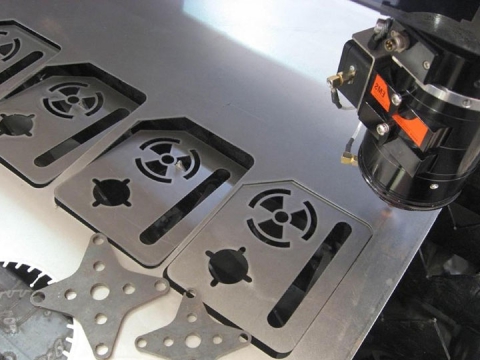

This machine is extremely stable and perfect for my job. I have been using this laser tube cutter for a month and it works just as expected. I use it to cut frames and all the metal tubes I use for fabrication and it performs much better than a plasma cutter. So far it can hold its own for metal tubing.

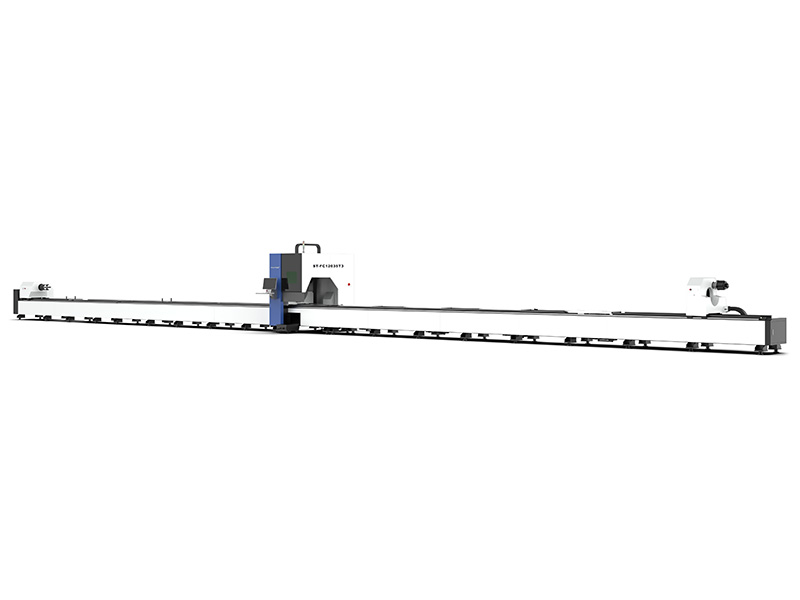

Industrial Tube Laser Cutter for Metal Pipes & Profiles

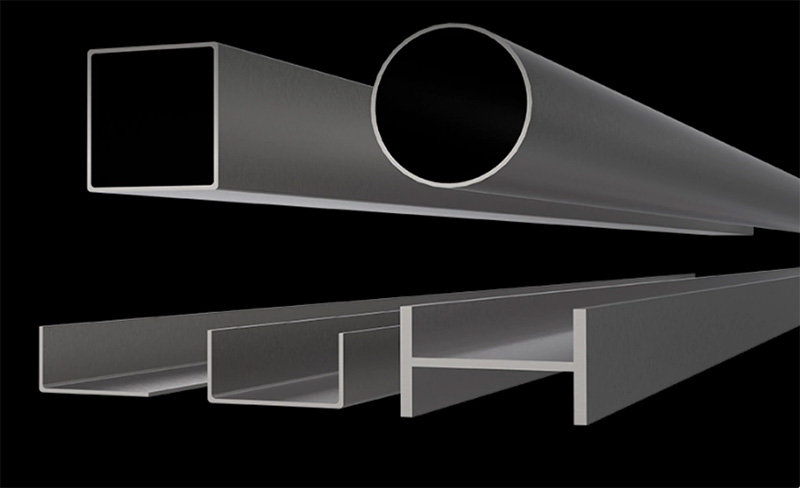

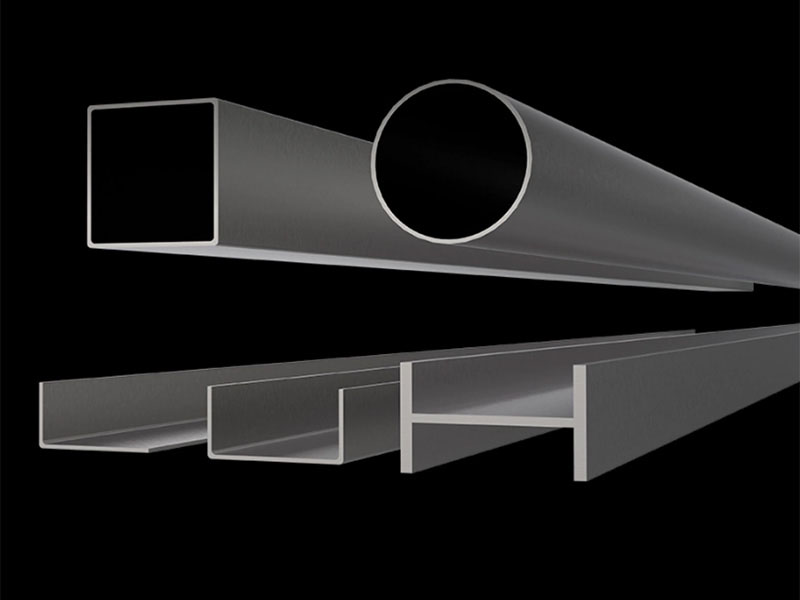

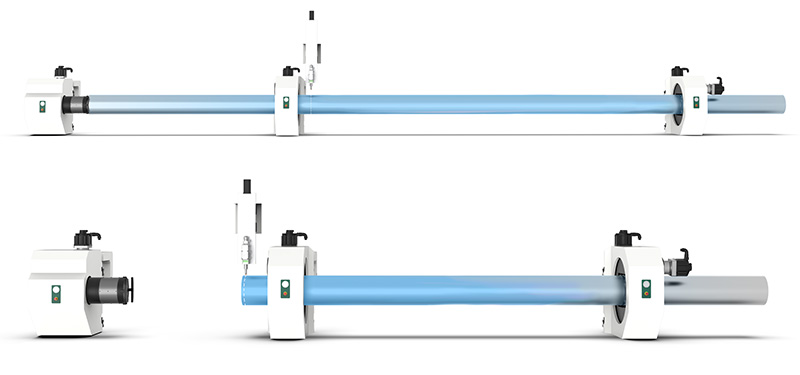

An industrial tube laser cutting machine with CNC controller is professional for creating precise cuts using an automatic feeder and 3 rotary chucks, allowing for all types of metal tube and profile options, including stainless steel, carbon steel, mild steel, aluminum, titanium, brass, copper, nickel and cobalt, as well as a diverse range of alloys for each. The ST-FC6020T3 is an economical and efficient metal pipe and profile cutter with a maximum cutting length of up to 12 meters, and a cutting diameter of up to 350 mm.

- Brand - STYLECNC

- Model - ST-FC6020T3

- Maker - Jinan Style Machinery Co., Ltd.

- Sizing - Φ15mm - Φ230mm

- Category - Fiber Laser Cutting Machine

- Laser Source - Raycus, IPG, MAX

- Power Option - 6000W, 12000W

- 180 Units in Stock Available for Sale Every Month

- Meeting CE Standards in Terms of Quality & Safety

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- 30-Day Money Back Guarantee for Your Purchase

- Free Lifetime Technical Support for End-Users & Dealers

- Online (PayPal, Alibaba) / Offline (T/T, Debit & Credit Cards)

- Global Logistics and International Shipping To Anywhere

An industrial tube laser cutter is an automatic CNC metal pipe cutting machine using a focused laser beam with high thermal energy to cut through the walls of tubes, creating structural components, plumbing systems, metal frames and brackets from a wide range of materials such as steel, aluminum, titanium, brass, copper, and their alloys. From state-of-the-art mechanical engineering and precision metal construction all the way to modern furniture manufacturing, as well as most pupular auto parts and medical devices, you can find industrial laser tube cutting machines everywhere.

