I have worked in metal fabrication all my life and have done every cutting procedure except laser cutting. So, when I saw the hype about expensive fiber laser cutters on social media, I was skeptical, to say the least. After some research, I decided to purchase the ST-FC3015FM for my auto parts store, as my growing business required higher-precision metal cuts. Fortunately, it didn't let me down. Every cut was very smooth and clean, exactly as I expected. Also, make sure you order a safety light curtain as you need to keep yourself safe. All in all, this is an excellent laser machine for any metalworker on a budget.

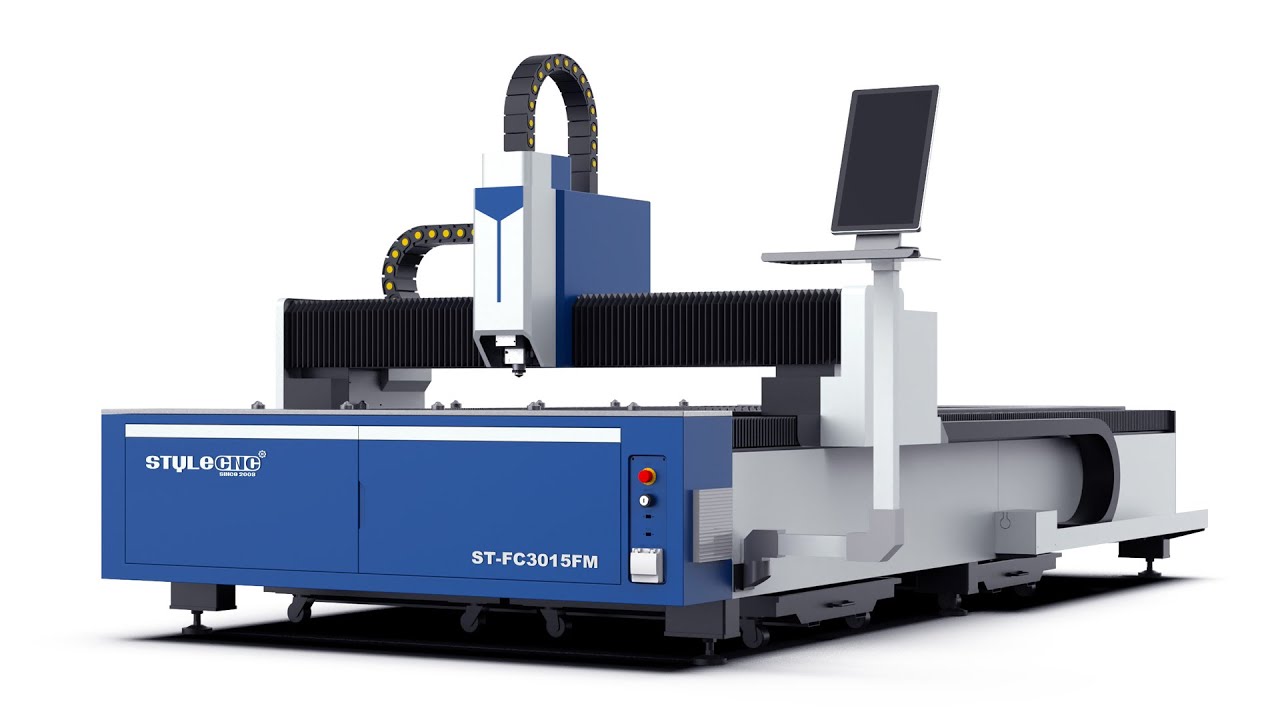

2026 Best Sheet Metal Laser Cutter for Sale (1500W - 6000W)

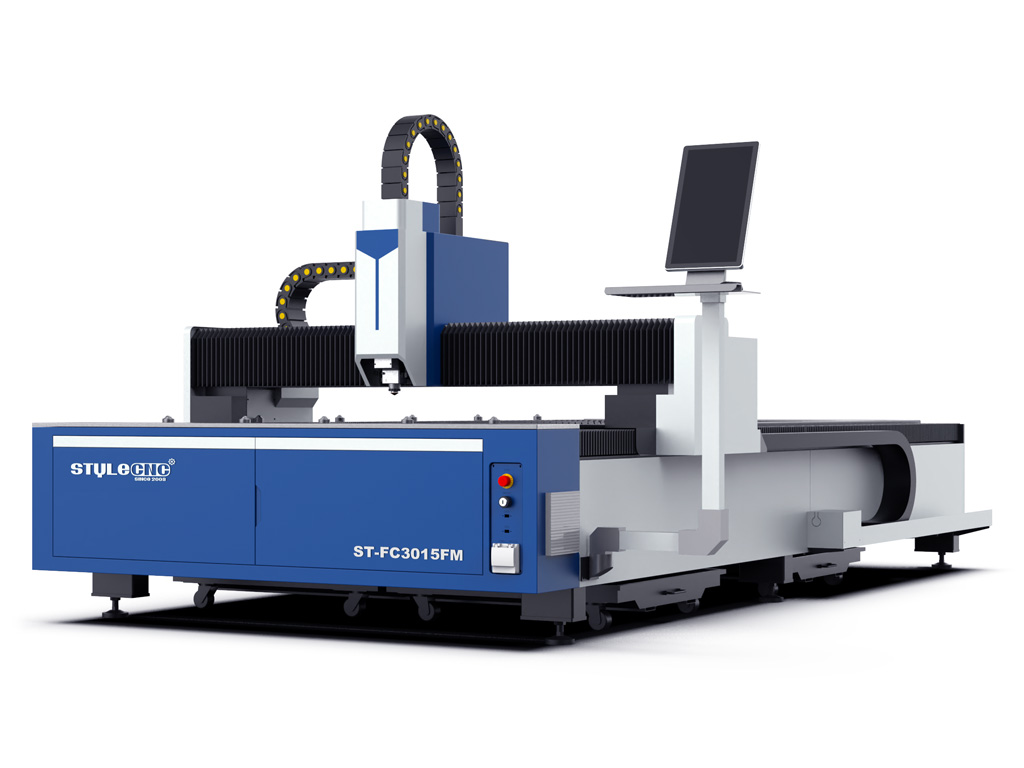

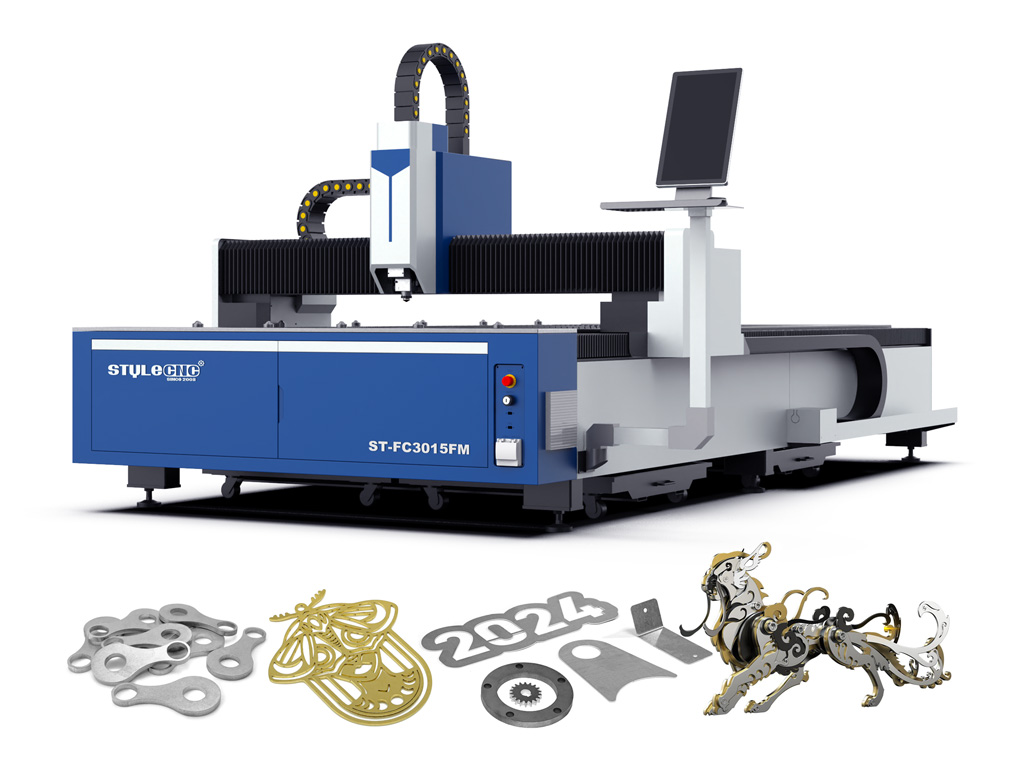

The best sheet metal laser cutter of 2026, ST-FC3015FM, is a full-size (5x10) automatic CNC metal cutting system with power capacities of 1500W, 2000W, 3000W, 4000W and 6000W for beginners and professionals to easily shape sheet metals from 1mm to 25mm with a maximum speed of 100 meters per minute, and create personalized metal signs, parts, crafts, artworks, gifts, logos, labels, letters, panels, screens and decorations. Now this affordable fiber laser sheet metal cutting machine for sale at cost price.

- Brand - STYLECNC

- Model - ST-FC3015FM

- Maker - Jinan Style Machinery Co., Ltd.

- Sizing - 5' x 10' (60" x 120", 1500mm x 3000mm)

- Category - Fiber Laser Cutting Machine

- Laser Source - Raycus, IPG, MAX

- Power Option - 1500W, 2000W, 3000W, 4000W, 6000W

- 180 Units in Stock Available for Sale Every Month

- Meeting CE Standards in Terms of Quality & Safety

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- 30-Day Money Back Guarantee for Your Purchase

- Free Lifetime Technical Support for End-Users & Dealers

- Online (PayPal, Alibaba) / Offline (T/T, Debit & Credit Cards)

