This fiber laser cutter is most likely the greatest thing I have ever purchased it fits perfectly in my livingroom (Wife doesn't like it there but I say its my house). I've been using it for about a month and cannot stop using it. I've started running out of metal to use basically everything in my house is made of metal my phone case is even metal. Metal is my life its my muse I cannot stop lasering my wife has threatend me of getting divorce but I don't care im going to make a metal wife, a wife that doesn't care about you shaving down there. I hate my wife and I'm going to make a better one. After that she will probably take the kids but that doesn't bother me I have a CNC laser metal cutting machine I can make new children if I want to.

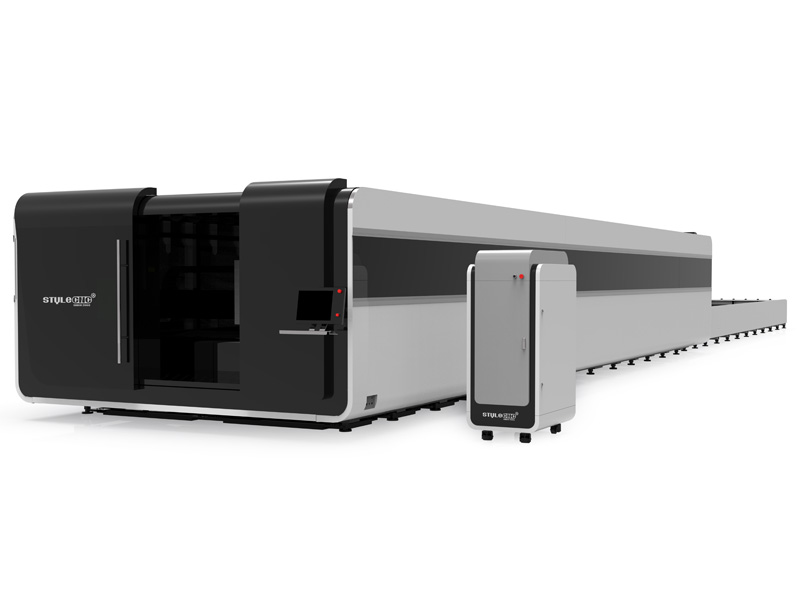

High Speed 12KW IPG Fiber Laser Cutter for Sheet Metal

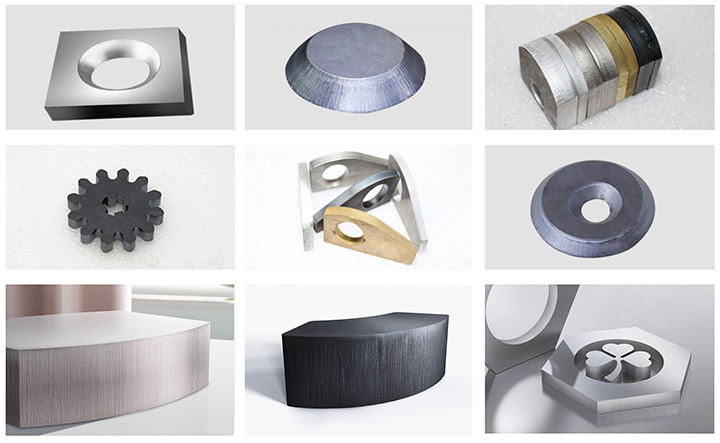

High-speed IPG fiber laser cutter is type of high-power and high-precision laser metal cutting machine that comes with the best 12000W IPG fiber laser source (the most popular fiber laser generator manufacturers and brands from the United States, Germany, and Russia) for commercial use of professional thicker sheet metal fabrication, including stainless steel, carbon steel, tool steel, mild steel, titanium, magnesium, brass, copper, iron, aluminum, alloy, as well as most rare metals in modern industrial manufacturing.

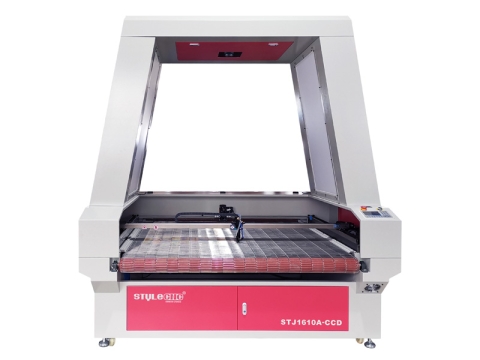

- Brand - STYLECNC

- Model - ST-FC12025GH

- Maker - Jinan Style Machinery Co., Ltd.

