Package came slightly damaged but the laser metal cutter machine is in good condition. STYLECNC support did a outstanding job of taking care of any of the issues I encountered. I've had the laser for three weeks and it works great. I'm using it to cut stainless steel kitchen utensils, cookware and bakeware, and all the metal parts involved in the fabrication, resulting in smoother and cleaner cuts than plasma cutting. Not an inexpensive option when you factor the cost of the unit, consumables, power to run it, the air compressor, industrial water chiller, and the working gases needed, but time is money, and this fiber laser is the right cutting tool if you're working on much more cuts. We will see how long it holds out for. All in all, I would definitely do business with STYLECNC in the future.

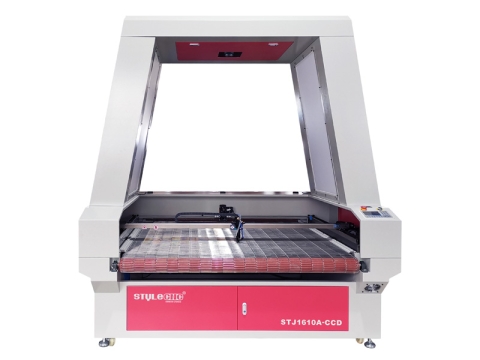

5x10 Industrial Fiber Laser Metal Cutting Machine for Sale

ST-FC3015LR 5x10 industrial fiber laser cutting table with 1500W, 2000W, 3000W and 6000W power options is used for precision cutting metal tubes and sheet metals all in one machine, which is user friendly and easy to operate for both beginners and professionals. It is a long-term partner that brings precision, efficiency, and cost-effectiveness for those businesses that require versatility and productivity within their operations. Now the best and affordable industrial 5x10 laser metal cutting table for sale at cost price.

- Brand - STYLECNC

- Model - ST-FC3015LR

- Maker - Jinan Style Machinery Co., Ltd.

- Sizing - 5' x 10' (60" x 120", 1500mm x 3000mm)

- Category - Fiber Laser Cutting Machine

- Laser Source - Raycus, IPG, MAX

- Power Option - 1500W, 2000W, 3000W, 6000W

- 180 Units in Stock Available for Sale Every Month

- Meeting CE Standards in Terms of Quality & Safety

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- 30-Day Money Back Guarantee for Your Purchase

- Free Lifetime Technical Support for End-Users & Dealers

- Online (PayPal, Alibaba) / Offline (T/T, Debit & Credit Cards)