- Global Logistics and International Shipping To Anywhere

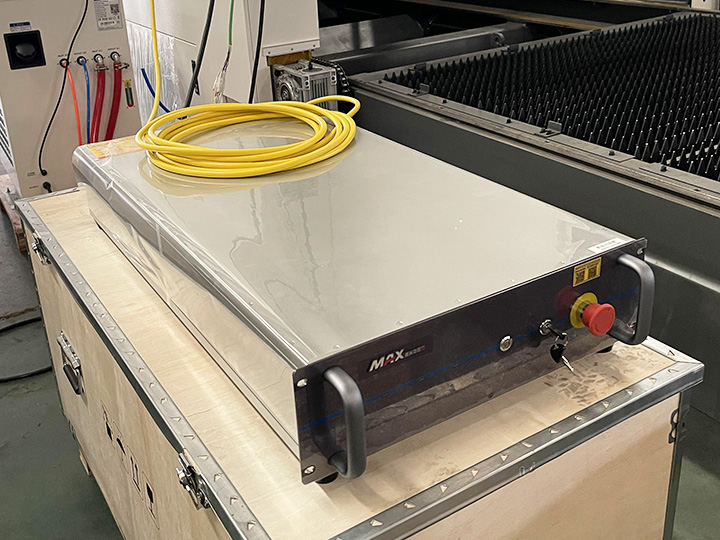

Imagine a machine that can easily combine speed and accuracy, using fiber laser sources from well-known brands in the industry, such as Raycus, IPG or MAX.

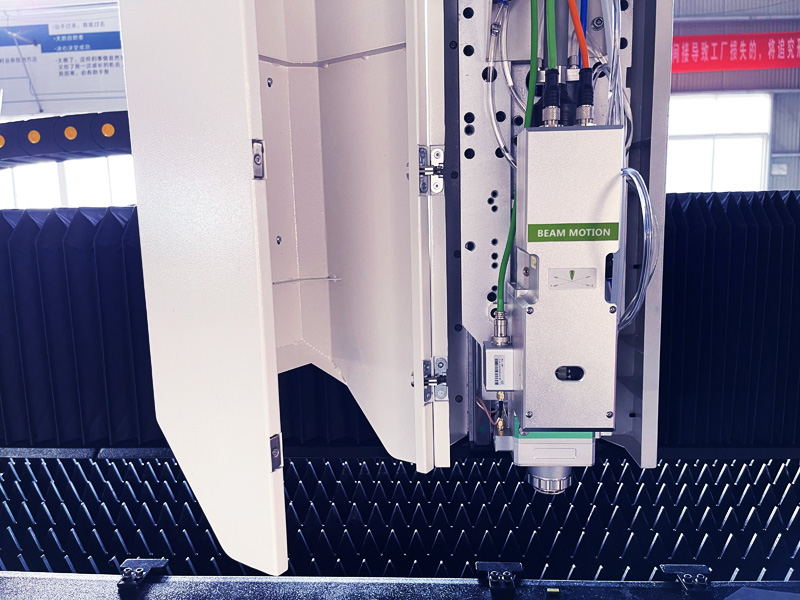

But what makes the ST-FC3015FM stand out is its steadfast dedication to new ideas and design that puts the user first. This machine is easy to use and comes with a Swiss Raytools Laser Cutting Head with autofocus. The user-friendly Cypcut Controller Software makes it easy for beginners and professionals to get precise cuts and make even the most complicated designs come to life.

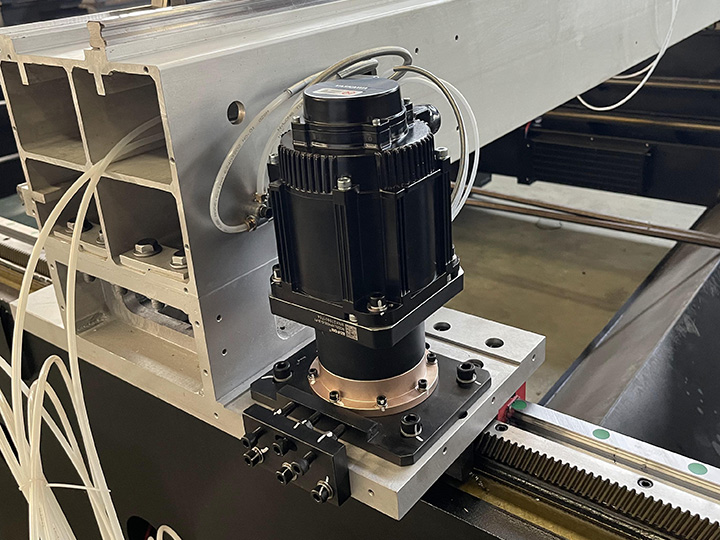

That being said, accuracy is only the start. With its Gear-Rack Transmission System and High Torque Japanese Yaskawa Drive Motors, the ST-FC3015FM can be used for a wide range of tasks. This machine guarantees that every job is done rapidly and accurately, no matter how complicated the design is or how many structural parts need to be made.

