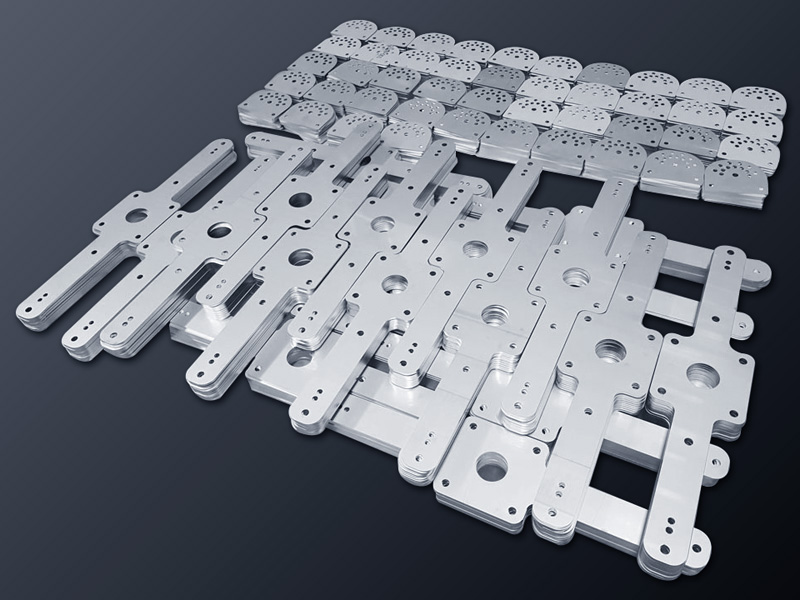

I bought this for my workshop to cut outer and inner car panels made of aluminum and steel with high precision cut requirements. The automatic fiber laser blanking system works great for the money. I would recommend purchasing this to anyone looking for the best budget coil fed laser cutting system. Be safe in cutting, it is a high power laser machine, follow the safety precautions.