- Global Logistics and International Shipping To Anywhere

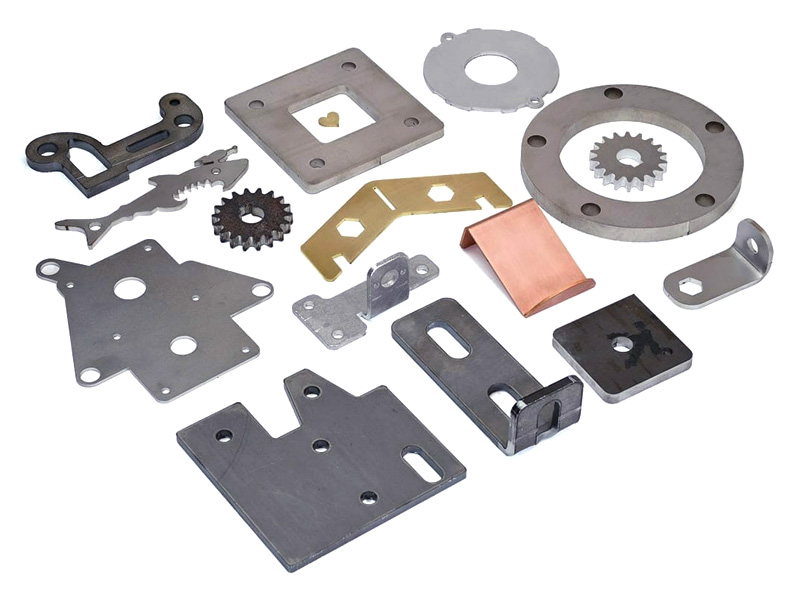

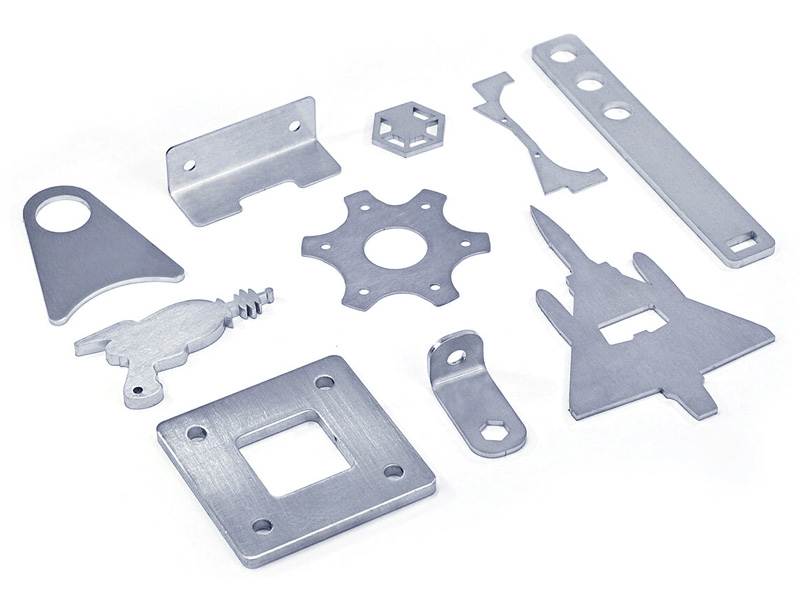

The 5x10 industrial fiber laser metal cutting machines are powerful, and designed for precision and efficiency in metal fabrication. The 5x10 foot large working area means that a wide range of sheet metal sizes can be handled, making them ideal for projects both on a small and large scale. It finds wide applications in industries related to automotive, aerospace, and construction due to its speed and reliability.