- Sizing - 2500mm x 12000mm (2500mm x 6000mm, 2000mm x 4000mm)

- Category - Fiber Laser Cutting Machine

- Laser Source - IPG, Raycus, MAX

- Power Option - 12000W, 20000W, 30000W, 40000W

- 180 Units in Stock Available for Sale Every Month

- Meeting CE Standards in Terms of Quality & Safety

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- 30-Day Money Back Guarantee for Your Purchase

- Free Lifetime Technical Support for End-Users & Dealers

- Online (PayPal, Alibaba) / Offline (T/T, Debit & Credit Cards)

- Global Logistics and International Shipping To Anywhere

What Is IPG Fiber Laser Cutter?

IPG fiber laser cutter is a type of automatic industrial laser cutting system with 12000W IPG laser generator and CNC controller for sheet metal fabrication with high speed and high precision. It is a high power laser cutting machine for thicker metal sheets, including carbon steel sheets, stainless steel sheets, aluminum sheets with the maximum thickness of 50mm, and the maximum cutting thickness of non-ferrous metal sheets (such as copper and titanium) is 20mm. The maximum cutting speed for thin metal sheets can be up to 80m/min. With higher IPG laser powers such as 15000W and 20000W, it can cut sheet metals up to 100mm thickness, and the cutting speed will be as faster as 100m/min for thin metals.

IPG is the world's largest manufacturer of fiber laser generators from USA, Germany, and Russia. It has become an absolute leader in fiber laser generators. The IPG product line is rich, covering high, medium and low power fiber laser generators and amplifiers. IPG fiber laser generator refers to a laser generator that uses rare-earth-doped glass fiber as the gain medium. Fiber lasers can reach unprecedented power. IPG fiber laser generators are low-cost, replacing traditional laser generators that are unstable or high maintenance costs. The flexible light guide system of fiber laser is very easy to integrate with robots or multi-dimensional workbenches. IPG fiber laser generator is small in size, light in weight, and movable in working position. IPG fiber laser generators perform better than traditional lasers in industrial applications. It has the best wavelength and best beam quality for metal fabrication. The IPG fiber laser generator has a long service life and is maintenance-free. Due to its extremely high stability, it greatly reduces the requirements for laser quality monitoring during operation. Simply put, it is excellent beam quality under high power, excellent electro-optical efficiency under high beam quality, and extremely small size, mobility and flexibility under high power and high beam quality.

High power is the advantage of IPG. A large number of IPG high-power (>1KW) fiber lasers have been used in industrial fields such as automobile manufacturing, shipbuilding, offshore platforms and oil pipelines, aerospace and technical processing all over the world. In Japan, thousands of IPG high-power fiber lasers have been sold to customers including Toyota, Mitsubishi, and Sumitomo. The successful application of these lasers shows that IPG fiber lasers have matured and become one of the technical tools of the manufacturing industry, especially in metal fabrication (cutting, welding, cladding, rapid prototyping).

Features and Advantages of High Speed 12KW IPG Fiber Laser Cutter for Sheet Metal Fabrication

⇲ High rigidity machine bed sequence welding. It is made of high quality carbon structural steel and section steel welded together. After 8 hours of heat treatment at 600℃, it is cooled in the oven for 24 hours.

After stress annealing, rough machining, and then vibration aging treatment, completely eliminate welding And the processing stress is large, the rigidity is good, the precision is high, may keep the normal use 20 years does not deform.

⇲ High stability: The design of the fiber laser optical path improves the beam quality while ensuring high-power laser output. The beam is transmitted in the optical fiber without contact with the air to avoid polluting the optical path, and has long-term stability.

Therefore, large laser cutting machines can be used in industrial environments with longer service life and higher requirements.

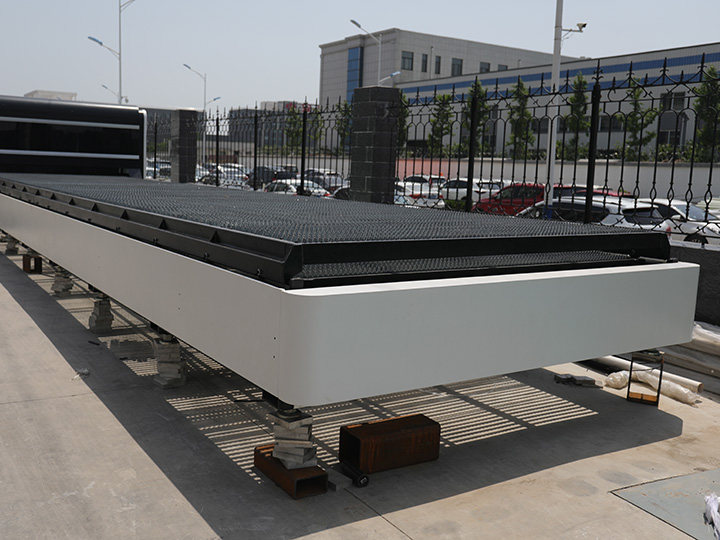

⇲ High-speed dual-motor exchange table:The independent movement of the two tables is unrelated, the accuracy is not affected by each other, and there is no need to pause to clean the residue, which is more efficient and convenient.