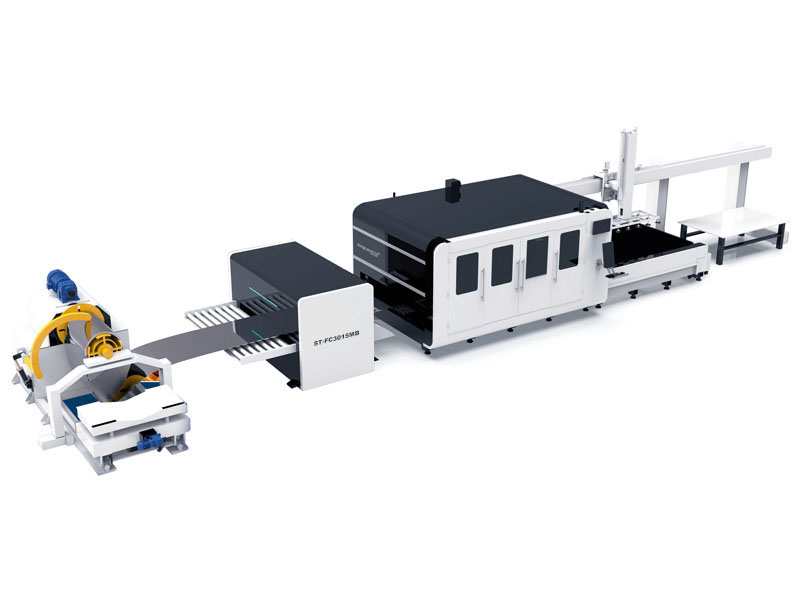

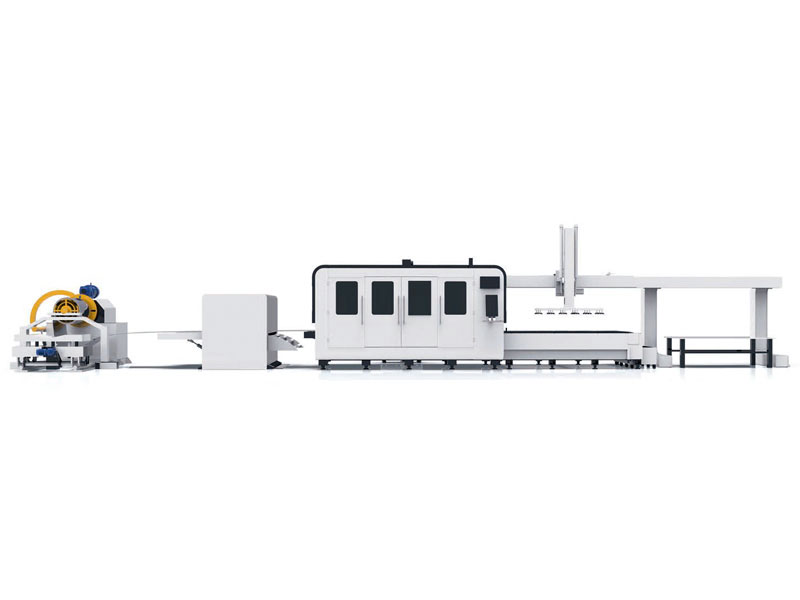

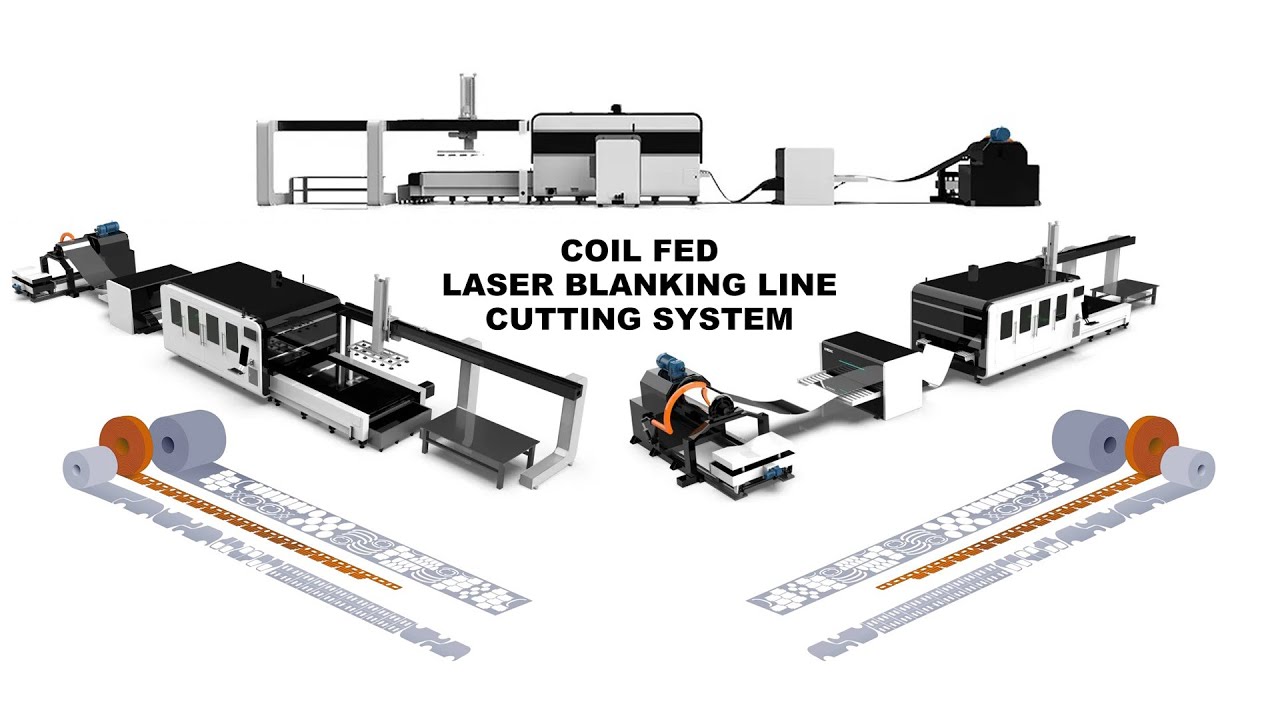

Automatic Coil Fed Laser Blanking Line & Cutting System

Looking for an affordable laser blanking line machine for coil fed cutting in sheet metal fabrication such as HVAC duct and fittings, metal cabinets, auto parts, kitchenware and accessories? Find and buy the best and affordable automatic coil fed laser blanking system with 1500W, 2000W, 3000W and 4000W fiber laser power options at cost price in 2025, featuring a smart CNC nesting and cutting software for getting the most out of metals, taking on a wide range of materials and uses for industrial batch manufacturing.