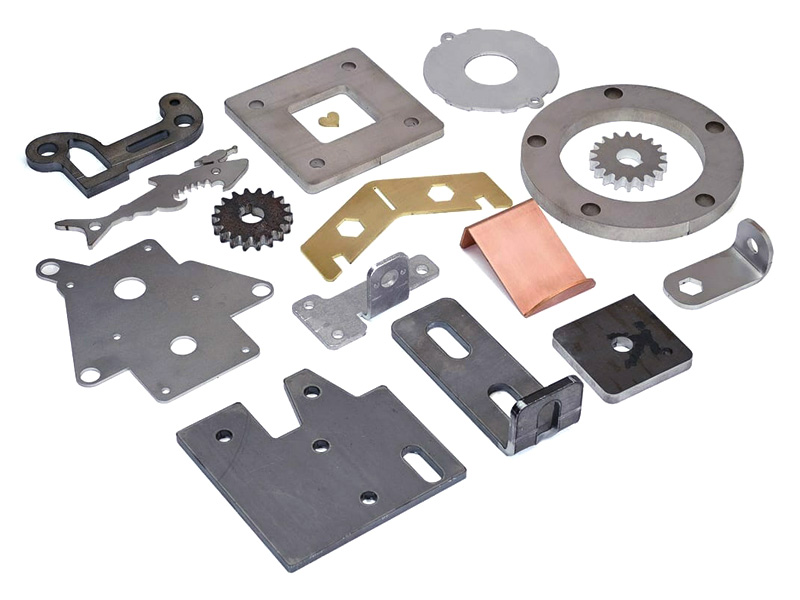

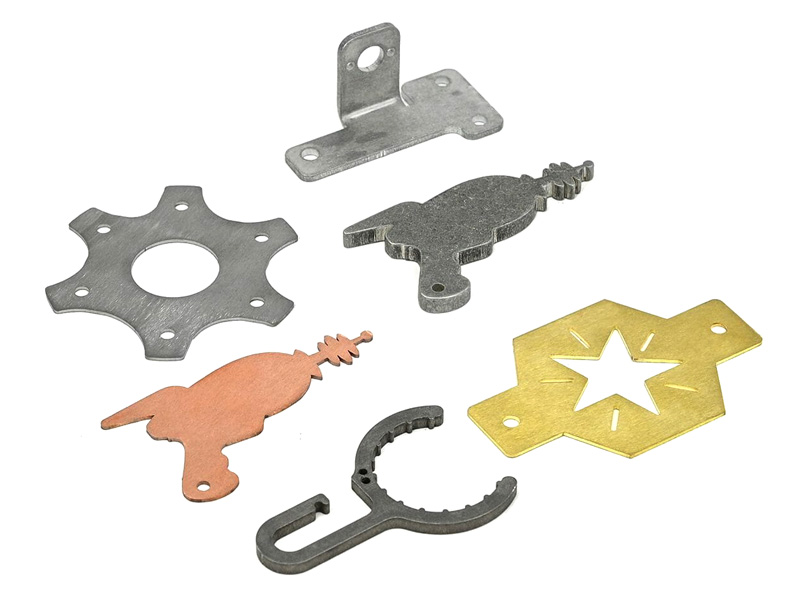

It gives clean cuts in various metals, including steel, aluminum, brass, and copper, using fiber laser technology. The advanced technology minimizes material wastage while maintaining high-quality finishes. This 5x10 model is highly efficient for businesses that require versatility and productivity within their operations.

Additionally, this equipment has user-friendly controls and low maintenance. The sturdily built and energy-efficient machine is cost-effective for industrial applications in metal cutting.

Why Invest in a 5x10 Fiber Laser Metal Cutting Machine?

Investing in a 5x10 fiber laser metal cutting machine can transform your business operations. This machine is not just a tool - it's a long-term asset that brings precision, efficiency, and cost-effectiveness to your workflow. Let's explore the key reasons why this investment is worth it:

Enhanced Productivity

The big working area of this 5x10 fiber laser cutter allows the handling of bigger sheets of metals, hence reducing the need for repositioning. This increases the speed of production, enabling you to complete your projects faster and increasing your overall output. It is perfect for meeting tight deadlines because it can cut many pieces at the same time.

Unmatched Precision

Fiber laser technology ensures clean, accurate cuts with minimal errors. This reduces material waste and ensures a perfect finish every time, even for intricate designs. Consistent precision enhances your reputation for delivering high-quality products.

Versatility in Applications

It works with a wide range of metals: steel, aluminum, and brass. Its versatility makes it suitable for various industries, from automotive to construction, allowing you to take on diverse projects. You can also use this model for creative tasks such as making custom designs or prototypes.

Cost Efficiency

Fiber lasers are energy-efficient and require less power than traditional cutting methods. They also have low maintenance costs, helping you save money in the long run while maintaining consistent performance. The reduced operational costs make it a profitable addition to any business.

Durability and Longevity

Built with industrial-grade materials, a 5x10 fiber laser cutter is designed to last. With proper maintenance, it provides reliable performance for years, making it a smart, long-term investment for your business. Its robust build ensures it can handle heavy workloads without compromising quality.

5x10 Industrial Fiber Laser Metal Cutting Machine Features and Advantages

⇲ Industrial fiber laser metal cutting machine adopts Raycus 1500 Watts laser device (option: IPG) with stable performance, the key parts can reach 100,000 hours.

⇲ Advanced CNC control system, it can read .ai, .plt, .dxf, .lxd, and ug code directly, easy to operate.

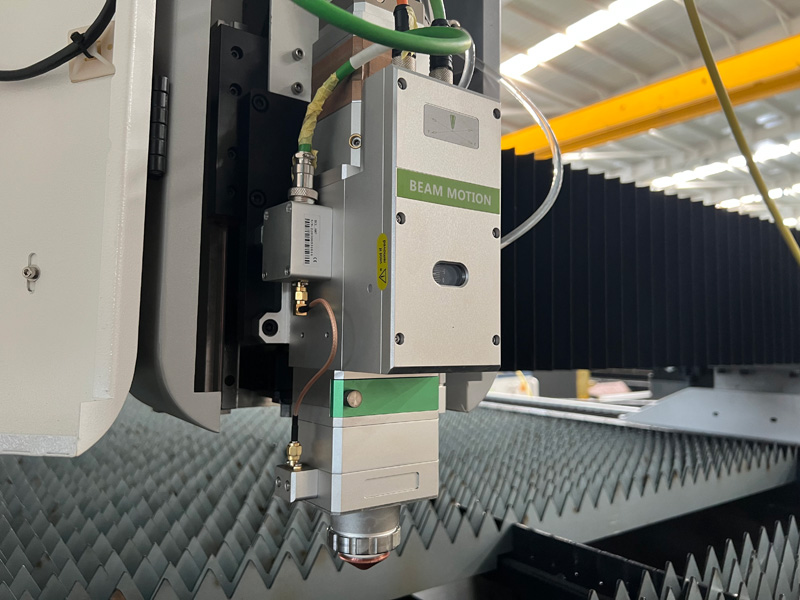

⇲ Intelligent cutting head capable of automatic height adjustment to maintain constant focal length and stable cutting quality.