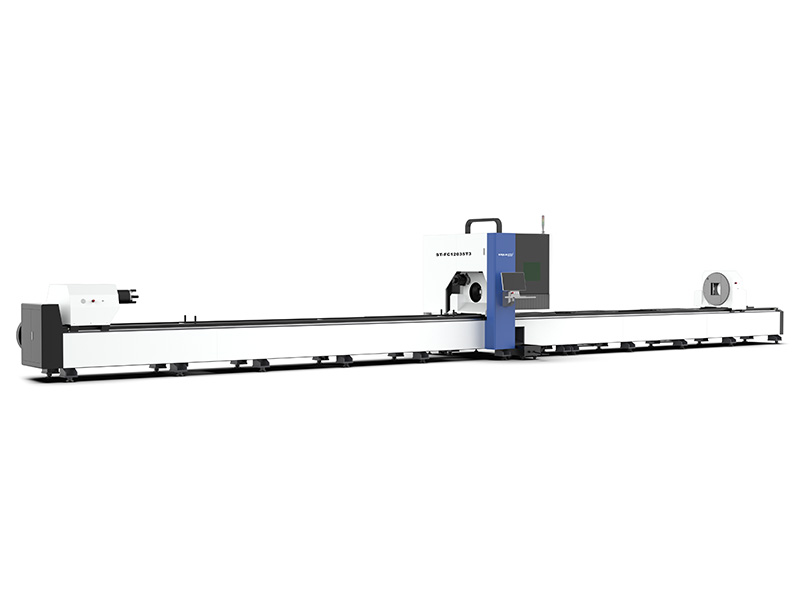

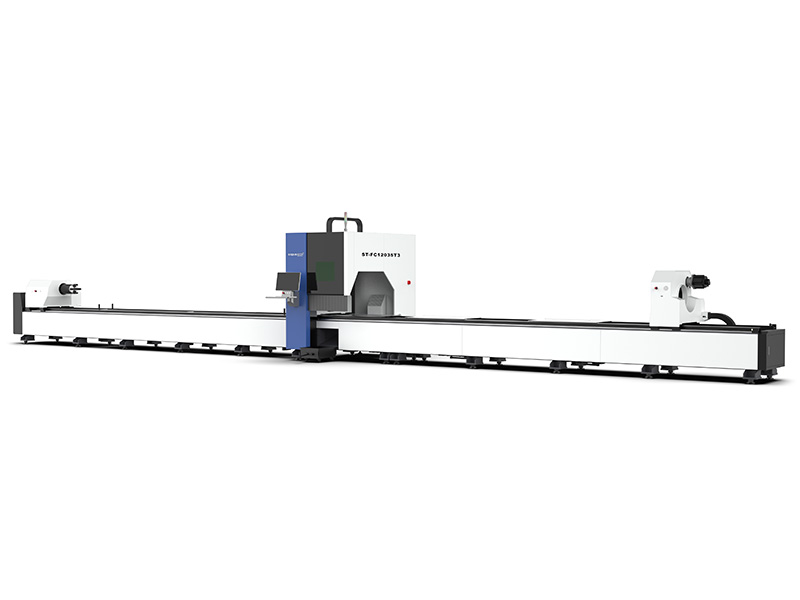

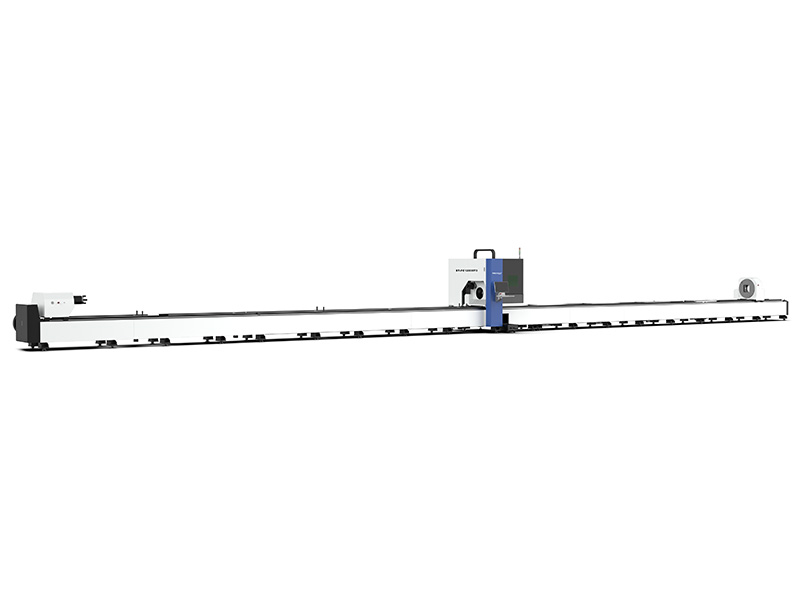

The ST-FC6020T3 industrial tube laser cutting machine is an economical and efficient three-chuck metal pipe and profile cutter with a maximum cutting length of up to 12 meters, a cutting diameter of up to 350 mm, and a single unit load-bearing capacity of up to 900 kg.

The machine adopts a horizontal bed design with strong load-bearing capacity and high cost performance, making it popular for cutting tubes, structural shapes, and channels in automotive parts, engineering machinery, aerospace sectors, oil pipelines, steel structures, building frames, elevator manufacturing, medical devices, fitness equipment, furniture making, electronic and technological components.

Features of Industrial tube laser cutter with three chucks

Heavy duty horizontal bed structure

The heavy-duty horizontal bed structure and high-strength crossbeam design, combined with precision manufacturing process, ensure the best dynamic performance, accuracy and stability during the operation of the tube cutter.

Zero material surplus processing

The standard three-chuck structure is convenient for short-tail cutting. The C2 and C3 chucks are hollow chucks, which can realize whole tube blanking.

The laser skip cutting process fundamentally minimizes manufacturing waste. The industrial tube laser cutting machine will help you maximize the use of every piece of material, reduce waste and improve cost-effectiveness during operation.