- Brand - STYLECNC

- Model - ST-FC3015MB

- Maker - Jinan Style Machinery Co., Ltd.

- Sizing - 5' x 10' (60" x 120", 1500mm x 3000mm)

- Category - Fiber Laser Cutting Machine

- Laser Source - Raycus, IPG, MAX, RECI

- Power Option - 1500W, 2000W, 3000W, 4000W

- 180 Units in Stock Available for Sale Every Month

- Meeting CE Standards in Terms of Quality & Safety

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- 30-Day Money Back Guarantee for Your Purchase

- Free Lifetime Technical Support for End-Users & Dealers

- Online (PayPal, Alibaba) / Offline (T/T, Debit & Credit Cards)

- Global Logistics and International Shipping To Anywhere

One thing that makes the ST-FC3015MB stand out is that it is very flexible. Unlike traditional press lines, this method makes it easy to change the geometry, so you don't have to buy expensive bending tools or do setup work. Manufacturers can easily change to meet new needs, which increases their flexibility and lowers their extra costs.

The ST-FC3015MB has a cutting-edge CNC processor that makes all of its cutting processes automatic, from unwinding the coil to sorting the parts with robots. This complete automation simplifies workflow operations, making them more productive while reducing the need for human input.

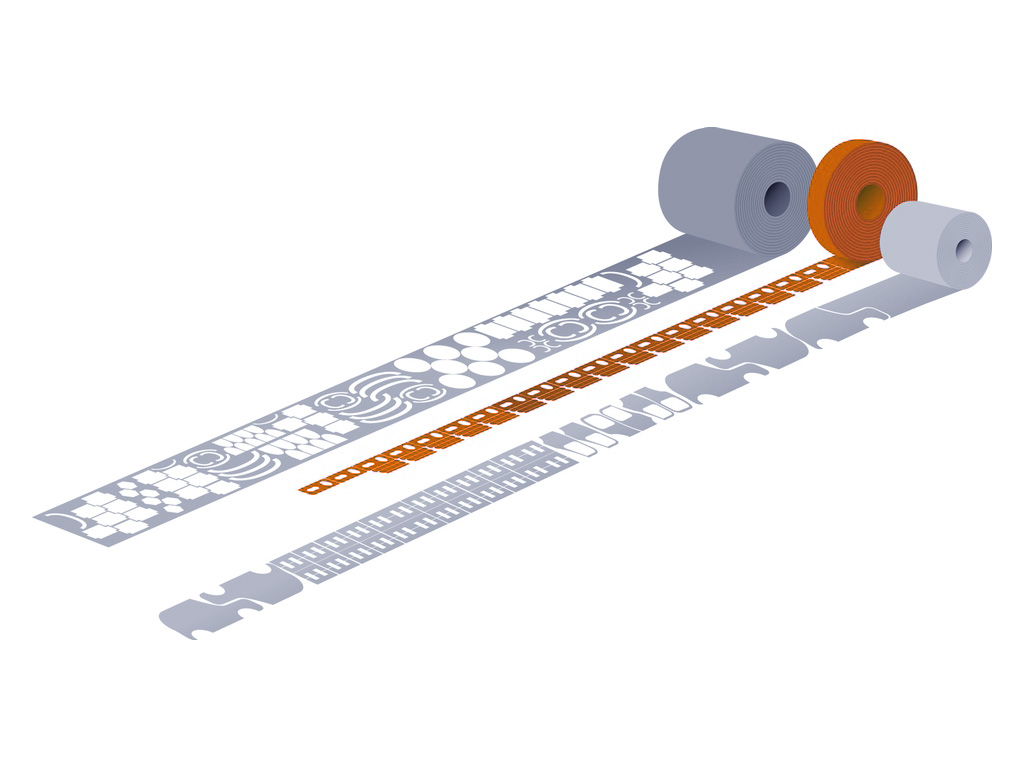

Intelligent software for getting the most out of materials

Leveraging the power of smart software, the ST-FC3015MB offers the best ways to nest and cut, making the best use of materials and managing waste efficiently. Components fit into the process perfectly, getting rid of scrap skeletons and making production more efficient.