⇲ Fully enclosed structure: environmentally, user friendly, and safer.

Applications of High Speed 12000W IPG Fiber Laser Cutting Machine for Sheet Metal Fabrication

It is suitable for the fast cutting of metal sheets, including stainless steel, carbon steel, manganese steel, galvanized sheet, alloy sheet, and rare metals. It is widely used in kitchen appliances, electric control boxes, mechanical equipment, electrical equipment, lighting, auto parts, display equipment, hardware processing.

Technical Parameters of High Speed 12KW IPG Fiber Laser Cutter for Sheet Metal Fabrication

| Brand | STYLECNC | ||

| Model | ST-FC12025GH | ST-FC6025GH | ST-FC4020GH |

| Working Area | 12000X2500mm | 6000X2500mm | 4000X2000mm |

| Laser Type | IPG (Raycus, MAX for Option) | ||

| Laser Power | 12000W (20000W, 30000W, 40000W for Option) | ||

| Power Supply Rated Voltage | 380V/50HZ/60HZ | ||

| Control System | Cypcut CNC control system | ||

| Max Acceleration | 2.5G | 2.0G | 1.5G |

| Repeated Positioning Accuracy | 0.02mm | ||

| Max Running Speed | 220m/min | 180m/min | 150m/min |

| Table change time | 55-65s | 25-35s | 15-25s |

| Maximum load of working platform | 19000KGS | 9300KGS | 5000KGS |

| Machine size | 27980*4345*2705mm | 15554*4345*2705mm | 11320*3690*2860mm |

| Machine weight | 27800KGS | 14500KGS | 11500KGS |

Details of High Speed 12000W IPG Fiber Laser Cutting Machine for Sheet Metal Fabrication

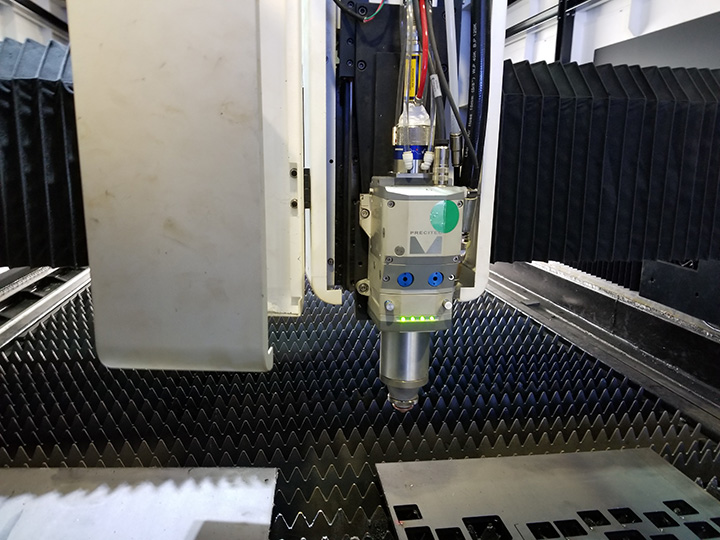

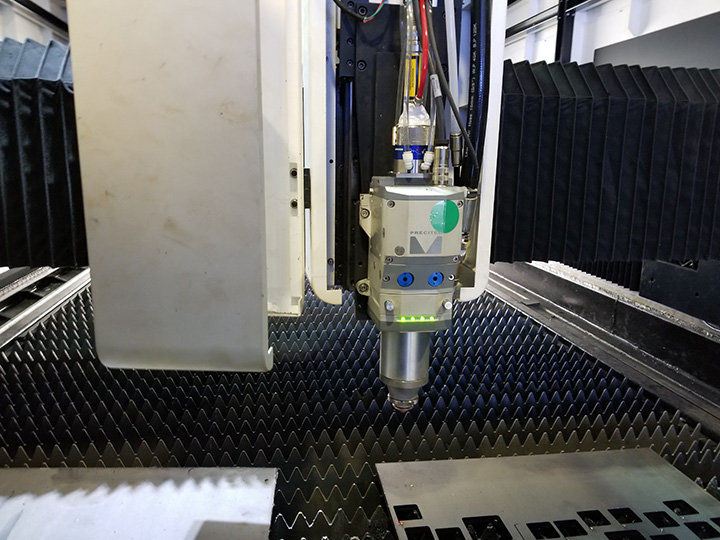

⇲ Germany Precitec ProCutter cutting head with automatic focus function: With automatic follow up system, can according to the height of the plate, adjust the size of the focal length.