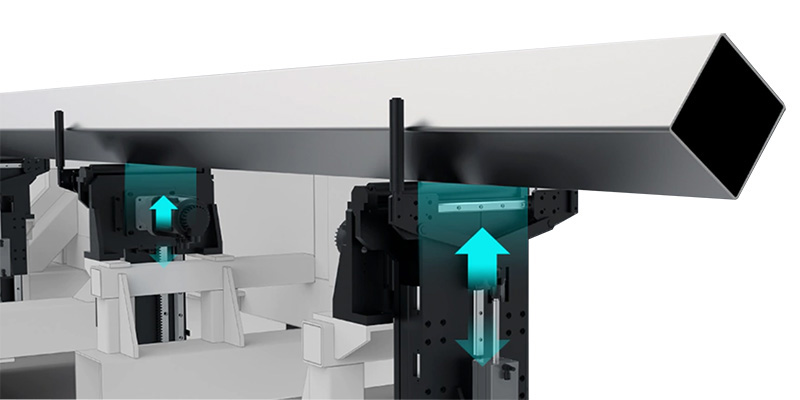

Servo support With buffer cylinder

Both the loading and unloading ends are actively supported by high-sensitivity servo drives to ensure cutting stability and improve precision.

Smart Tubepro controller

The industrial tube laser cutting machine is equipped with professional nesting software to achieve efficient management of production progress and price calculation.

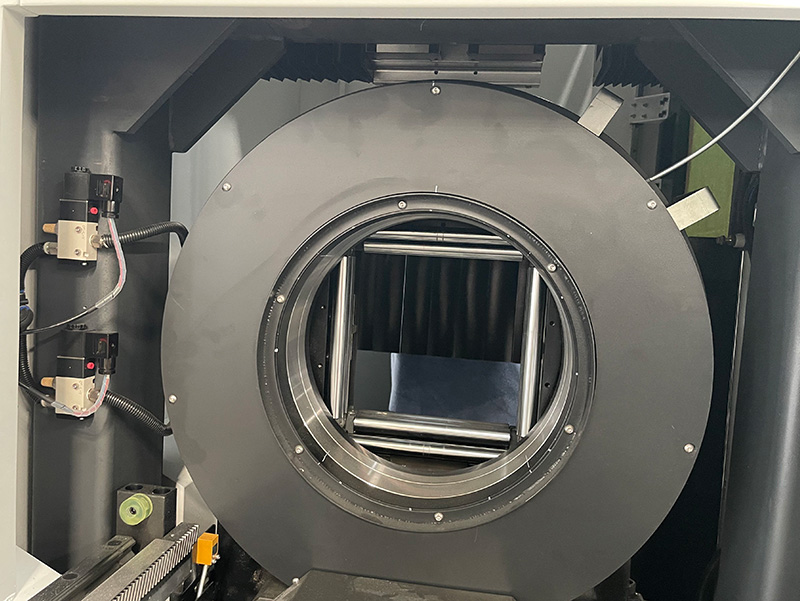

The square chuck design allows cutting of round and square tubes with the same maximum diameter, with a cutting range of 20mm to 350mm.

The high-power 12000W laser generator adopts water cooling and modular design, with compact structure, highly integrated system, maintenance-free, high reliability, high beam quality and high beam stability, which makes it an ideal laser source for industrial pipe cutting.

Double control water chiller

Hanli chiller cools the laser source and laser cutting head at the same time, with stable and reliable performance, extremely low failure rate, and significant energy saving effect, helping you save electricity bills.

Automatic metal tube loading system (Optional)

The multifunctional loading support structure is optional, which can meet the automatic loading of round tubes, rectangular tubes, metal pipes and profiles, increase the loading speed, ensure a hands-free operating environment and reduce labor costs.

Technical parameters of Industrial Tube Laser Cutter for Metal Pipes & Profiles

| Model | ST-FC6020T3+S6 | ST-FC12035T3+S6/S12 |

| Laser power | 3KW, 6KW,12KW | |

| Tube cutting length | 6300mm | 12500mm |

| Tube cutting diameter | Φ15-Φ230mm □15-230mm | Φ20-Φ350mm □20-350mm |

| Maximum tube weight | 300KGS | 900KGS |

| Max. chuck rotating speed | 120r/min | 80r/min |

| Y axis maximum speed | 110m/min | 80m/min |

| X maximum acceleration | 1.5G | 0.8G |

| Control system | EtherCAT bus control | |

| Positioning accuracy | ±0.05mm/m | |

| Repeated positioning accuracy | ±0.03mm/m | |

| Power Supply | 380V/50HZ/3P (Options: 220V with transformer) | |

| Dimensions | 16800*2730*2300mm | 22780*2900*2460mm(S6) / 28700*2300*2450mm(S12) |

| Overall weight | 8200KGS | 16000KGS(S6)/21000KGS(S12) |

Industrial Tube Laser Cutter for Metal Pipes & Profiles Projects