Taking on a wide range of materials and uses

With its laser blanking and automatic coil feeding system, the ST-FC3015MB is designed to meet the needs of current metal fabrication. It makes the business more productive, profitable, and ready for the future because it works well with storage systems and other machines.

What Is A Laser Blanking Line?

A laser blanking line is a type of automatic coil fed laser cutting system with fiber laser generator used for large series sheet metal fabrication instead of the expensive mechanical stamping press lines with bending tools to save materials, costs and time. Laser blanking lines respond flexibly to your manufacturing, offering multiple stacking options to meet your blank handling needs and improve cut quality.

Features & Advantages of Automatic Coil Fed Laser Blanking Line & Cutting System

Stackers, laser blanking systems and coil lines can be customized according to your requirements. A leveler capable of leveling aluminum and steel with higher strength is optional for coil lines. Laser cutting systems are available with setups of single head or multiple heads, with flexible cutting and nesting software that optimizes material usage and makes changeover as easy as entering a telephone number.

A laser blanking line combines an automatic metal coil feeding system with a precision fiber laser cutting machine to provide a flexible and efficient feeding laser cutting solution for various coil materials and complex shape cuts.

Laser blanking lines take advantage of their flexible and efficient capabilities to cut coils directly into parts. Due to the use of coils, it offers many advantages over feed systems such as raw material savings due to higher material efficiency, consistent work rates and lower cost per part. Laser blanking also reduces power consumption compared to alternatives such as stamping lines.

You can gain the following benefits from using a coil fed laser punching solution:

Flexible Production

Changes to the geometry produced are flexible and easy to implement compared to a press line. Using the laser as the tool completely eliminates the cost of bending tooling, maintenance, storage and setup operations.

Automatic Cutting Process

With a CNC controller, you can fully automate the cutting process - from unwinding coils and flattening metal slats to robot-based component removal and sorting. This system completes all the tasks of a fully automatic cutting center.

Software Optimization

The laser software will suggest optimal nesting and separation cutting strategies. This means you can rely on the highest possible material utilization and efficient waste management. Thanks to this software, components do not get stuck in the scrap skeleton during disassembly.

Reduce Production Process

From raw material to finished product in one system. Significantly reduce human intervention and intermediate inventory.

Improve Adaptability

The ability to produce any part at any time. Coil-fed laser solutions enable users to face unexpected production stops and react faster to changing customer needs.

Material Combination

Laser cutting is not limited by the strength of the material. It can machine carbon steel, stainless steel, copper, brass and aluminum.

Save Material Costs

Save up to 16% when purchasing materials compared to sheet merchandise. At the same time, material utilization can be increased by up to 16% thanks to more efficient nesting.

Reduce Manufacturing Costs

The use of materials is fully optimized; the amount of waste is reduced, about 10% less than conventional punching. Eliminates mold design and procurement costs.

Reduce Setup Costs

Significant savings in foundation costs, no need for loops and pressed pits. No need for elevated workshops with heavy-duty overhead cranes. All of this makes this setup more modular and portable should it need to be relocated at some point.

Reduce Production Maintenance

Avoid complex mold maintenance work, simple maintenance operations, less downtime and less expensive consumables.

Reduce Space

Huge space saver. No die storage is required.

Automatic Storage

The highly productive, highly automated laser blanking system can be flexibly connected to a storage system. Finished cut parts can be transported to other connected machines, e.g. for automatic part bending.

Automatic Laser Cutting Robot

Coil Leveler

Automatic Metal Coil Feeding System

Automatic Uncoiler

Technical Parameters of Automatic Coil Fed Laser Blanking Line & Cutting System

| Model | ST-FC3015MB |

| Laser Source | Raycus (IPG, MAX, RECI for Option) |

| Laser Power | 1500W (2000W, 3000W, 4000W for Option) |

| Maximum Working Area | 1500mm x 3000mm |

| Dimensions | (5480mm + 8034mm) x 4850mm x (2650mm + 300mm) |

| Repeated Location Accuracy | ±0.03mm |

| Maximum Acceleration | 1.5G / 2.0G |

| Maximum Cutting Speed | 120m/min |

| Voltage & Frequency | 380V 50Hz/60Hz |

Application Materials of Automatic Coil Fed Fiber Laser Blanking System

It is used for coil laser blanking with stainless steel, mild steel, carbon steel, alloy steel, spring steel, iron, galvanized iron, galvanized sheet, aluminum, copper, brass, bronze, gold, silver, titanium, and other metals.