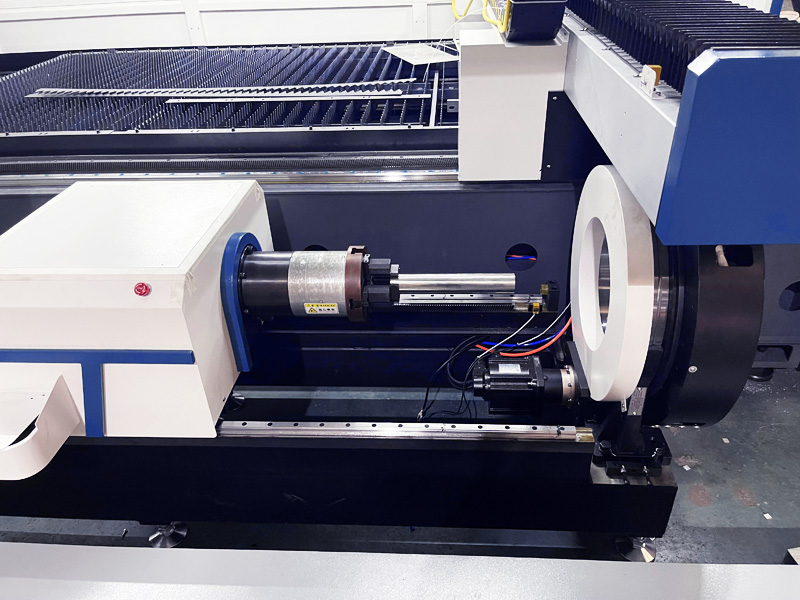

The ST-FC3015FM lets you be creative and make it your own in a lot of different ways with available upgrades like the Auto Feeding System and Rotary Attachment. This machine lets you be creative and take your metalworking to a whole new level. You can use it to make unique metal signs, decorative panels, and more.

Sheet metal fabrication usually cuts with hand tools, handheld tin snips, electric shears, electric scissors, electric nibblers, wire cutters, plasma cutters, flame cutters, CNC punching machines, CNC shearing machines, water jet cutters, and laser cutters. Various sheet metal cutting tools have their advantages and disadvantages, the accuracy, speed and cost all vary.

What Is A Sheet Metal Cutter?

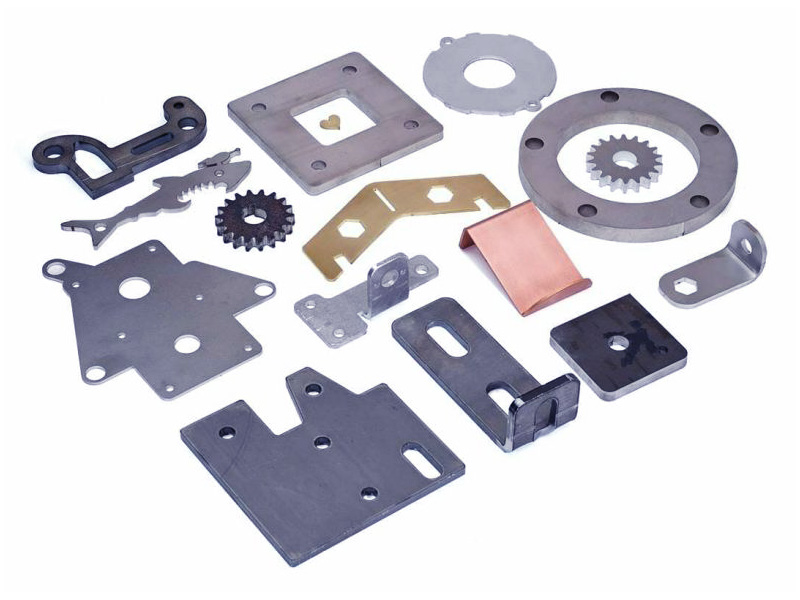

A sheet metal cutter is a power tool that cuts metal plates into various shapes and silhouettes with a handheld tin snip, electric shear, scissor, nibbler, laser beam, wire, plasma, oxyacetylene flame, and water jet. Sheet metal cutters can cut cold rolled sheets (SPCC) and hot rolled sheets (SHCC), galvanized steel, copper (true copper), copper, aluminum sheet (6061, 6063, duralumin), aluminum profiles, stainless steel (mirror, brushed, frosted). Although traditional sheet metal cutting tool has their unique advantages, however, its cutting accuracy, quality and speed are far inferior to those of laser sheet metal cutting machines.

What Is A Sheet Metal Laser Cutter?

A sheet metal laser cutter is an automatic precision laser metal cutting system that cuts metal plates of aluminum, aluminized steel, carbon steel, copper, brass, galvanized steel, galvalume, high strength steel, hot rolled steel, stainless steel, and titanium into various shapes and contours with a fiber laser beam. Compared with hand tools, CNC laser sheet metal cutting features high precision, high quality, high speed, and flexible processing (dieless), and has become the first choice to cut metal parts in sheet metal fabrication, construction machinery, saw blade cutting, grain machinery, textile machinery, agricultural machinery, computer case, electrical cabinet, and elevator manufacturing. With a CNC controller, it can automatically handle complex and delicate jobs on sheet metals. With a drill attachment, it can even cut holes in metal plates. With the popularization of laser technology, it is gradually replacing CNC punching, CNC shearing, plasma cutting, flame cutting, and more metal cutting tools.

How Does A Laser Cut Through Sheet Metal?