⇲ Imported high precision transmission device which works perfectly with servo system, thus it can make sure cutting precision and efficiency.

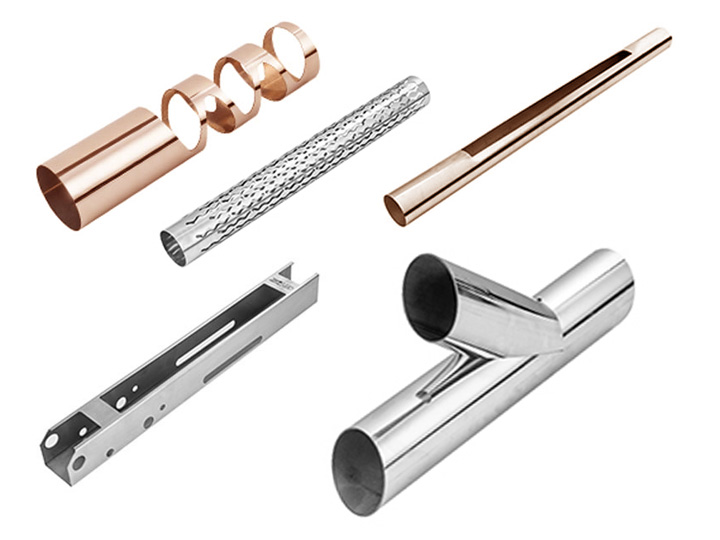

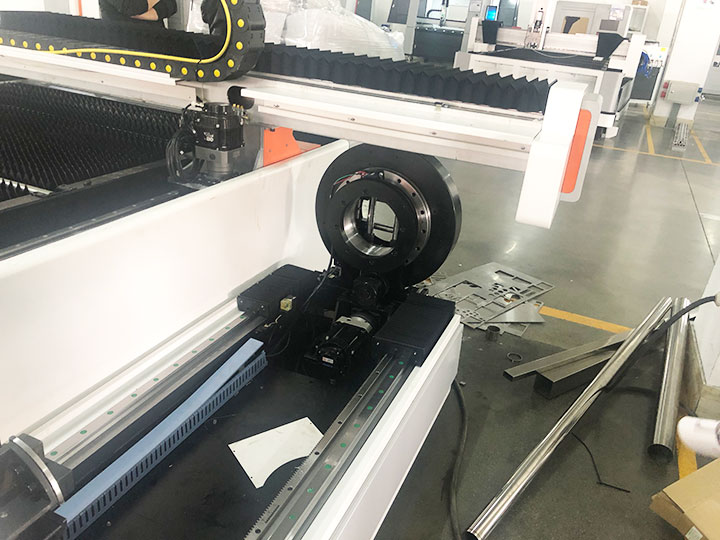

ST-FC3015LR is an upgraded model from ST-FC3015L, it can cut most of the sheet metals, metal plates, metal tubes, and metal pipes. Greatly saving the cost of purchasing two kinds of machines, saving more than 50% of workshop space, and doubling production efficiency.