Application Industries of Automatic Coil Fed Fiber Laser Cutting System

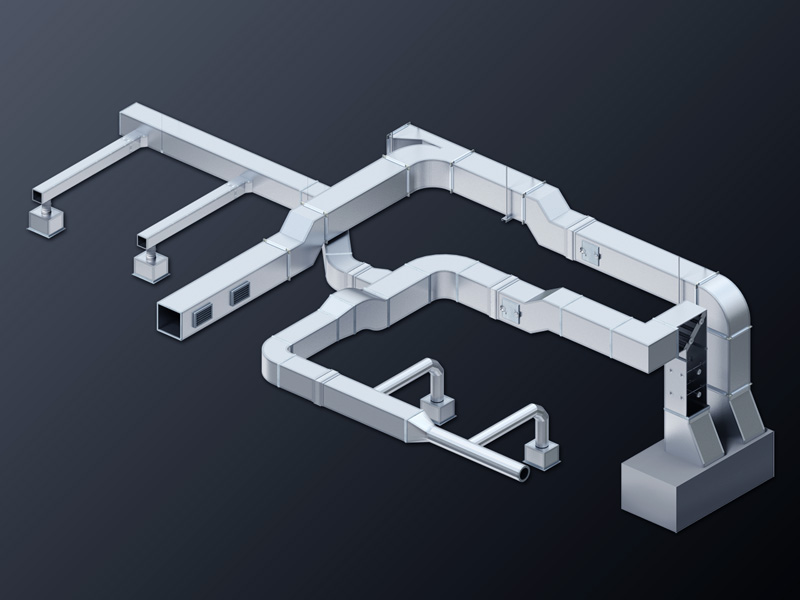

It is used in HVAC duct and fittings, metal cabinets, auto parts, metal doors, machinery and equipment, agricultural machinery, animal husbandry machinery, medical equipment, construction, kitchenware and accessories, advertising signs, hardware lighting, door and window manufacturing, decoration, mining equipment, ship aviation, iron tower manufacturing, hangers, shelves, and more metal fabrication industries.

Automatic Coil Fed Laser Blanking Line & Cutting Machine Projects

Coil Fed Laser Blanking System for Metal Kitchen Cabinets Making Projects

Coil Fed Laser Blanking Line for HVAC Duct & Fittings Making Projects

Coil Fed Laser Blanking Line for Metal Parts Cutting Projects

Coil Fed Laser Blanking System for Auto Parts Making Projects

Package of Automatic Coil Fed Laser Blanking Machine

• Strong water resit bottom in plywood.

• Laser source (separated plywood case) and spare parts on the laser bed.

• Corner protect by foam and fixed by protective film.

• All covered by strong and hard protective film.

• Vacuum packing.

• Inside steel frame protector.

• Plywood packing and steel strip outside fixed the box.

• Finishing packing by normal container or frame container.

Pre-Sale Service of Automatic Coil Fed Fiber Laser Blanking Line

Free sample cutting service

For free sample cutting/testing, please send us your CAD file (.plt or .ai), we will do cutting in our factory and make video to show you the cutting process and result, or send samples to you to check the cutting quality.

Progressing solution design

According to customer’s product processing requirement, we can design the unique solution that supports higher manufacturing efficiency and better processing quality for customer.

Customized machine design

According to customer's application, we may revise our machine according to customer's convenience and high production efficiency.