A laser cutting machine uses a DSP or CNC controller (with CAM software) to focus a high-powered laser beam onto sheet metal, heating and melting or vaporizing the material along a CAD-designed tool path to create precise metal cuts. Laser metal cutters work with an auxiliary gas (such as oxygen or nitrogen) to blow away the slag to prevent oxidation for clean cuts, and laser cutting far exceeds traditional mechanical cutting in terms of precision and speed, making it an ideal tool for cutting complex geometries and intricate edges in modern sheet metal fabrication.

Laser Sheet Metal Cutter Applied Industries

Laser sheet metal cutters are widely applied across various industries due to their accuracy, speed and efficiency, including aerospace for creating complex components, automotive manufacturing for precision part cutting and shaping, advertising sign making, precision machinery manufacturing, personalized customization for metal home decorations and cabinets, tool and die creation, medical device manufacturing, electronics for precision circuit board production, construction for structural metal cuts, jewelry for intricate designs, and general metal fabricators.

Laser Cuttable Sheet Metal Materials

Laser sheet metal cutting machines are versatile tools used to cut a wide range of metal materials, including stainless steel, carbon steel, mild steel, tool steel, galvanized steel, silicon steel, aluminum, brass, copper, nickel, titanium, magnesium, iron, silver, gold, and various alloys, making them ideal for modern metal fabrication. They are able to quickly and precisely cut through thin sheets using lower laser power, and thicker plate using higher laser power, resulting in smooth and clean cuts for intricate designs, prototypes, and production runs, enhancing efficiency and product quality.

Sheet Metal Laser Cutter Machine Technical Parameters

| Model | ST-FC3015FM |

| Brand | STYLECNC |

| Table Size | 1500x3000mm (5'x10') |

| Laser Power | 6000W (1500W, 2000W, 3000W, 4000W for Option) |

| Laser Source | Max (IPG, Raycus for Option) |

| Laser Type | Fiber Laser |

| Max Running Speed | 100m/min |

| Repeated Positioning Accuracy | 0.02mm |

| Max Acceleration | 1.0G |

| Voltage | 380V/3PH or 220V/3PH |

| Price Range | $15,000.00 - $43,000.00 |

Features of Sheet Metal Laser Cutter Machine with Fiber Laser Source

1. The Raytools autofocus laser cutting head from Swiss works with a professional autofocus system to ensure that sheet metal cutting is more convenient.

2. The world's best Cypcut laser sheet metal cutting control system and software are included with the machine, which are user-friendly and easy to use for both beginners and professionals, and files in DXF or AI format are available, allowing on-site drawing in this software.

3. An industrial chiller is used to cool the laser head and laser generator to reduce the heat generated by the laser head when cutting metal to facilitate continuous cutting and improve productivity.

4. MAX Laser, a world-leading laser brand, works with power options of 1500W, 2000W, 3000W, 4000W and 6000W, allowing for high precision, high speed and high quality.

5. High-speed rack and pinion drive system - X and Y axis moving speed can reach up to 100m/min.

6. High torque servo motor is used to improve sheet metal cutting speed and accuracy.

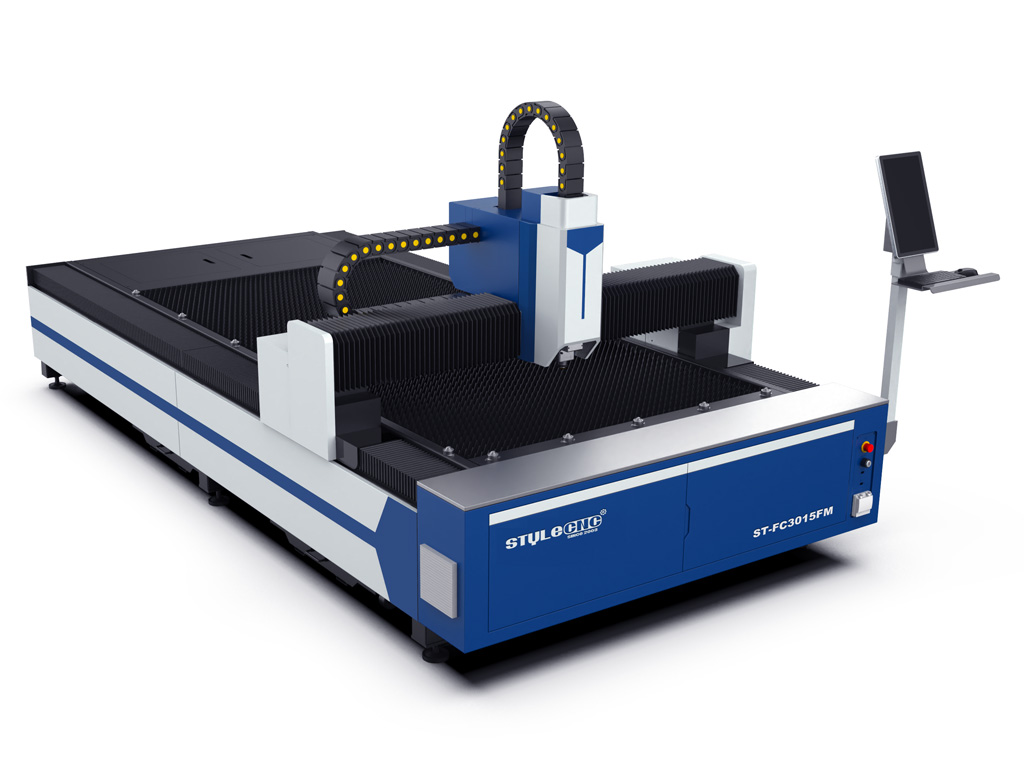

7. 5x10 laser cutting table (sawtooth) with strong load-bearing capacity is a built-in configuration.