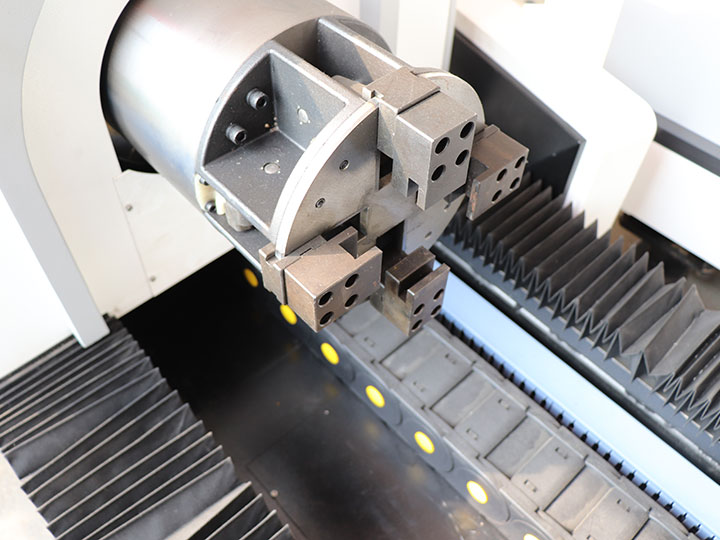

The metal tube cutting capacity is widely used in sports equipment, various types of pipe, water pipes, oil pipelines, and other industries, it is suitable to cut various special-shaped pipe materials such as round pipe, square pipe, rectangular pipe, oval pipe, etc.

5x10 Industrial Fiber Laser Metal Cutting Machine Technical Parmeters

| Model | ST-FC3015L | ST-FC3015LR |

| Working Area | 1500mmx3000mm (5x10 feet) | |

| Tube cutting dimension | No | Diameter 240mm,Length 6000mm |

| Laser Power | 1500W (2000W, 3000W, 6000W for Option) | |

| Repeat Location Accuracy | ±0.02mm | |

| Max Acceleration | 1G | |

| Max Cutting Speed | 80m/min | |

| Machine Occupy Space | 4050 x 4197 x 1860mm | 4050 x 5650 x 1860mm |

| Machine Weight | 2300 KGS | 4000 KGS |

| Voltage | 380V or 220V | |

5x10 Industrial Fiber Laser Metal Cutting Machine Projects

5x10 Industrial Fiber Laser Metal Cutting Machine Details

5x10 Industrial Fiber Laser Metal Cutting Machine Package

⇲ Strong water resit bottom in plywood.

⇲ Laser source (separated plywood case) and spare parts on the laser bed.

⇲ The corner is protected by foam and fixed by a protective film.

⇲ All are covered by strong and hard protective film.

⇲ Vacuum packing.

⇲ Inside steel frame protector.

⇲ Plywood packing and steel strip outside fixed the box.

⇲ Finishing packing by normal container or frame container.

Maintenance Tips for Long-Lasting Performance

Proper maintenance of your 5x10 industrial fiber laser cutting machine is one sure way it will serve efficiently and last for years. Poor maintenance can lead to periods of downtime and expensive repairs. Here are practical tips to keep your machine as good as new.

• Clean the Optical Components Regularly: Dust and debris can affect the laser beam quality and cutting precision. Use approved cleaning solutions and lint-free cloths to clean lenses and mirrors periodically. This helps maintain consistent performance.

• Check the Cooling System: The cooling system prevents overheating and ensures the laser operates at optimal temperature. Regularly inspect coolant levels and replace the fluid as recommended by the manufacturer to avoid overheating issues.

• Inspect Moving Parts: Regularly check components like rails, bearings, and belts for wear and tear. Lubricate these parts to ensure smooth operation and prevent mechanical failures during cutting.

• Keep the Machine Software Updated: Manufacturers frequently release software updates to improve machine performance and fix bugs. Updating the software ensures your machine operates with the latest features and optimizations.

• Schedule Professional Maintenance: Even with regular care, periodic professional servicing is essential. Trained technicians can identify potential problems early and ensure all components function at their best.

Consistent maintenance not only extends the lifespan of your fiber laser machine but also ensures reliable, high-quality cutting results, keeping your business productive and cost-efficient.

STYLECNC Pre-Sale Service for 5x10 Industrial Metal Laser Cutting Machine

1. Free sample cutting service:

For free sample cutting/testing, please send us your CAD file (.plt or .ai), we will do the cutting in our factory and make a video to show you the cutting process and result or send samples to you to check the cutting quality.

2. Progressing Solution Design:

According to the customer’s product processing requirement, we can design a unique solution that supports higher manufacturing efficiency and better processing quality for customers.

3. Customized machine design:

According to the customer's application, we may revise our machine according to the customer's convenience and high production efficiency.