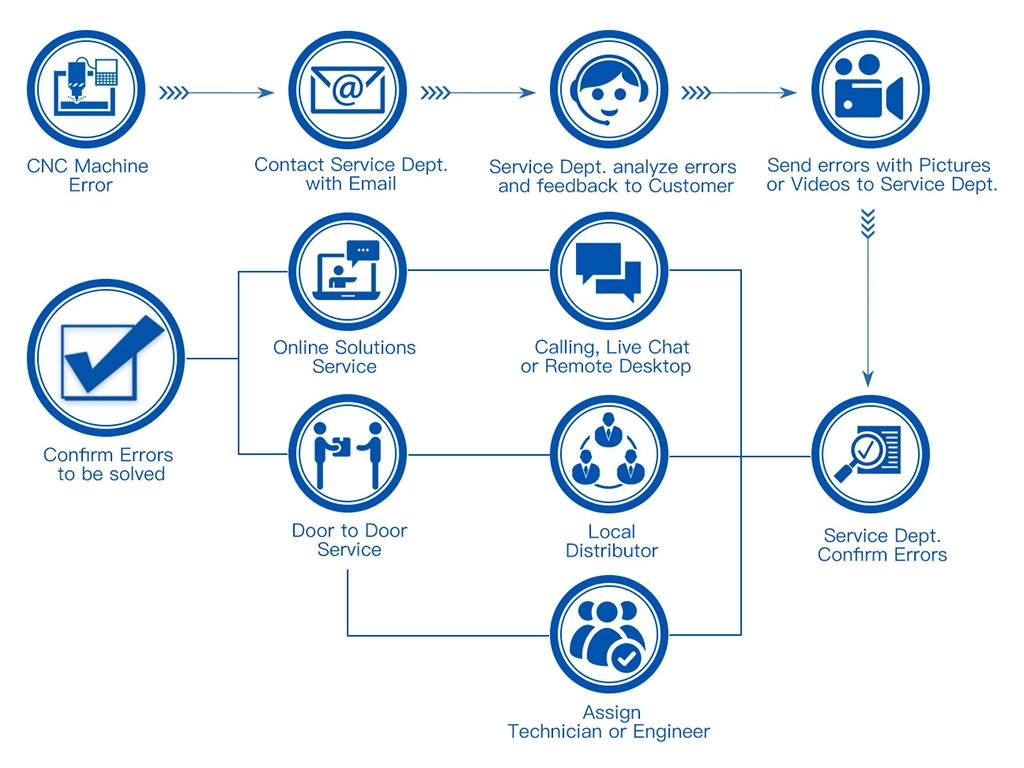

After-Sale Service for Automatic Coil Fed Fiber Laser Blanking System

• We will supply the laser machine with training video and user's manual in English for installing, operation, maintenance and trouble-shooting, and shall give technical guide by remote,such as TeamViewer, E-mail, Telephone, Mobile, Whatsapp, Skype, 24/7 online chat, and so on, when you meet some problem of installation, operation or adjusting. (Recommended)

• You can come to our laser machine factory for training.We will offer professional guidance. Direct and effective face-to-face training. Here we have assembled equipment, all sorts of tools and testing facility. Training Time: 3~5 days (Recommended)

• Our engineer will do a door-to-door instruction training service at your local site. We need your help to deal with the visa formality, prepaid traveling expenses and accommodation to us during the business trip and service period before their dispatch. It's better to arrange a translator (if no English-speaking) for our engineers during the training period.

Warranty for Automatic Coil Fed Fiber Laser Blanking Line

• The entire machine comes with 1-year limited warranty (excluding consumable parts).

• Long life-time maintenance, after-sale department will offer 24/7 English online support.

• Except the damage artificially, we are responsible for offering the fittings free of charge during warranty.

• After the warranty period expired, the buyer only need to pay the actual maintenance cost.

• Certificate support: CE, FDA, SGS.

If you have an idea to get a free quotation of coil fed fiber laser blanking system, please answer the questions as following and tell us by email, so that we can recommend the most suitable laser machine and quota the affordable price to you directly.

• Do you need to cut metal sheets/plates, metal pipes/tubes only or both?

• If need to cut tubes, What is your tube length, diameter and max thickness?

• For cutting metal sheet, what is the max working area required?

• After processed, what the materials will be used for? (Applications)

• Which seaport is the nearest to you?

• Do you have any experience in the coil fed laser blanking system?

• What is your online chat way? Such as Skype, Whatsapp.

• Are you an end user or reseller?

Andrew Doyle

Jiří

I bought this laser blanking line to upgrade my business for making air conditioning systems, heater housings, heat exchangers, protective covers and a variety of parts & accessories with aluminum, mild steel, stainless steel, galvanized steel and pre-painted steel. Got the setup done in 1 hour. Easy to cut with a short learning curve. Well worth the investment.