8. Automatic oil supply lubrication is used to ensure the machine runs smoothly and with high precision.

9. The X-axis beam is aircraft-grade aluminum casting, replaced with the welded steel gantry, more light-footed to make the whole machine work very fast.

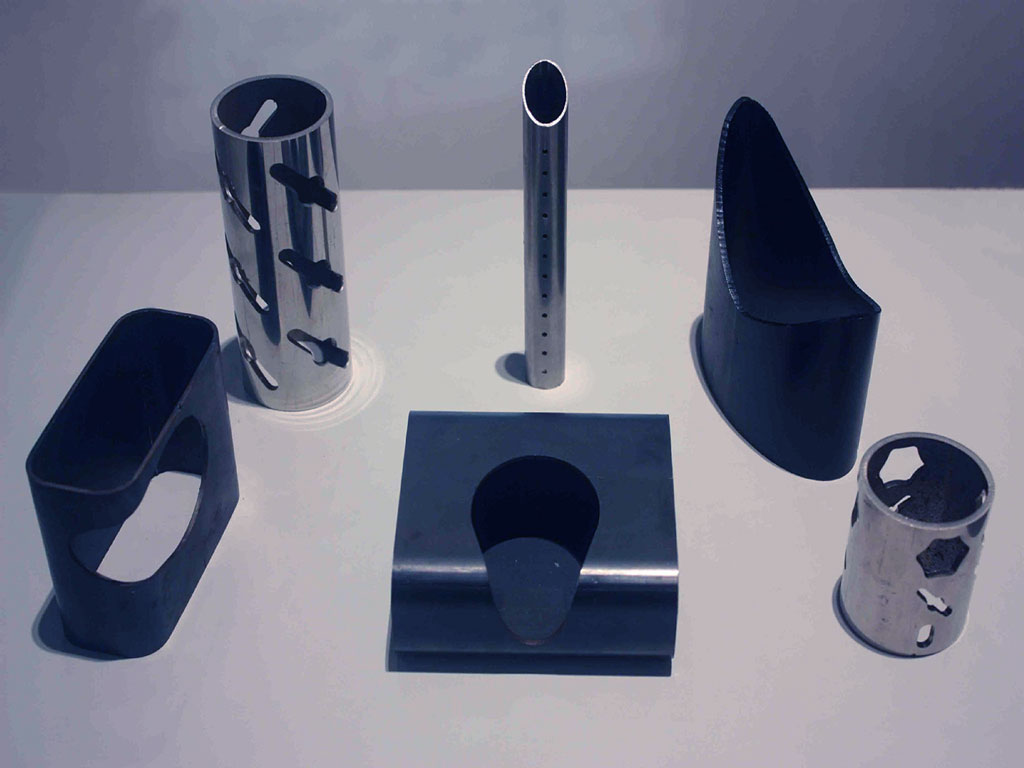

10. A metal pipe & tube cutting device is optional.

This rotary attachment is built into the side of the machine to cut metal tubes. The machine body is designed with a long X-axis so that the laser head can move directly to this rotary attachment to cut metal pipes after cutting the metal plate. Square or round tubes with a maximum length of 6m and a diameter of 20mm to 220mm are feasible.

Affordable Laser Cutter for Sheet Metal Cutting Projects

How Much Does A Sheet Metal Laser Cutter Cost?

There is a wide variety in the types of sheet metal laser cutters based on table size, features, quality, stability, productivity, durability, performance and origin which all factor into a sheet metal laser cutter's price.

If you average all the different sheet metal laser cutters on the market, you'll arrive at a price of $10,000, which is now, as of 2026, skewed heavily to affordable consumer laser sheet metal cutters for home and hobbyist use.

Most entry-level CO2 laser sheet metal cutters start at $6,000, while some beginner-level fiber laser sheet metal cutting machines can be as expensive as $15,000. The higher-end sheet metal laser cutting systems, such as enthusiast and professional sheet metal laser cutting machines, can cost anywhere from $18,000 to $32,000, depending on the machine's power (available in 1500W, 2000W, 3000W, 4000W, 6000W, 8000W, 10000W, 12000W, 15000W, 20000W, 30000W, 40000W, and 60000W) and capabilities. In addition, the enterprise/industrial laser sheet metal cutting machines are pricey to own and operate, typically ranging from $36,000 to $100,000.