⇲ Germany IPG laser generator, more stable, higher precison, energy saving, longer lifetime than normal generator.

• High photoelectric conversion rate can reach 45%, other brands are only about 25%. Save much electricity cost.

• German brand, good quality, laser power weakened slower than other brand.

• High market share, a certain degree of reaction to brand strength and quality.

• Low failure rate, only 3%.

• Light power can be seen in real time.

• After-sale service spots all over the world, problems can be resolved in time.

⇲ Blade table: Feeding system with rolls. It is easy to load heavy sheet and metal sheets can be protected by avoiding scratched.

⇲ A camera is installed inside the protective cover to oversee real-time operation within the cover and shoot any possible problems timely.

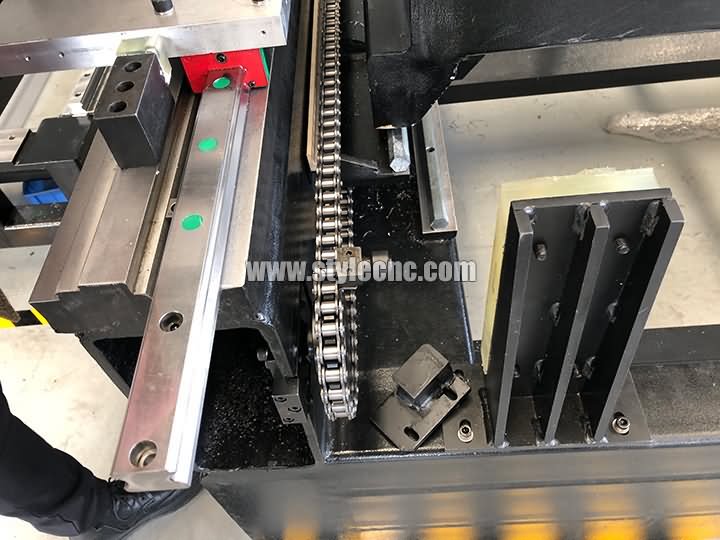

⇲ The internal structure of the bed adopts the aircraft metal honeycomb structure, which is welded by a number of rectangular tubes.

Stiffeners are arranged inside the tubes to increase the strength and tensile strength of the bed, it also increases the resistance and stability of the guide rail so as to effectively avoid the deformation of the bed.

⇲ High speed parallel exchange platform design, Simultaneous exchange of two worktables, stable and reliable transmission mode, shorter exchange time and improved frequency converter.

High Speed 12KW IPG Fiber Laser Cutter for Sheet Metal Fabrication Projects

Package of High Speed 12KW IPG Fiber Laser Cutter for Sheet Metal Fabrication

⇲ Sturdy waterproof plywood bottom.

⇲ Laser source (separate plywood box) and spare parts are available on the laser bed.

⇲ The corners are protected with foam and fixed with a protective film.

⇲ All covered with strong and hard protective film.

⇲ Vacuum packaging.

⇲ Internal steel frame protector.

⇲ Plywood packaging and outer steel straps to secure the box.

⇲ Complete packaging with ordinary containers or frame containers.

Pre-Sale Service of High Speed 12000W IPG Fiber Laser Cutting Machine for Sheet Metal Fabrication

Free Sample Cutting Service

For free sample making, please send us your CAD file (.plt or .ai), we will cut it in our factory and make a video to show you the cutting process and results, or send you the sample to check the quality.

Advance Solution Design

Based on customers' product cutting requirements, we can design unique solutions for customers to support higher manufacturing efficiency and better cutting quality.

Custom Machine Design

Depending on the customer's application, we can modify our machines for customer convenience and high production efficiency.

After-Sale Service of High Speed 12000W IPG Fiber Laser Cutting Machine for Sheet Metal Fabrication

