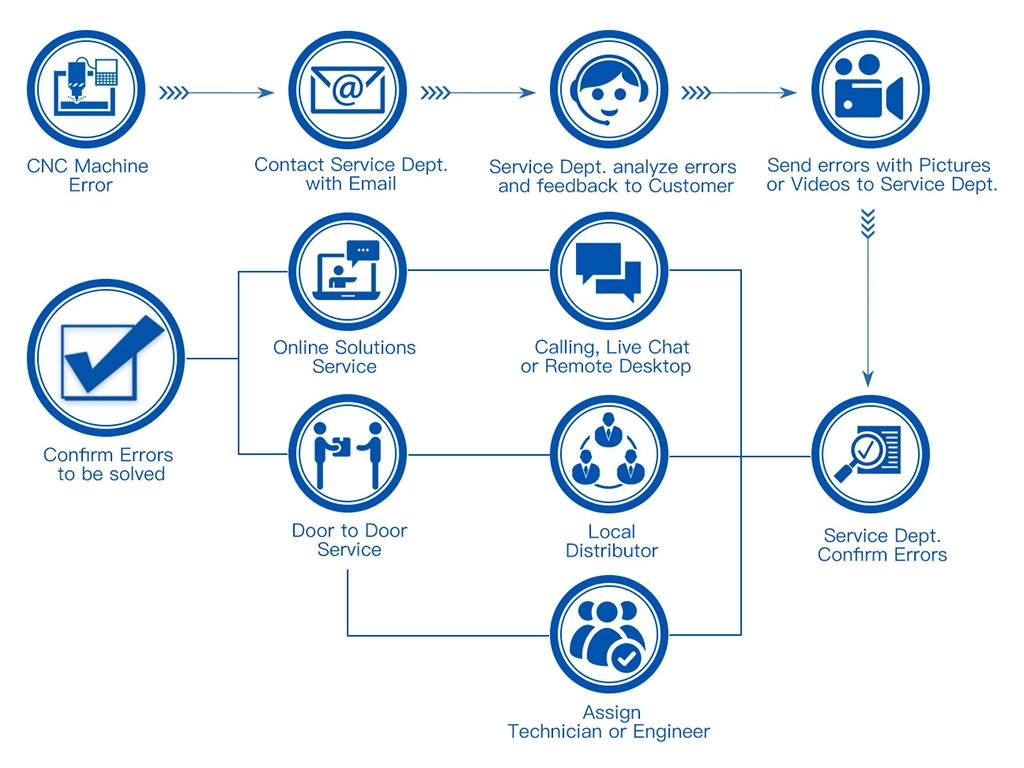

After-Sale Service of Portable Metal Laser Cutter

1. We will supply the laser machine with training video and user's manual in English for installing, operation, maintenance and trouble-shooting, and shall give technical guide by remote,such as TeamViewer, E-mail, Telephone, Mobile, Whatsapp, Skype, 24/7 online chat, and so on, when you meet some problem of installation, operation or adjusting. (Recommended)

2. You can come to our laser machine factory for training.We will offer professional guidance. Direct and effective face-to-face training. Here we have assembled equipment, all sorts of tools and testing facility. Training Time: 3~5 days (Recommended)

3. Our engineer will do a door-to-door instruction training service at your local site. We need your help to deal with the visa formality, prepaid traveling expenses and accommodation to us during the business trip and service period before their dispatch. It's better to arrange a translator (if no English-speaking) for our engineers during the training period.

Warranty for 5x10 Fiber Laser Cutter with Fully Enclosed Cover

1. The entire machine comes with 1-year limited warranty (excluding consumable parts).

2. Long life-time maintenance, after-sale department will offer 24/7 English online support.

3. Except the damage artificially, we are responsible for offering the fittings free of charge during warranty.

4. After the warranty period expired, the buyer only need to pay the actual maintenance cost.

5. Certificate support: CE, FDA, SGS.

If you have an idea to get a free quotation of 5x10 fiber laser cutter with fully enclosed cover for metal, please answer the questions as following and tell us by email, so that we can recommend the most suitable laser machine and quota the affordable price to you directly.

1. Do you need to cut metal sheets/plates, metal pipes/tubes only or both?

2. If need to cut tubes, What is your tube length, diameter and max thickness?

3. For cutting metal sheet, what is the max working area required?

4. After processed, what the materials will be used for? (Applications)

5. Which seaport is the nearest to you?

6. Do you have any experience in the portable fiber laser cutter?

7. What is your online chat way? Such as Skype and Whatsapp.

8. Are you an end user or reseller?

Don Pall

Sam Buzacott

I was on the fence about this purchase for several months. I wanted to be able to cut sheet metals of different thicknesses, but 32 thousands of dollars is a big investment despite this model being one of the best options available. I finally came across the reviews for the ST-FC3015PH and that pushed me to make the purchase. So far so good. Unbelievable quick shipping. The metal laser cutter arrived well packaged against damage, with all components. Nothing missing. I was able to set it up easily.