Package for Laser Sheet Metal Cutting Table

1. Strong water resit bottom in plywood.

2. Laser source (separated plywood case) and spare parts on the laser bed.

3. Corner protected by foam and fixed by a protective film.

4. All are covered by strong and hard protective film.

5. Vacuum packing.

6. Inside steel frame protector.

7. Plywood packing and steel strip outside fixed the box.

8. Finishing packing by normal container or frame container.

Pre-Sale Service for Laser Sheet Metal Cutting System

Free Sample Cutting Service

For free sample cutting/testing, please send us your CAD file (.plt or .ai), we will do the cutting in our factory and make a video to show you the cutting process and result or send samples to you to check the cutting quality.

Progressing Solution Design

According to the customer’s product processing requirement, we can design a unique solution that supports higher manufacturing efficiency and better processing quality for customers.

Customized Machine Design

According to the customer's application, we may revise our machine according to the customer's convenience and high production efficiency.

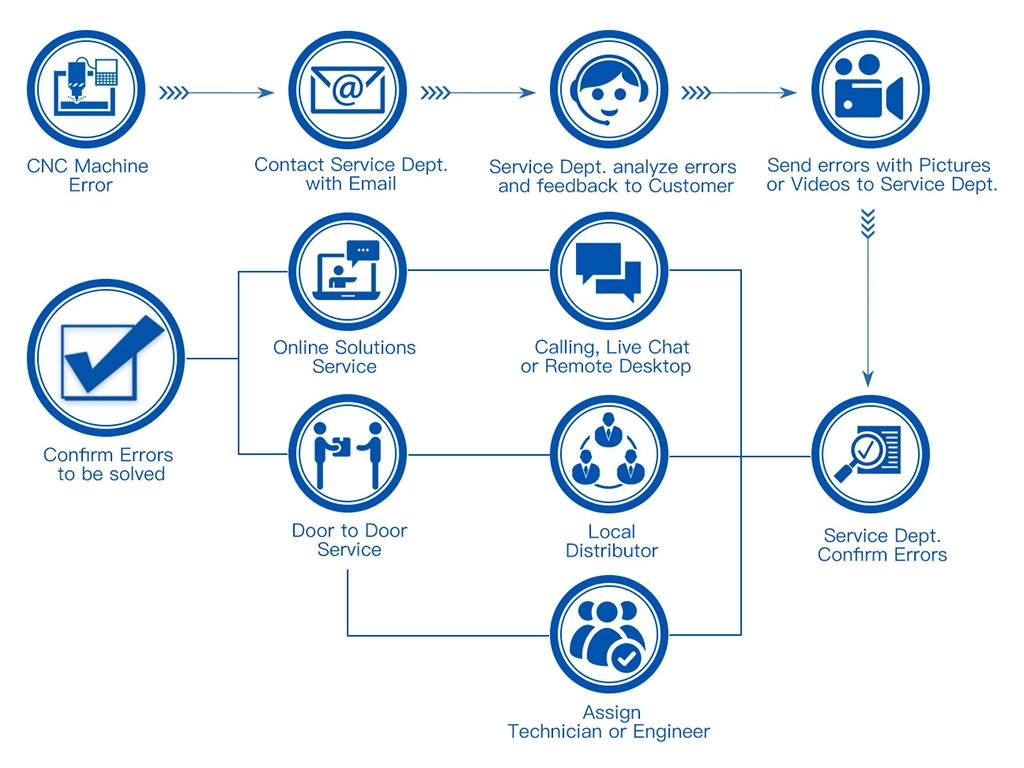

After-Sale Service for Laser Sheet Metal Cutting Machine

1. We will supply the laser machine with a training video and user's manual in English for installation, operation, maintenance, and troubleshooting, and shall give technical guidance by remote, such as TeamViewer, E-mail, Telephone, Mobile, WhatsApp, Skype, 24/7 online chat, and so on when you meet some problem of installation, operation or adjusting. (Recommended)

2. You can come to our laser machine factory for training. We will offer professional guidance. Direct and effective face-to-face training. Here we have assembled equipment, all sorts of tools, and a testing facility. Training Time: 3~5 days (Recommended)

3. Our engineer will do a door-to-door instruction training service at your local site. We need your help to deal with the visa formality, prepaid traveling expenses, and accommodation for us during the business trip and service period before their dispatch. It's better to arrange a translator (if not English-speaking) for our engineers during the training period.

Warranty for Laser Sheet Metal Cutting Machine

1. The entire machine comes with 1-year limited warranty (excluding consumable parts).

2. Long lifetime maintenance, the after-sale department will offer 24/7 English online support.

3. Except for the damage artificially, we are responsible for offering the fittings free of charge during warranty.

4. After the warranty period expires, the buyer only needs to pay the actual maintenance cost.

5. Certificate support: CE, FDA, SGS.

Sheet Metal Laser Cutter Maintenance Tips

You can keep your sheet metal laser cutter running smoothly and lasting as long as possible. Regular upkeep helps improve accuracy and prevent costly repairs. Following these tips helps keep your sheet metal laser cutter in top condition, ensuring accurate cuts and smooth operation. Here are some easy maintenance tips to follow.

1. Clean the Lens: Dust and debris can affect the laser's accuracy. Wipe the lens with a soft, clean cloth regularly to maintain clear laser output.

2. Check the Cooling System: Ensure the cooling system is functioning properly. A well-maintained cooling system prevents overheating and protects the machine from damage.