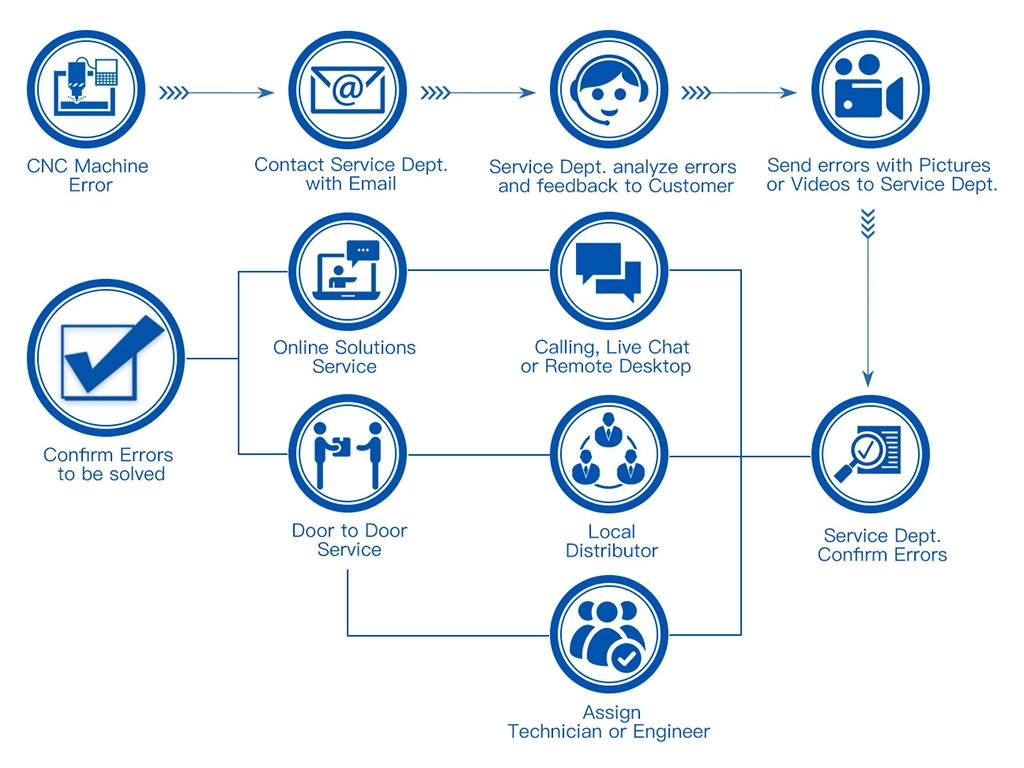

STYLECNC After-Sale Service for Industrial 5x10 Metal Laser Cutting Machine

⇲ We will supply the laser machine with a training video and user's manual in English for installation, operation, maintenance, and troubleshooting, and shall give technical guidance remotely, such as TeamViewer, E-mail, Telephone, Mobile, Whatsapp, Skype, 24/7 online chat, and so on, when you meet some problem of installation, operation or adjusting. (Recommended)

⇲ You can come to our laser machine factory for training. We will offer professional guidance. Direct and effective face-to-face training. Here we have assembled equipment, all sorts of tools, and a testing facility. Training Time: 3~5 days (Recommended)

⇲ Our engineer will do a door-to-door instruction training service at your local site. We need your help to deal with the visa formality, prepaid traveling expenses, and accommodation for us during the business trip and service period before their dispatch. It's better to arrange a translator (if not English-speaking) for our engineers during the training period.

STYLECNC Warranty for Industrial 5x10 Metal Laser Cutting Machine

⇲ The entire machine comes with 1-year limited warranty (excluding consumable parts).

⇲ For lifetime maintenance, the after-sale department will offer 24/7 English online support.

⇲ Except for the damage artificially, we are responsible for offering the fittings free of charge during warranty.

⇲ After the warranty period expires, the buyer only needs to pay the actual maintenance cost.

⇲ Certificate support: CE, FDA, SGS.

If you have an idea to get a free quotation for Fiber Laser Metal Pipe Cutting Machine, please answer the questions as follows and tell us by email, so that we can recommend the most suitable laser machine and quota the affordable price to you directly.

⇲ Do you need to cut metal sheets/plates, metal pipes/tubes only, or both?

⇲ If need to cut tubes, What is your tube length, diameter, and max thickness?

⇲ For cutting metal sheets, what is the maximum working area required?

⇲ After processing, what the materials will be used for? (Applications)

⇲ Which seaport is the nearest to you?

⇲ Do you have any experience in the fiber laser cutting machine?

⇲ What is your online chat way? Such as Skype and WhatsApp.

⇲ Are you an end user or a reseller?