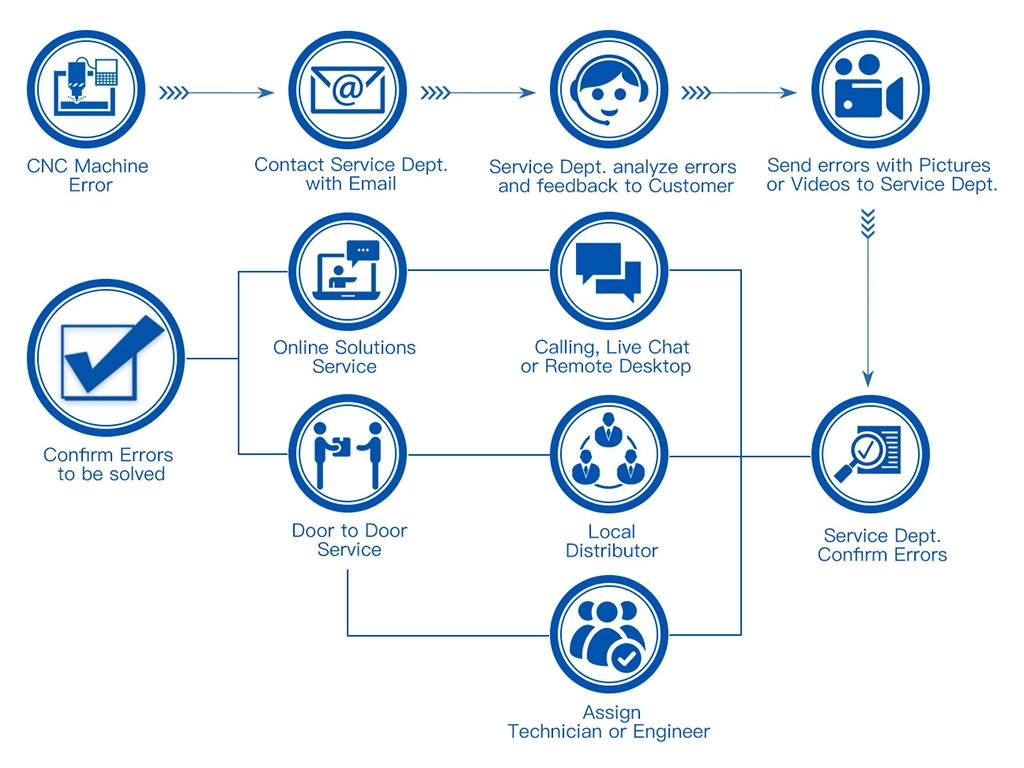

✔ We can provide the laser machine with training video and user's manual in English for setup, operation, maintenance and trouble-shooting, and shall give technical guide by remote, such as TeamViewer, Email, Phone, WhatsApp, Skype, 24/7 online chat, and so on, when you meet some problem of installation, operation or adjusting.

✔ You can come to our laser machine factory for training. We can offer professional guidance. Direct and effective face-to-face training. Here we have assembled equipment, all kinds of tools and testing facility. Training Time: 3~5 days.

✔ Our engineers can provide on-site guidance and training services in your local area. We need your help with visa procedures, travel expenses and accommodation during travel and pre-deployment service. It is best to arrange an interpreter for our engineers during the training (If no English-speaking).

Warranty of High Speed 12KW IPG Fiber Laser Cutter for Sheet Metal Fabrication

✔ The entire machine comes with 1-year limited warranty (excluding consumable parts).

✔ Lifetime maintenance, 24/7 online support provided by the after-sales department.

✔ Except for man-made damage, we are responsible for providing free replacement of spare parts during the warranty period.

✔ After the warranty expires, the buyer only needs to pay the actual repair cost.

✔ CE, FDA, SGS certification.

If you have an idea to get a free quotation of IPG fiber laser cutting machine, please answer the questions as following and tell us via email, so that we can directly recommend the best machine to you and quote an affordable price.

✔ Do you want to cut sheet metal, tubing or both?

✔ What is the maximum length, diameter and thickness of the pipe you want to cut?

✔ What is the maximum sheet metal cutting size?

✔ What are you cutting metal for?

✔ Which shipping port is closest to you?

✔ Do you have experience using fiber laser cutting machines?

✔ What is your live chat tool? Whatsapp, Telegram or Skype.

✔ Are you an end user or a reseller?

Samuel

Edward Stratton

The IPG laser metal cutter is easy to setup and use for a novice user, it cuts great on 1/2 inch stainless steel sheet and 9/16 aluminum sheet at a higher speed up to 160 inches per minute, as well as works on 2 inch mild steel plate at a lower speed of 20 inches per minute. It cuts through with smooth edges, much better than the plasma cuts. In additional, it's an automatic precision metal cutting tool with CNC controller, almost no need of manual intervention.

Eric

BEST laser cutter for metal we have ever purchased. For 10 hours daily working, it still keeps high precision and high cutting speed. I really love it. HIGHLY recommend STYLECNC for any future purchases. In addition, the ST-FC12025GH has a couple of upgrade options with larger tables, higher laser powers, and more laser brands except for IPG. Satisfied to have a decent automatic cutting tool and a company behind it to support it.