3. Inspect the Nozzles: Regularly check the laser nozzles for any blockages. Clean or replace them as needed to ensure efficient cutting performance.

4. Lubricate Moving Parts: Apply a light lubricant to moving parts like rails and bearings. This reduces friction and wear over time.

5. Tighten Screws and Bolts: Vibrations during operation can loosen screws and bolts. Check and tighten them regularly to keep the machine stable.

6. Monitor Air and Gas Levels: Ensure air or gas supplies used for cutting are at the correct levels. This ensures consistent cutting performance.

FAQs

If you would like to get a free quote for the best and budget-friendly laser sheet metal cutter, please answer a few questions below and let us know via email so we can recommend an ideal laser machine and quote you an affordable price.

1. Do you need to cut sheet metal, tubing, or both?

2. If you plan to cut tubing, what is the maximum length, diameter, and thickness of your tubing?

3. If you plan to cut sheet metal, what is the maximum working area required?

4. What types of metal materials do you need to cut? For what business? (Application)

5. Do you have experience in using and operating a sheet metal laser cutting machine?

6. Are you an end user or a distributor (wholesale and retail prices vary)?

7. How can we get in touch with you (Email or WhatsApp)?

8. What is the nearest seaport to your destination (for calculating shipping costs and final price)?

What is a Laser Cutting Machine?

A laser cutting machine is a high-precision manufacturing tool that uses a high-powered laser beam as a knife to separate materials into multiple parts with clean and smooth cut edges, creating high-quality shapes and contours. Typically, fiber lasers specialize in cutting metals, while CO2 lasers are used to cut wood, cloth, leather, paper, plastic, and acrylic.

What is a Laser Metal Cutter?

A laser metal cutter refers to an automated cutting tool that uses a high-energy fiber laser beam with the instructions of a CNC controller to cut through steel, aluminum, titanium, brass and copper, resulting in precision metal parts.

How to Buy a Laser Cutter for Metal?

Getting an ideal laser cutter for metal is not a one-day job. You'll have to invest a lot of time to discover and compare before you can find a machine that's worth your money and gets the most out of it. To this end, STYLECNC has outlined 5 beginner-friendly steps based on years of experience. Whether you are a novice or a professional, you can get started easily.

Step 1: Evaluate your needs of metal fabrication, such as cutting table size, metal material length, width and thickness, laser type and power, and set a budget you can afford.

Step 2: Explore and research the right models for your needs from popular manufacturers, read customer reviews online and compare their features and costs.

Step 3: Go to the manufacturer's website or contact your local dealer for a real-life demo or free quote.

Step 4: If possible, join online forum communities such as Reddit, Maker Forums, Signs101, and Quora for insights and advice.

Step 5: Once you find your right model, proceed with your purchase through an authorized dealer or directly from the manufacturer, and make sure you acquire necessary spare parts and safety gear for operation.

Khalinga Herath

Nguyễn Huy Tưởng

I've been on the fence about buying a laser cutter to manufacture thicker sheet metal parts with precision, now and I finally decided to give the ST-FC3015FM a go. Arrived to my workshop in 30 days. Assembled in 45 minutes, easy to operate with a short learning curve. I've been experiencing this machine for a few months, I'm already up and running and have cut out a lot of metal parts, most of which turned out quite well. From thinner 1/16-inch stainless steel sheets to thicker 1/2-inch duralumin plates, the ST-FC3015FM can cut easily and produce smooth and clean cut edges. Its user-friendly CNC controller system seamlessly integrates with the CAD software I have been using, allowing for fast file transfer and real-time cutting parameter debugging. A full-size 4x8-foot mild steel plate with a thickness of 1/8-inch can be automatically cut into 24 metal parts in 36 minutes without additional manual operation, simplifying production process, improving quality and efficiency. I'm happy with my purchase and I'm motivated to continue with my new business of custom automotive and aerospace parts. However, the initial cost is higher for home users and small businesses, but it is worth the money. All in all, it is a must-have tool for large metal fabricators and a top choice for companies serious about growth to increase productivity.

Joe Soto

Ever since I have received this laser I have reached out to STYLECNC regarding issues with brass and aluminum alloys (cuts with burrs). I waited a full 12 hours for a response, during which time I had to try to adjust cut parameters myself with the manual to troubleshoot (not yet resolved). As a result, with Ben's help, I reduced the laser power and increased the auxiliary gas pressure to get rid of this trouble, resulting in smooth and clean cuts. What pisses me off is waiting so long. Their explanation was jet lag, but it turned out well anyway. In addition, I tried to sever 1/4" stainless steel and 1/2" mild steel with different laser powers, working as expected and cutting through with ease. So far, every cut is slag-free, requires no grinder for additional cleanup, and wastes less metal than traditional mechanical cutting tools. It will take me some time to get used to this new metal laser cutter machine, requiring a little practice to play with it.

Derek Christian

No issues putting it together. Starts easily. Cuts extremely well. My first task with this machine was to cut the 3/8 steel plate, and it cut much better than the industrial units I am used to. I should mention that this fiber laser machine does NOT require you to touch the work to start the cutting with CNC controller which makes it VERY easy to use. A great laser cutter for sheet metal at a great price.